Temperature sensing system of DC power distribution cabinet for supplying power to high-performance computer room

A technology for DC power distribution cabinets and computer rooms. It is applied to thermometers, parts of thermometers, and measuring devices. It can solve the problem of not being able to sense the operating temperature of the connection points of the main components of the power distribution cabinet in real time and not suitable for large-area configurations. , Hidden danger points cannot be grasped in real time, etc., to achieve the effect of ensuring the accuracy and reliability of data transmission, improving the ability of fault maintenance, and improving the ability to resist environmental interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

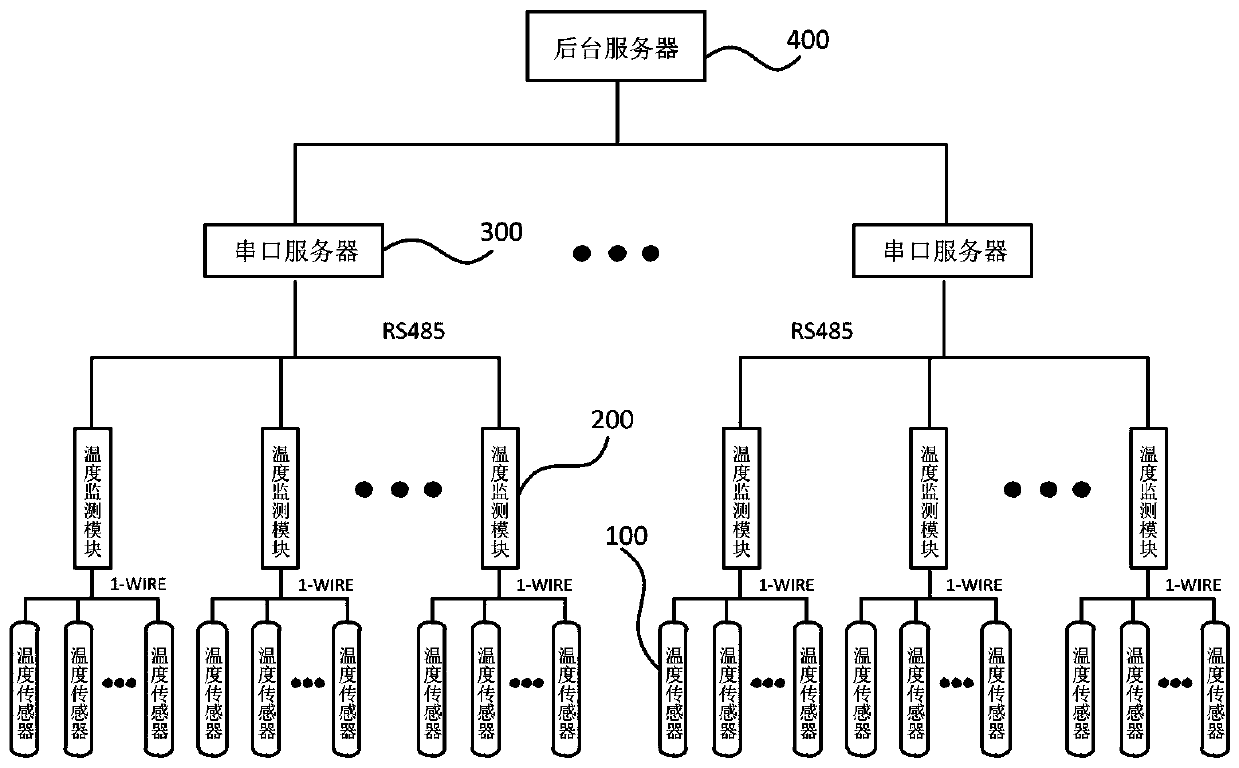

[0038] Such as figure 1 , figure 2 As shown, this embodiment provides a temperature sensing system for a DC power distribution cabinet for power supply in a high-performance computer room,

[0039] include:

[0040] A number of temperature sensors 100 are mounted on the incoming and outgoing busbars of the circuit breaker in the DC power distribution cabinet, specifically on the busbar closer to the wiring, for collecting temperature data and transmitting the data according to the pre-configured communication address. temperature data;

