Long distance diagnosis real time tracking system and method thereof

A remote diagnosis and real-time tracking technology, applied in special data processing applications, measuring devices, instruments, etc., can solve problems such as deviation, uncontrollable non-routine workload, technical status and fault information not timely and comprehensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be further described below in conjunction with the specific embodiments shown in the accompanying drawings.

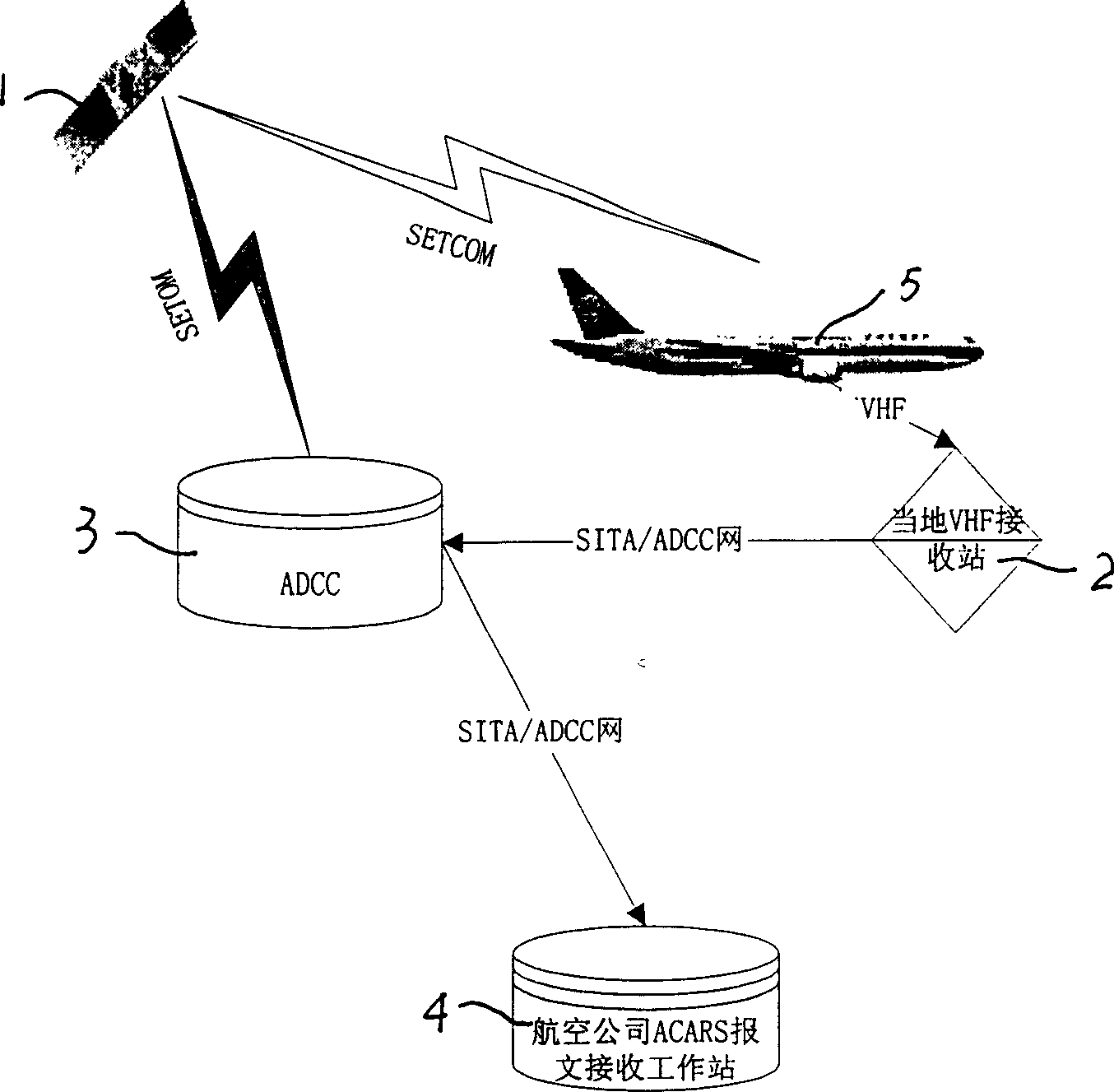

[0093] figure 1 It is a schematic diagram of ACARS message transmission mechanism;

[0094] If the plane is flying over the Pacific Ocean, ACARS will transmit the data (SETCOM) to the satellite through the satellite communication system, and the satellite will transmit the data to the ADCC network; if the plane is flying over the airport, ACARS will transmit the data to the local very high frequency ground workstation (VHF receiving station), and then transfer the data to the ADCC network.

