Patents

Literature

147results about "Screening rigid plastic containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS20030066672A1Eliminate needHeat dissipationMolten spray coatingScreening gaskets/sealsMolten stateThermal spraying

Heat dissipation and electromagnetic interference (EMI) shielding for an electronic device having an enclosure. An interior surface of the enclosure is covered with a conformal metallic layer which, as disposed in thermal adjacency with one or more heat-generating electronic components or other sources contained within the enclosure, may provide both thermal dissipation and EMI shielding for the device. The layer may be sprayed onto the interior surface in a molten state and solidified to form a self-adherent coating.

Owner:PARKER INTANGIBLES LLC

Thermal-sprayed metallic conformal coatings used as heat spreaders

InactiveUS6965071B2Eliminate needReduce device temperatureMolten spray coatingScreening gaskets/sealsElectromagnetic interferenceEngineering

Owner:PARKER INTANGIBLES LLC

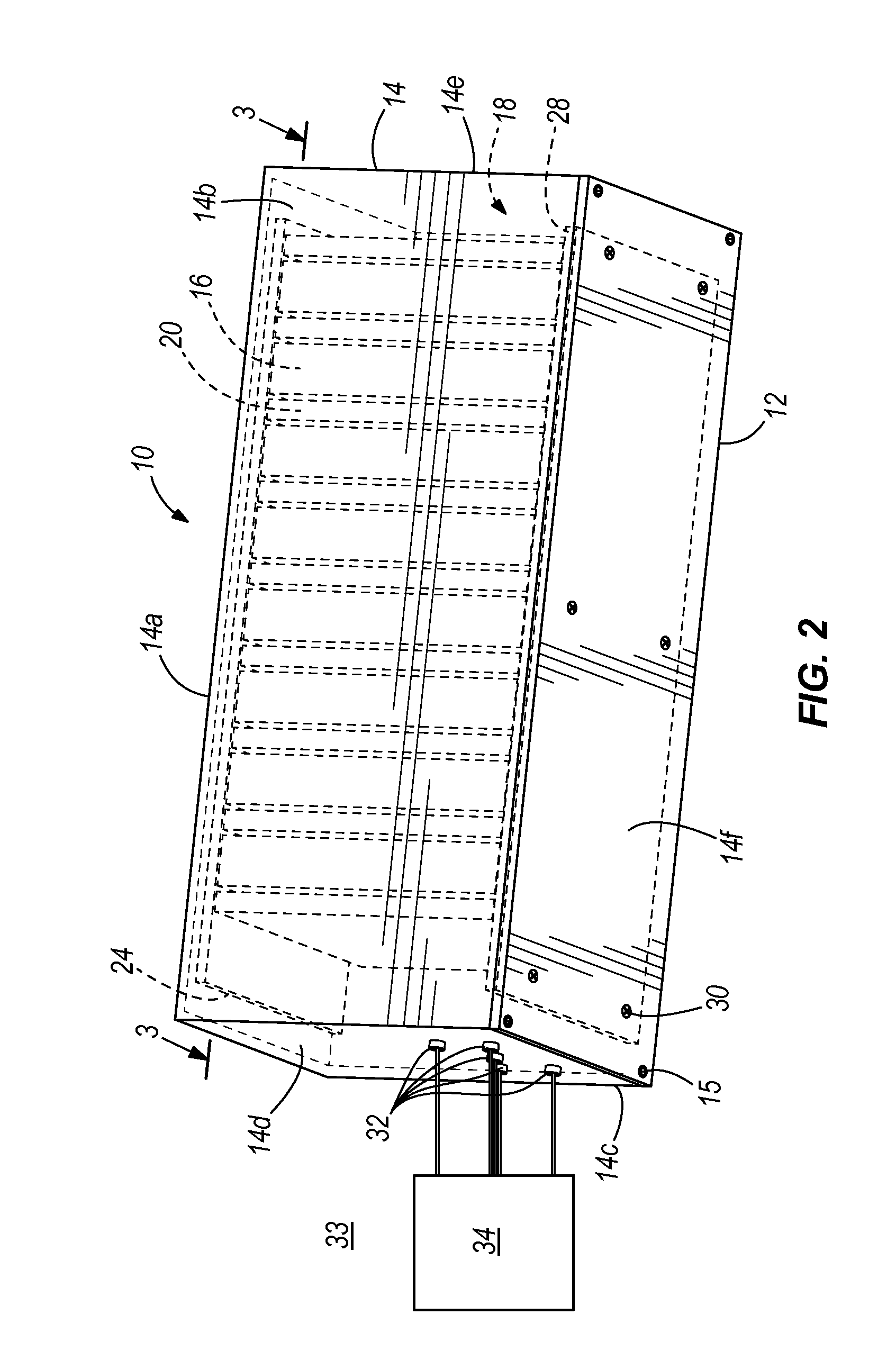

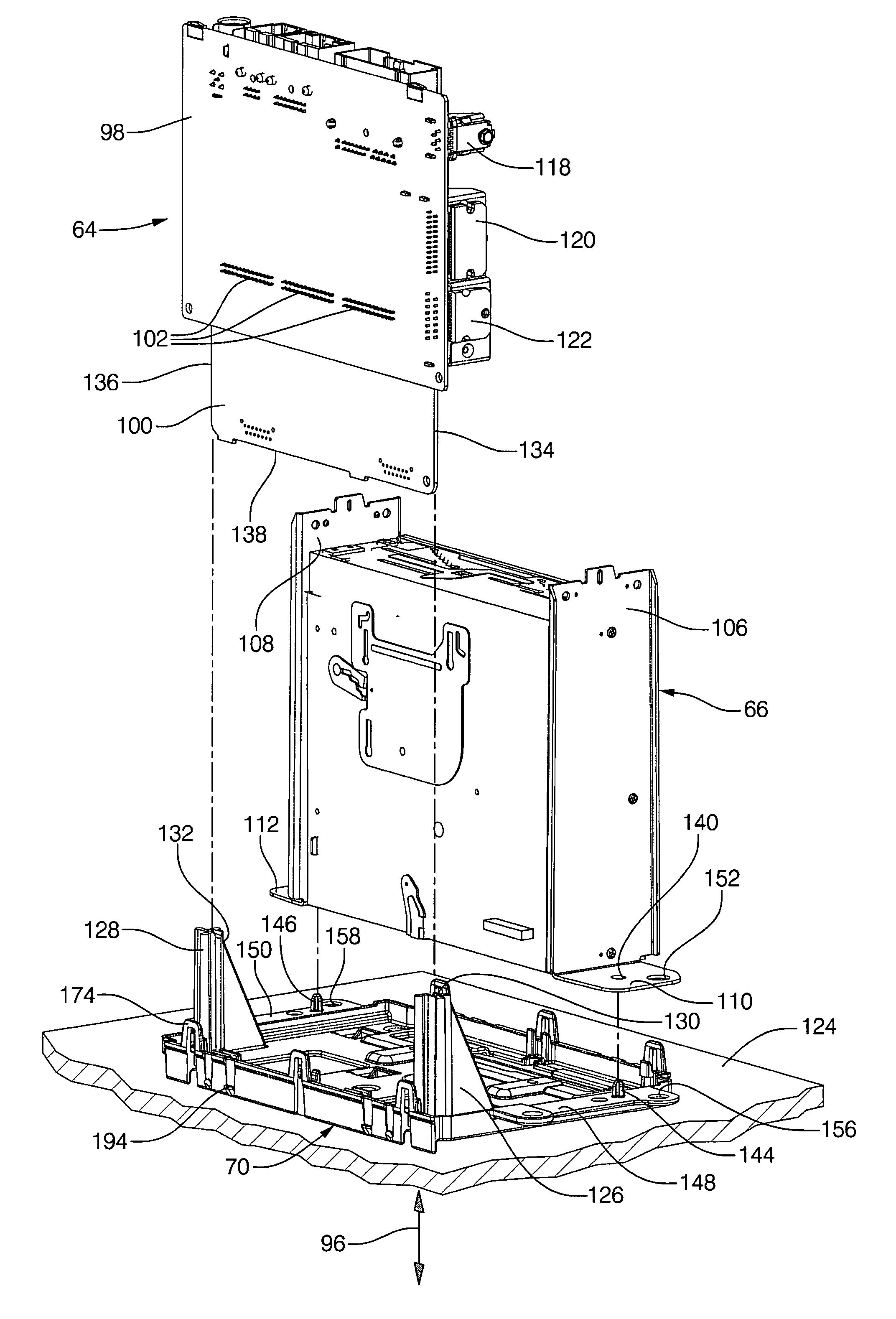

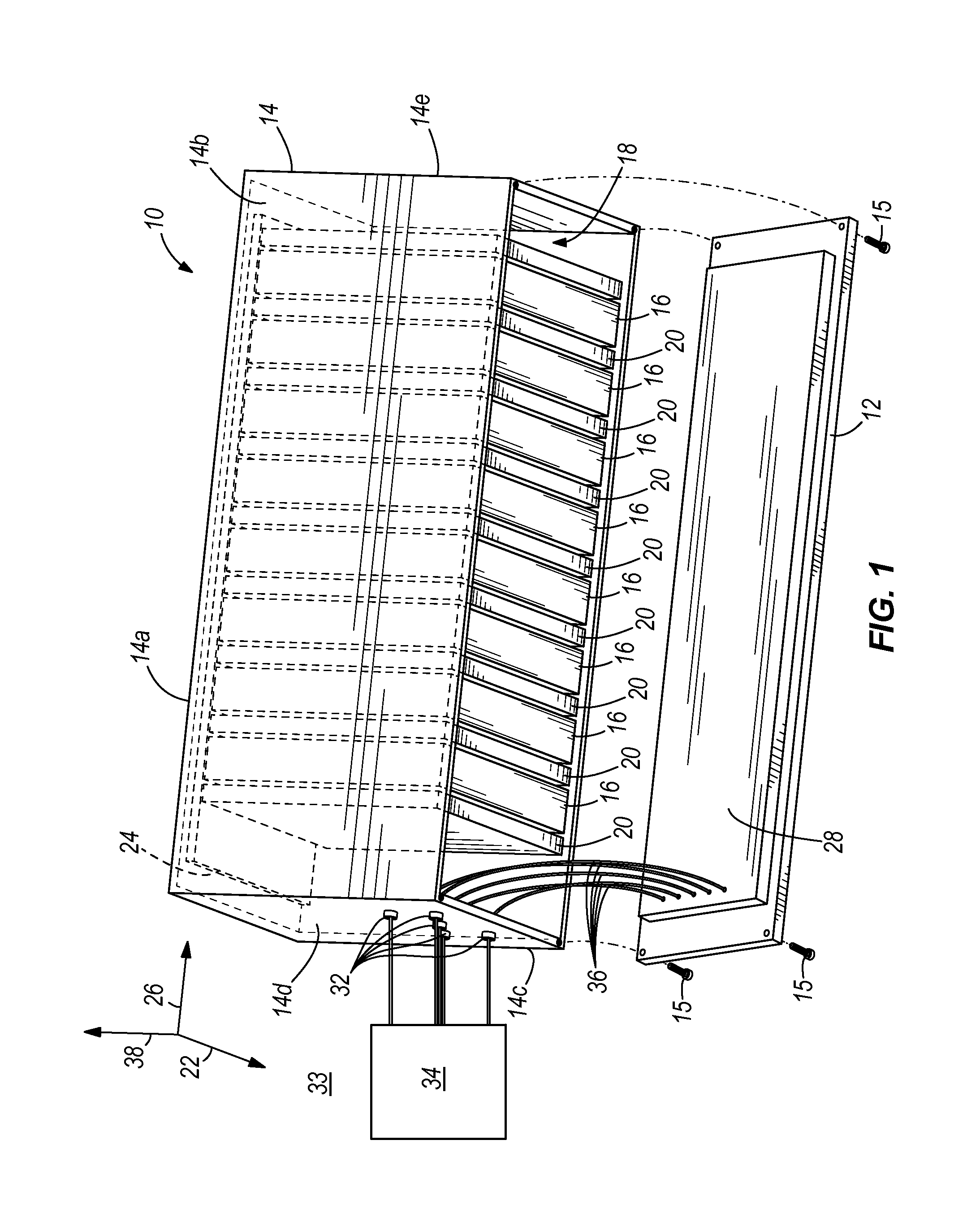

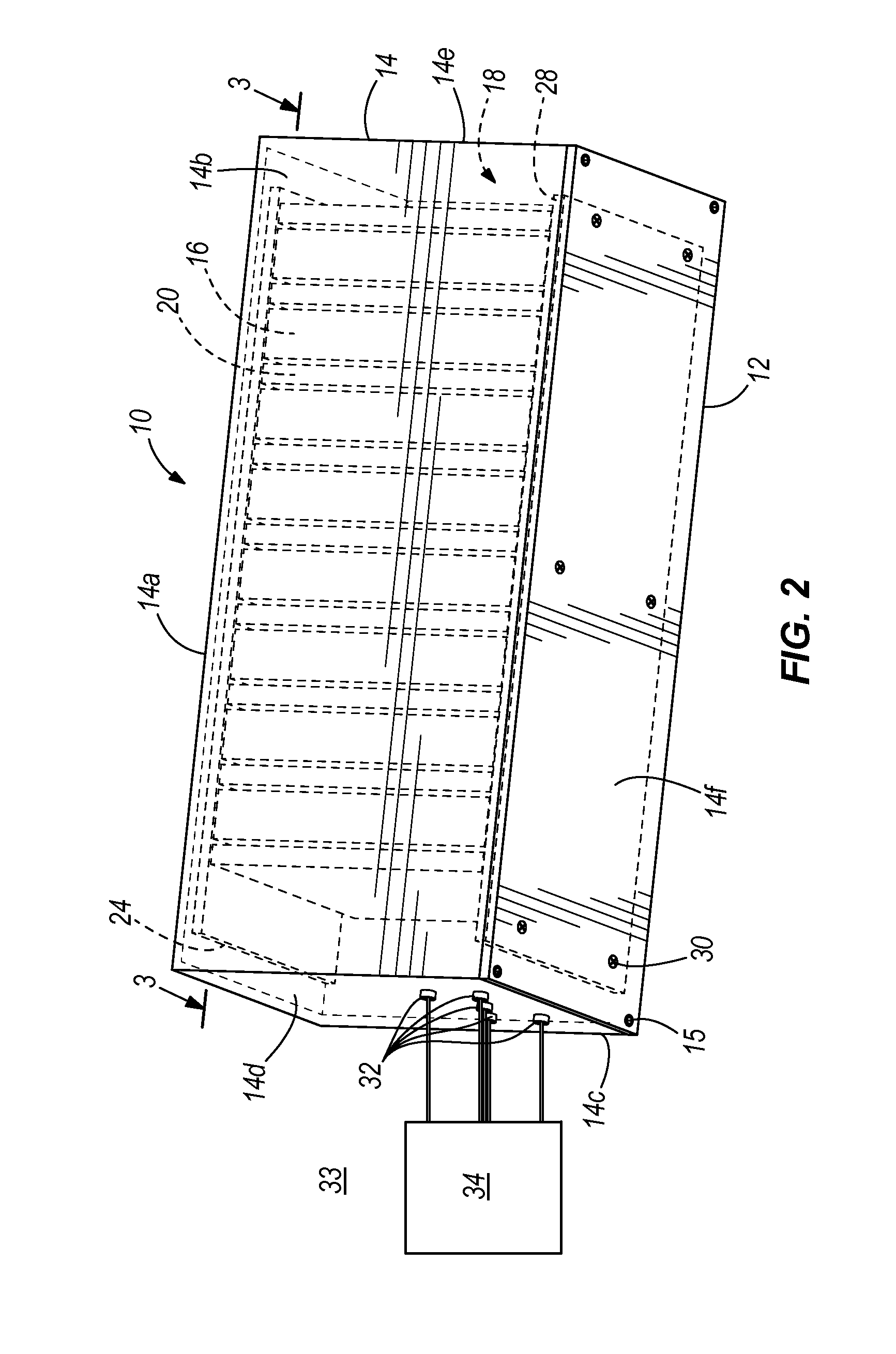

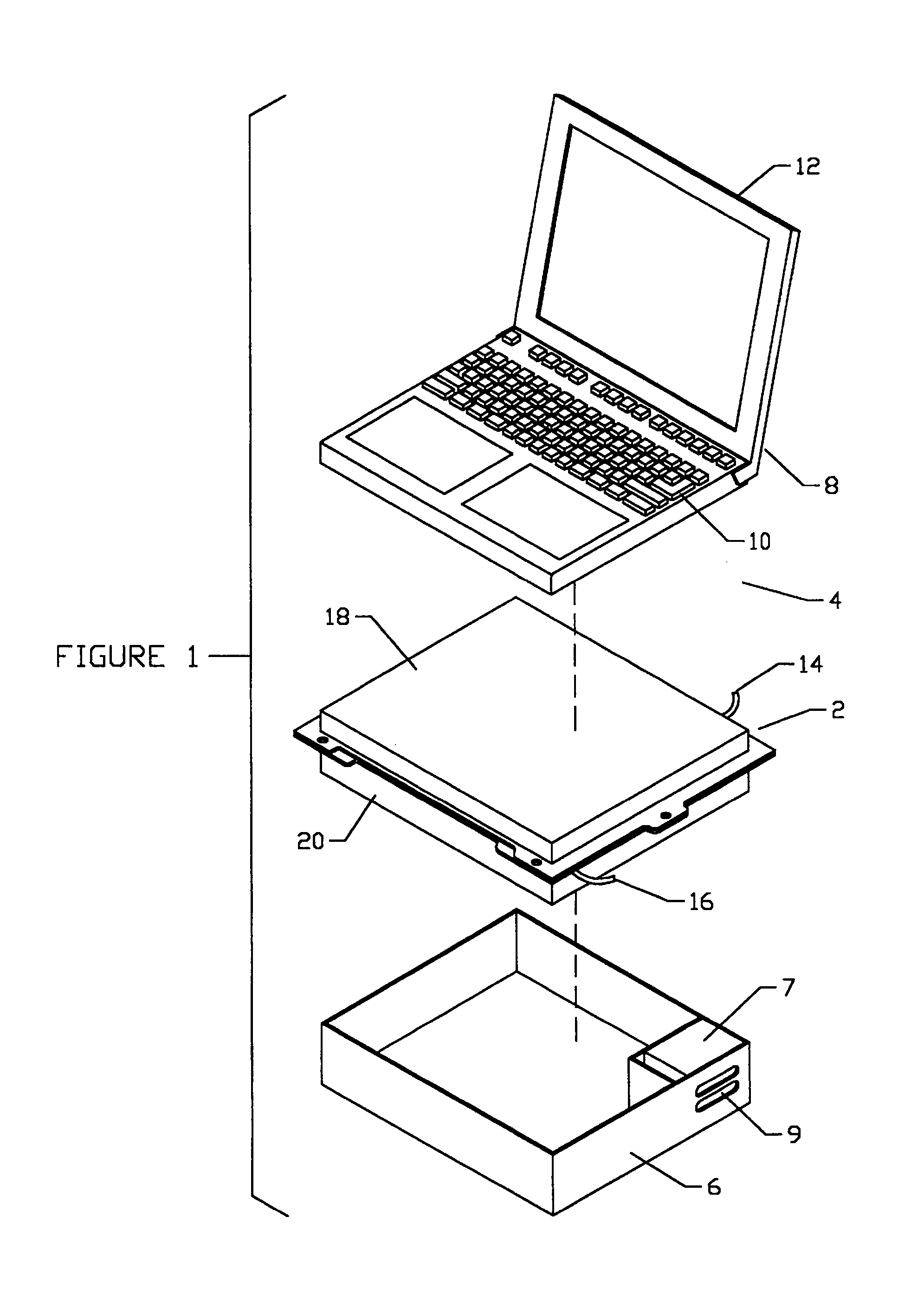

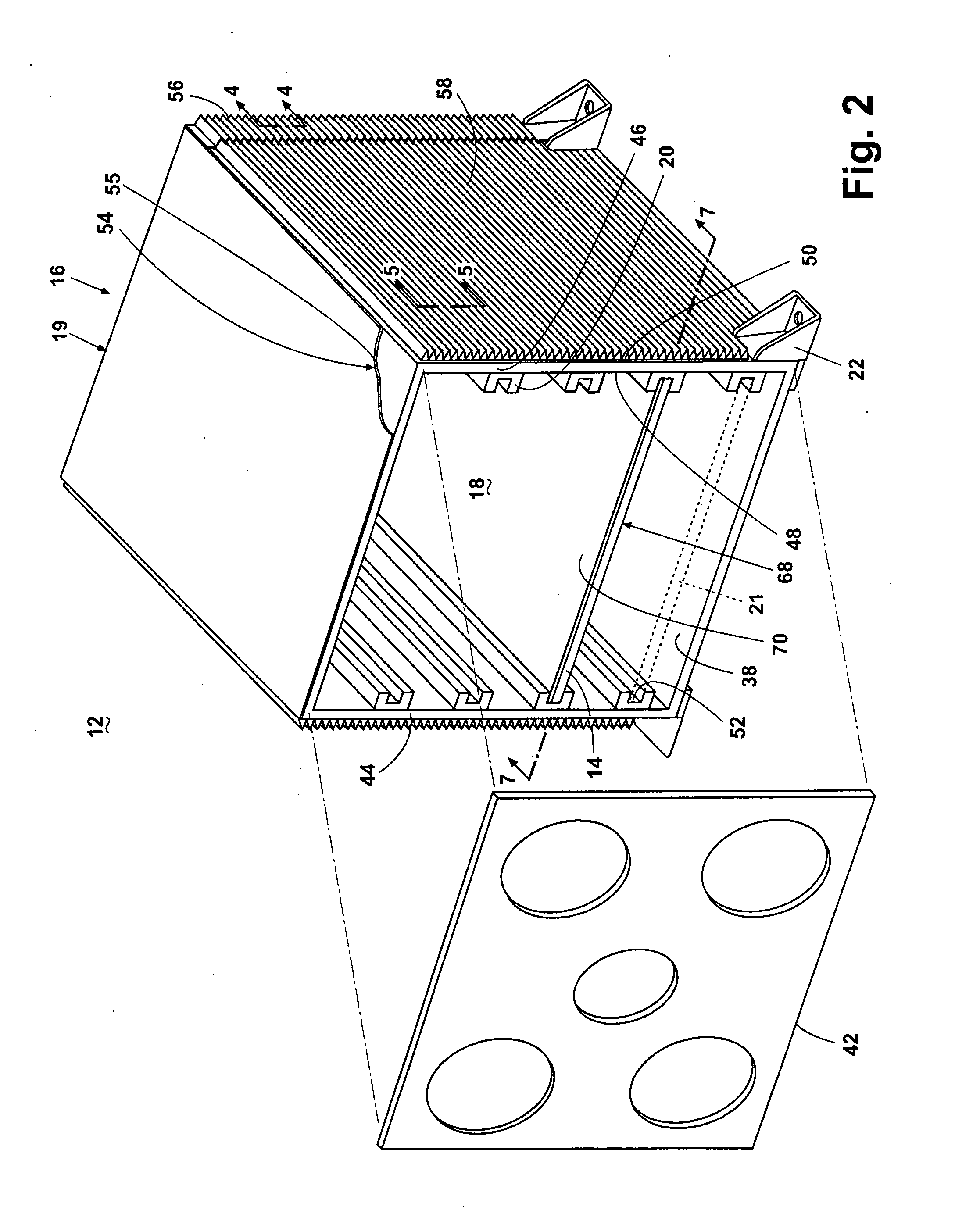

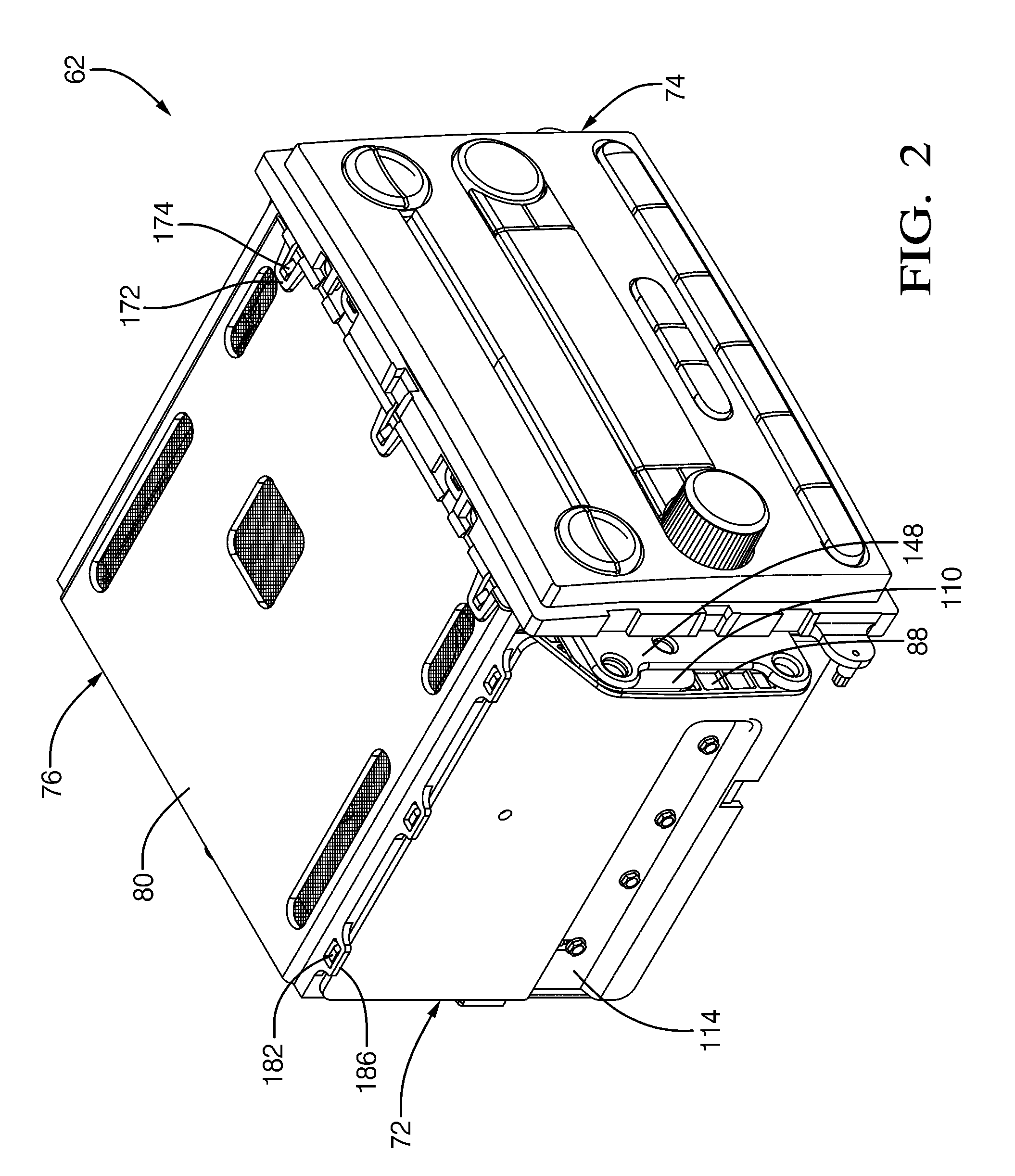

Chassis system and method for holding and protecting electronic modules

InactiveUS8873238B2Wave amplification devicesPrinted electric component incorporationElectricityElectric power

A chassis system includes a body, a lid, a cavity, a backplane, and an electrically conductive connector. The lid is removably attached to the body such that when the lid is attached to the body a cavity within the body is completely enclosed by the body and the attached lid. The lid and the body are made of at least one material that does not allow electromagnetic waves to enter the cavity. The backplane is attached to the body or the lid. The electrically conductive connector is attached to the body or lid. The connector is in wired or wireless communication with the backplane for allowing electricity or data to flow between the electrically conductive connector and the backplane. The chassis system may be used to environmentally protect one or more electronic modules inserted into the cavity of the chassis system.

Owner:THE BOEING CO

Methods and apparatus for EMI shielding in multi-chip modules

InactiveUS7648858B2Cross-talk/noise/interference reductionSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:TAIWAN SEMICON MFG CO LTD

