Network terminal cabinet system for distributed control system (DCS) instruction

A terminal and instruction technology, applied in the field of network terminal cabinet system for DCS instruction, can solve the problems of no record of state change time, prolonged fault analysis and processing time, large investment cost, etc., and achieves low cost, simple structure and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings, but these embodiments are not limiting.

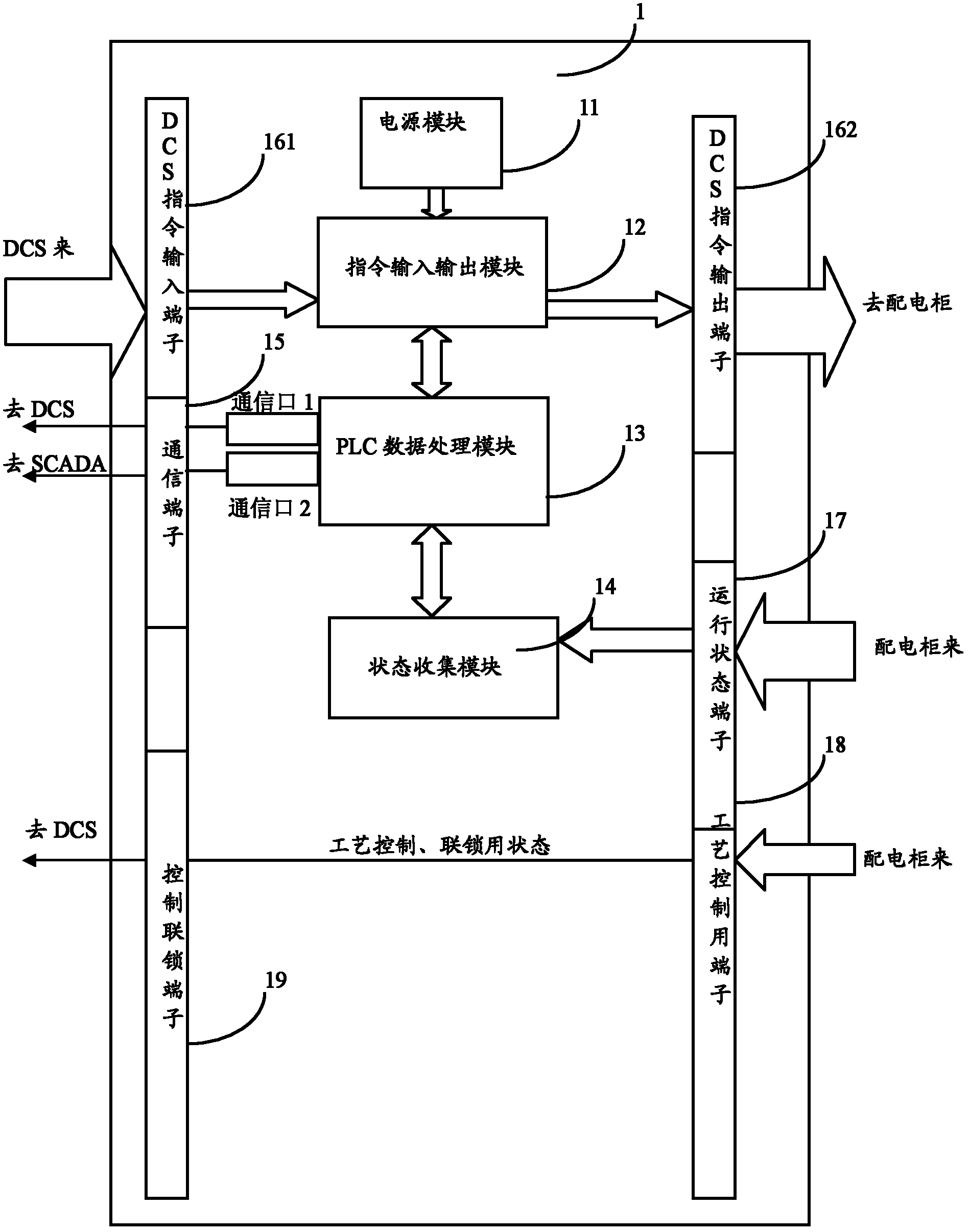

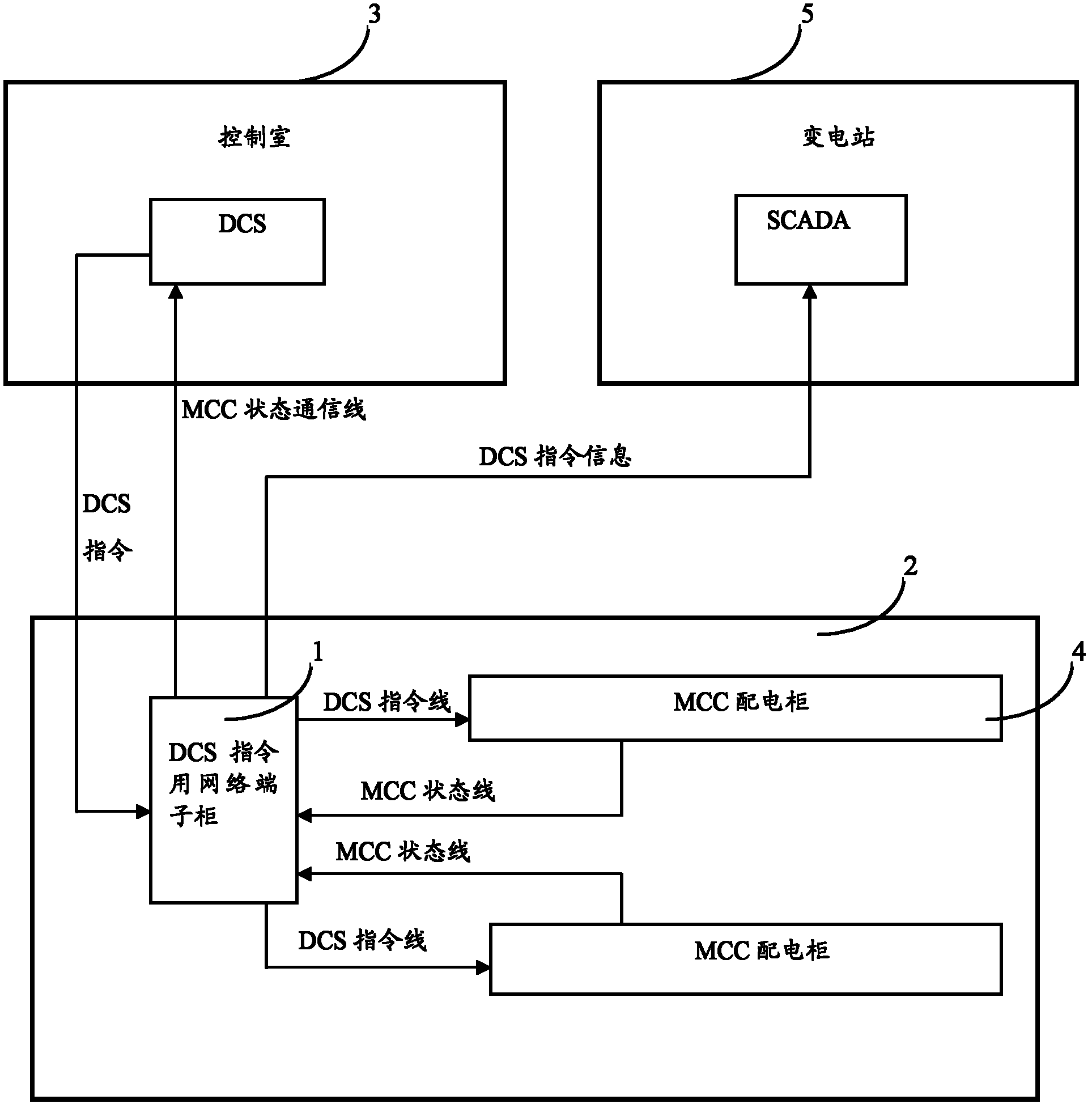

[0028] like figure 1 as shown, figure 1 It is a structural diagram of the network terminal cabinet system for DCS commands. A network terminal cabinet system 1 for DCS commands according to the present invention includes a DCS command input terminal 161, a DCS command output terminal 162, a running status terminal 17, a process control terminal 18, and a control interlock terminal 19. The system also includes Following device: power supply module 11, DCS instruction input and output module 12, PLC data processing module 13, state collection module 14 that are connected with power supply module 11, the communication terminal 15 that is connected with PLC data processing module 13, connect with state collection module 14 The running status terminal 17, the PLC data processing module 13 is also connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com