Manufacturing method of insulated wire

A manufacturing method, technology of insulated wires, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve problems such as shedding, abnormal outer diameter, etc., and achieve the effect of ensuring long-term durability and stable manufacturing

Inactive Publication Date: 2016-04-27

HITACHI METALS LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

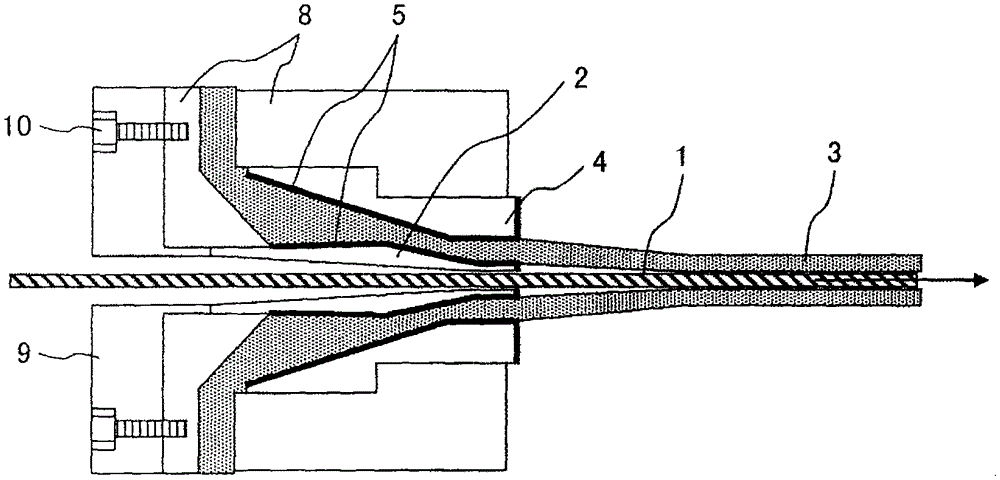

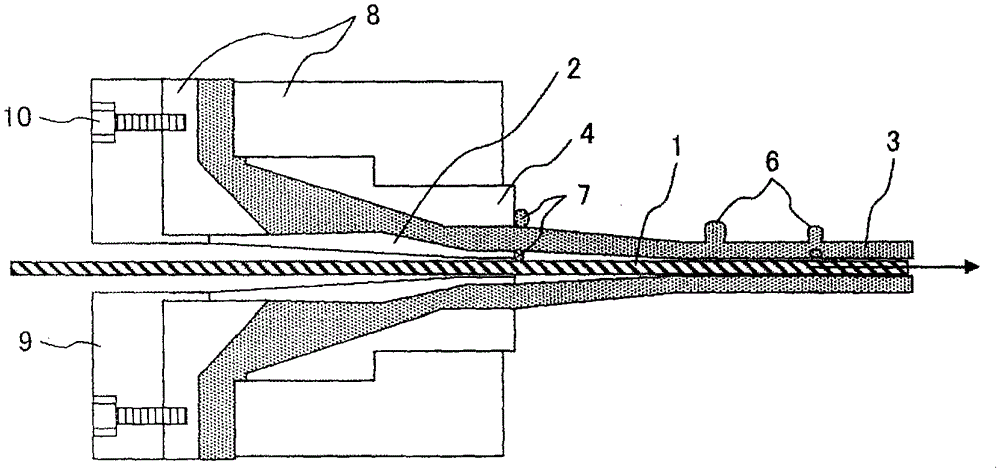

[0003] On the other hand, in the manufacture of insulated wires (especially extrusion coating of insulating coatings), there is a problem that residues such as degradation products and decomposition products of coating resins (sometimes referred to as "eye gum") accumulate during production. On the extrusion surface (outside of the front end) of the molding die, it falls off in some places and adheres to the product, resulting in product defects such as abnormal outer diameter.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

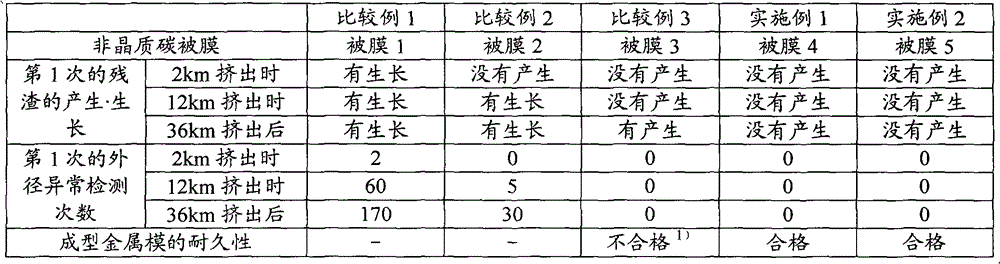

[0035] Hereinafter, the present invention will be described in detail based on examples. However, the present invention is not limited to the examples employed here, and appropriate combinations and improvements are possible within a range that does not change the gist.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Login to View More

Abstract

PROBLEM TO BE SOLVED: To provide a manufacturing method in which a good quality insulated wire can be stably manufactured by preventing cuttings (die drool) from occurring at the tip of a molding die during extrusion coating of an insulation coating layer and securing long-term durability of the molding die.SOLUTION: The manufacturing method of the insulated wire related to the present invention is the manufacturing method of the insulated wire in which a conductor and resin composition are inserted into the molding die and the extrusion coating of the insulation coating layer is performed to the outer periphery of the conductor. The molding die is equipped with an amorphous carbon coating film on a surface in contact with at least the resin composition. The amorphous carbon coating film contains nitrogen, and nitrogen is bonded to carbon constituting the amorphous carbon coating film.

Description

technical field [0001] The present invention relates to a technique for manufacturing an insulated wire, and more particularly to a method for manufacturing an insulated wire in which an insulating coating is extruded and coated. Background technique [0002] As a covering material for insulated wires, polyvinyl chloride (PVC) has been widely used in the past, but in recent years, due to the rising trend of environmental protection, the switch to halogen-free insulated wires is progressing. As such a halogen-free insulated wire, for example, an insulated wire having an insulating coating layer in which an environment-friendly flame retardant (metal hydroxide such as magnesium hydroxide or aluminum hydroxide) is added to a polyolefin material is known. [0003] On the other hand, in the manufacture of insulated wires (especially extrusion coating of insulating coatings), there is a problem that residues such as degradation products and decomposition products of coating resins...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B13/00H01B13/14B29C48/30

Inventor 菊池龙太郎本多史明

Owner HITACHI METALS LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com