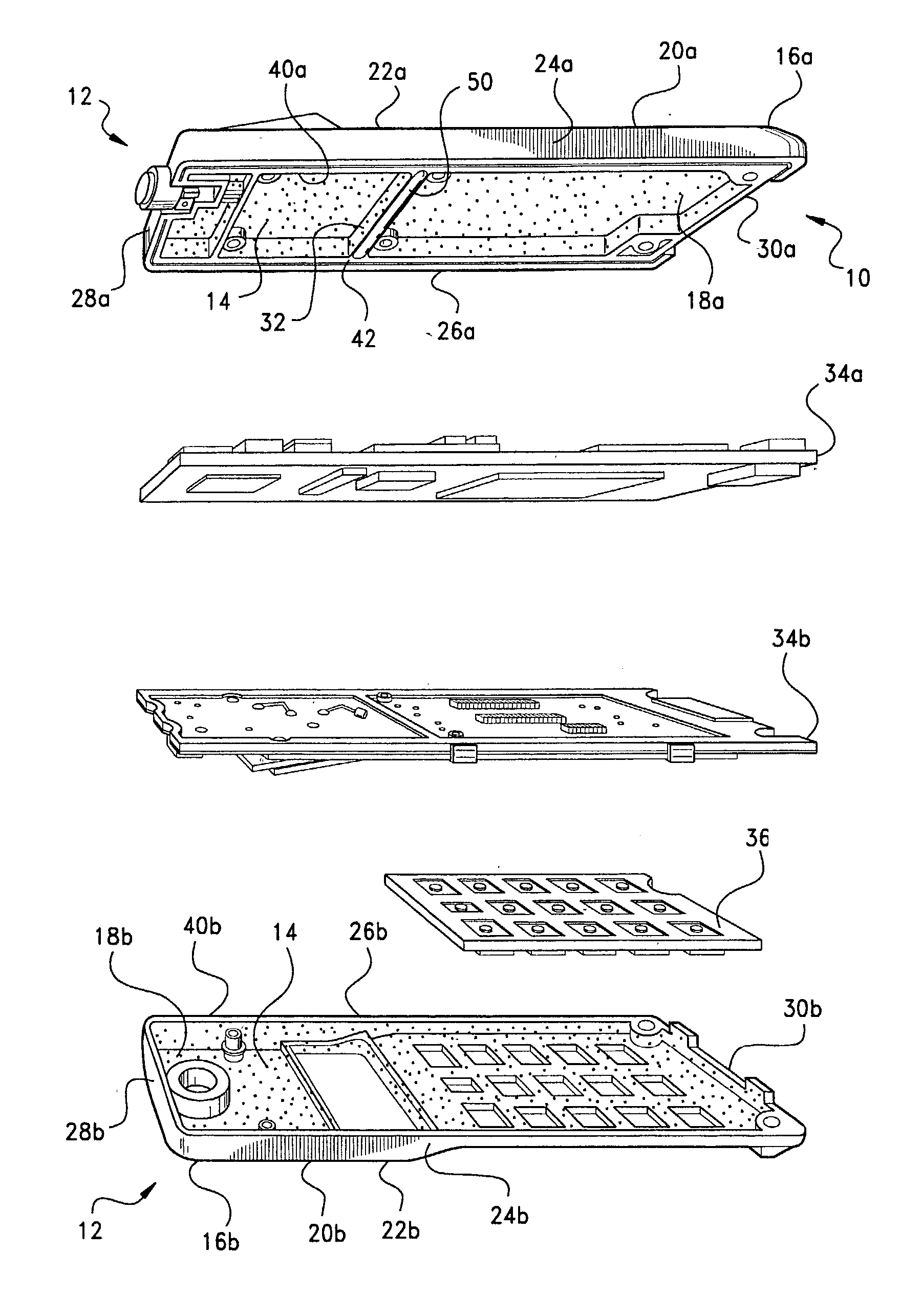

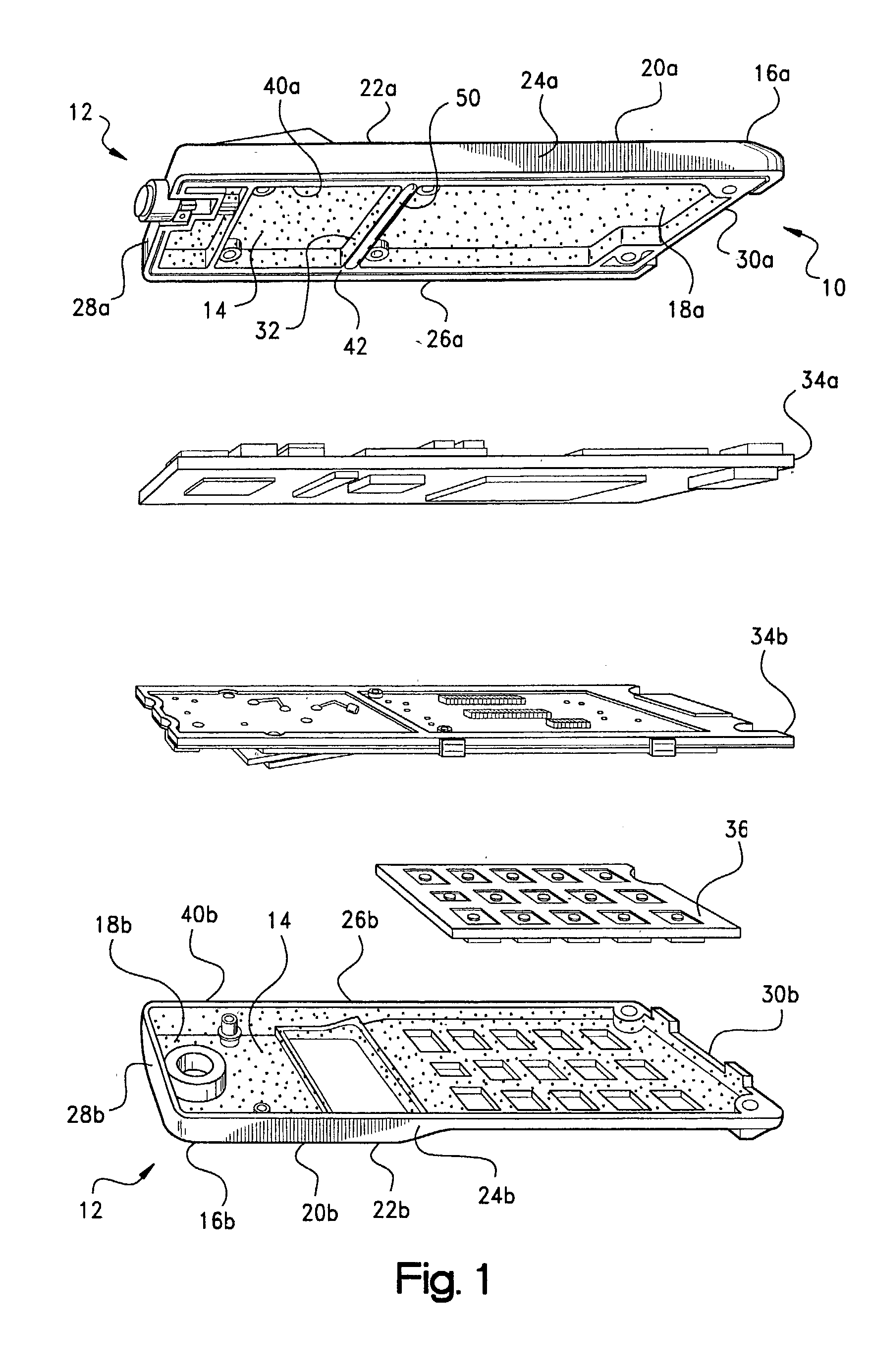

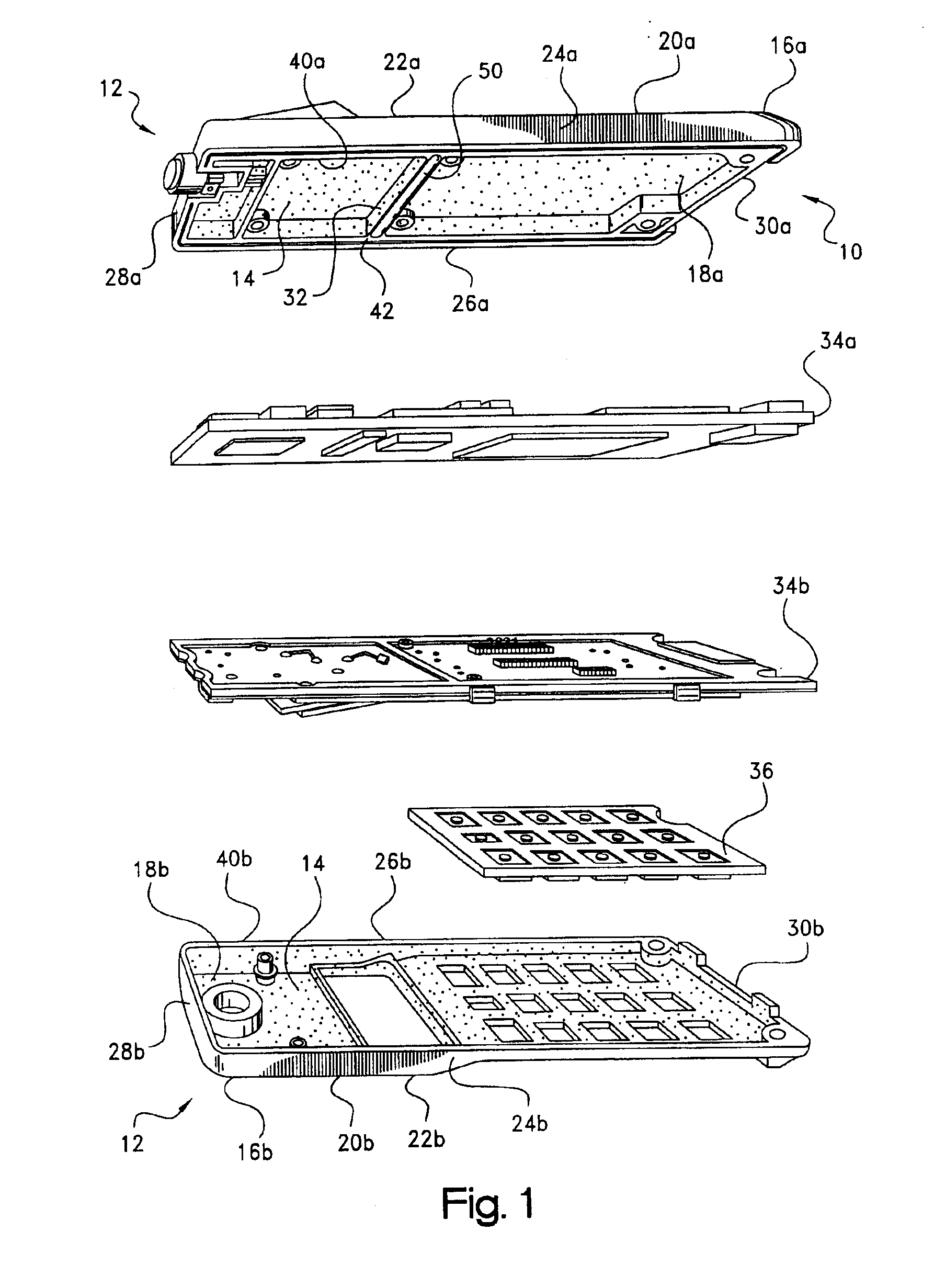

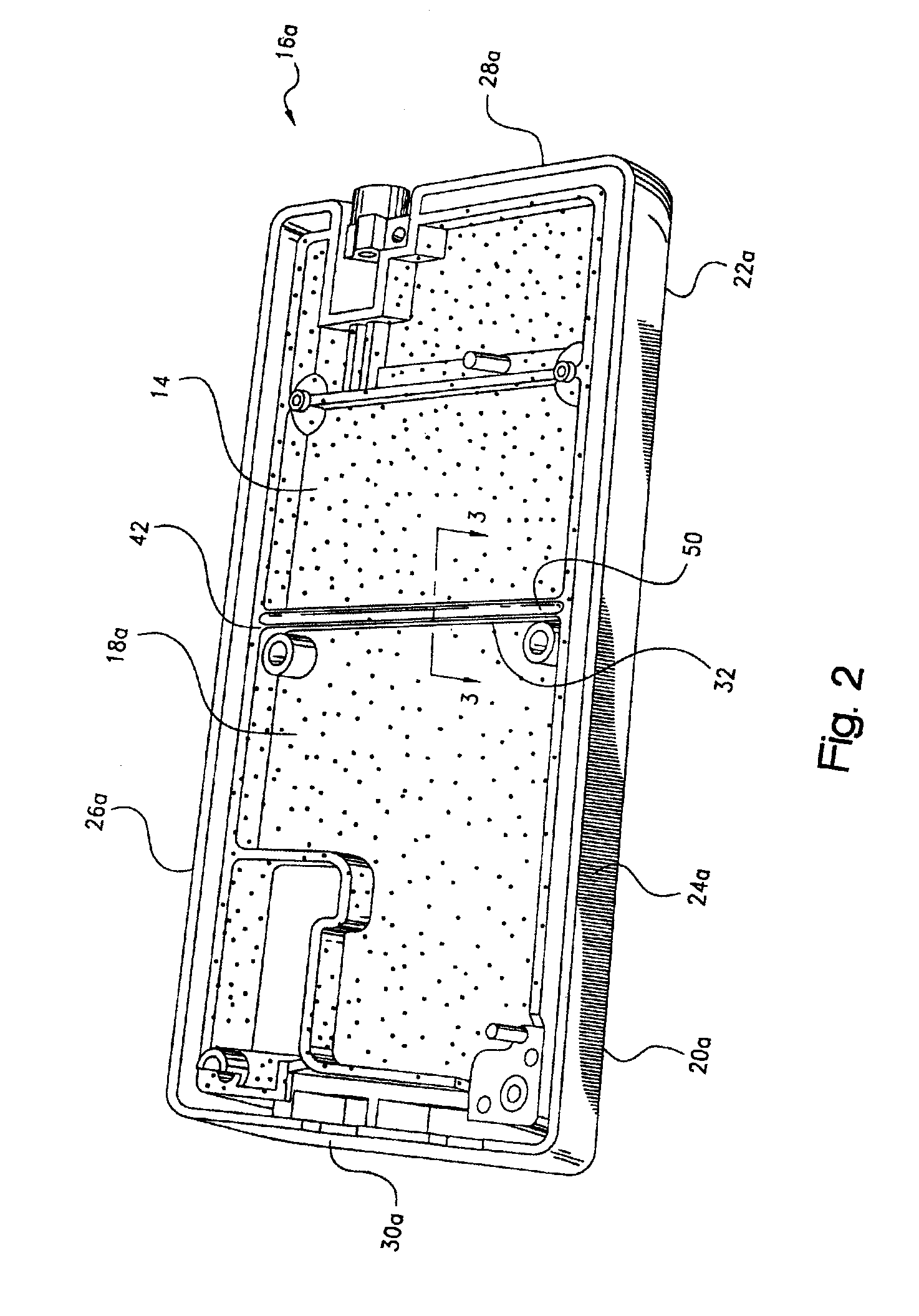

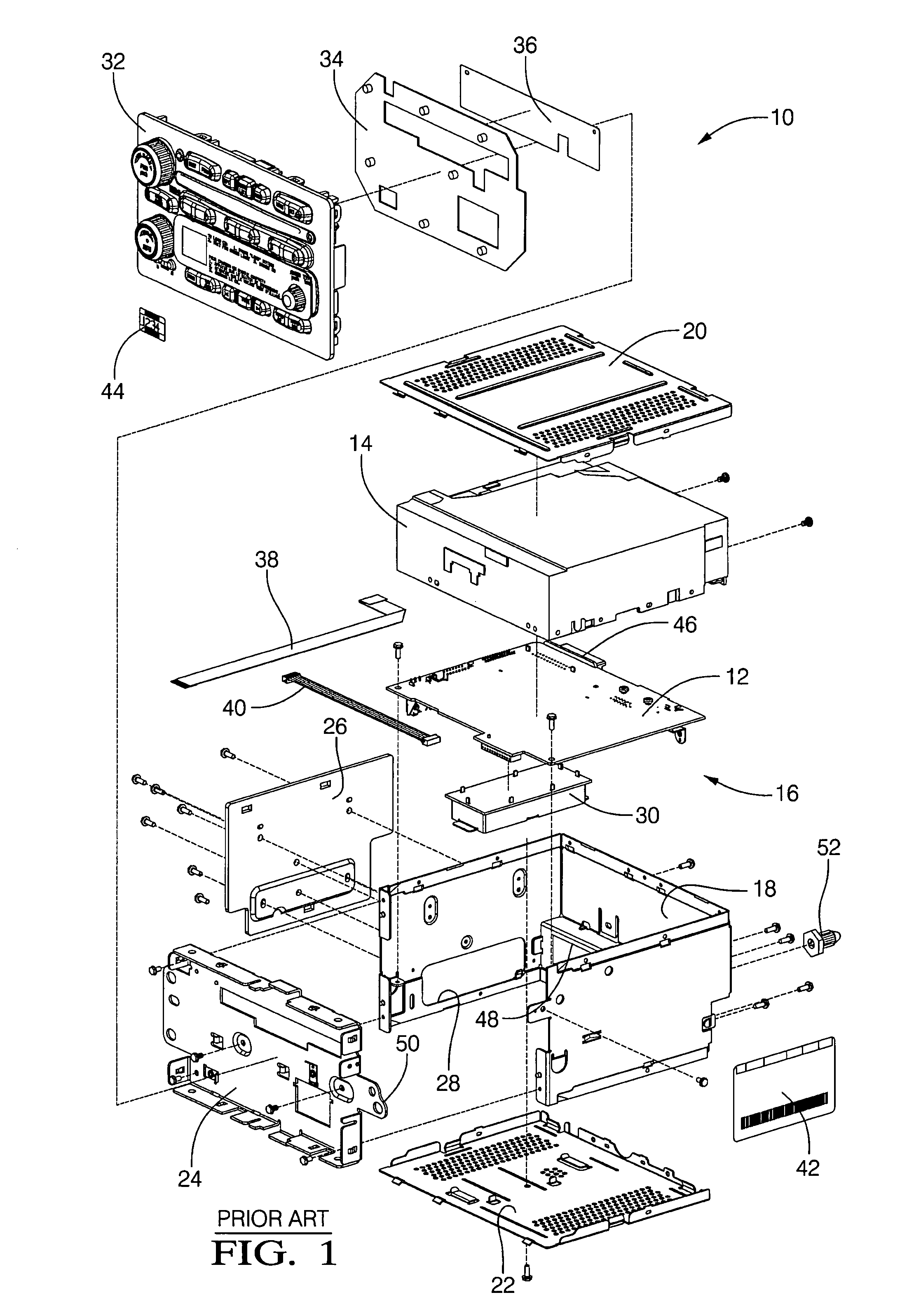

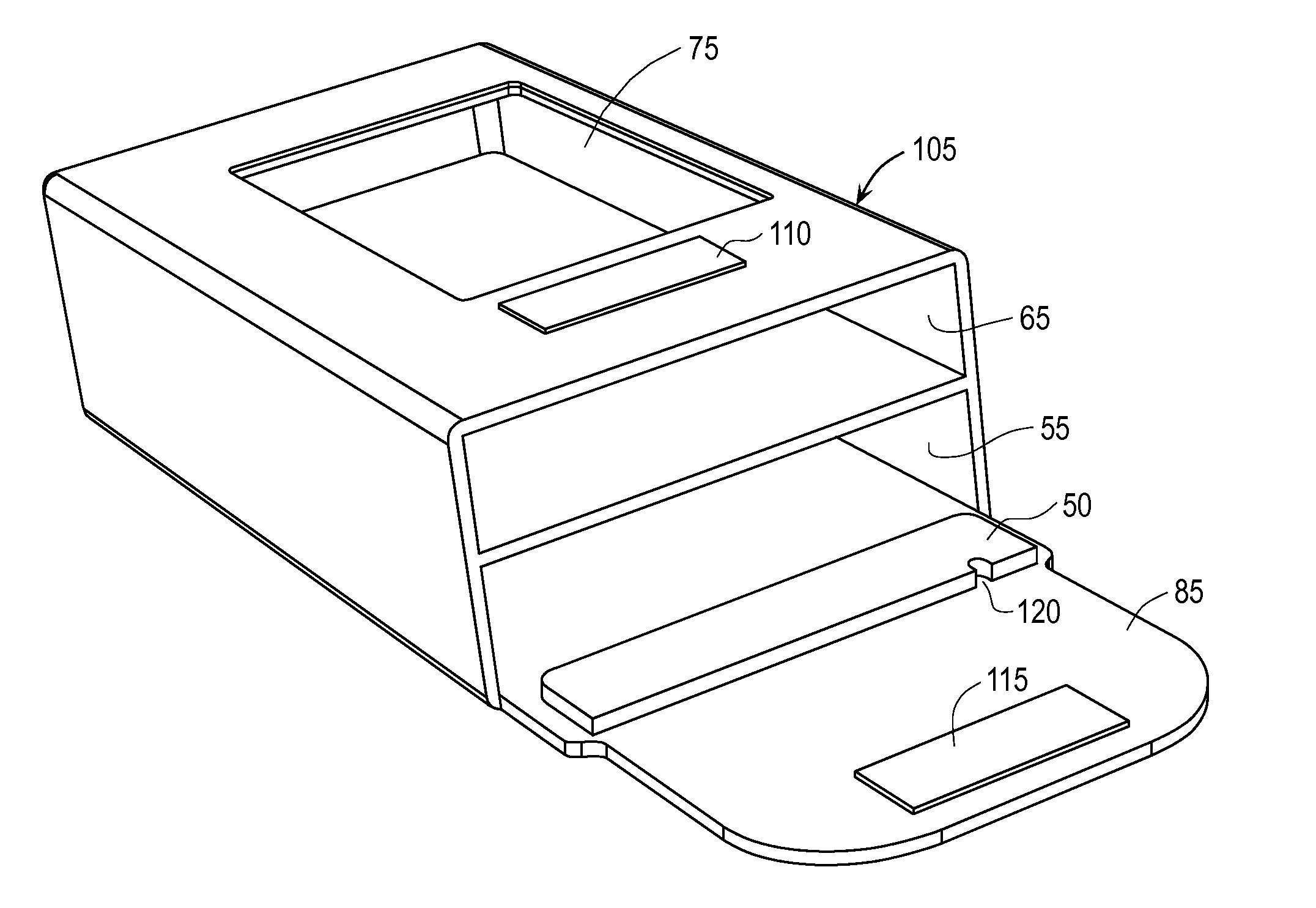

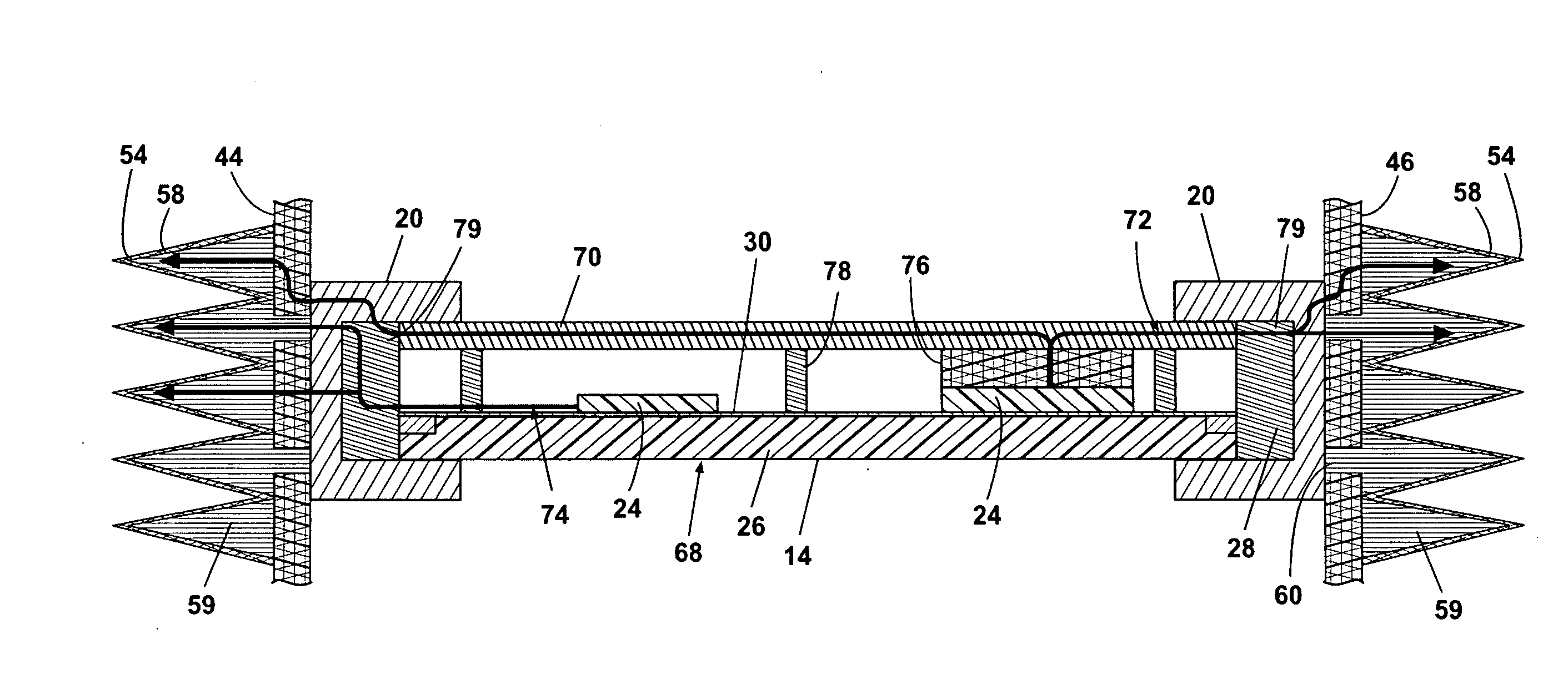

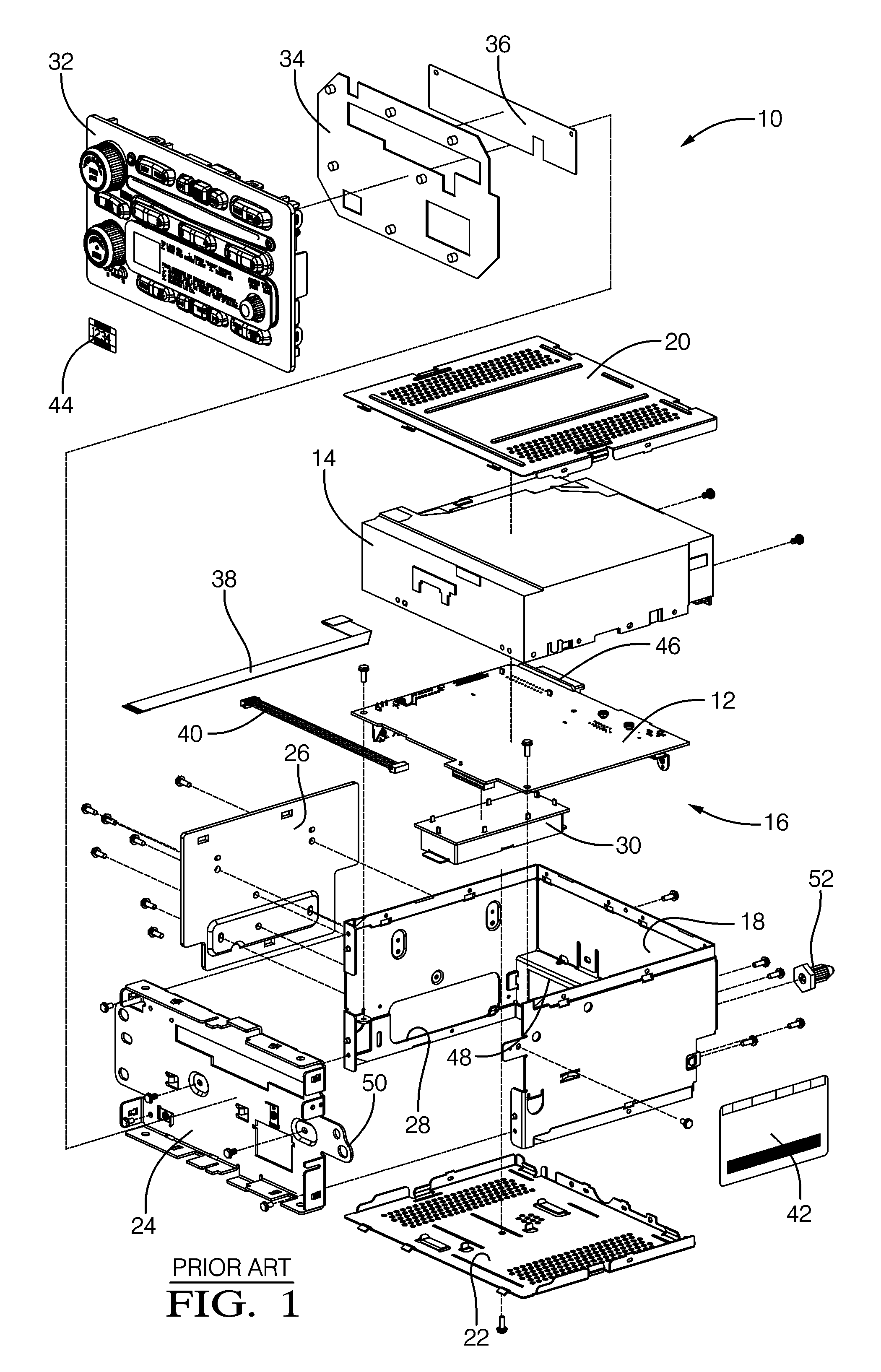

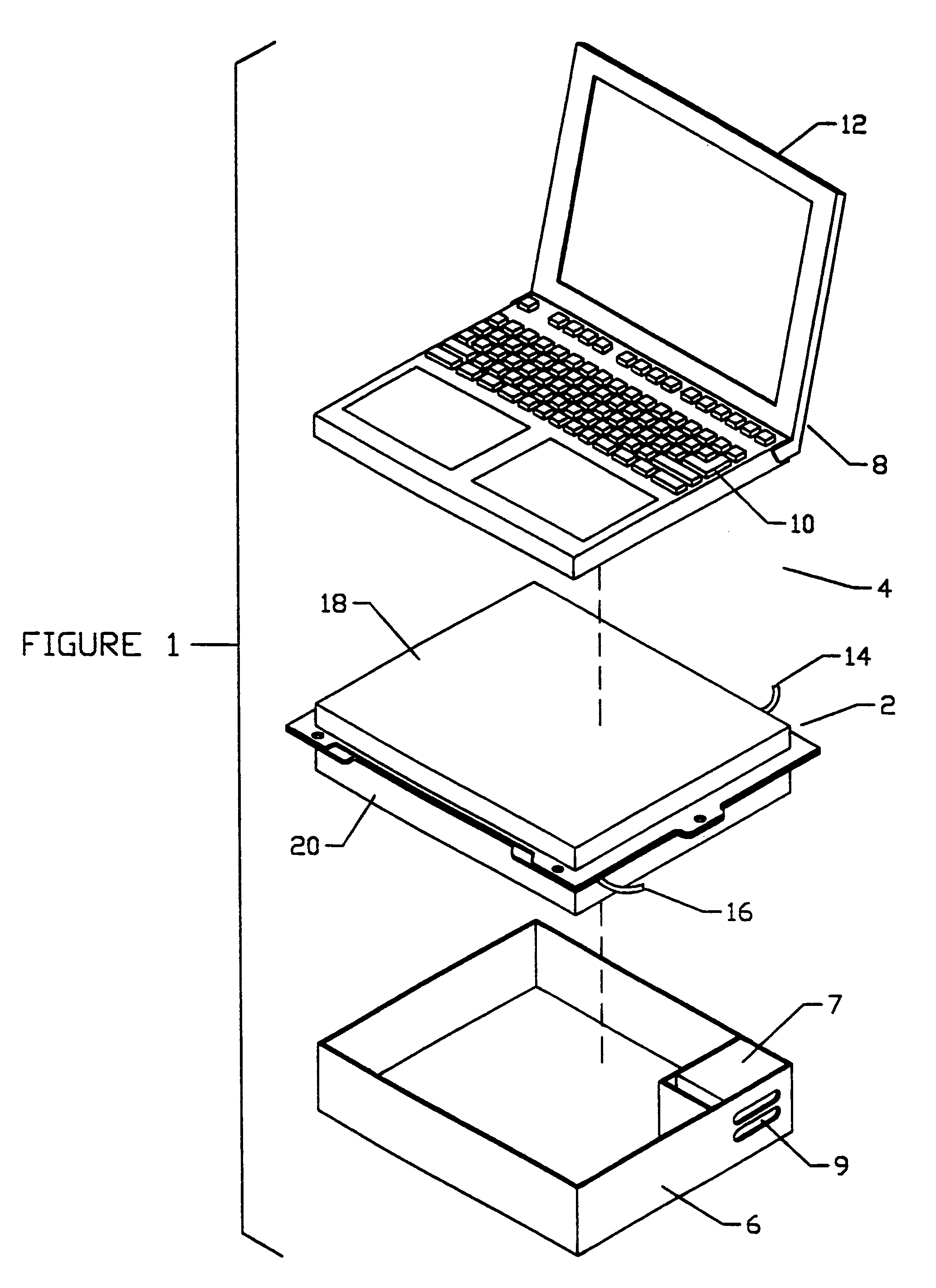

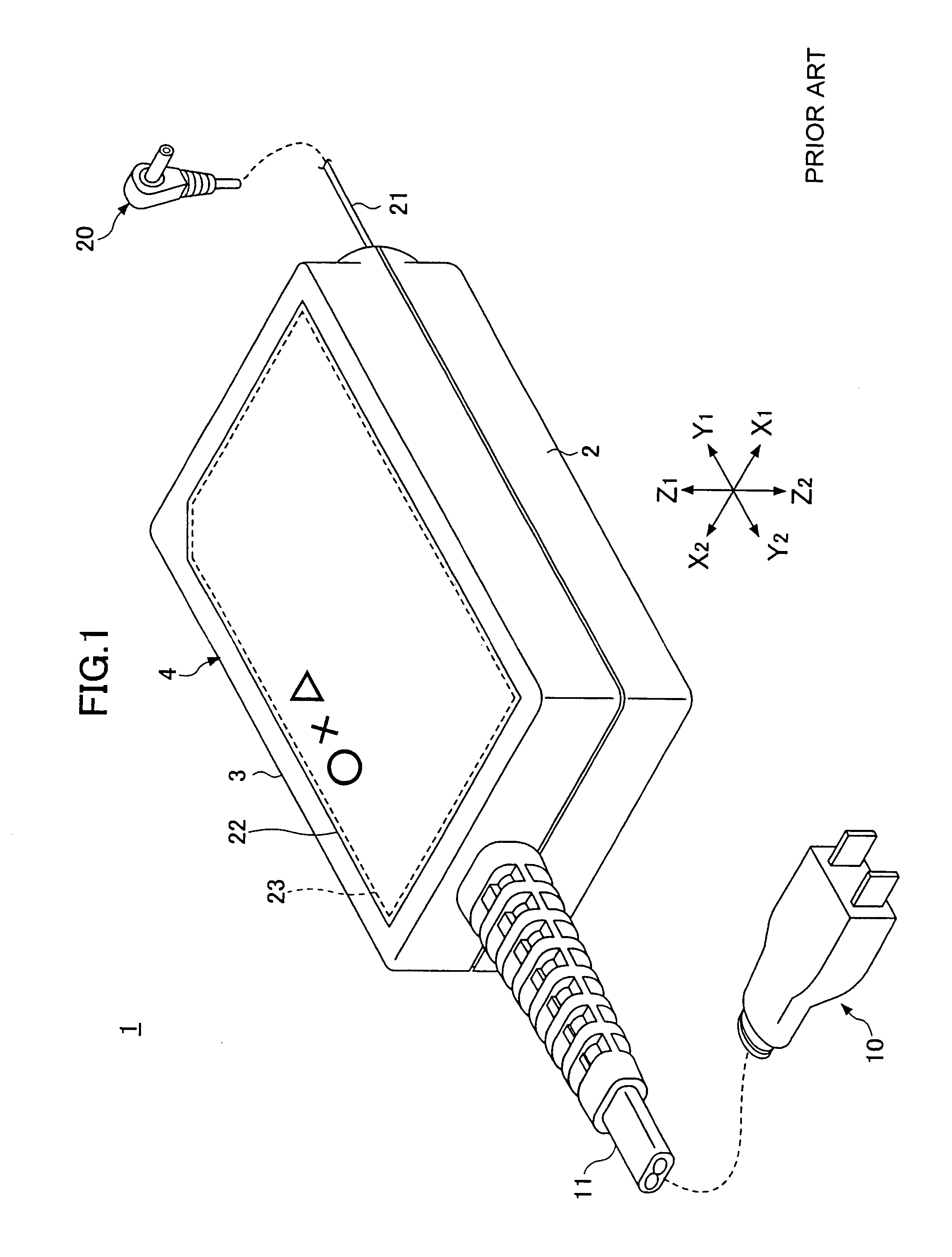

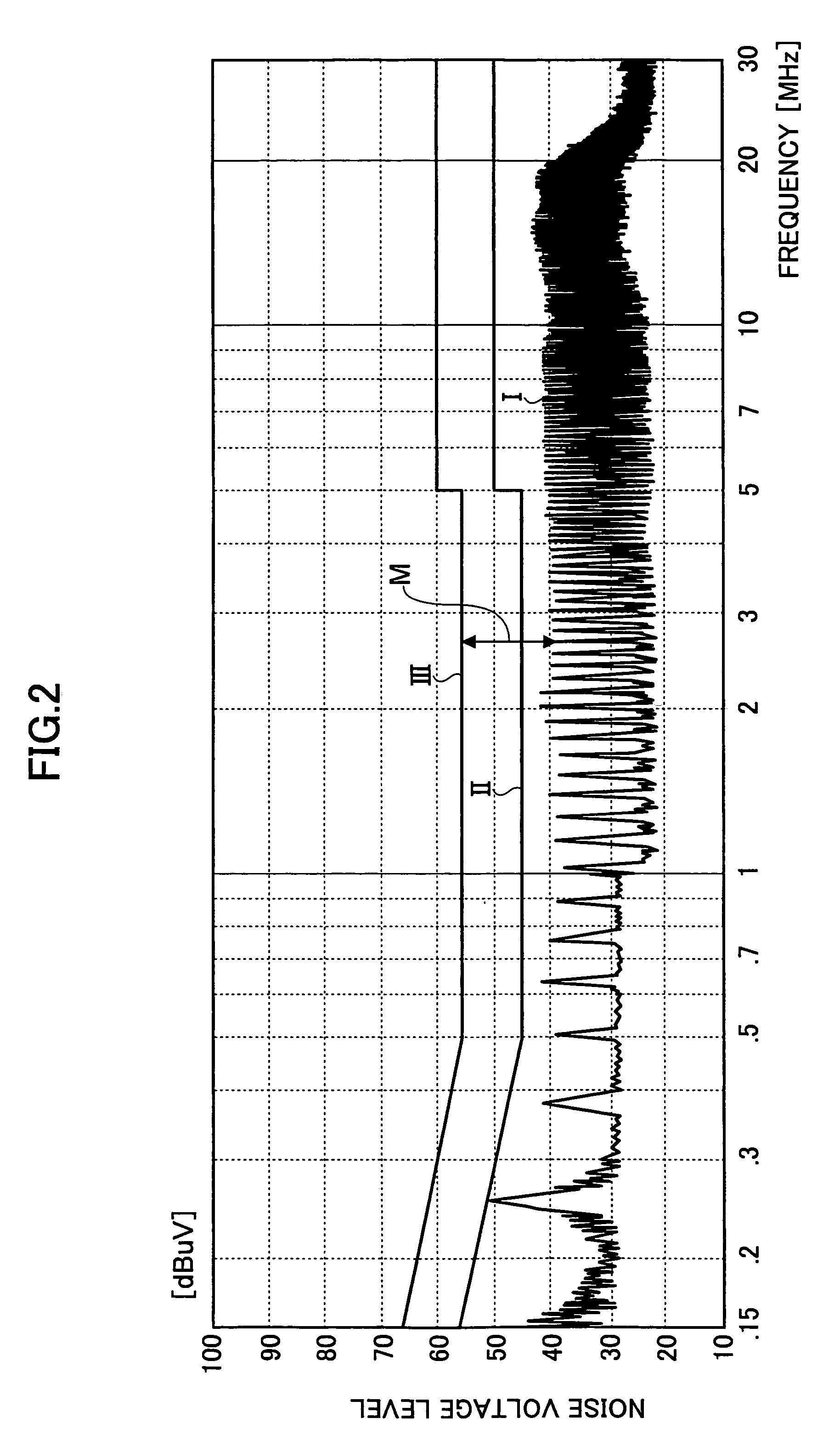

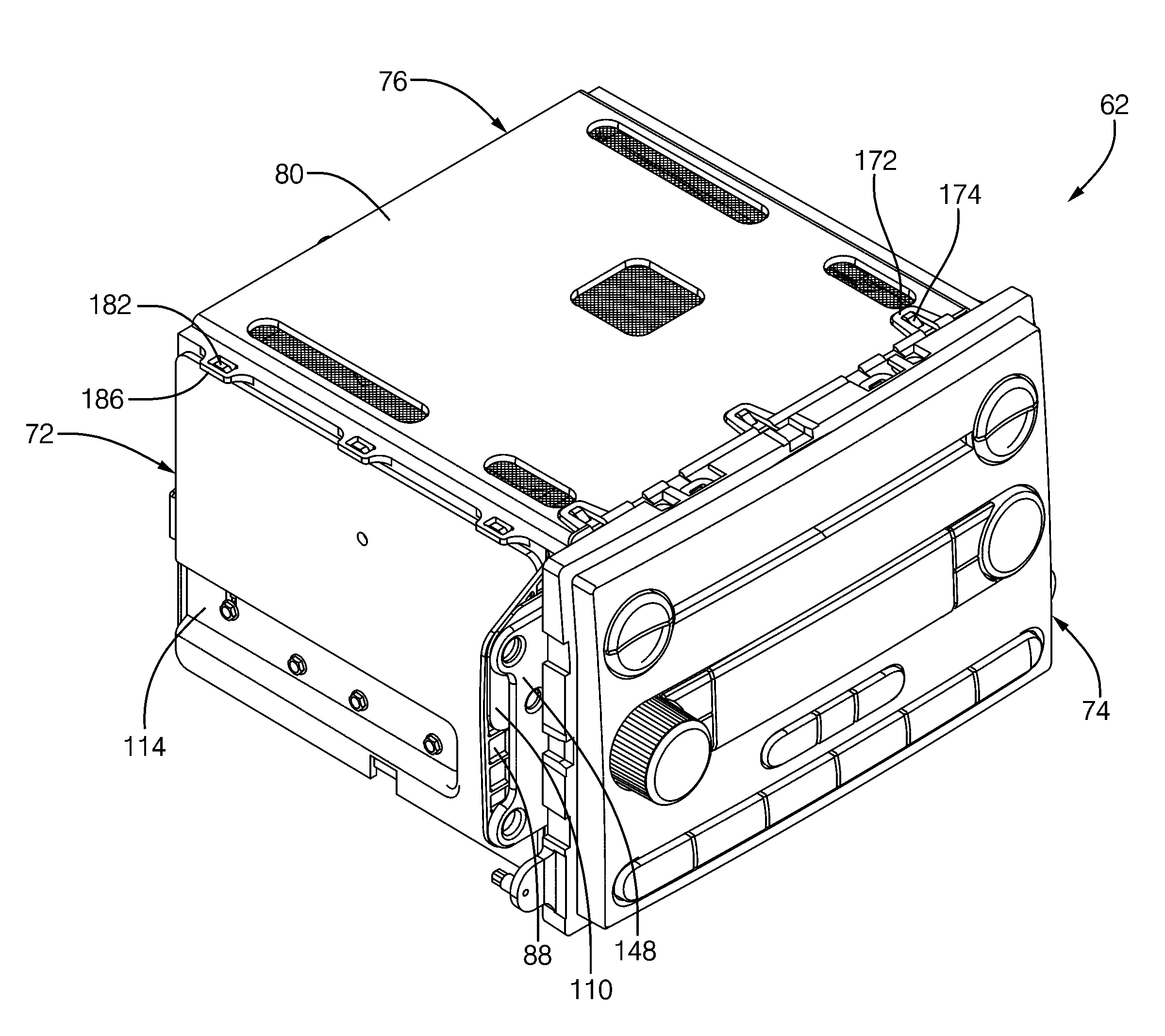

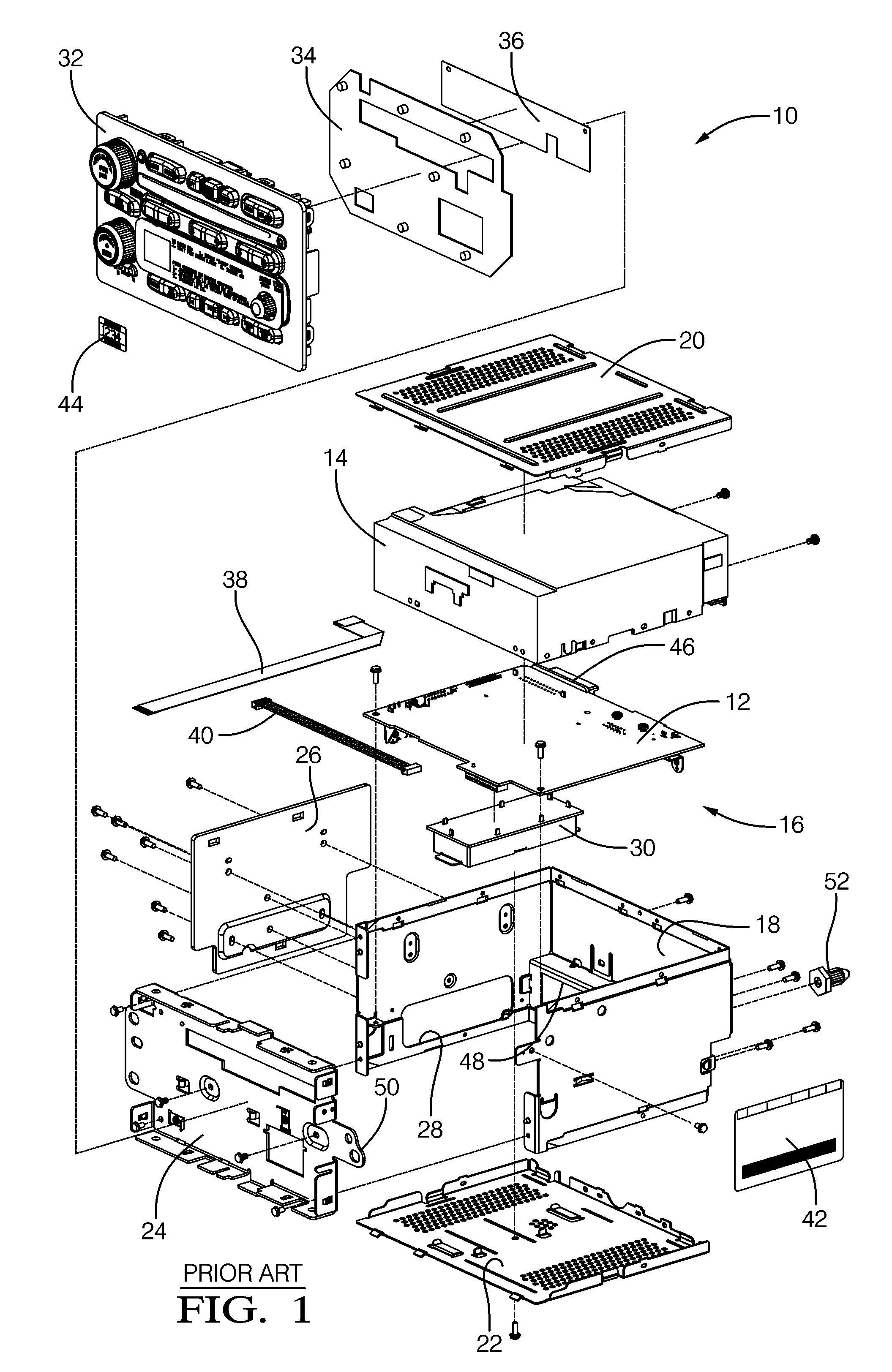

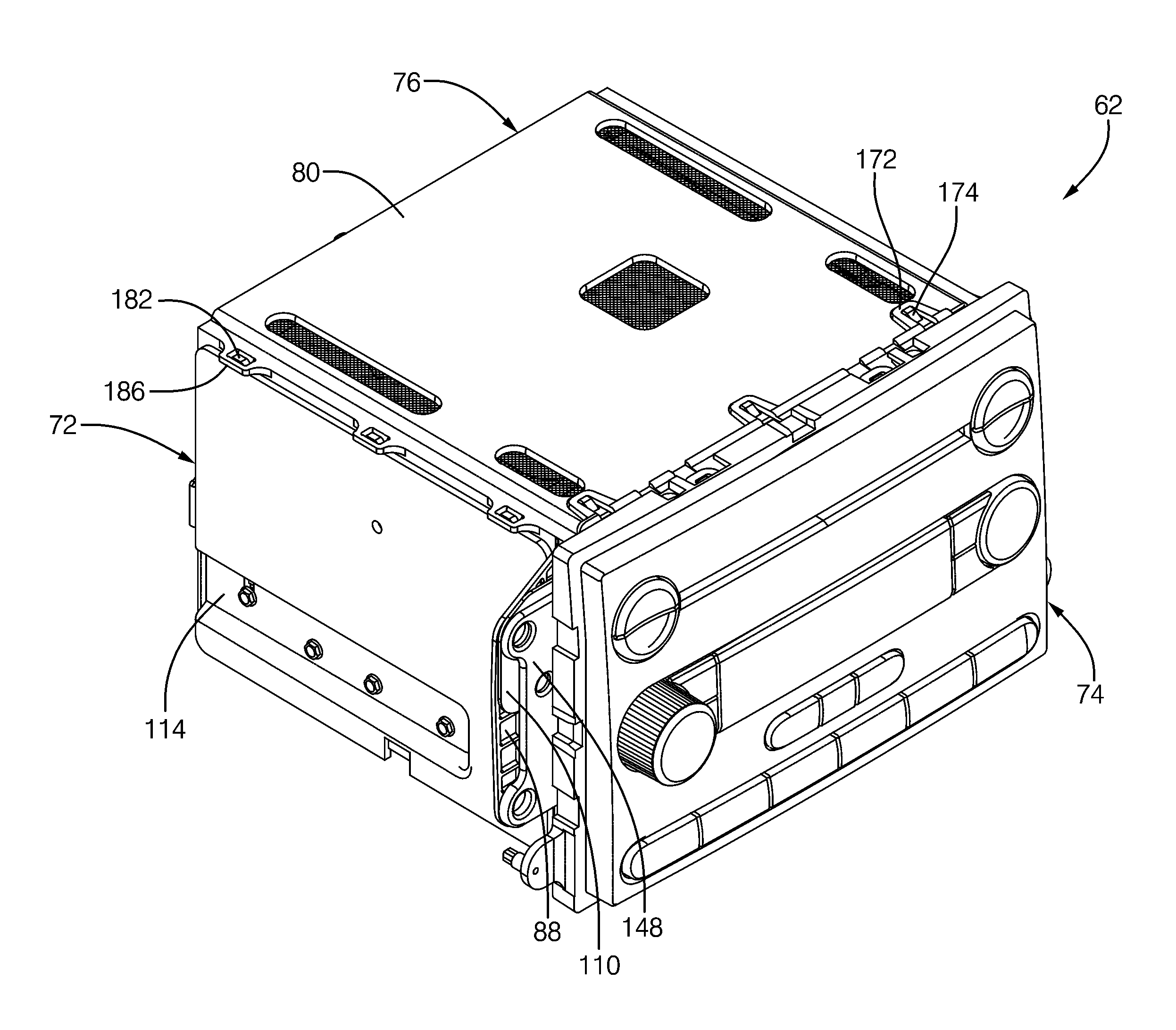

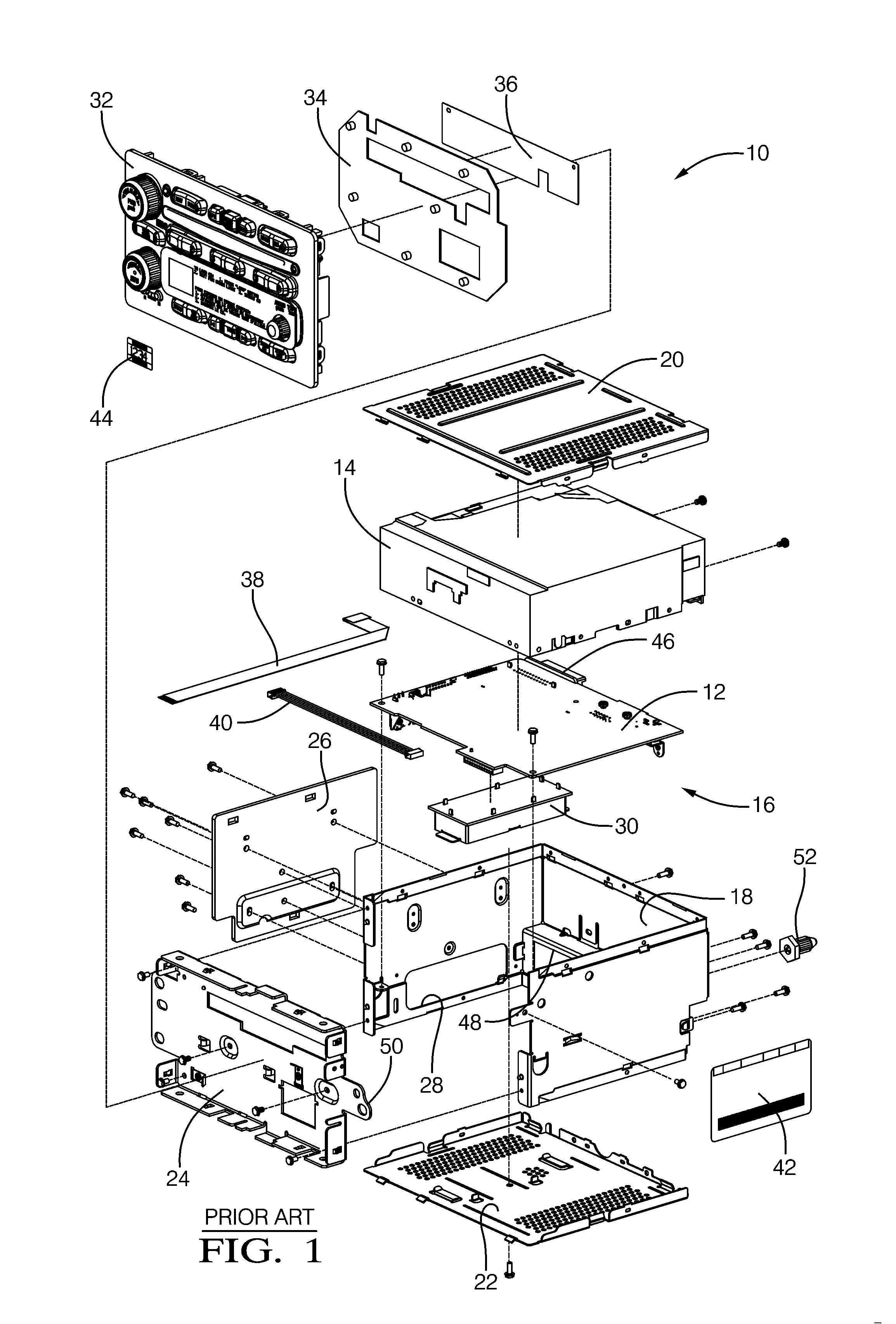

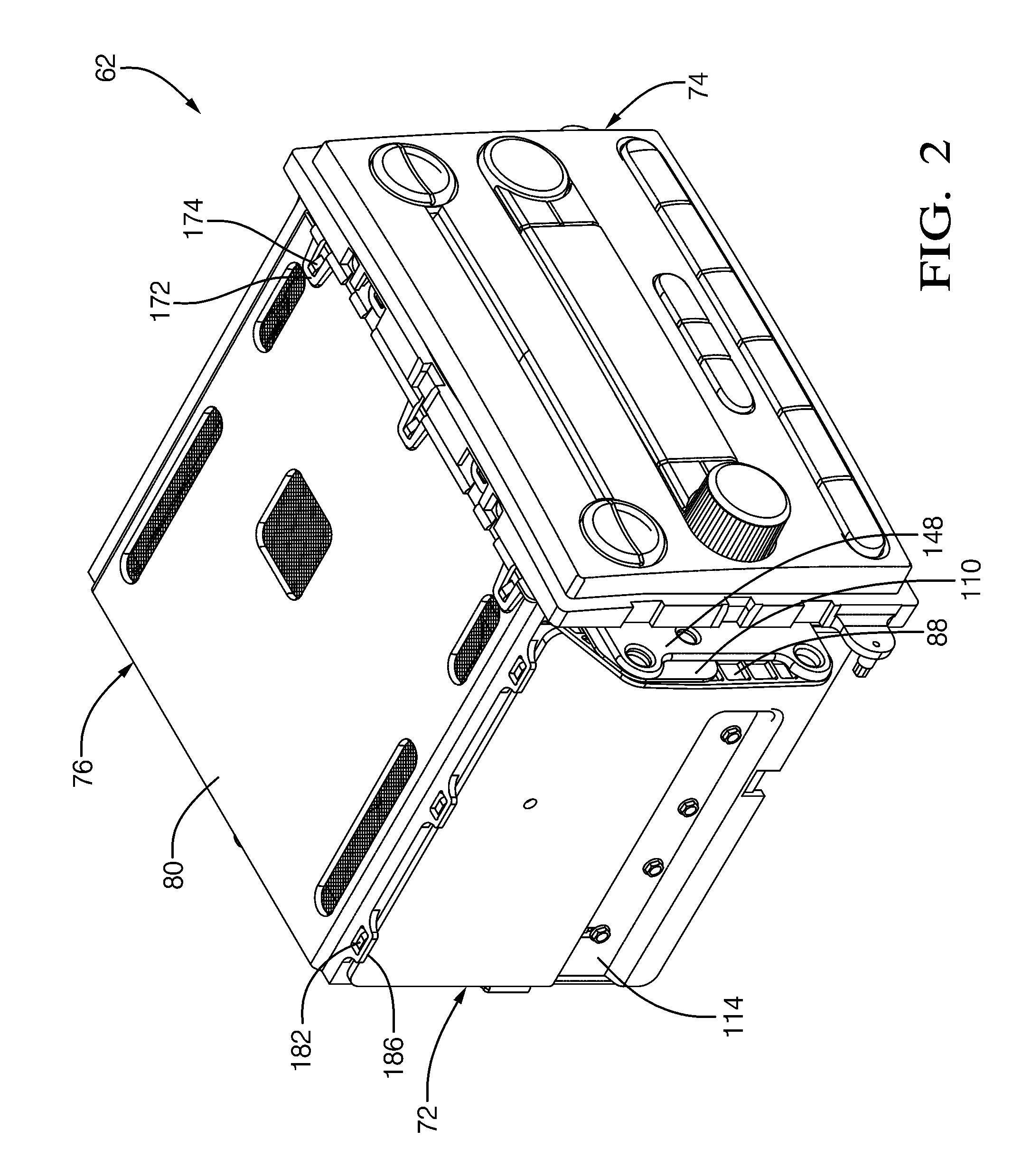

Lightweight audio system for automotive applications and method

InactiveUS7733659B2Minimizes required handlingMinimize the numberShielding materialsMechanical apparatusRadio receptionRadio receiver

A lightweight radio / CD player for vehicular application is virtually “fastenerless” and includes a case and frontal interface formed of polymer based material that is molded to provide details to accept audio devices such as playback mechanisms (if desired) and radio receivers, as well as the circuit boards required for electrical control and display. The case and frontal interface are of composite structure, including an insert molded electrically conductive wire mesh screen that has been pre-formed to contour with the molding operation. The wire mesh provides EMC, RFI, BCI and ESD shielding and grounding of the circuit boards via exposed wire mesh pads and adjacent ground clips. The PCB architecture is bifurcated into a first board carrying common circuit components in a surface mount configuration suitable for high volume production, and a second board carrying application specific circuit components in a wave soldered stick mount configuration. The major components and subassemblies are self-fixturing during the final assembly process, eliminating the need for dedicated tools, fixtures and assembly equipment. The major components and subassemblies self-interconnect by integral guide and connection features effecting “slide lock” and “snap lock” self-interconnection. The radio architecture includes improved push buttons employing 4-bar living hinge linkage and front loaded decorative trim buttons.