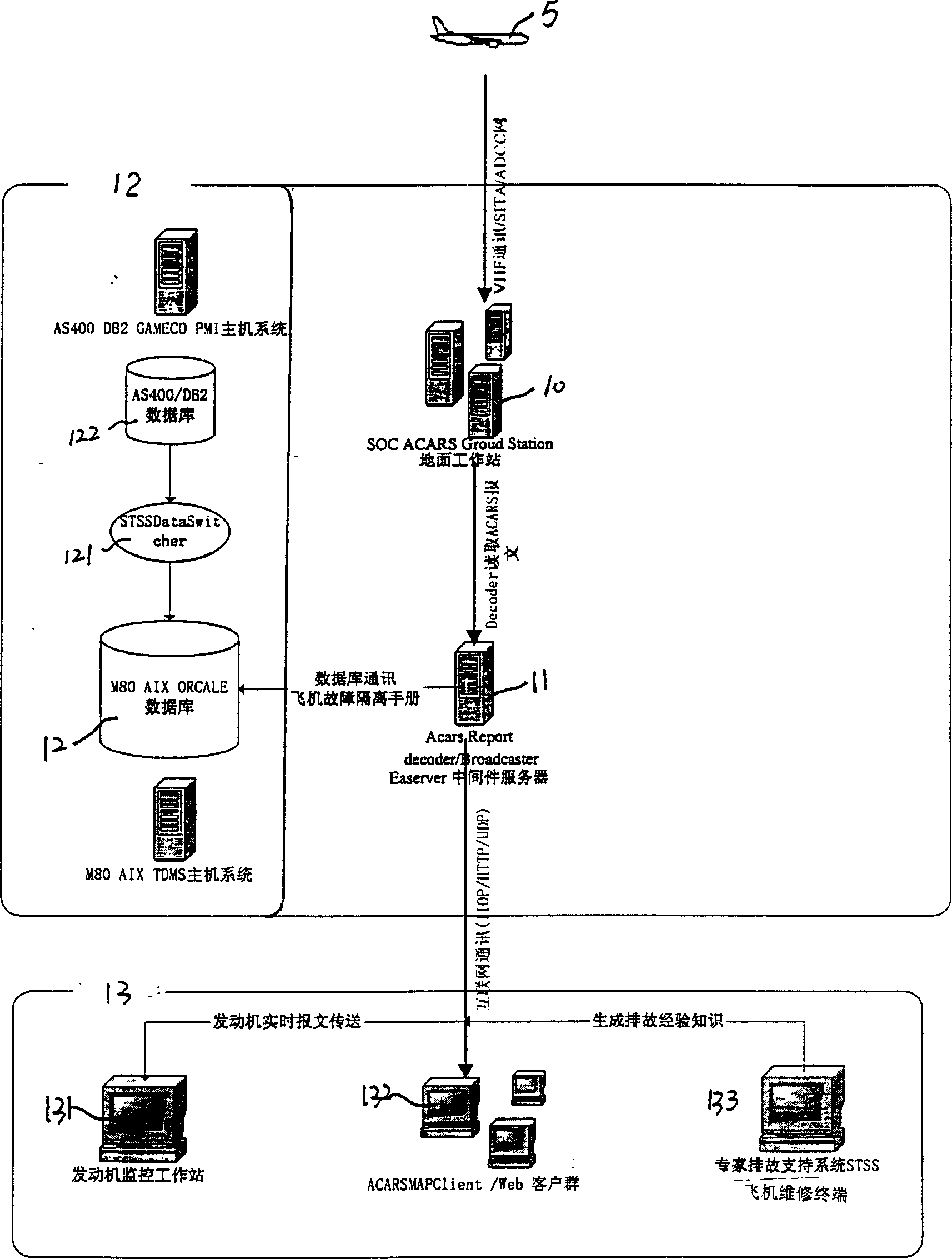

[0095] figure 2 is a system data flow chart of one of the embodiments of the present invention;

