Method for manufacturing PCB (Printed Circuit Board), PCB and electronic equipment

A technology of electronic equipment and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., and can solve the problems of laser head wear and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] see figure 2 as well as Figures 3a-3d , the present embodiment provides a method for manufacturing a circuit board, comprising:

[0027] Step 101 , respectively fixing at least two functional modules and a shielding frame on a substrate of a circuit board, wherein the shielding frame is located between the at least two functional modules.

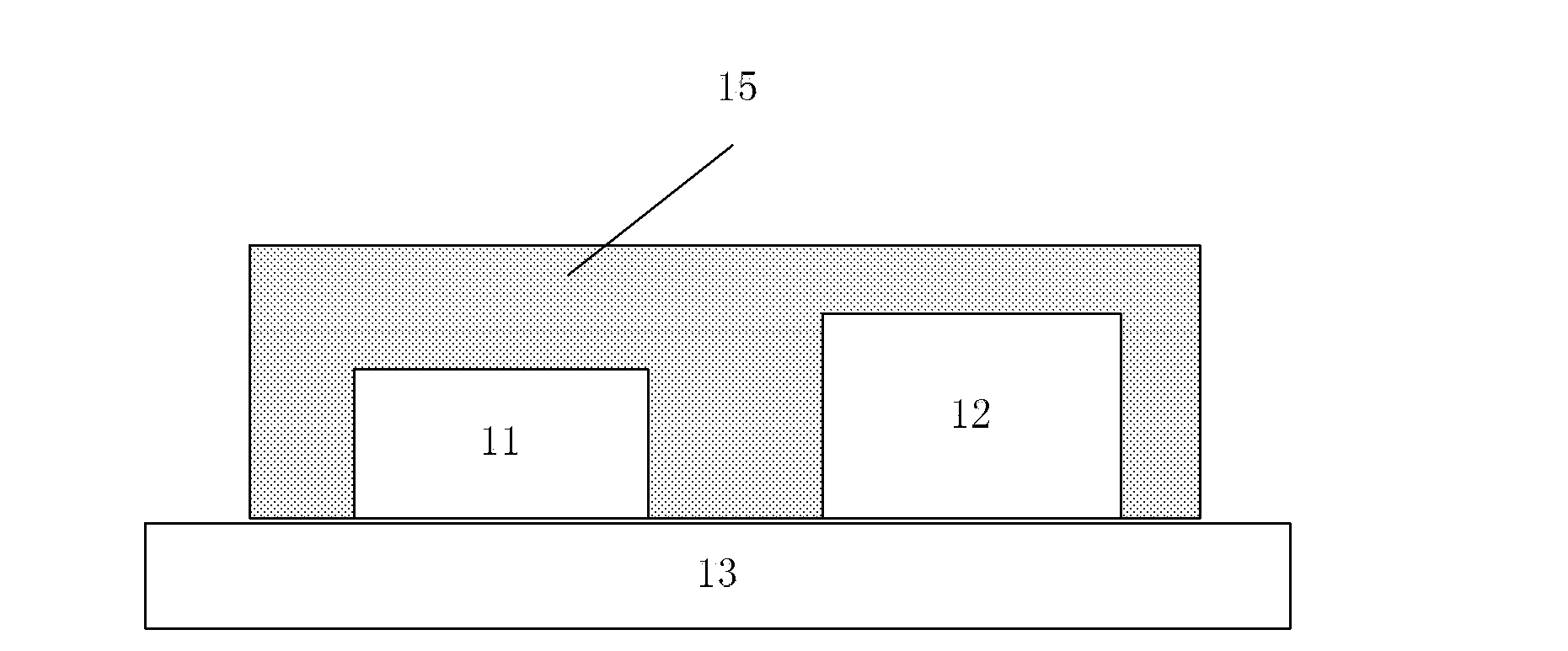

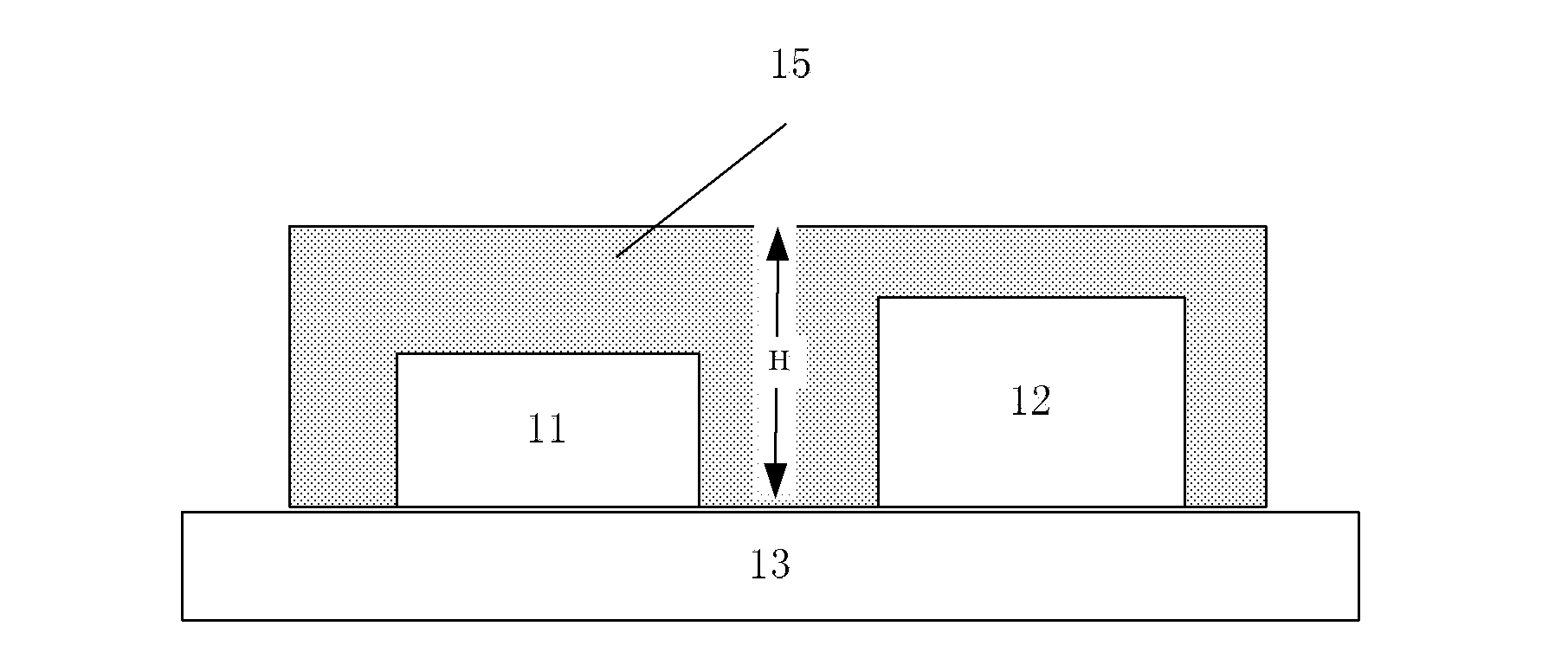

[0028] Take two function modules as an example, see Figure 3a As shown, the functional module 21 , the functional module 22 and the shielding frame 23 are fixed on the substrate 24 of the circuit board, and the shielding frame 23 is located between the functional modules 21 and 22 .

[0029] Step 102: Plastic-encapsulate the at least two functional modules and the shielding frame with a plastic-sealing material to cover the at least two functional modules and the shielding frame.

[0030] see Figure 3b As shown, the functional modules 21 , 22 and the shielding frame 23 are plastic-sealed with a plastic sealing material 25 to ...

Embodiment 2

[0042] see Figure 4 , use the manufacturing method of a kind of circuit board that provides among the embodiment 1 to make mobile phone circuit board in the present embodiment, its method process comprises:

[0043] Step 201. Solder the baseband circuit, the radio frequency circuit and the shielding frame on the substrate of the circuit board respectively, wherein the shielding frame is located between the baseband circuit and the radio frequency circuit.