Owner:APTIV TECH LTD

Chassis system and method for holding and protecting electronic modules

A chassis system includes a body, a lid, a cavity, a backplane, and an electrically conductive connector. The lid is removably attached to the body such that when the lid is attached to the body a cavity within the body is completely enclosed by the body and the attached lid. The lid and the body are made of at least one material that does not allow electromagnetic waves to enter the cavity. The backplane is attached to the body or the lid. The electrically conductive connector is attached to the body or lid. The connector is in wired or wireless communication with the backplane for allowing electricity or data to flow between the electrically conductive connector and the backplane. The chassis system may be used to environmentally protect one or more electronic modules inserted into the cavity of the chassis system.

Owner:THE BOEING CO

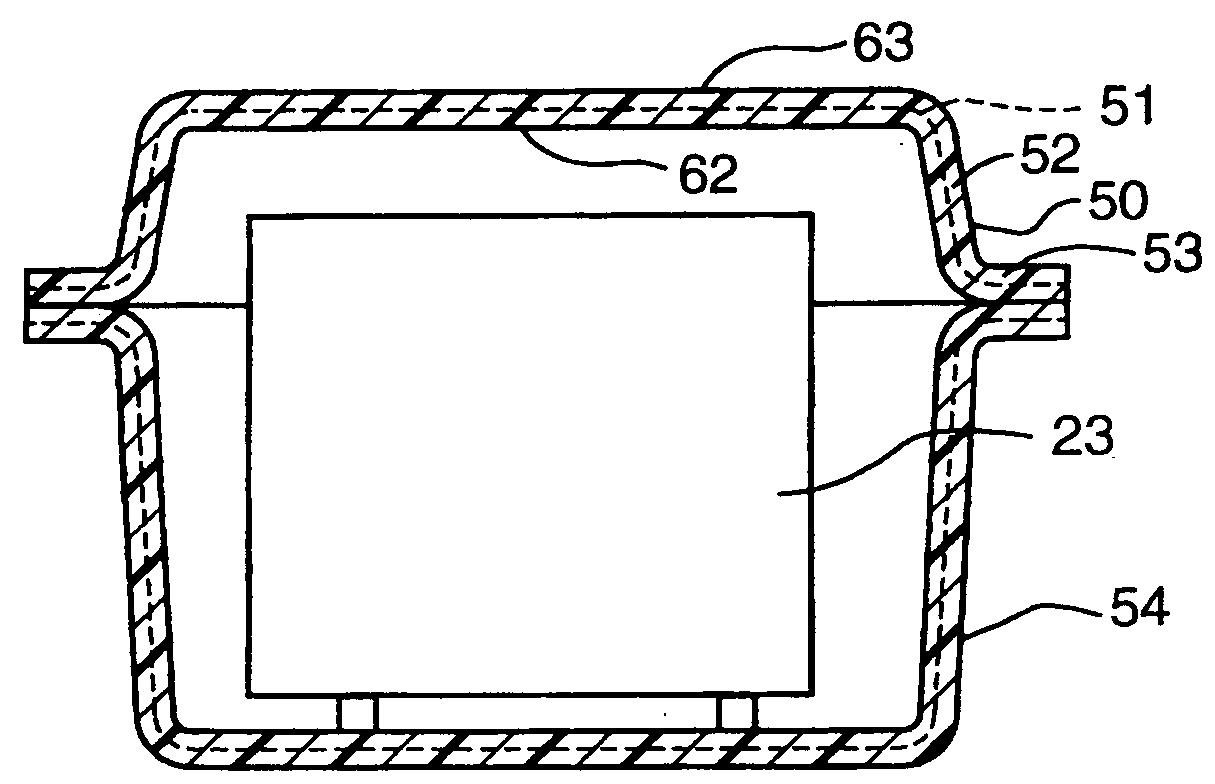

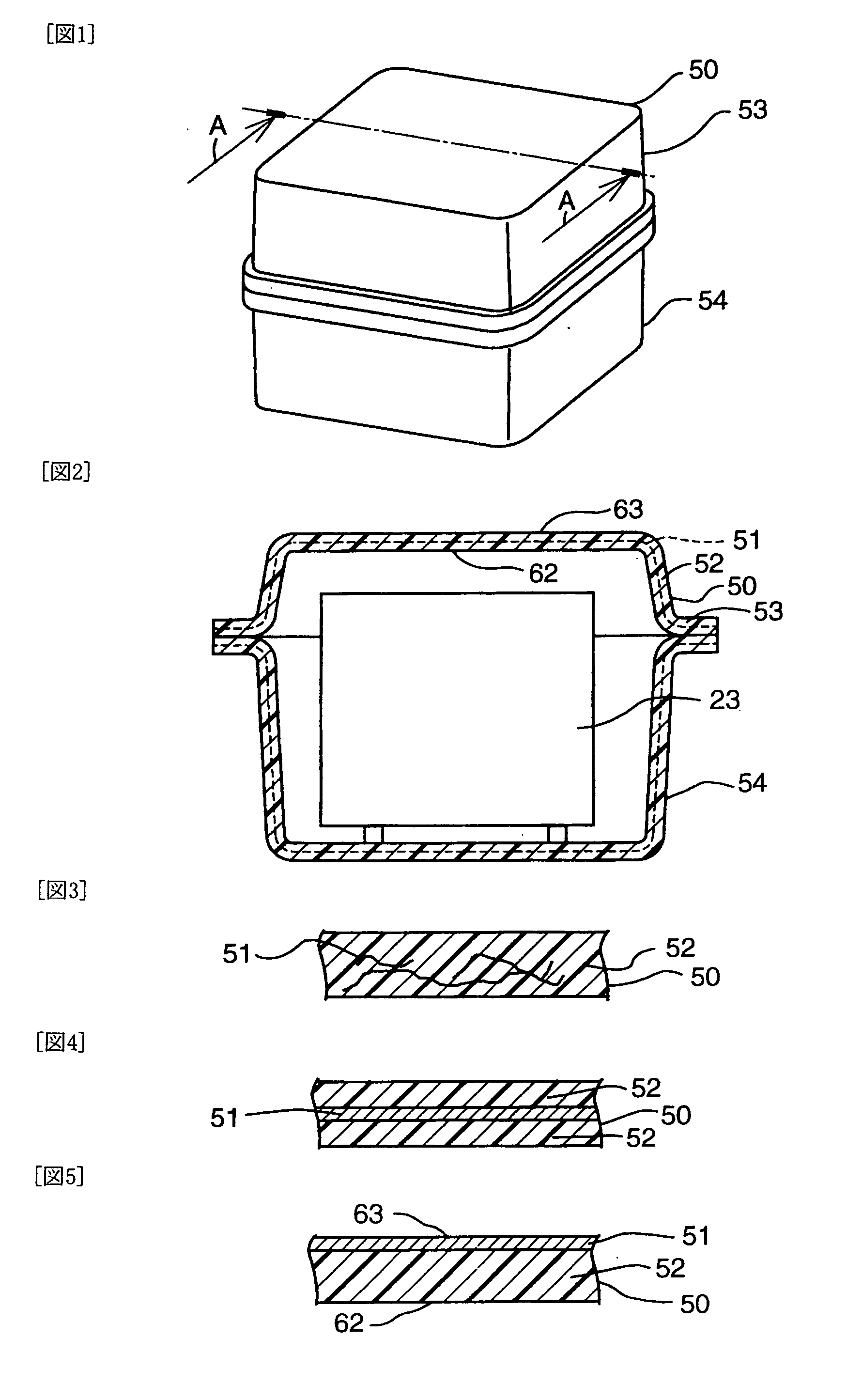

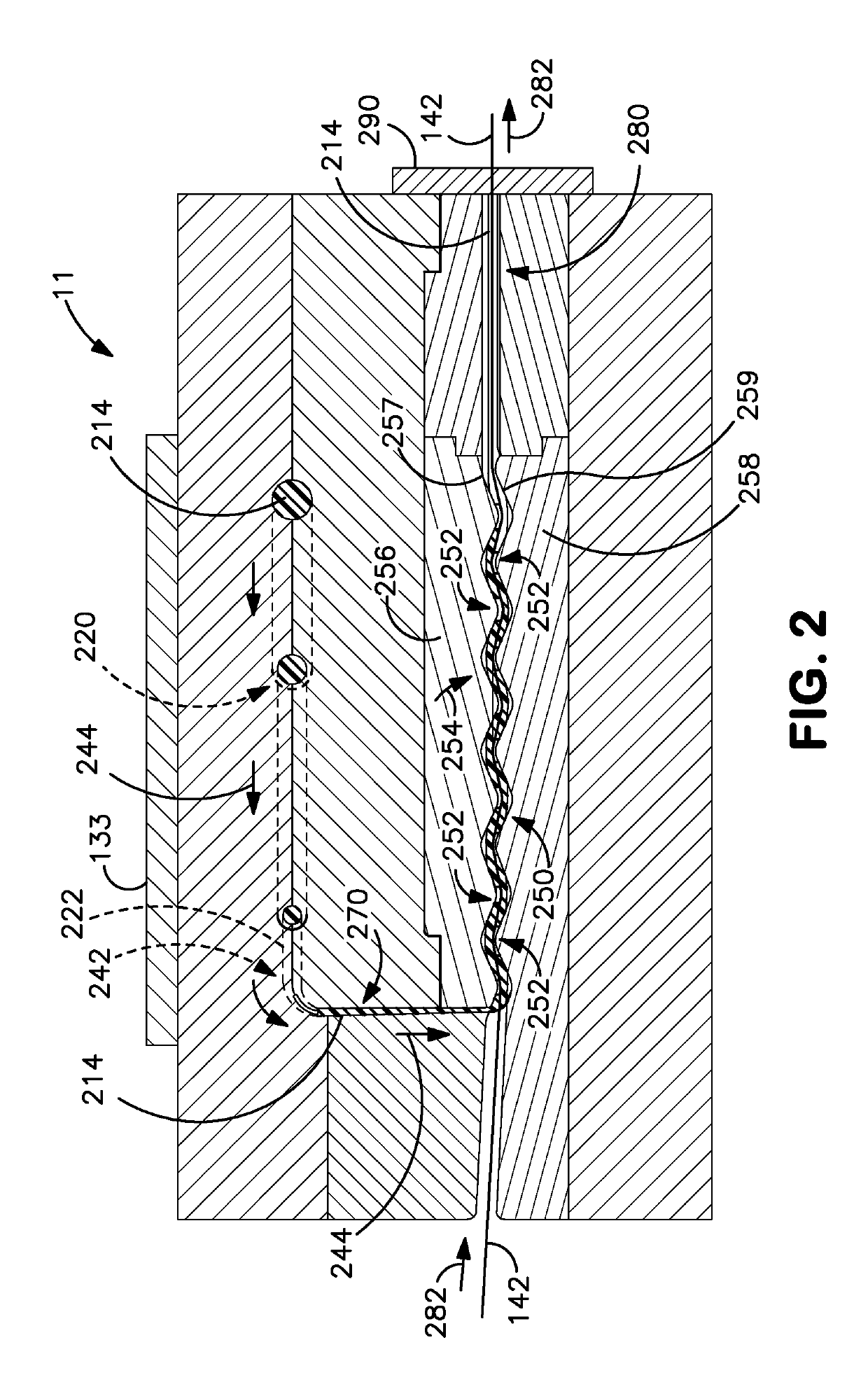

Fuel Cell Stack Casing

InactiveUS20090130530A1Limit and prevent leakageAvoid enteringFuel cell auxillariesCell component detailsFuel cellsEngineering

A fuel cell stack casing for housing a fuel cell stack. The fuel cell stack casing may include a resin and an electromagnetic wave damping material, for example, a conductive material. In addition, the fuel cell stack may be electromagnetically shielded by the electromagnetic wave damping material. The fuel cell stack casing may include a plurality of members coupled to each other such that conductive materials contained in the members are electrically connected to each other. An inside surface of the casing may be an insulating surface. A plurality of apertures for ventilation may be formed in a wall of the casing such that the apertures are spaced from each other. The apertures may be covered with a cover.

Owner:TOYOTA JIDOSHA KK

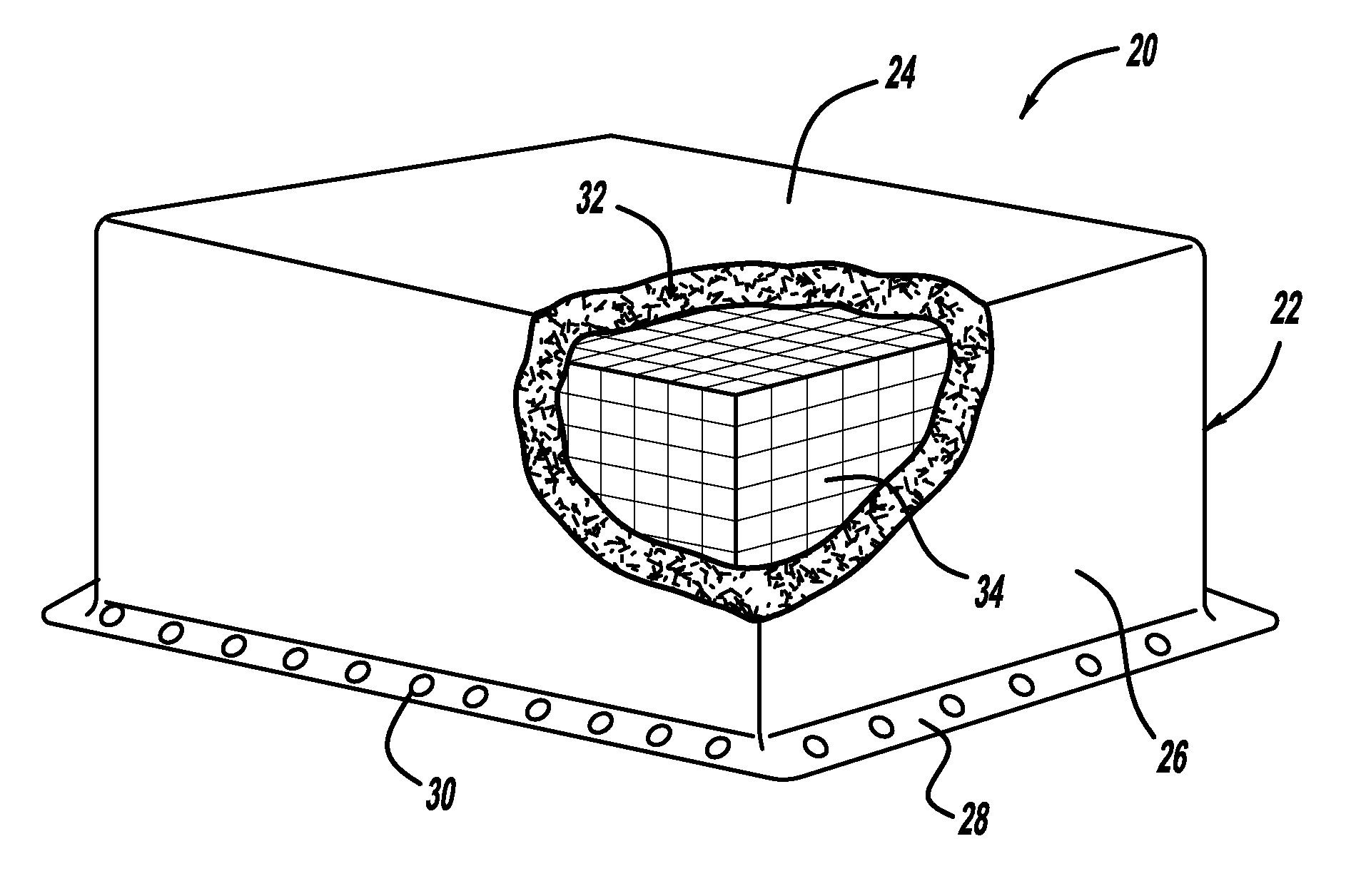

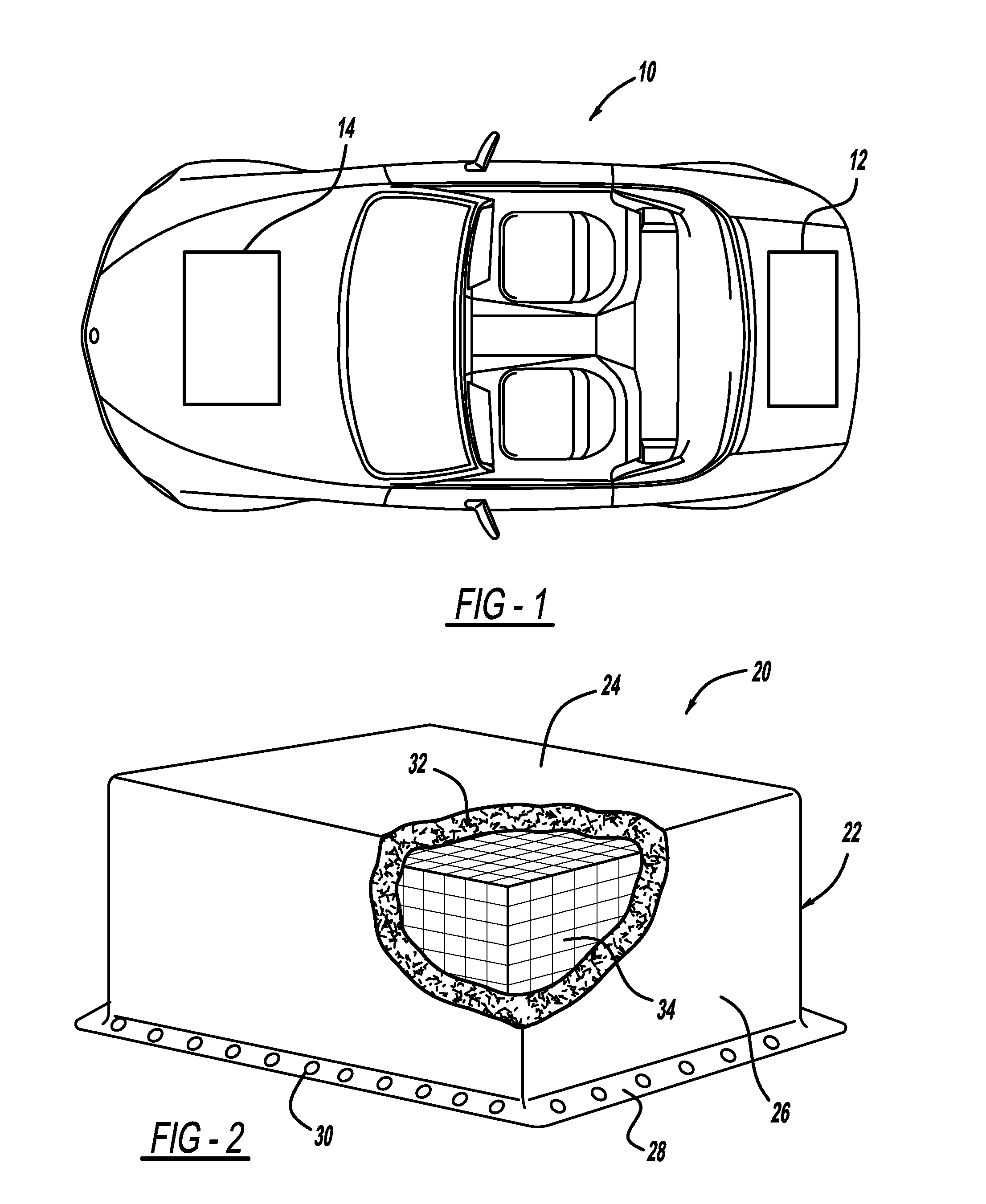

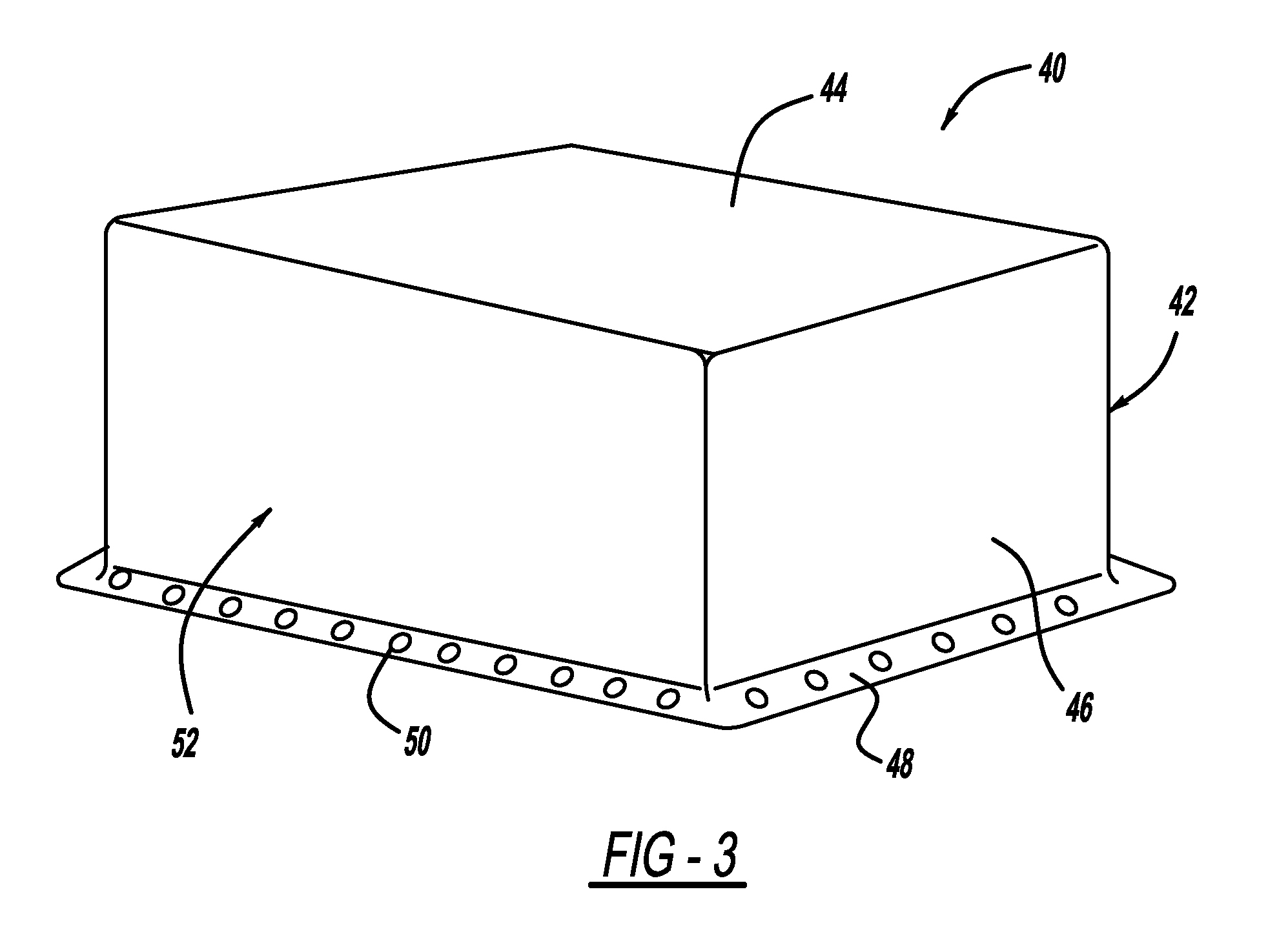

Encapsulated emi/rfi shielding for a non-conductive thermosetting plastic composite phev battery cover

A cover for a high voltage vehicle battery is disclosed that is made of a light weight, non-conductive thermoset plastic composite, such as a polyester resin matrix, and includes an EMI / RFI shield. In one embodiment, the EMI / RFI shield is a Faraday cage including a ferrous mesh that is molded into the thermoset plastic composite so that it is completely encapsulated therein. In another embodiment, the EMI / RFI shield is an acrylic polymer coating including nickel plated copper flakes formed on an outside surface of the thermoset plastic composite.

