Fiber collecting mechanism for automatic optical fiber winding machine

A technology of optical fiber ring winding machine and driving mechanism, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of inaccurate counting and no delay, and achieve the effect of uniform fiber ring, no delay and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

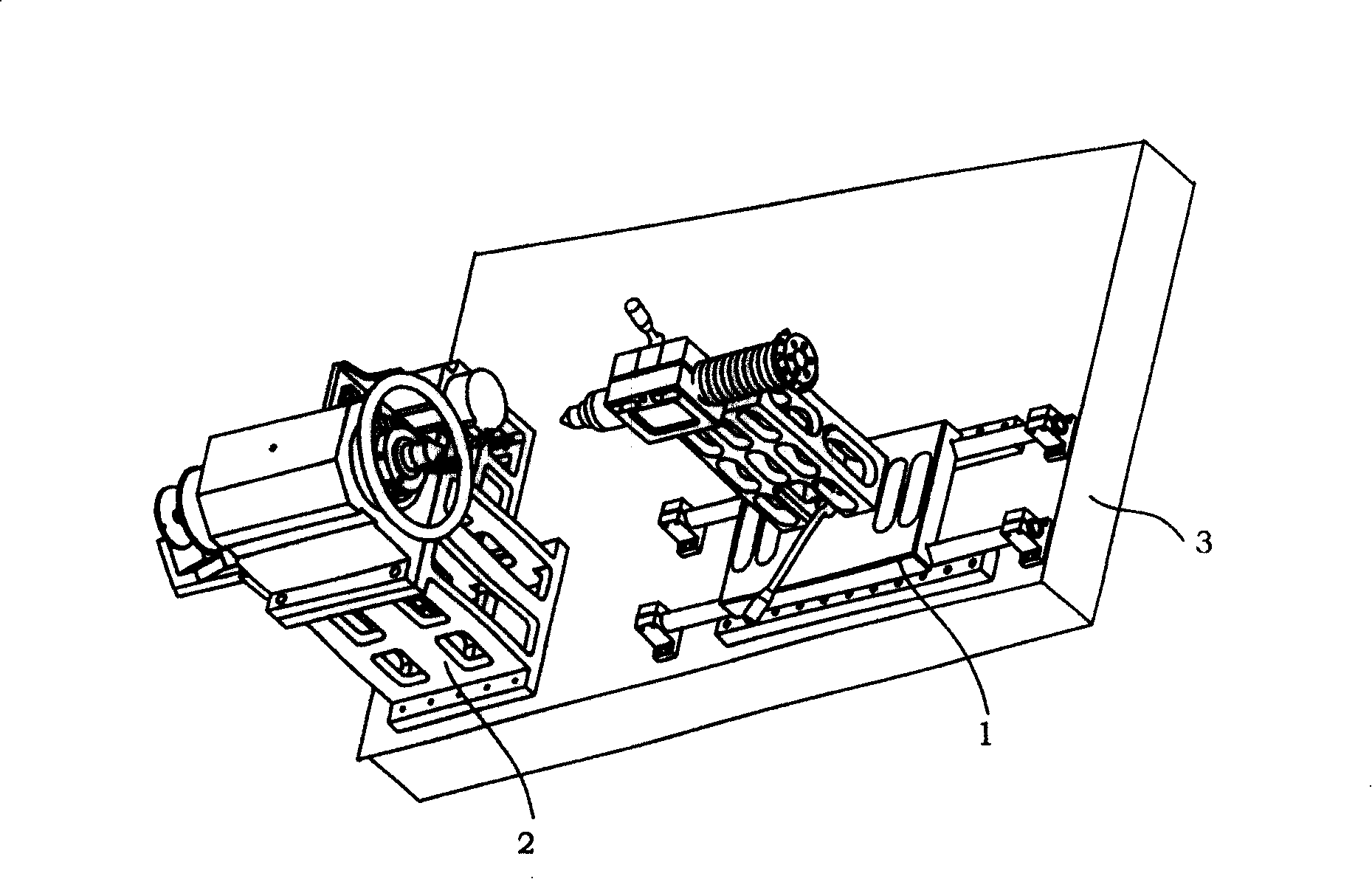

[0030] The present invention is a fiber collection mechanism of an automatic optical fiber winding machine, which is composed of two parts: a fiber collection sliding mechanism 1 and a fiber collection driving mechanism 2, and the fiber collection sliding mechanism 1 and the fiber collection driving mechanism 2 are installed on the automatic fiber optic winding machine on the coaxial line of the worktop 3 (see figure 1 shown); where,