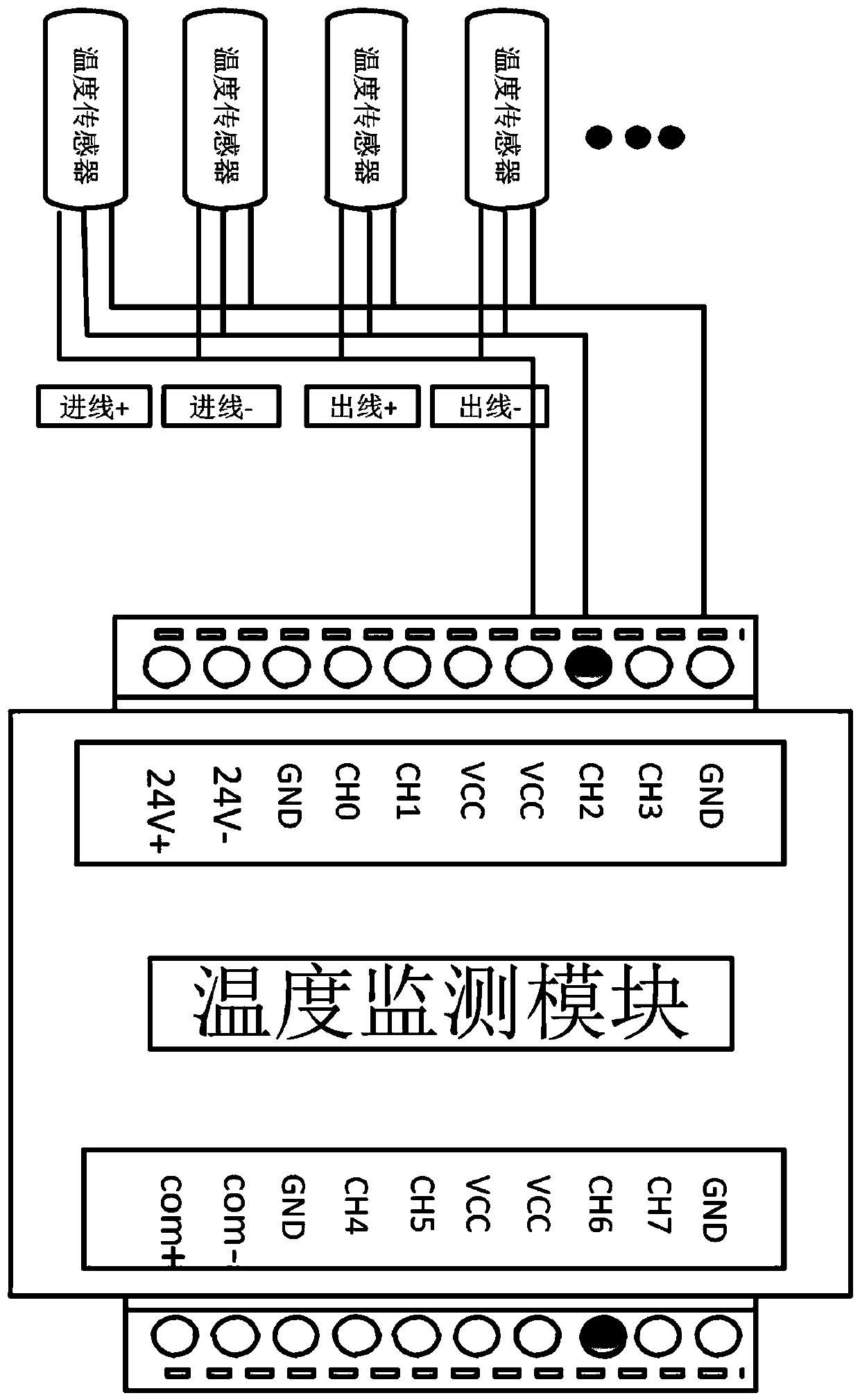

[0041]The temperature monitoring module 200 is connected to several temperature sensors 100 through the "1-WIRE" bus, and is used to centrally receive the temperature data transmitted by several temperature sensors 100, integrate and form a temperature data set before transmission; in addition, the temperature monitoring module 200 is also used for the setting of upward communication parameters, such as baud rate, parity, etc., and provide...

Embodiment 2

[0050] The difference between this embodiment and the previous embodiments is that since the power supply voltage level loaded in the high-performance computer room DC power distribution cabinet is DC300V, the temperature sensor 100 needs to work or even work in a strong electric environment for a long time; therefore, the temperature sensor 100 The surface is encapsulated with an outer sheath made of high temperature resistant and flame retardant material. The setting of the outer sheath can prevent the temperature sensor 100 from being damaged by the strong electric environment.

[0051] Further, the outer sheath is a heat-shrinkable sleeve. The heat-shrinkable tube facilitates the packaging of the conventional temperature sensor 100 and has low manufacturing cost.

