Stainless steel wire annealing and heating process system

A technology of stainless steel wire and process system, which is applied in the field of annealing technology, can solve the problems of large variable factors of protective gas, easy explosion of hydrogen gas, high cost, etc., reduce cooling consumption time and heat source, good metallographic structure, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

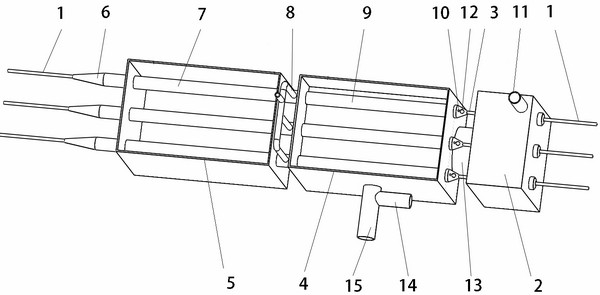

[0029] like figure 1 The shown stainless steel wire annealing and heating process system has a plurality of stainless steel wires arranged in parallel. According to the walking route, each stainless steel wire passes through its own oven steel pipe section, exposed section, wire feeding steel pipe section, annealing furnace steel pipe section, cooling Pipe section, wire outlet pipe section.

[0030] The wire feed steel pipe section, the annealing furnace steel pipe section, the cooling pipe section and the wire outlet pipe section are interconnected pipelines.

[0031] A reducing gas pipeline is connected between the steel pipe section of the annealing furnace and the cooling pipe section. The entrance of the wire feeding steel pipe section has an opening for the outflow of reducing gas and the entry of stainless steel wire. It can be used for the outflow of stainless steel wire, but not for the outflow of reducing gas.

Embodiment 2

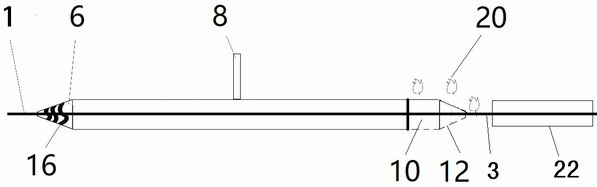

[0033] like figure 2 As shown, using the device in the first embodiment, the pipe wall of the wire-feeding steel pipe section is preset with a plurality of downward air outlet holes arranged along the length direction as openings for the reducing gas to be discharged step by step, and the air is mixed with the air. Oxygen in the reactor is ignited at the outlet to generate heat, heating the tube wall, so that the stainless steel wire is heated for the second time, and the stainless steel wire is instantly heated online to the second stage temperature required for annealing.

[0034] By controlling the speed of the steel wire, the diameter data of the wire feeding tube, the diameter data of the steel wire, the pressure or flow of the alkane (especially butane) gas, etc., the three sections of the steel wire can be controlled to be heated section by section, and the final temperature reaches the required annealing temperature. temperature. Next, the wire is pulled out after bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com