Load driving device and system

一种负载驱动、负载单元的技术,应用在电路领域,能够解决调整管损耗大、接线复杂、驱动器发热等问题,达到节约成本、降低复杂度、接线简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

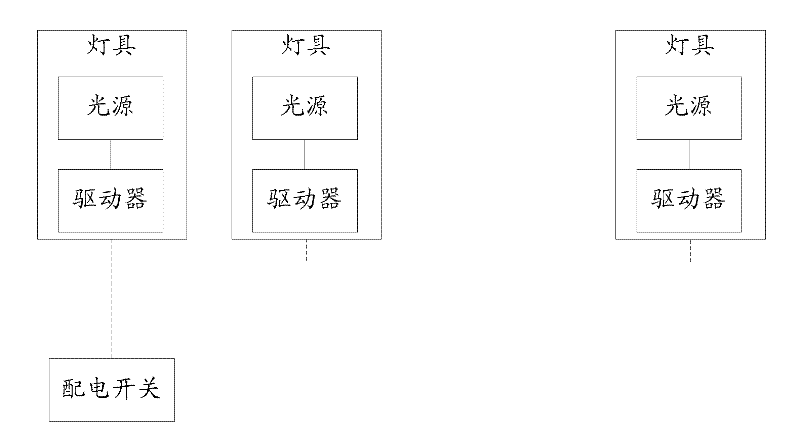

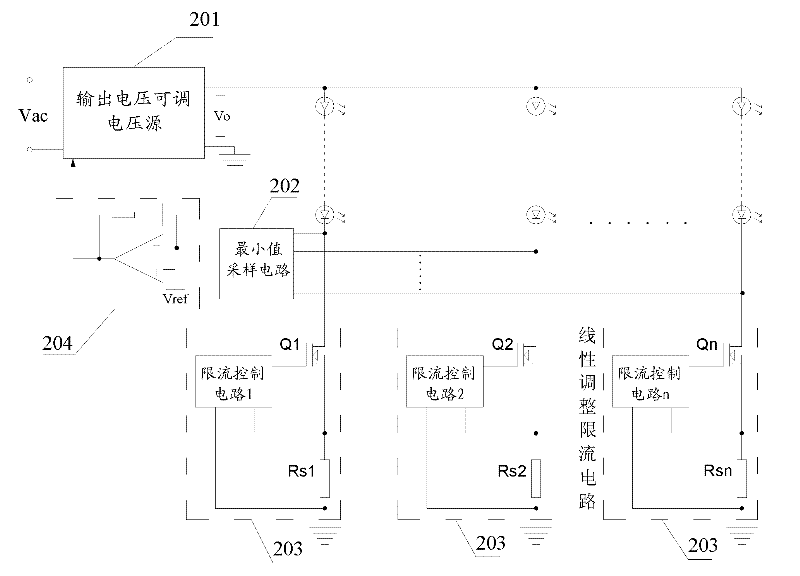

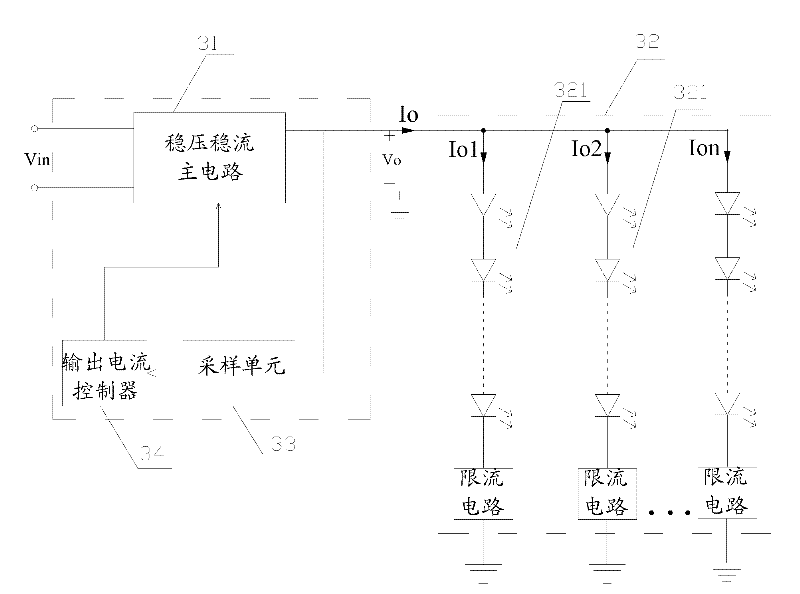

[0061] Hereinafter, specific implementations of the load driving device and system according to the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0062] The load driving device of the embodiment of the present invention includes the following structure:

[0063] The voltage-stabilizing and current-stabilizing main circuit is used to perform voltage conversion on the input voltage under the control of the output current controller, and provide electric energy to the load unit of the subsequent stage;

[0064] The sampling unit is connected to the output terminal of the main circuit for voltage and current stabilization, and is used for sampling the output characteristic parameters of the main circuit for voltage and current stabilization, and sending the sampled signal to the output current controller;

[0065] Output current controller, the input terminal is connected with the output terminal of the sampling u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com