[0044] In this embodiment, description is made by taking the baseband circuit as the first functional module and the radio frequency circuit as the second functional module as an example, but the first functional module and the second functional module are not limited thereto. For example, SMT can be used to weld the baseband circuit and the radio frequency circuit to the substrate of the PCB. In this embodiment, a shielding frame is welded between the baseband circuit and the radio frequency circuit, and the shielding fra...

Embodiment 3

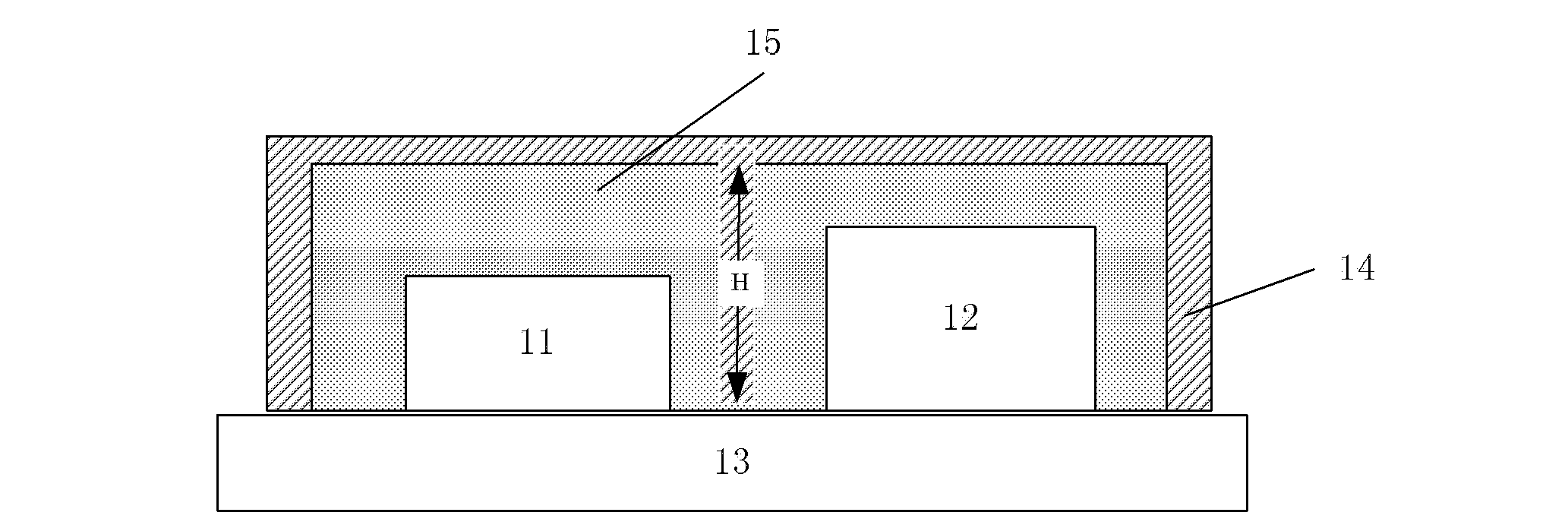

[0058] This embodiment provides a circuit board made using the method provided in Embodiment 1, refer to Figure 3d , the circuit board includes: a substrate 24, at least two functional modules 21, 22, and a shielding frame 23, wherein the at least two functional modules 21, 22, and the shielding frame 23 are fixed to the substrate 24, so The shielding frame 23 is located between the at least two functional modules 21, 22, the sides of the shielding frame 23 and the at least two functional modules 21, 22 are covered by a plastic sealing material 25, and the shielding frame 23 above The outer surface of the plastic sealing material 25 is covered with a conductive material 26 , and the outer surface of the conductive material 26 is covered with an insulating material 27 .

[0059] In this embodiment, the functional modules are all functional modules on the PCB, which may be baseband circuits, radio frequency circuits, antennas, etc., which are not specifically limited in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com