Owner:GM GLOBAL TECH OPERATIONS LLC

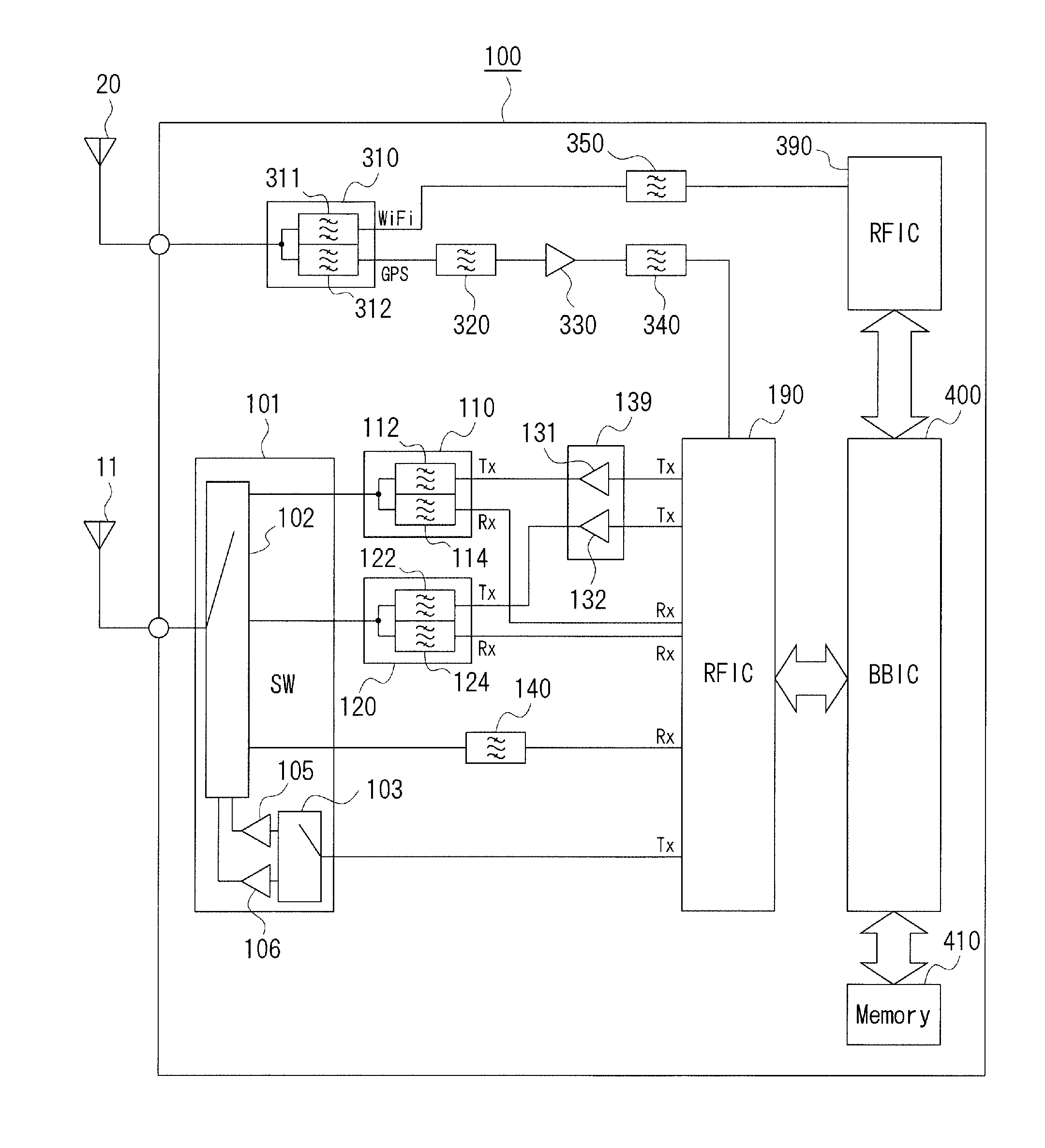

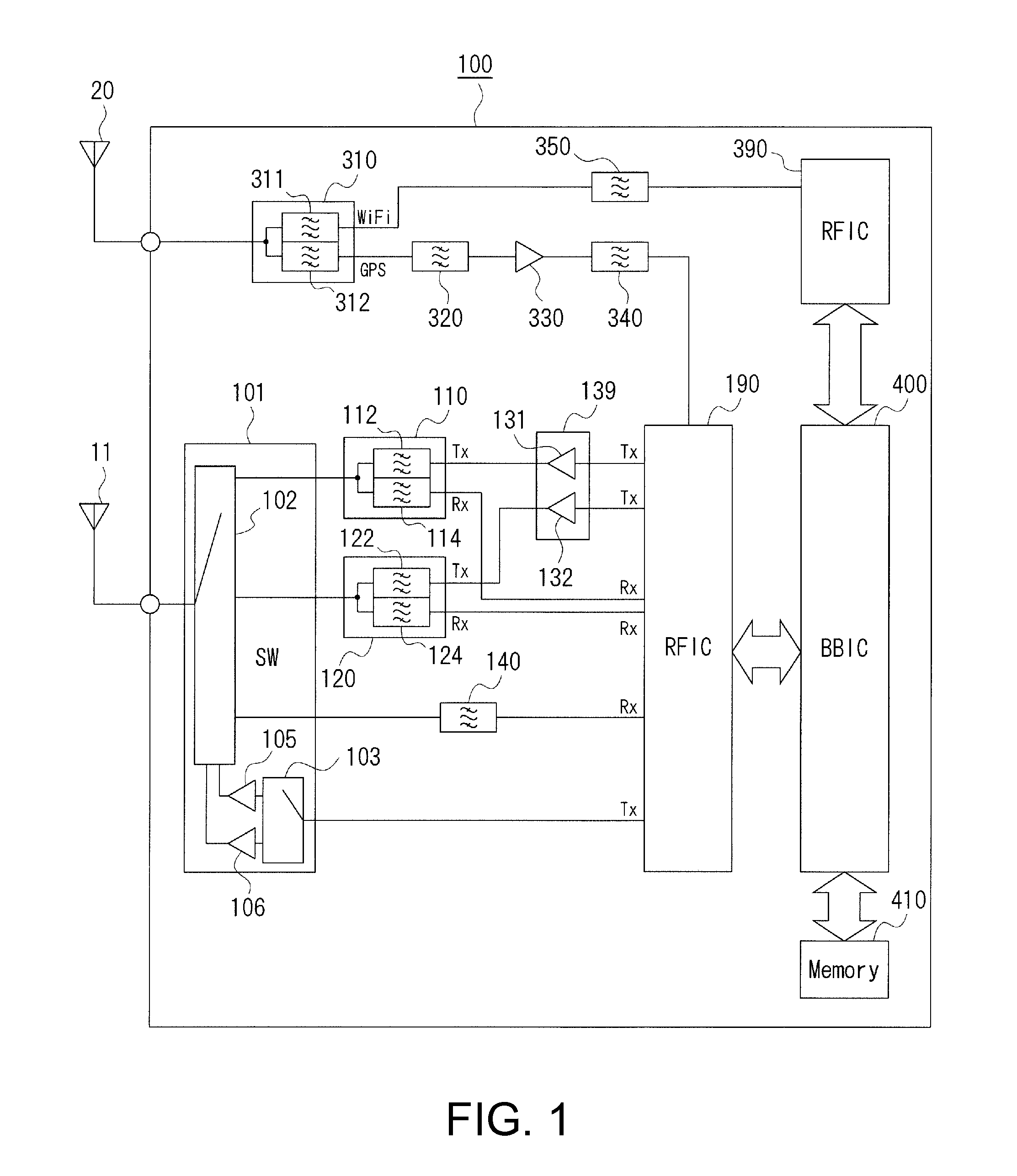

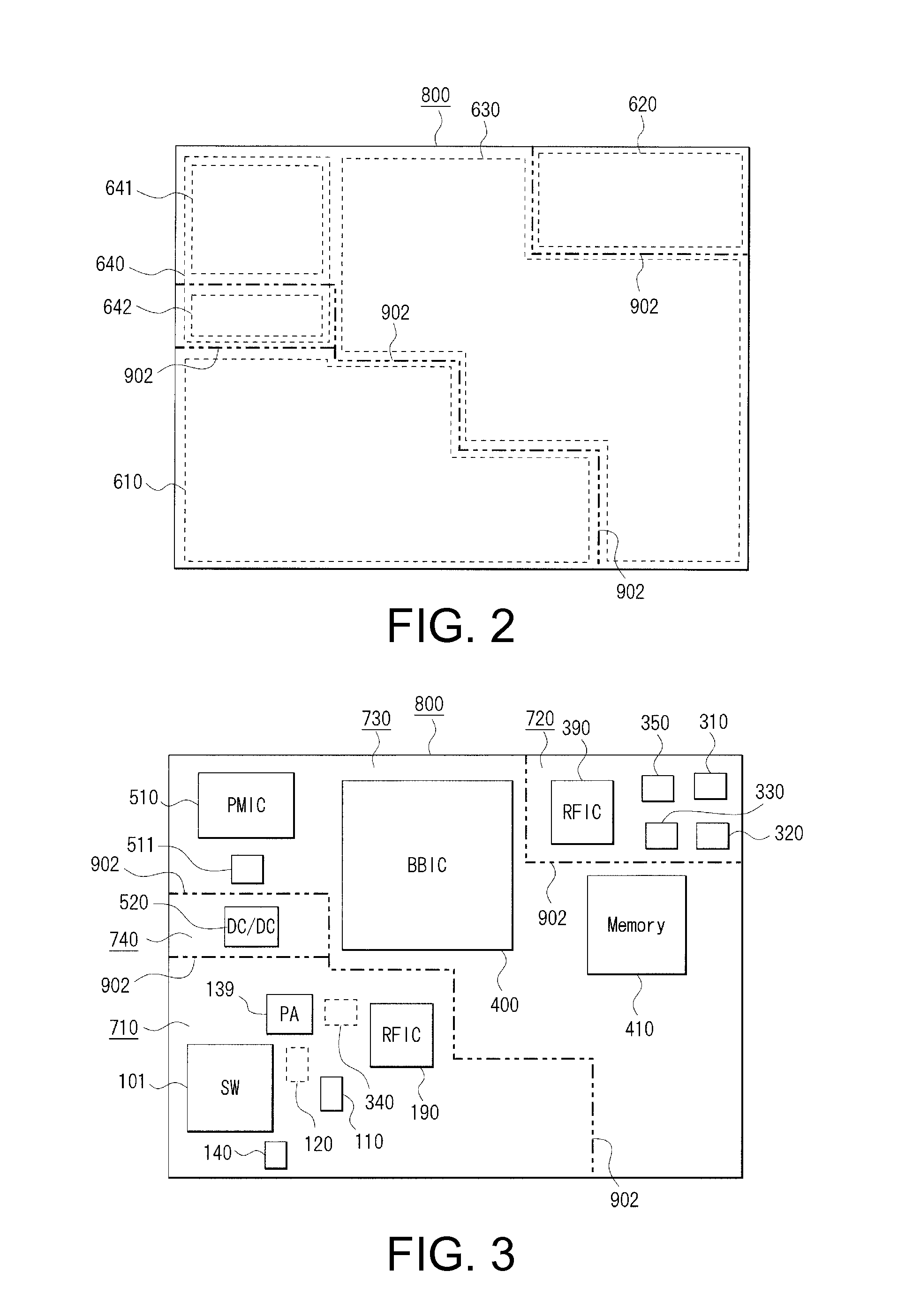

Communication module

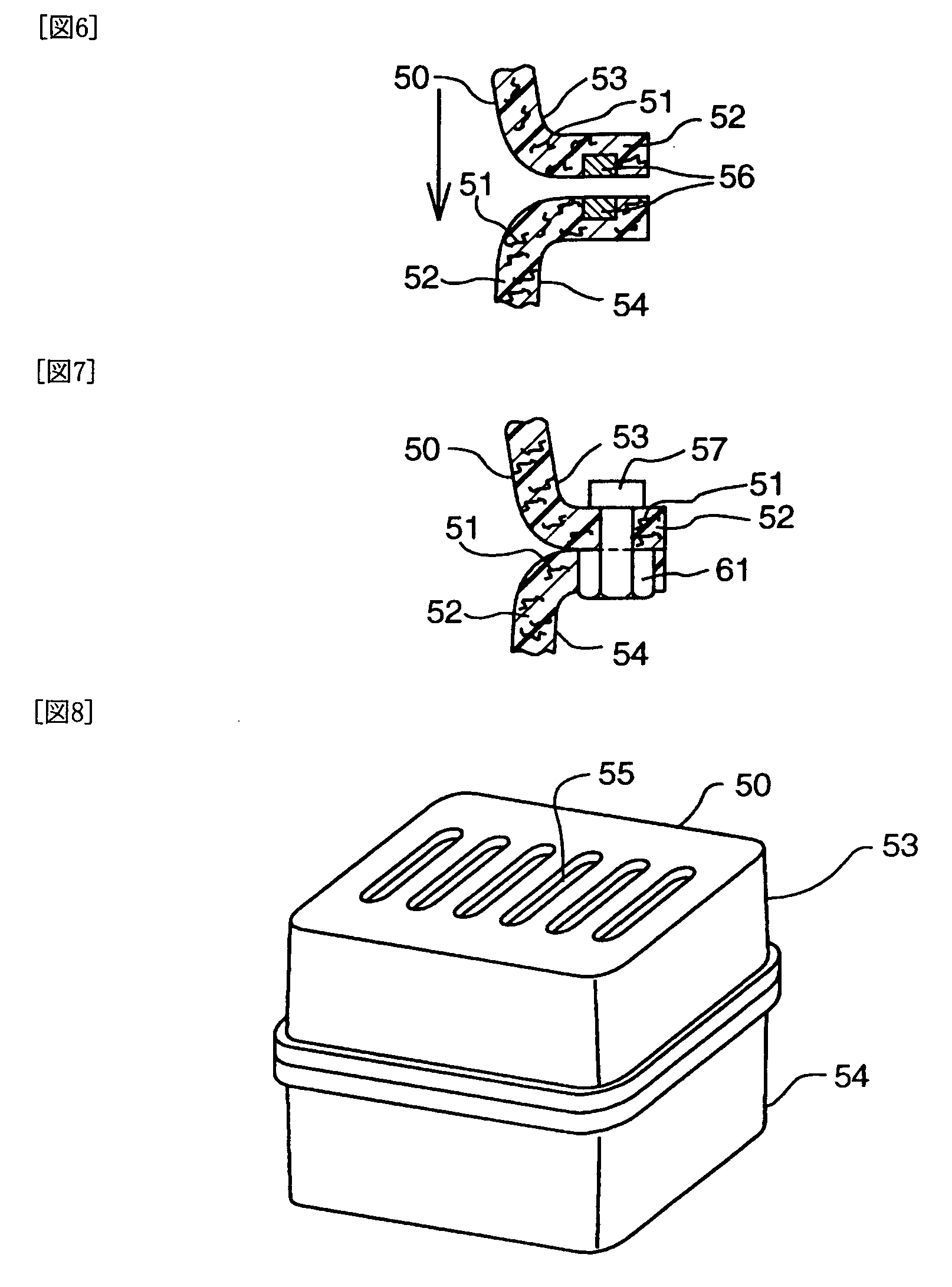

ActiveUS20150119102A1Improve installation densityImprove cooling efficiencySemiconductor/solid-state device detailsCross-talk/noise/interference reductionComputer moduleElectronic component

A communication module includes a circuit substrate having a first high-frequency processing section related to mobile phone communication, a second high-frequency processing section that processes reception signals related to satellite positioning systems, a system section having a baseband processing section and application processing section, and a power circuit section, a sealing member covering the electronic components mounted on the circuit substrate, a conductive shield layer formed on a surface of the sealing member, and a shield wall formed in the sealing member so as to demarcate a mounting area of the first high-frequency processing section and a mounting area of the second high-frequency processing section.

Owner:TAIYO YUDEN KK

Electronic Module for Use in an Automotive Vehicle

ActiveUS20190159371A1Shielding materialsCasings/cabinets/drawers detailsComputer moduleElectromagnetic shielding

An electronic module that comprises a housing; a cover that is disposed over the housing to define an interior; and one or more electronic components positioned within the interior is provided. At least a portion of the housing, cover, or both contain a polymer composition that exhibits an in-plane thermal conductivity of about 1 W / m-K or more as determined in accordance with ASTM E 1461-13 and an electromagnetic shielding effectiveness of about 20 dB or more as determined at a frequency of 1 GHz in accordance with EM 2107A.

Owner:TICONA LLC

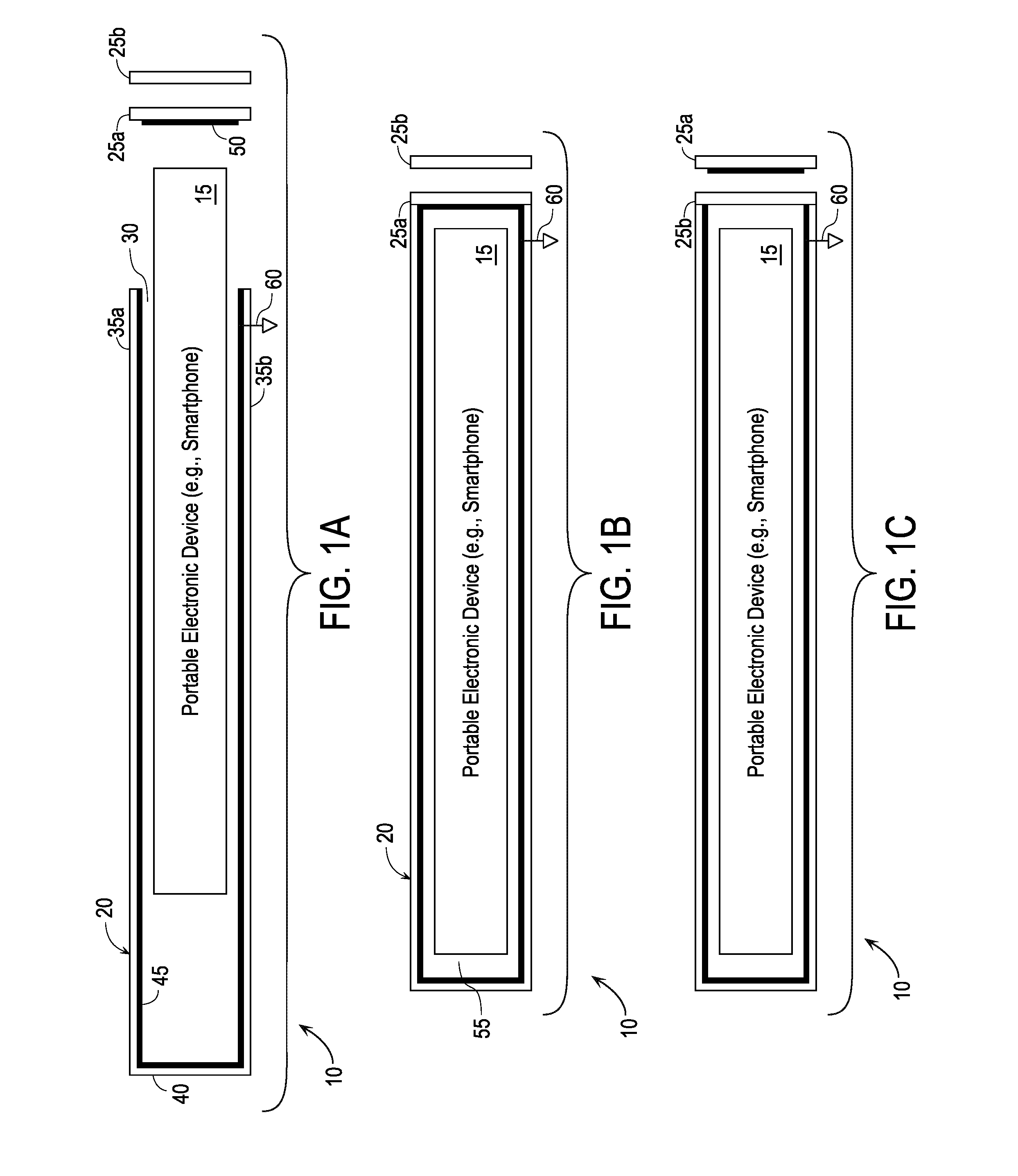

Configurable Shield for Hand-Held Electronic Device

ActiveUS20130206470A1Improve functionalityImprove the usefulnessElectric discharge tubesElectric connection structural associationsHand heldEngineering

A shield for a portable electronic device includes a pouch with an opening sized to accommodate the portable device and a flap. The pouch includes shielding material inside the pouch and on the flap. When the flap is closed, the shielding material inside the pouch and the shielding material on the flap together substantially surround the device, thereby substantially preventing RF signals emitted by the device from leaving the shield, and further substantially preventing RF signals impinging on the shield from outside from reaching the device. When the flap is open, the shielding material inside the pouch and the shielding material on the flap leave a gap, thereby allowing RF signals emitted by the device to leave the shield, and further allowing RF signals impinging on the shield from outside to reach the device. The shield further includes a compartment for a charger and one or more power cord adapters.