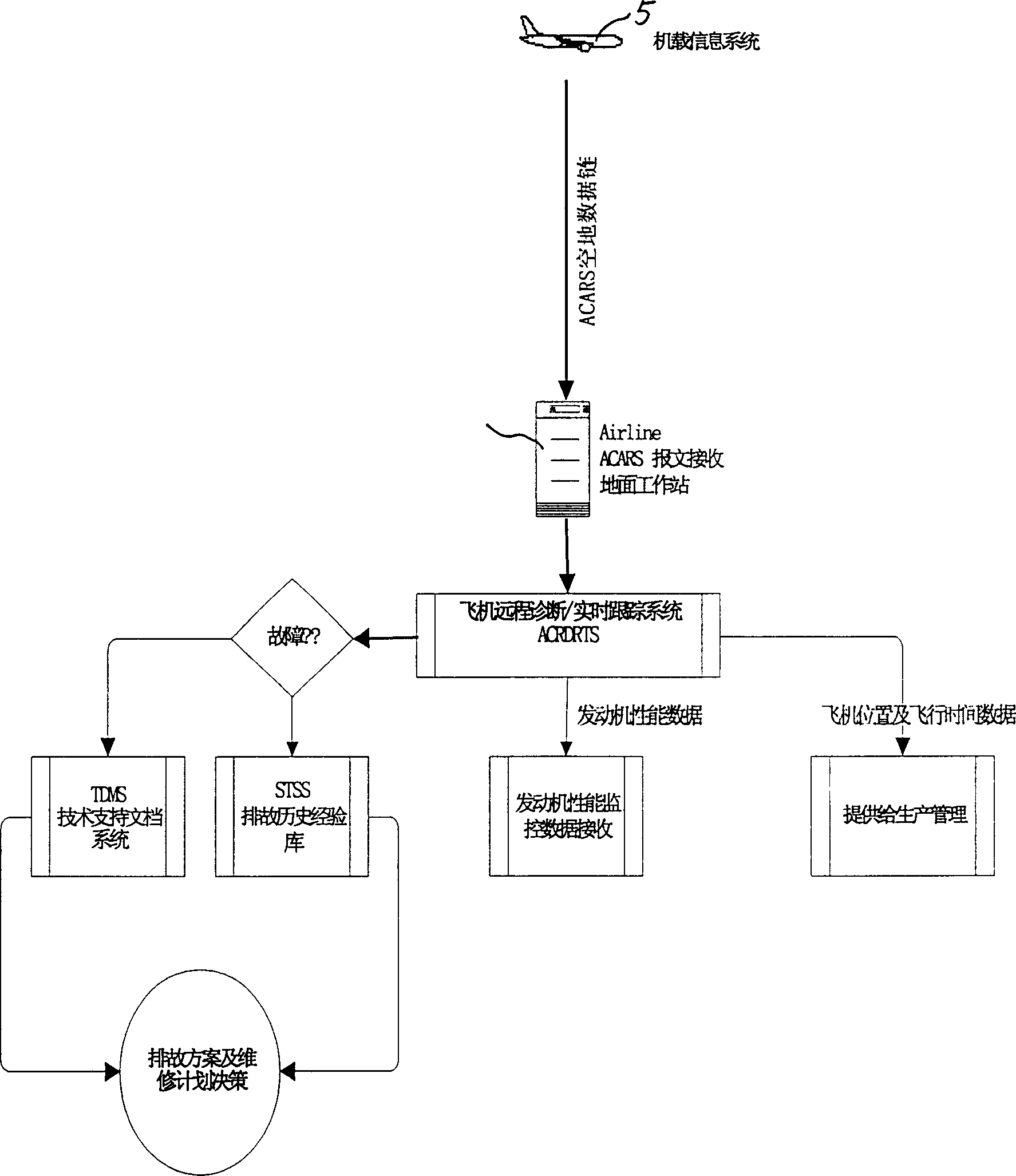

[0096] image 3 is a system operation block diagram of one of the embodiments of the present invention;

[0097] Figure 4 It is a block diagram of software operation of one of the embodiments of the present invention.

[0098] figure 2 , 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com