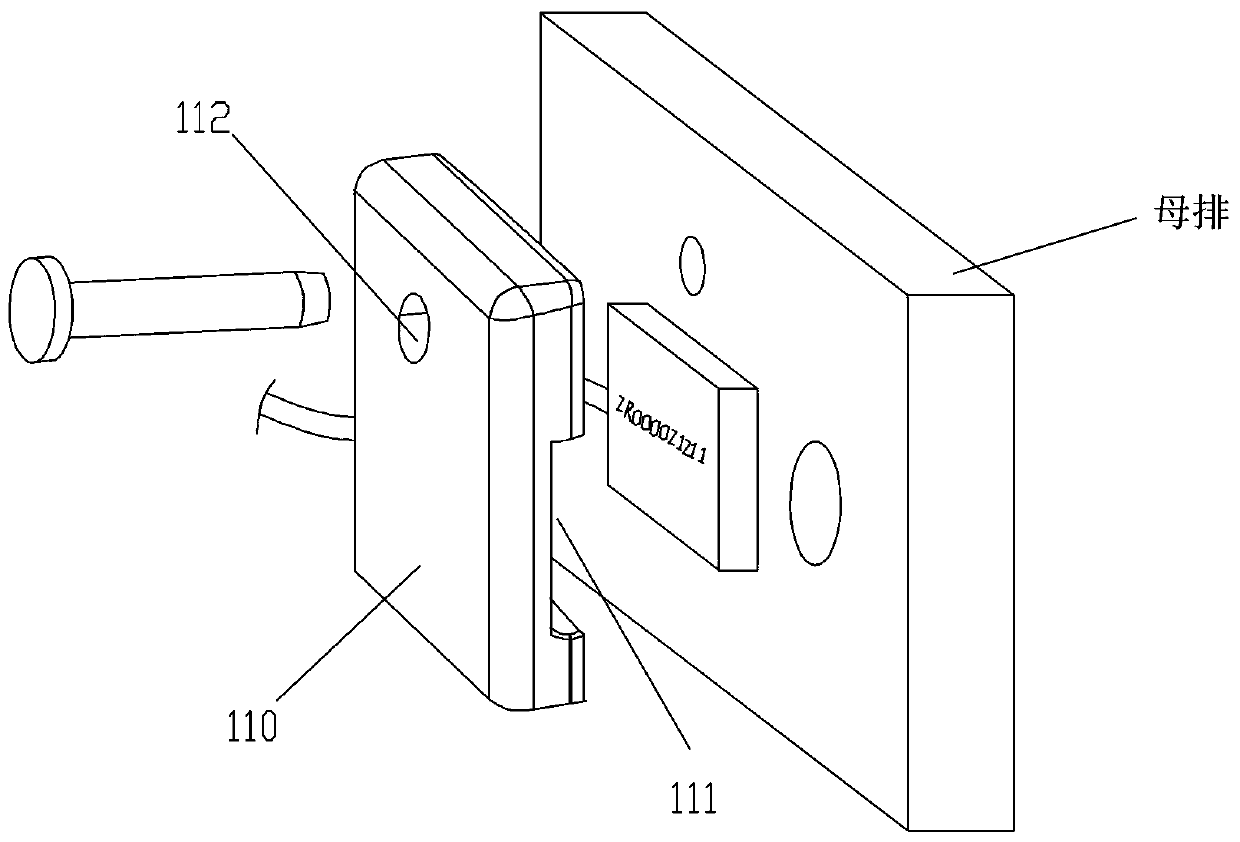

[0052] Such as image 3 As shown, the temperature sensor 100 is limited and fixed on the incoming and outgoing busbars through the insulating clip 110. The insulating clip 110 fixes the temperature sensor 100 ...

Embodiment 3

[0057] The difference between this embodiment and the previous embodiment is that, if Figure 4 As shown, the background server 400 includes an alarm module 410, which is used to classify the temperature data and the temperature data corresponding to the temperature data according to the communication address and the pre-stored communication address mapping table with the same DC power distribution cabinet as a group. The installation location of the temperature sensor, and compare the temperature data with the preset alarm threshold, if it is greater than the preset alarm threshold, an alarm signal is sent, and the communication address mapping table stores the data of the installation location of the temperature sensor 100 corresponding to the communication address , which are uploaded by the system personnel according to the installation situation of the temperature sensor 100 in advance.

[0058] The temperature data is grouped together in the same DC power distribution ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com