A kind of glycopyrrolate injection and preparation method thereof

A technology of glycopyrronium bromide and injection, which is applied in the field of preparation of glycopyrronium bromide injection, can solve the problems of toxic reaction, side effect of benzyl alcohol, large adsorption of main drug content, etc., achieves improved stability, wide application range, The effect of reducing the amount of heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of glycopyrrolate injection includes the following steps:

[0024] 1) Add sodium chloride and 50~90% of the formula amount of water for injection into the preparation tank. After dissolving, add the remaining amount of water for injection and pH regulator to adjust the pH to 1.0~4.0 to obtain solution A;

[0025] 2) At a constant temperature of 30~40℃, put glycopyrrolate into solution A, stir until it is completely dissolved, and then coarsely filter through a 0.45μm microporous membrane in the filtrate tank, and then pass through 0.22μm The microporous membrane is used for terminal filtration to obtain intermediate products;

[0026] 3) Fill the filtrate can in a container made of neutral borosilicate material, seal it, and then steam sterilize it at 115-121℃ for 8-30 minutes to obtain glycopyrrolate injection.

[0027] The invention controls the endotoxin of the auxiliary materials and performs fine filtration of the material liquid, thereby reducing the ...

Embodiment 1

[0030] A preparation method of glycopyrrolate injection includes the following steps:

[0031] 1) Add 50% volume of water for injection and 7.0g of sodium chloride to the preparation tank, add the remaining amount of water for injection after dissolving, add 0.1ml of hydrochloric acid, then add 0.01g of sodium hydroxide, adjust the pH to 2.5 to obtain a solution A;

[0032] 2) Under the constant temperature condition of 35℃, throw 0.1g glycopyrronium bromide into solution A, stir until it is completely dissolved, and then coarsely filter through 0.45μm microporous membrane in the filtrate tank, and then pass through 0.22μm The microporous membrane is used for terminal filtration to obtain intermediate products;

[0033] 3) Fill the filtrate can in a container made of neutral borosilicate material, seal, and then steam sterilize at 121°C for 15 minutes to obtain glycopyrrolate injection.

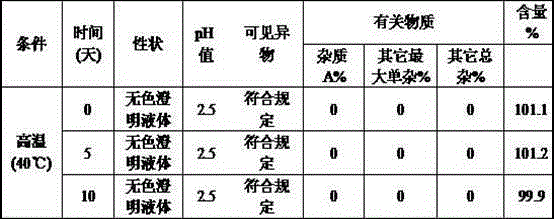

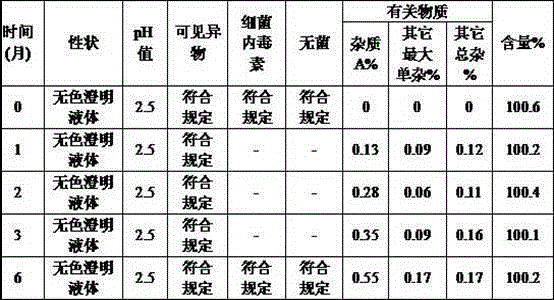

[0034] In this example, the glycopyrrolate injection was made into 1000 injections, and the pH o...

Embodiment 2

[0036] A preparation method of glycopyrrolate injection includes the following steps:

[0037] 1) Add 80% volume of water for injection and 9.0g of sodium chloride to the preparation tank, add the remaining amount of water for injection after dissolution, then add 0.1ml of hydrochloric acid, adjust the pH to 3.0, and obtain solution A;

[0038] 2) Under the constant temperature condition of 30℃, throw 0.2g glycopyrronium bromide into solution A, stir to completely dissolve, in the filtrate tank through a 0.45μm microporous membrane for coarse filtration, and then through 0.22μm The microporous membrane is used for terminal filtration to obtain intermediate products;

[0039] 3) The filtrate can be filled in a neutral borosilicate container, sealed, and then steam sterilized at 115°C for 30 minutes to obtain glycopyrrolate injection.

[0040] In this example, the glycopyrrolate injection was made into 1000 injections, and the pH of the glycopyrrolate injection was 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com