Composite automotive low-voltage alternating current frequency modulation motor

A frequency-modulated motor and composite technology, which is applied to electric components, electrical components, electromechanical devices, etc., can solve the problems of complex internal structure, high maintenance cost and low efficiency of the motor, and achieve small size, compact space and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

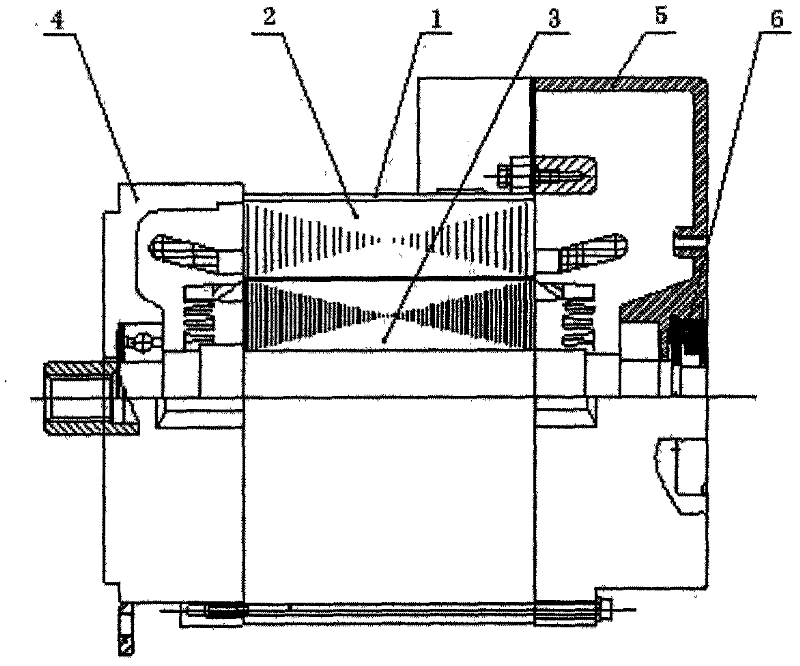

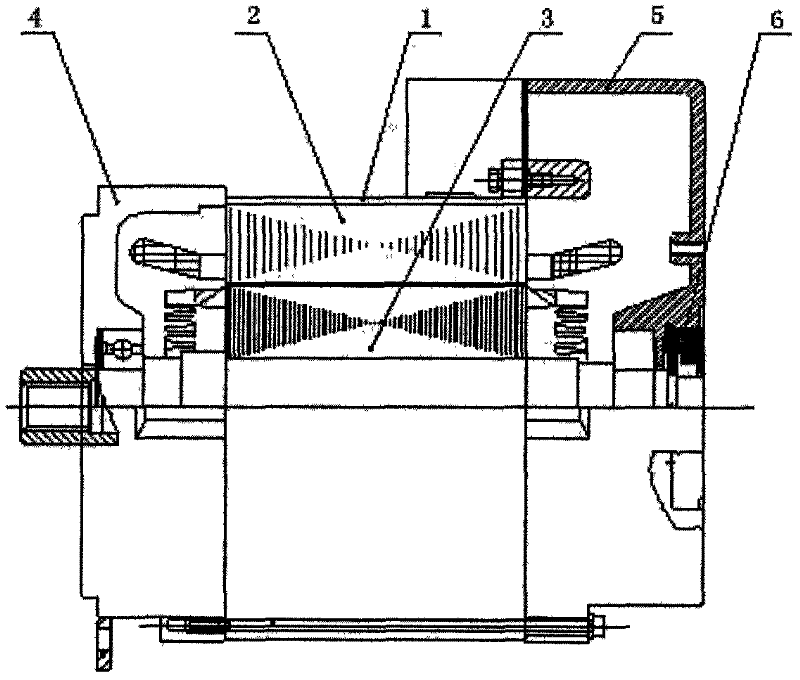

[0010] see figure 1 , a composite vehicle low-voltage AC frequency modulation motor provided by the present invention includes a base 1, a stator 2 located inside the base 1, and a composite rotor 3, the composite rotor 3 is fixed on the motor shaft, and the stator 2 adopts The composite rotor 3 is made of 35% copper and 65% silicon steel sheet structure.

[0011] The machine base 1 is provided with a front end cover 4 and a rear end cover 5, and the material of the machine base 1, the front end cover 4 and the rear end cover 5 is aluminum.

[0012] Sensors 6 are arranged inside the motor and on the rear cover of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com