Owner:DAVIS PAUL FITZGERALD

Folding component housing

A foldable blank includes a substrate and a conducting layer. The substrate is folded so as to form a component housing. When the substrate is folded to form a housing, the conducting layer provides electrical shielding to devices situated within the housing. The housing has holes situated therein to accommodate air flow and external connections to devices located within the housing. The housing may be employed to envelop a chassis manufactured from expanded polypropylene.

Owner:DMT FEINWERKTECHN KOMPLETTLOSUNGEN

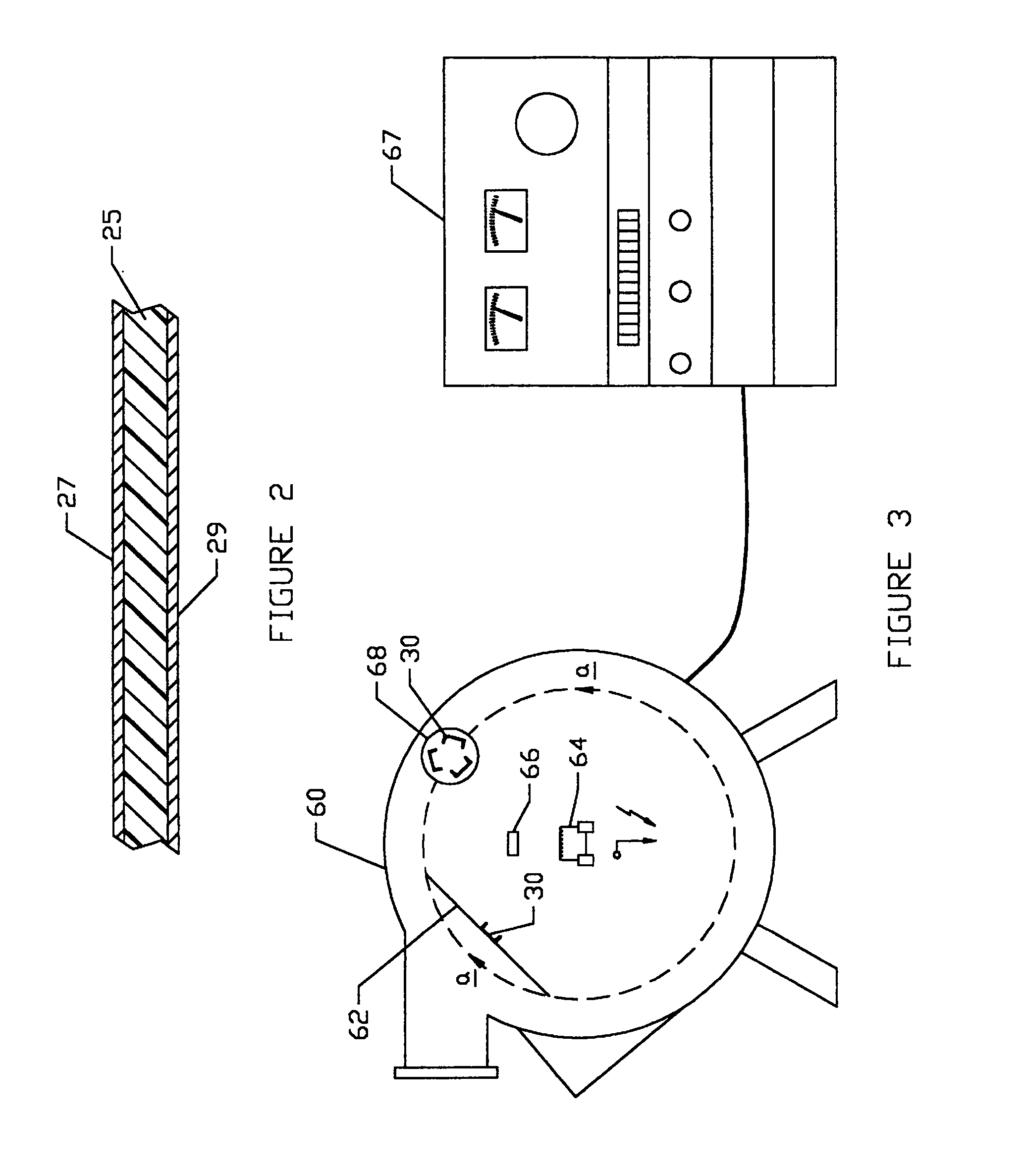

Electromagnetic Interference Shields for Electronic Devices

InactiveUS20070199738A1Improve the immunityShielding materialsVacuum evaporation coatingElectromagnetic interferencePersonal computer

Owner:WAVEZERO

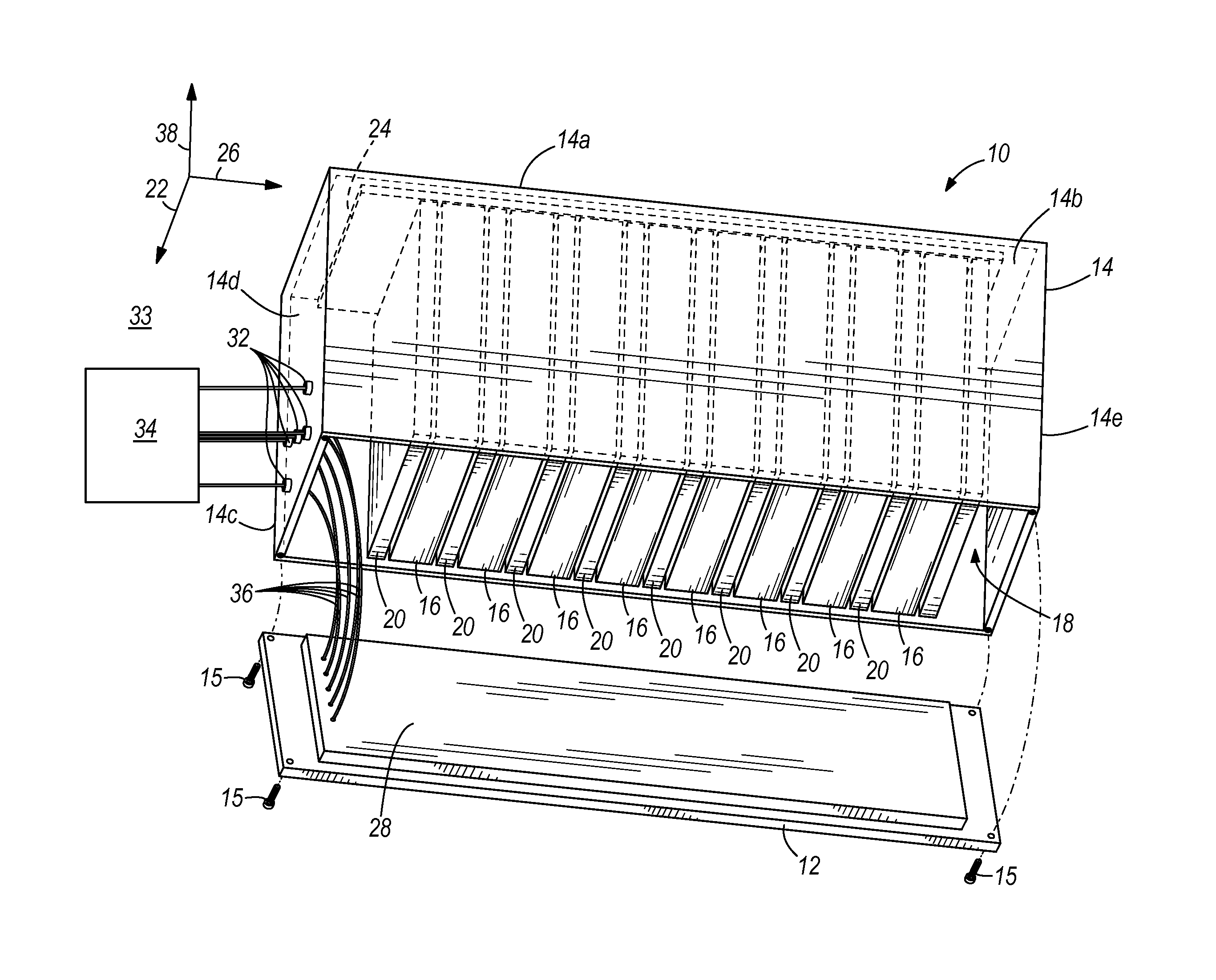

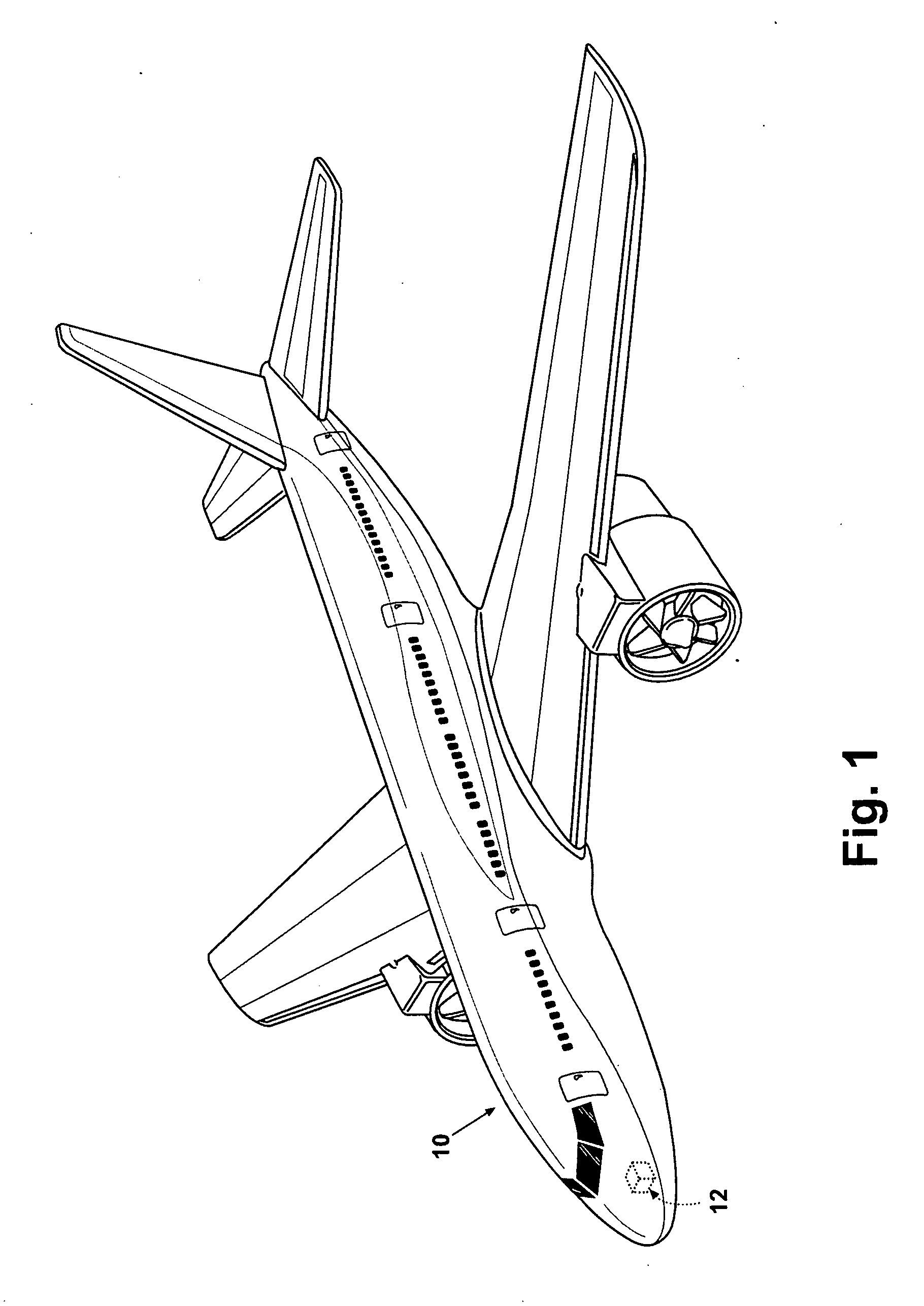

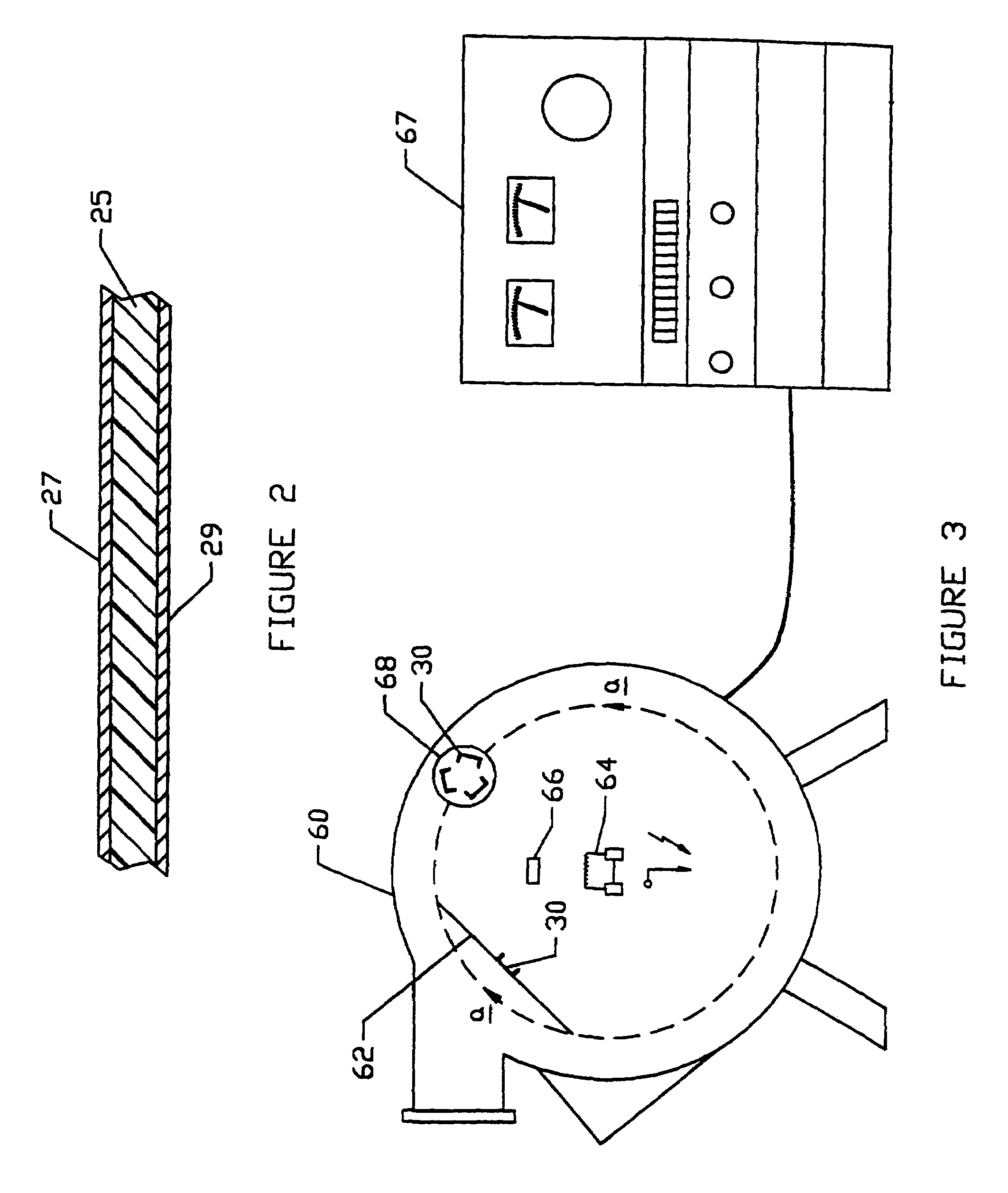

Avionics Chassis

ActiveUS20100319948A1Installation of lighting conductorsPrinted circuit aspectsAviationLightning strike

An avionics chassis comprises a composite housing, a radio wave shield, and a lightning strike conductive path, wherein the radio wave shield attenuates electromagnetic interference entering and leaving the housing, and the lightning strike conductive path directs the current from a lightning strike away from an interior of the housing.

