Test system for simulating action of rapid traffic moving load

A technology of moving load and test system, which is applied in the field of traffic engineering, can solve the problems that have not been found in the research report of high-speed traffic moving load test simulation device, and achieve the effect of wide application range and high simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

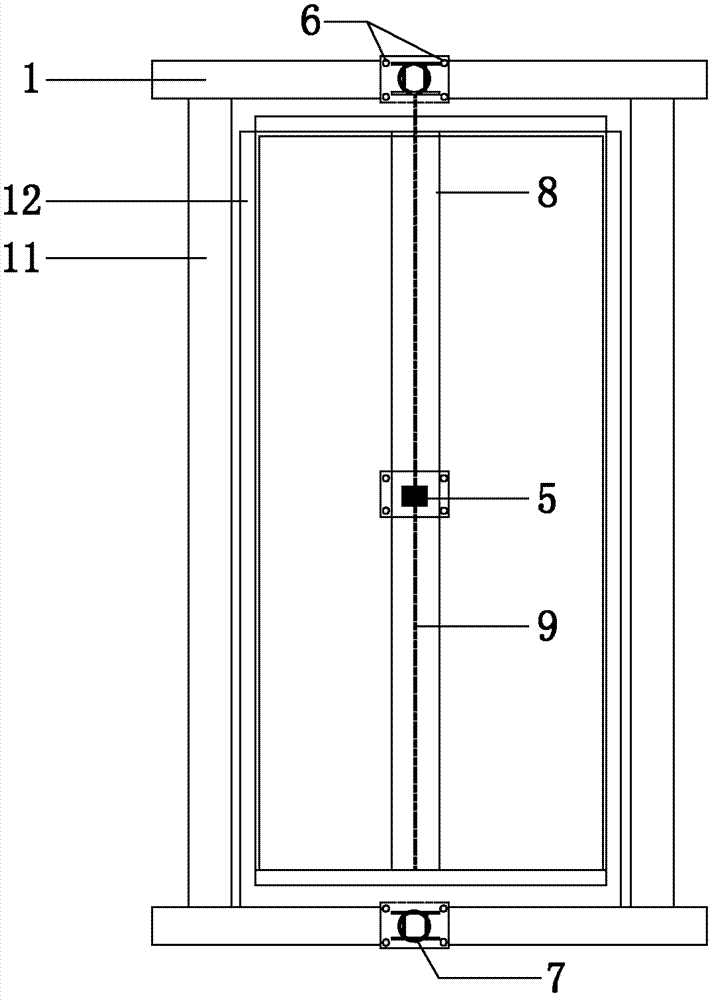

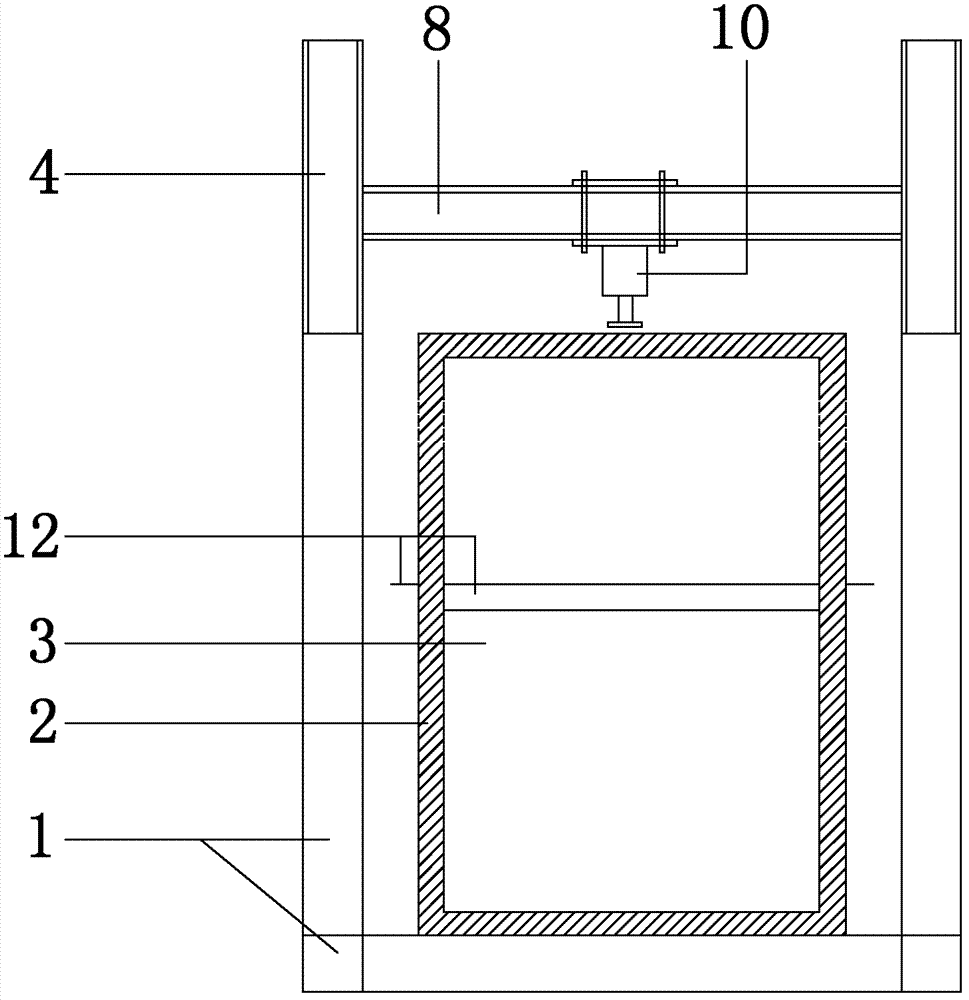

[0024] Such as Figure 1-2 The test system for simulating the moving load of high-speed traffic in the present invention includes a load-bearing frame 1, a channel steel frame 2, plexiglass 3, a vertical loading frame 4, a moving loader 5, a forward moving loader 6, a reverse moving loader 7, Vertical loading beam 8 , mobile loading track 9 , vertical loading actuator 10 and support beam 11 . The model tank is composed of channel steel skeleton 2 and plexiglass 3, and a reinforced angle steel 12 is set in the middle of the model tank. The use of plexiglass 3 can facilitate the observation of the displacement of the soil and piles in the test; the model tank and the bearing frame are independently designed and processed, The model slot can be pushed into the carrying frame 1 by one end; the forward moving loader 6 and the reverse moving loader 7 can generate moving loads simulating high-speed traffic; the moving loader 5 can move at high speed in the moving limit rail 9 . Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com