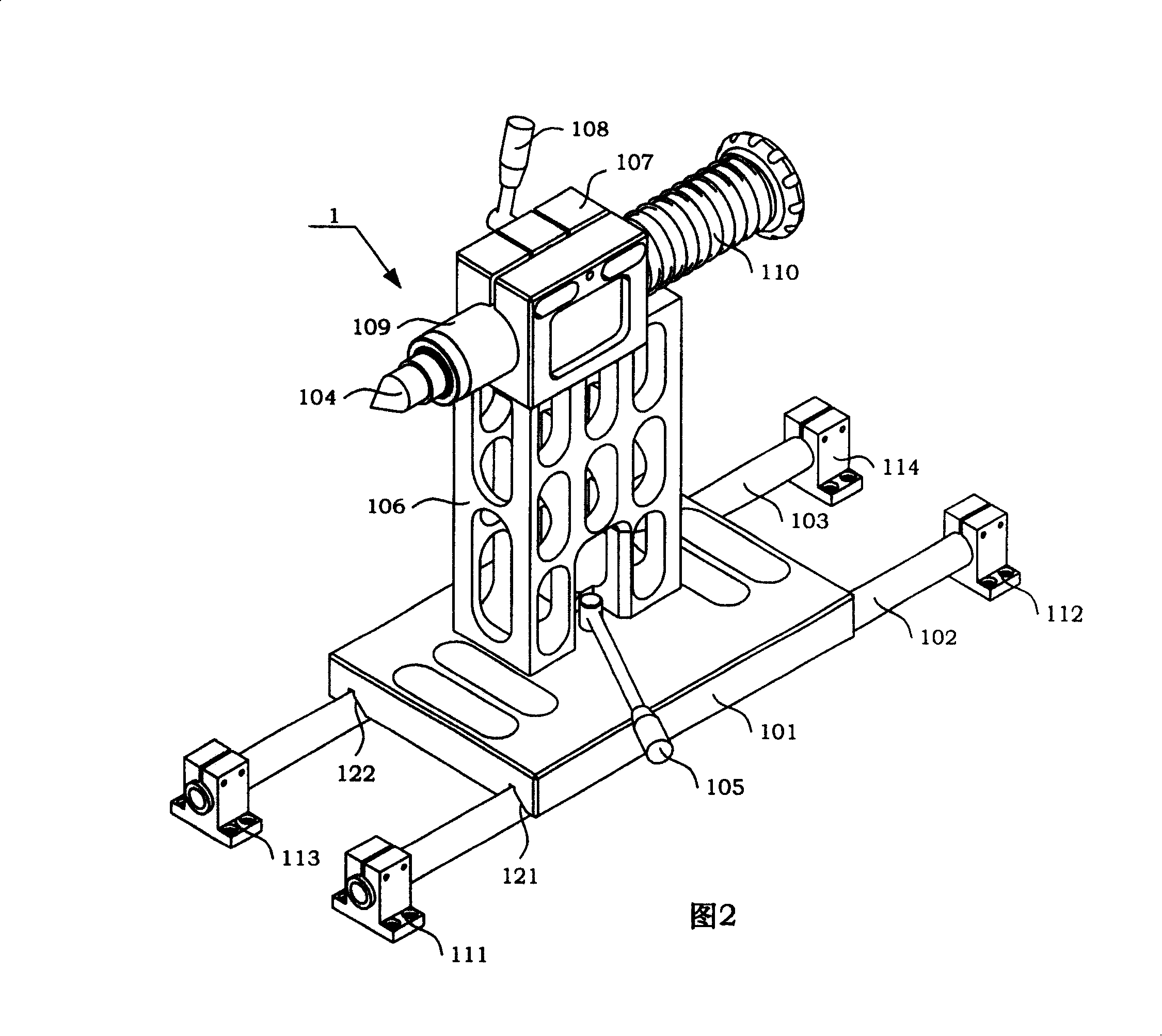

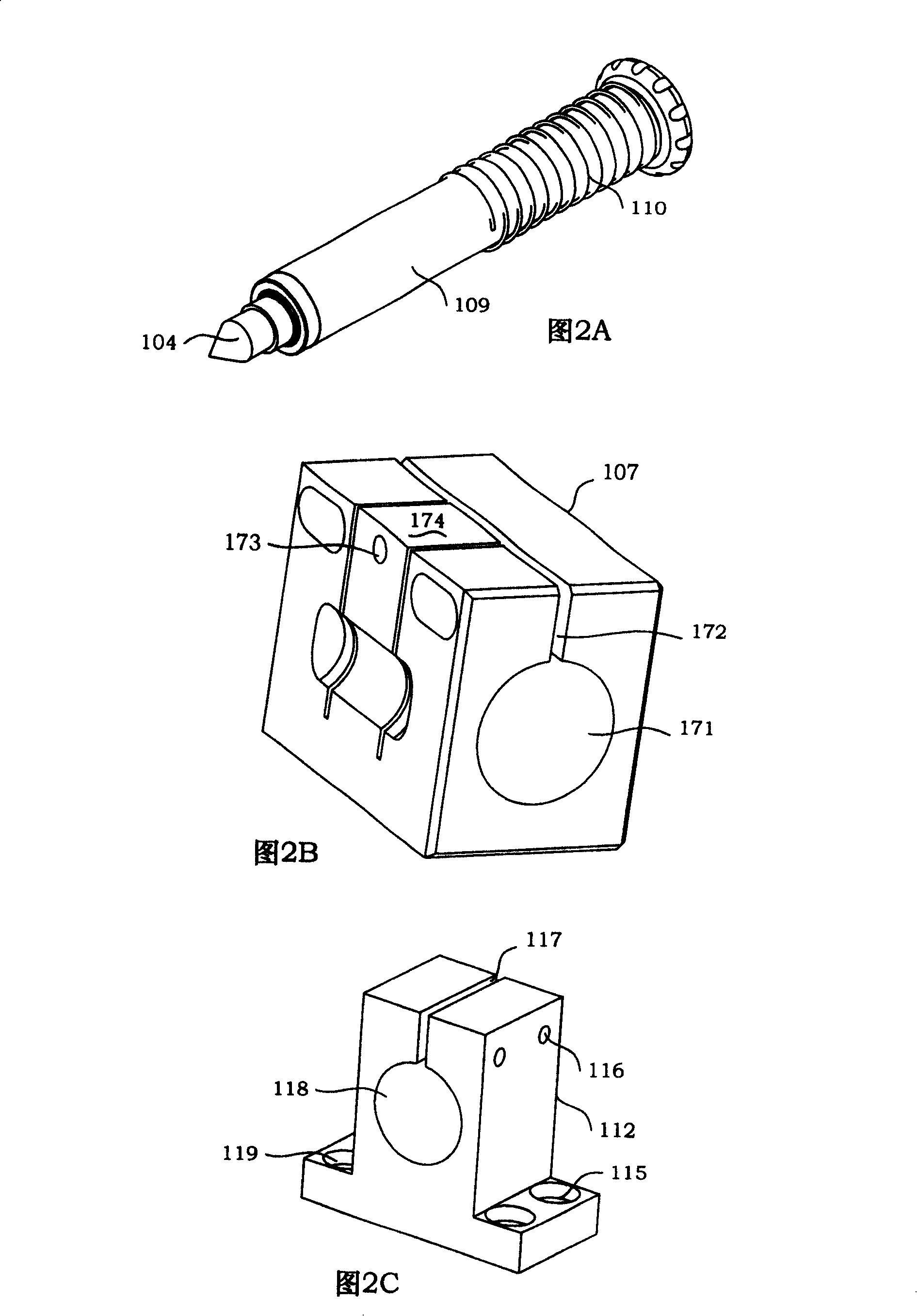

[0031] The two ends of the front slide rail 103 of the fiber collecting sliding mechanism 1 (shown in Fig. 2) are respectively installed on the mounting base C 113 and the mounting base D 114, and the two ends of the rear slide rail 102 are respectively installed on the mounting base A 111 and the mounting base B 112, the positional relationship of the four mounts is: mount A 111 is parallel to mount C 113, mount B 112 is para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com