Electrical performance debugging device for marine electric valve

A technology of electric valves and electrical performance, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as unusable valves, economic losses, failures, etc., to reduce repeated installation work, avoid economic losses, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

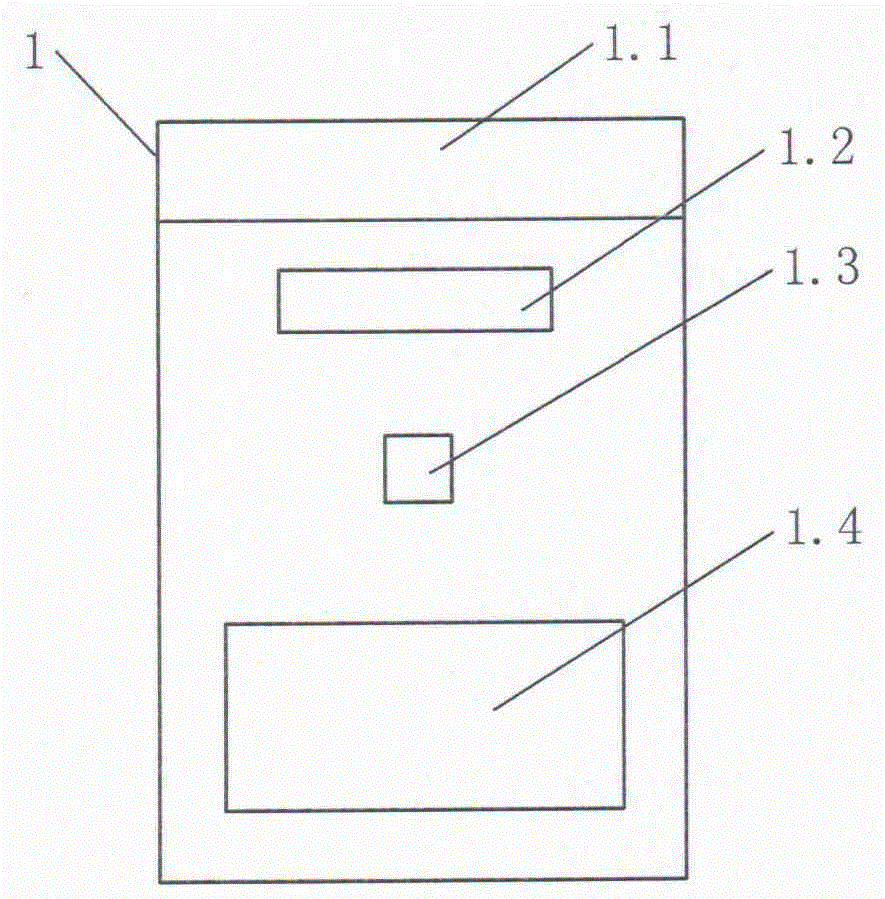

[0031] 1. Debugging platform structure

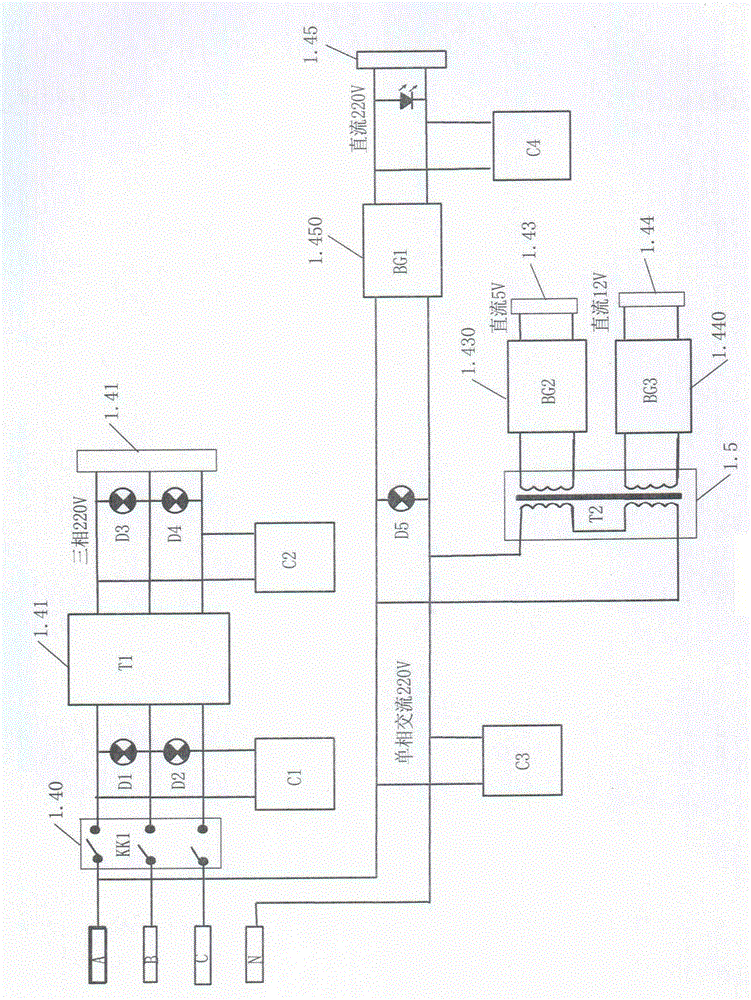

[0032] according to figure 1 As shown: the debugging platform is composed of an operation panel 1.1, a main control circuit board 1.2 in the cabinet, a three-phase four-wire 380V power switch 1.3, and a power converter 1.4 in the cabinet.

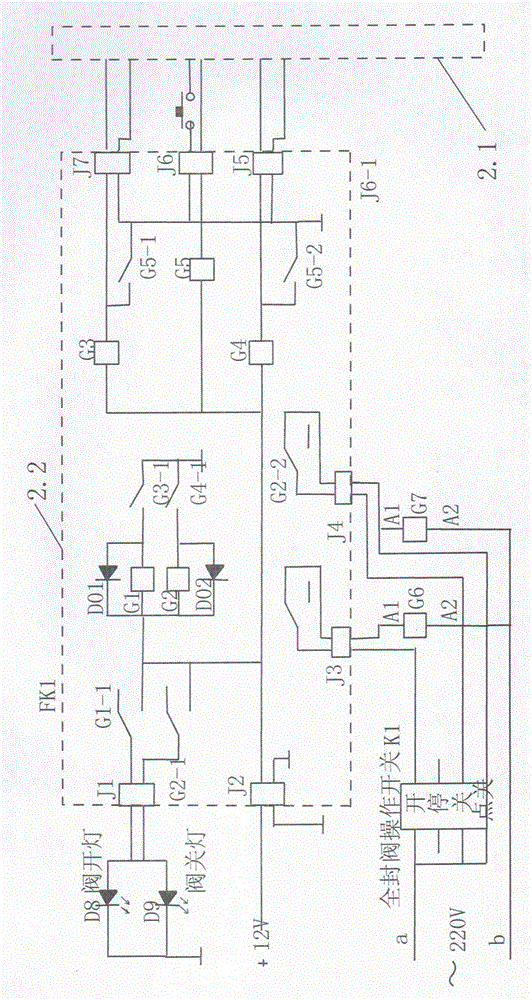

[0033] 2 Composition of the debugging console panel

[0034] according to figure 2 As shown, there are three-phase 380VD1, three-phase 220VD2, single-phase 220VD3 and DC 220VD4 indicator lights on the upper part of the operation panel 1.1, positive sequence indicator light D7, switch timing display screen X1 and X2 on the middle part, and zero reset indicator on the right side. Switches N1 and N2 are also equipped with a light check switch N3 and an over-torque cut-off switch N4. The lower part is provided with lights on and off, indicator lights D8 and D9, lights on, over-torque lights and lights off indicators D10, D11, D12. Lamp, light-off indicator light D13 and D14, the bottom fully sealed v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com