Low-cogging-torque motor stator and assembling method thereof

A technology of cogging torque and motor stator, which is used in electromechanical devices, manufacturing stator/rotor bodies, electrical components, etc. The process is simple, the winding process is convenient, and the manufacturing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

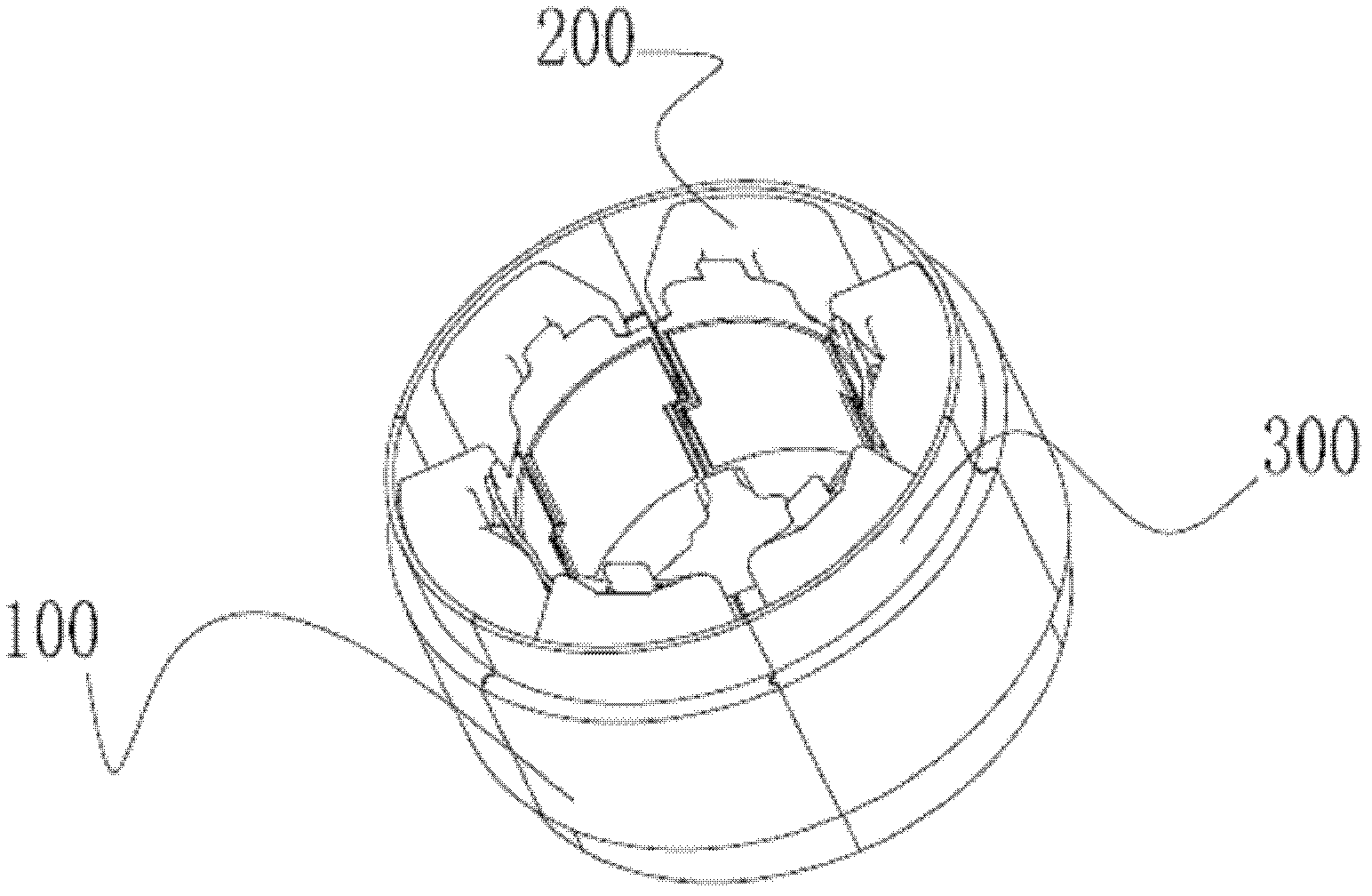

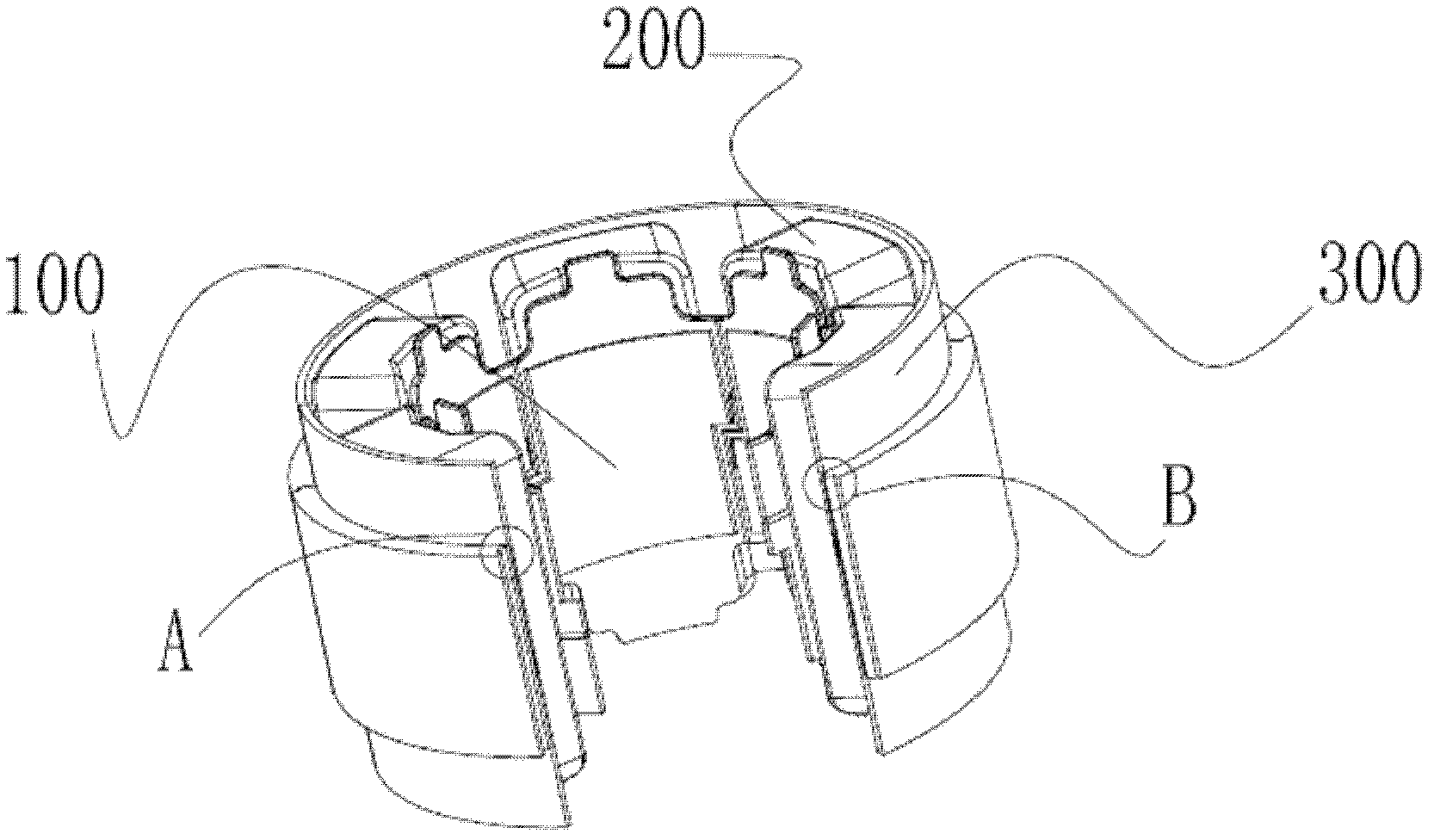

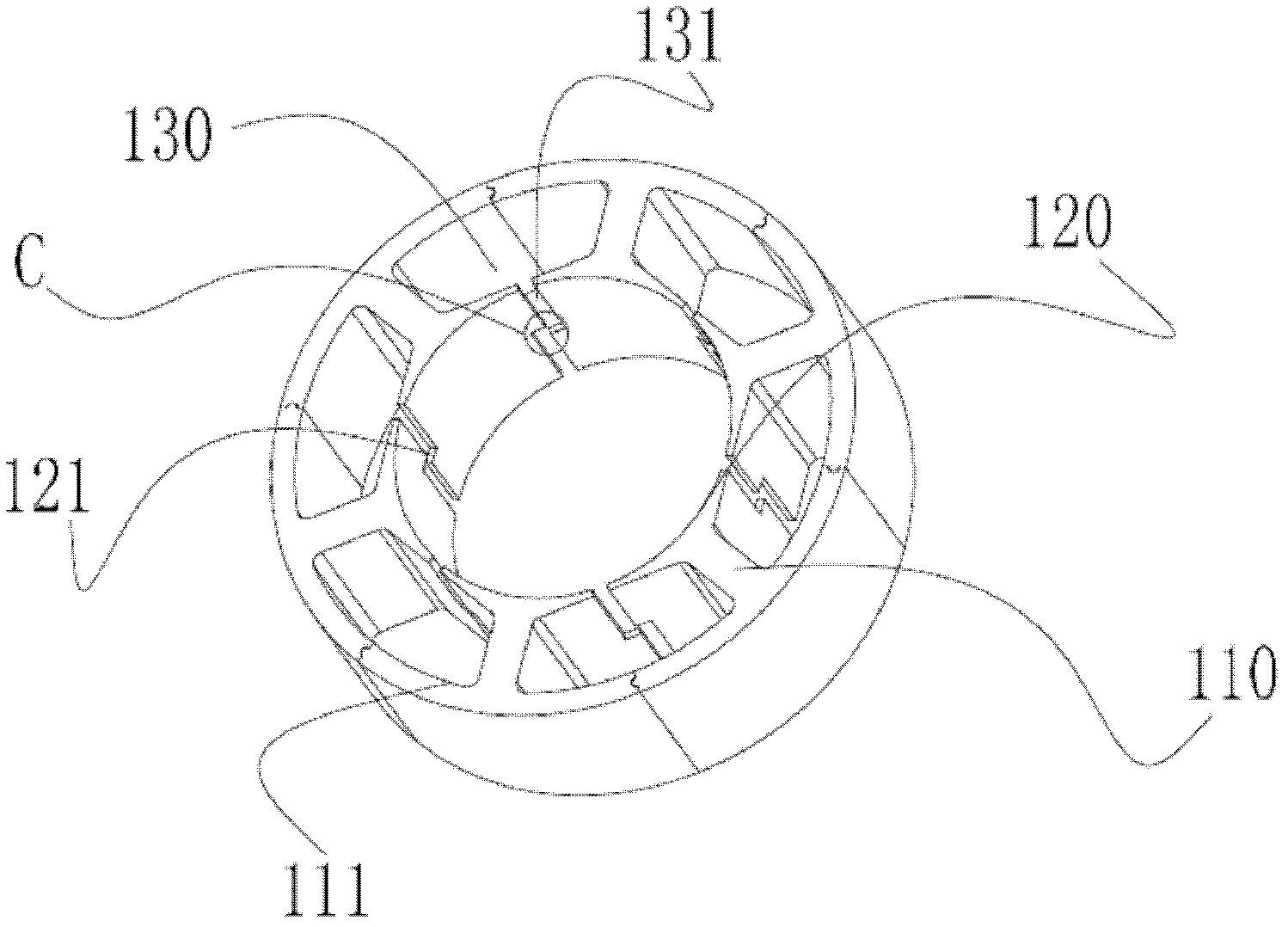

[0035] Embodiment 1. A stator of a low cogging torque motor, comprising a stator core 100 and a stator coil 200, wherein: the inner circumference of the stator core 100 integrally extends a plurality of stator teeth 110 distributed at intervals, and the ends of the stator teeth 110 are provided with The pole shoe 120 forms a stator slot 130 between adjacent stator teeth 110, and the stator coil 200 is placed in the stator slot 130. A step 121 is provided on both sides of each pole shoe 120. The step 121 corresponds to the step 121 on the adjacent pole piece 120 to form a bent notch 131 .

Embodiment 2

[0036] Embodiment 2. A stator of a low cogging torque motor, comprising a stator core 100 and a stator coil 200, wherein: two sides of each pole shoe 120 are provided with two steps 121 distributed at intervals, and the The step 121 of the pole shoe 120 is matched with the step 121 on the adjacent pole shoe 120 to form a notch 131 in a bent shape, and the rest is the same as that of the first embodiment.

Embodiment 3

[0037] Embodiment 3. A stator of a low cogging torque motor, comprising a stator core 100 and a stator coil 200, wherein: each side of each pole piece 120 is provided with three steps 121 distributed at intervals. The step 121 of the pole shoe 120 is matched with the step 121 on the adjacent pole shoe 120 to form a notch 131 in a bent shape, and the rest is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com