Owner:GENERAL ELECTRIC CO

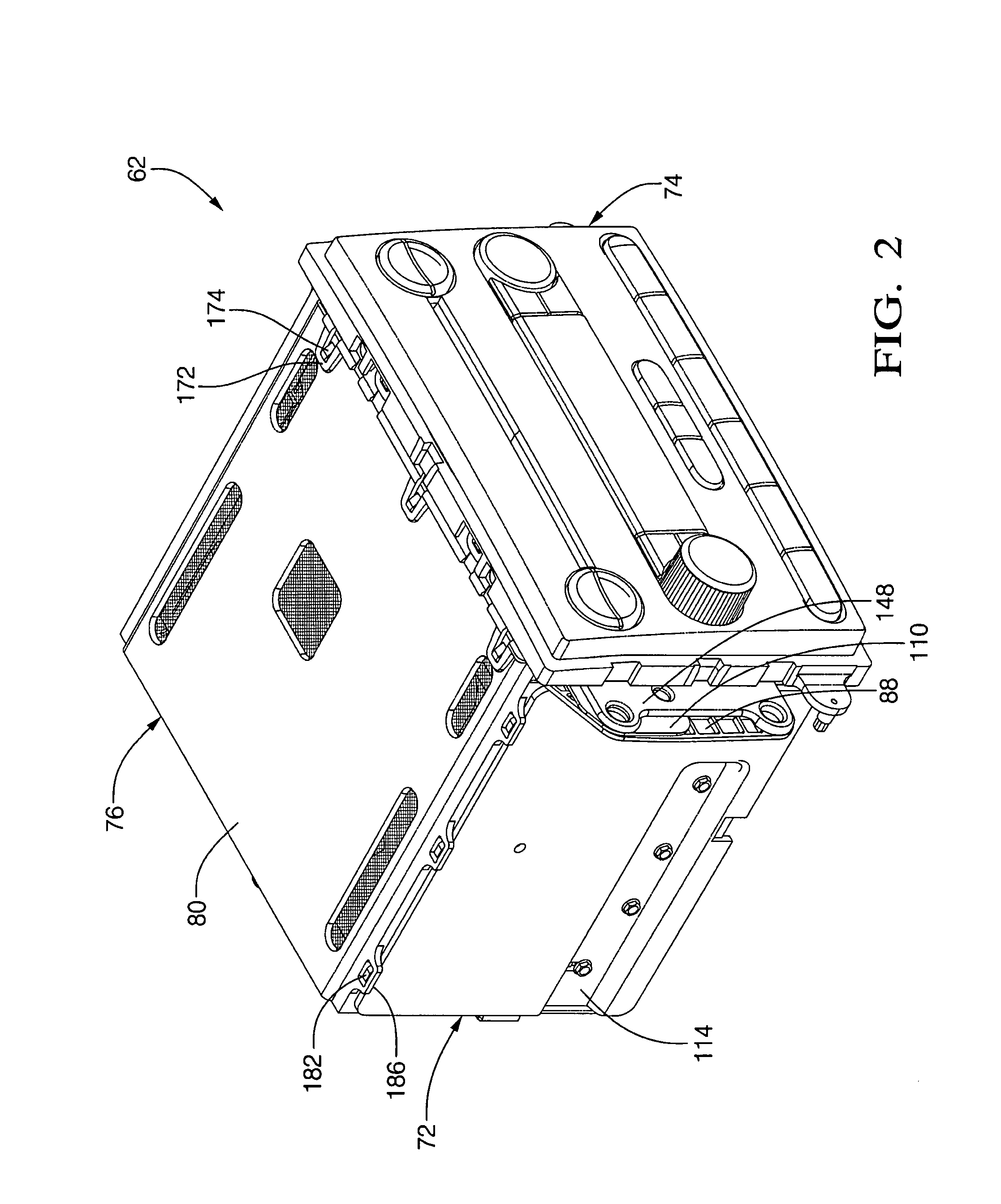

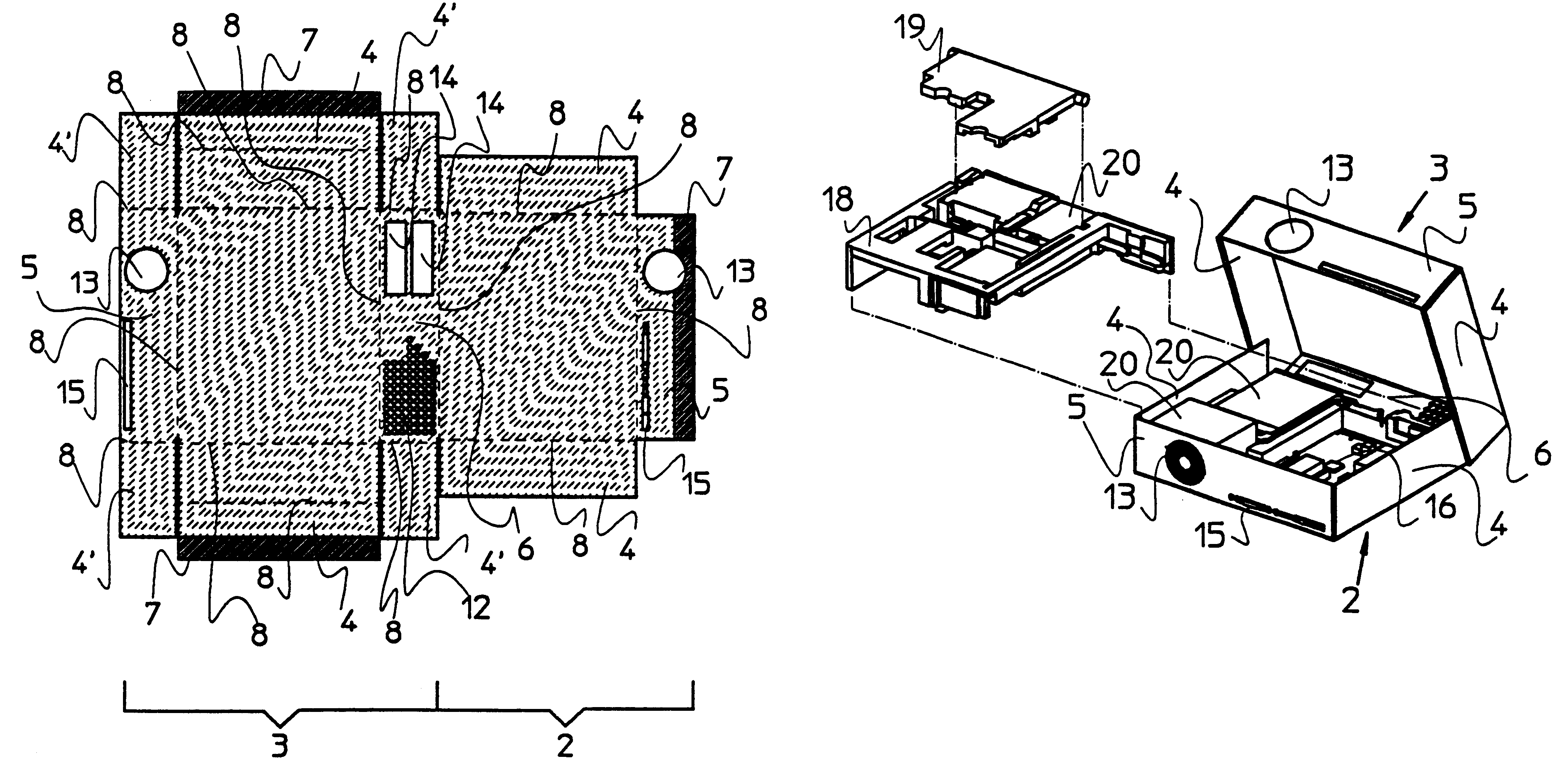

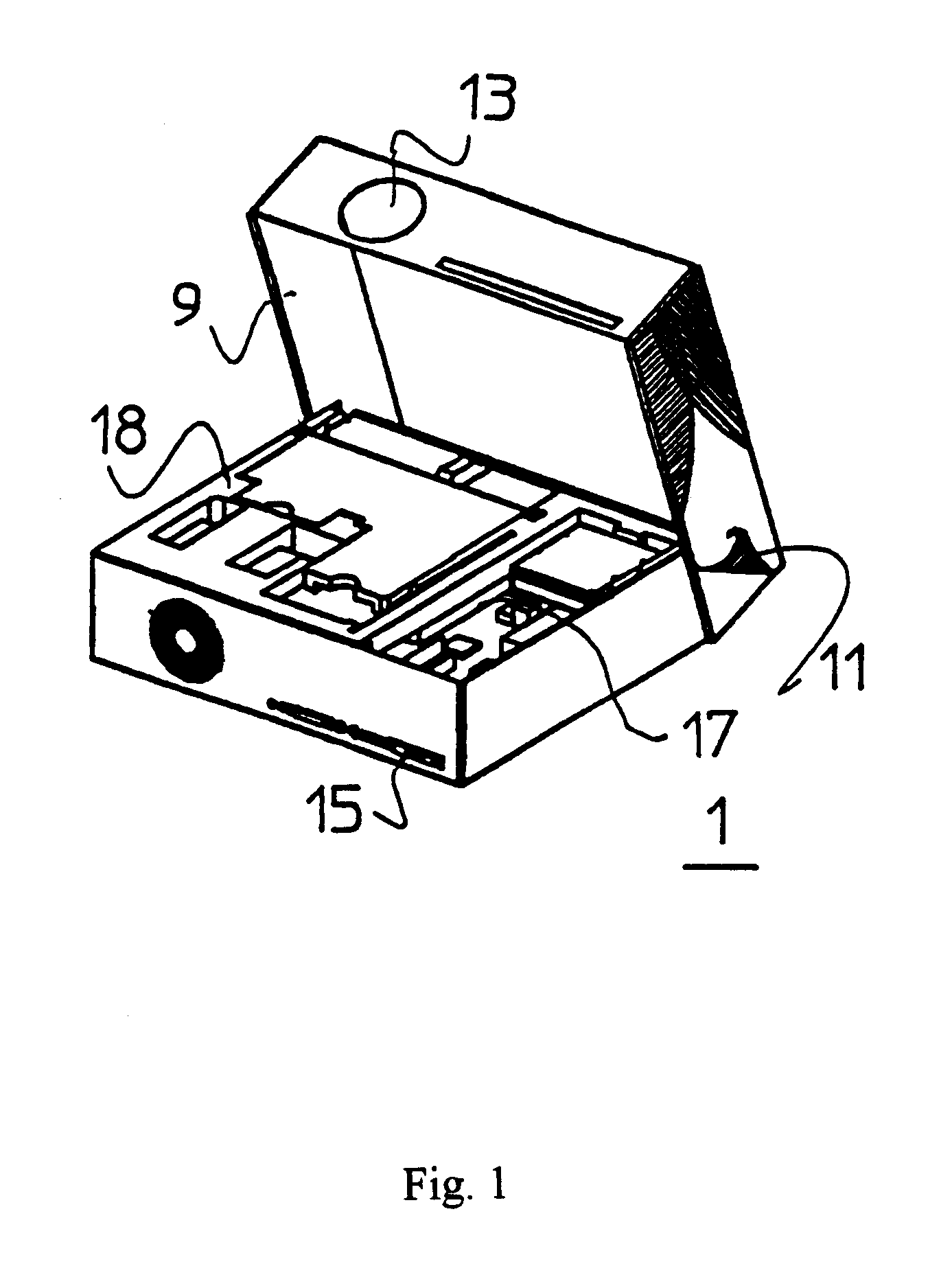

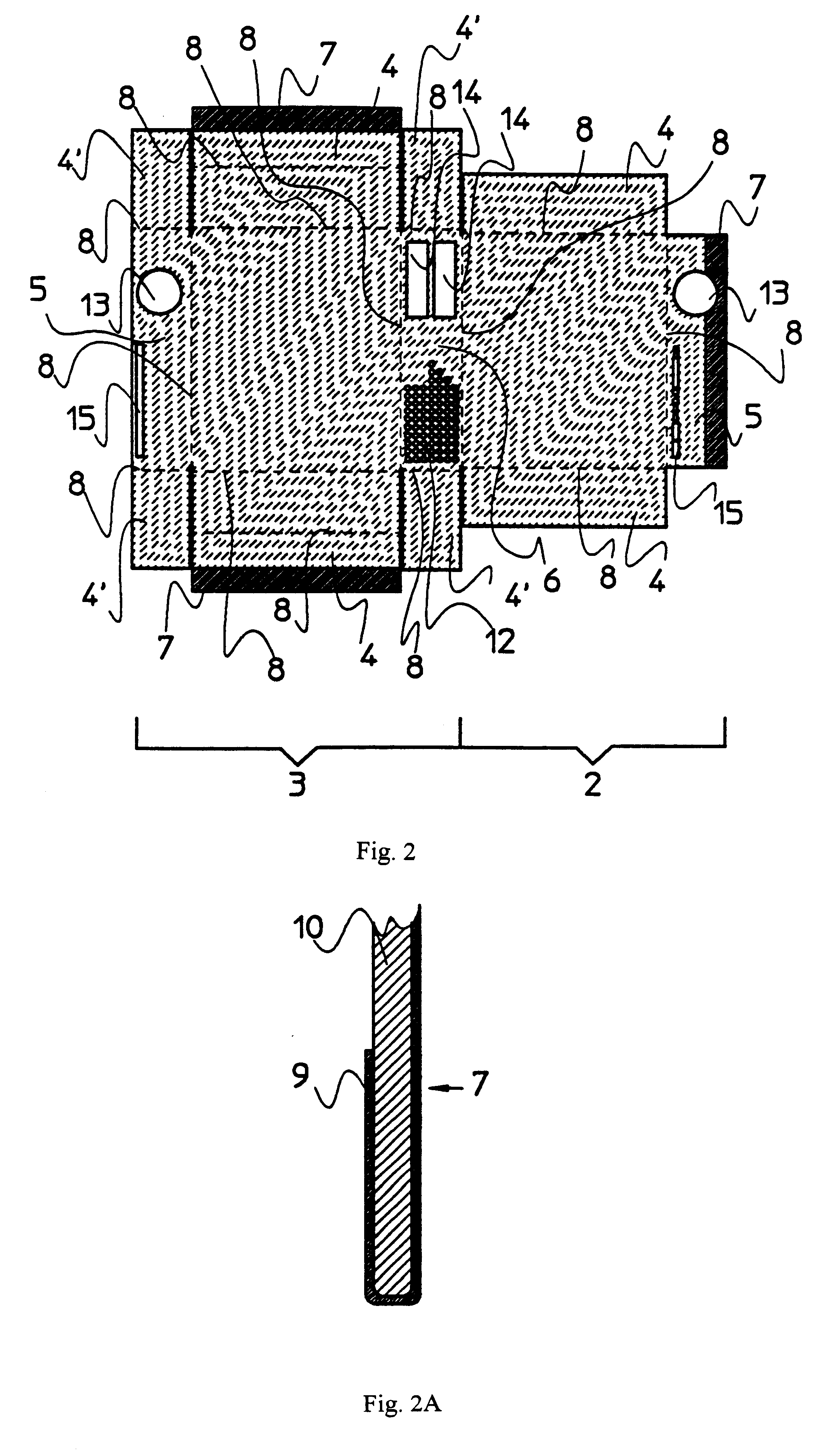

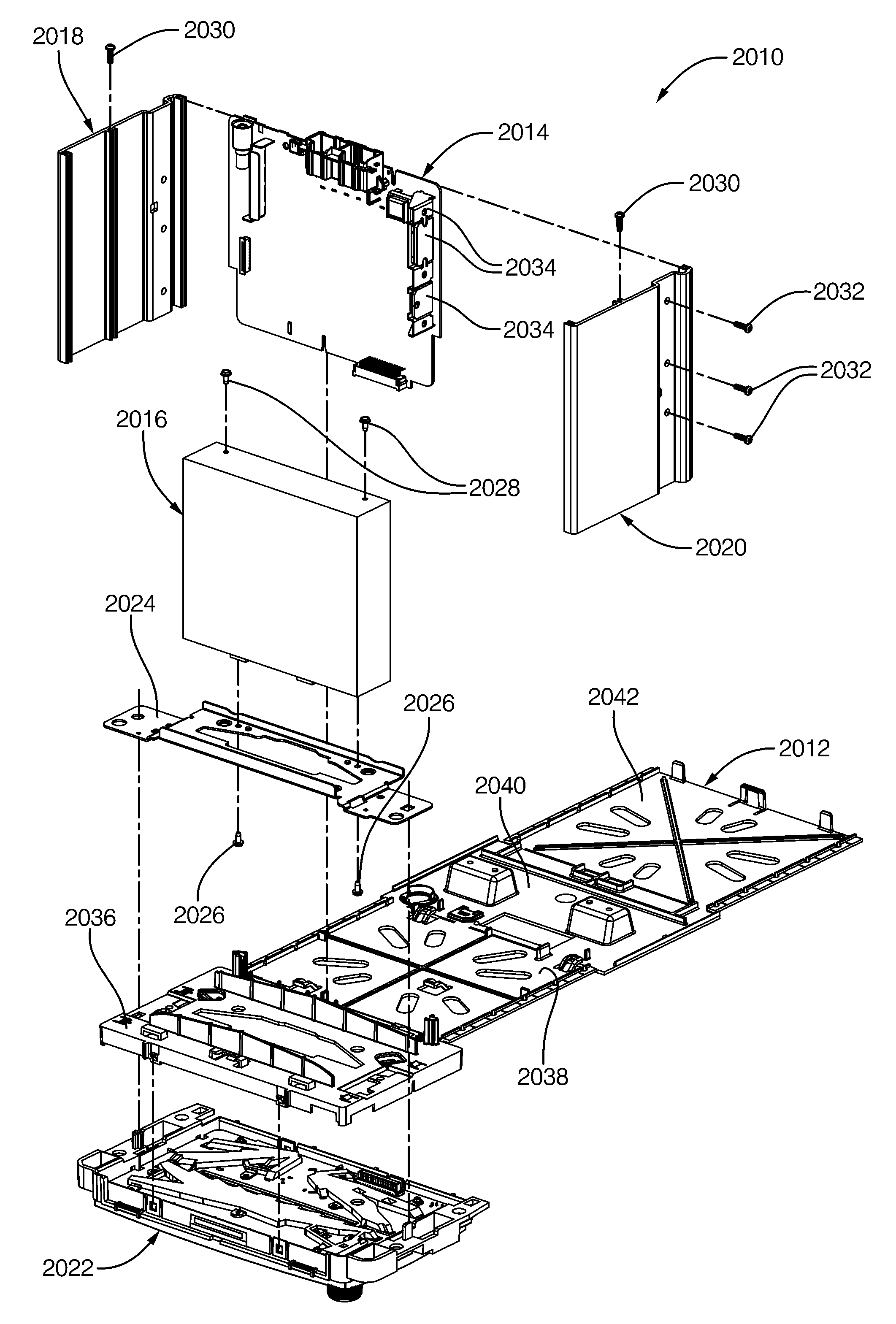

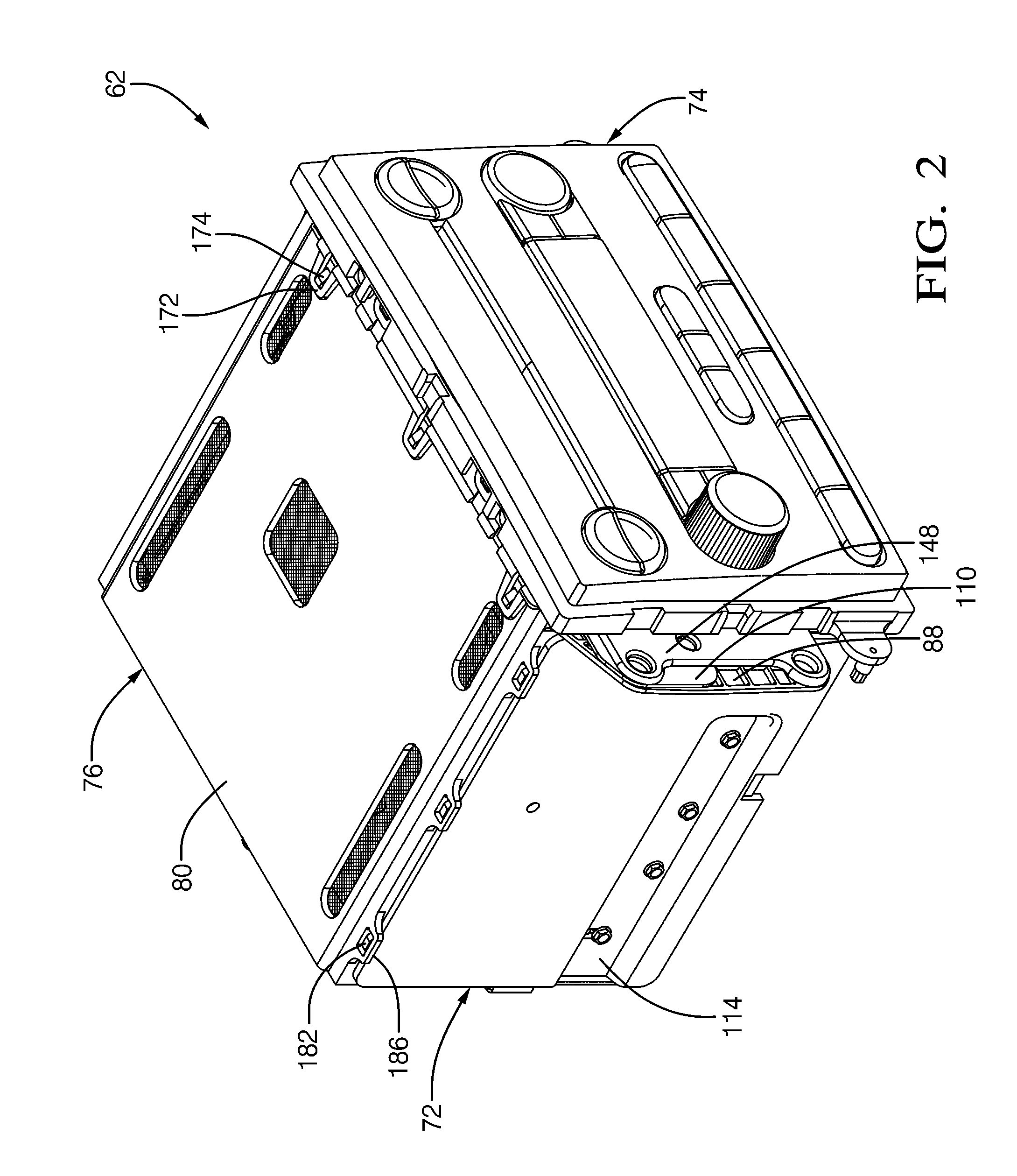

Lightweight audio system for automotive applications and method

ActiveUS20100188834A1Minimizes required handlingMinimize the numberShielding materialsMechanical apparatusRadio receiverRadio reception

A lightweight radio / CD player for vehicular application is virtually “fastenerless” and includes a fold-up case formed of polymer based material that is molded to provide details to accept audio devices such as playback mechanisms (if desired) and radio receivers, as well as the circuit boards required for electrical control and display. The case is of composite structure, including an insert molded electrically conductive wire mesh screen that has been pre-formed to contour with the molding operation. The wire mesh provides EMC, RFI, BCI and ESD shielding and grounding of the circuit boards via exposed wire mesh pads and adjacent ground clips. Side wall closure members are extruded of aluminum defining self-engaging attachment features for affixing to the case, providing electrical self-grounding with the wire screen and thermal grounding with internal power devices. The major components and subassemblies are self-fixturing during the final assembly process, eliminating the need for dedicated tools, fixtures and assembly equipment. The major components and subassemblies self-interconnect by integral guide and connection features effecting “slide lock” and “snap lock” self-interconnection.

Owner:APTIV TECH AG

Electromagnetic interference shields for electronic devices

InactiveUS7358447B2Improve the immunityShielding materialsVacuum evaporation coatingElectromagnetic interferencePersonal computer

Owner:DEEP COAT +1

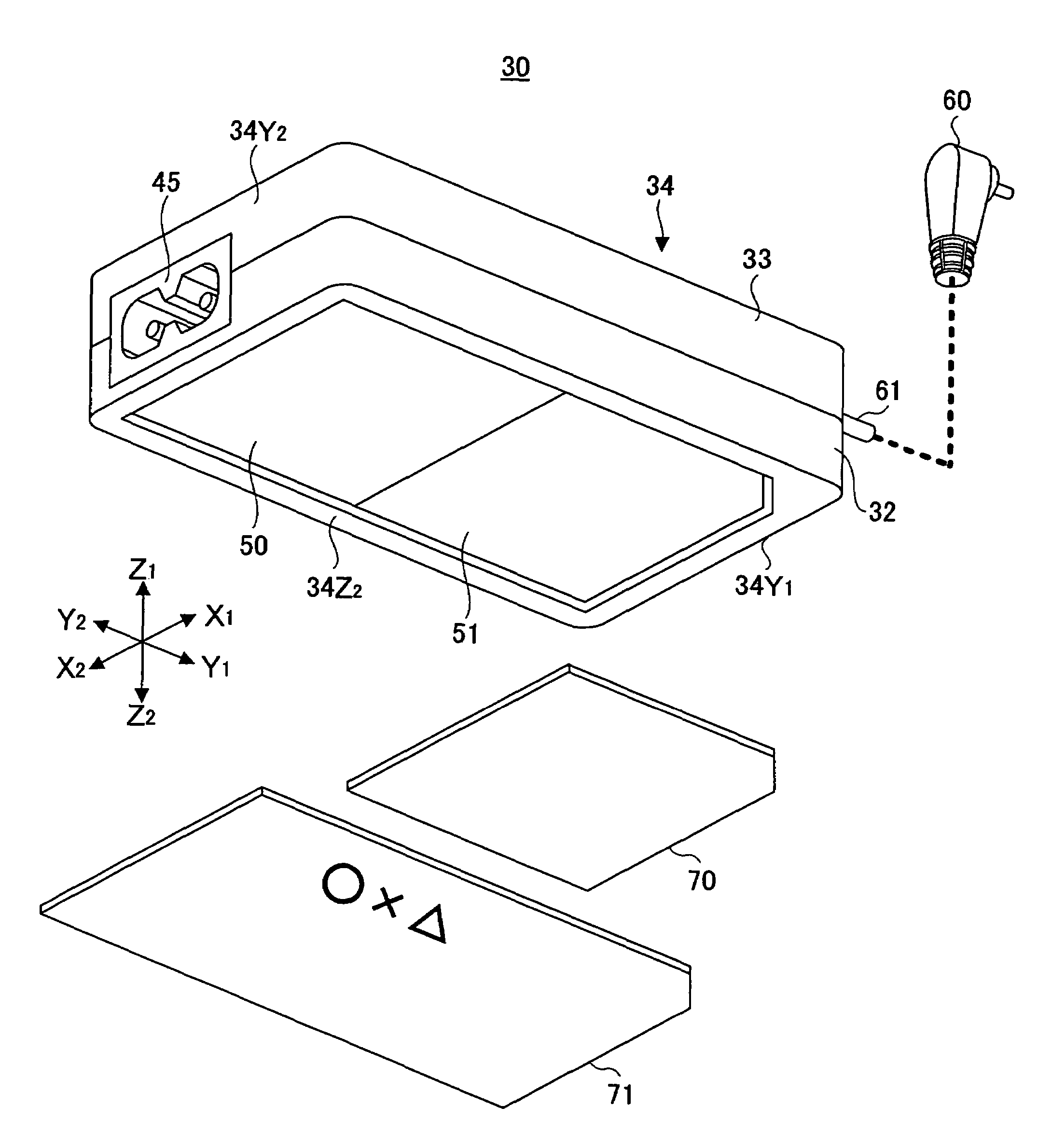

AC adapter with heat radiation sheet

InactiveUS7300302B2Quality improvementAc-dc conversion without reversalCoupling device detailsAC adapterEngineering

An AC adapter has a synthetic resin case, a switching regulator circuit assembly with an AC input terminal in the synthetic resin case, a synthetic resin name plate, and a metallic Bsheet for heat radiation separate from the resin name plate. A surface of the case has a first concave portion for the name plate and a second concave portion for the metallic sheet in the first concave portion, the metallic sheet being attached in the second concave portion with the name plate attached in the first concave portion and covering the attached metallic sheet.

Owner:MITSUMI ELECTRIC CO LTD

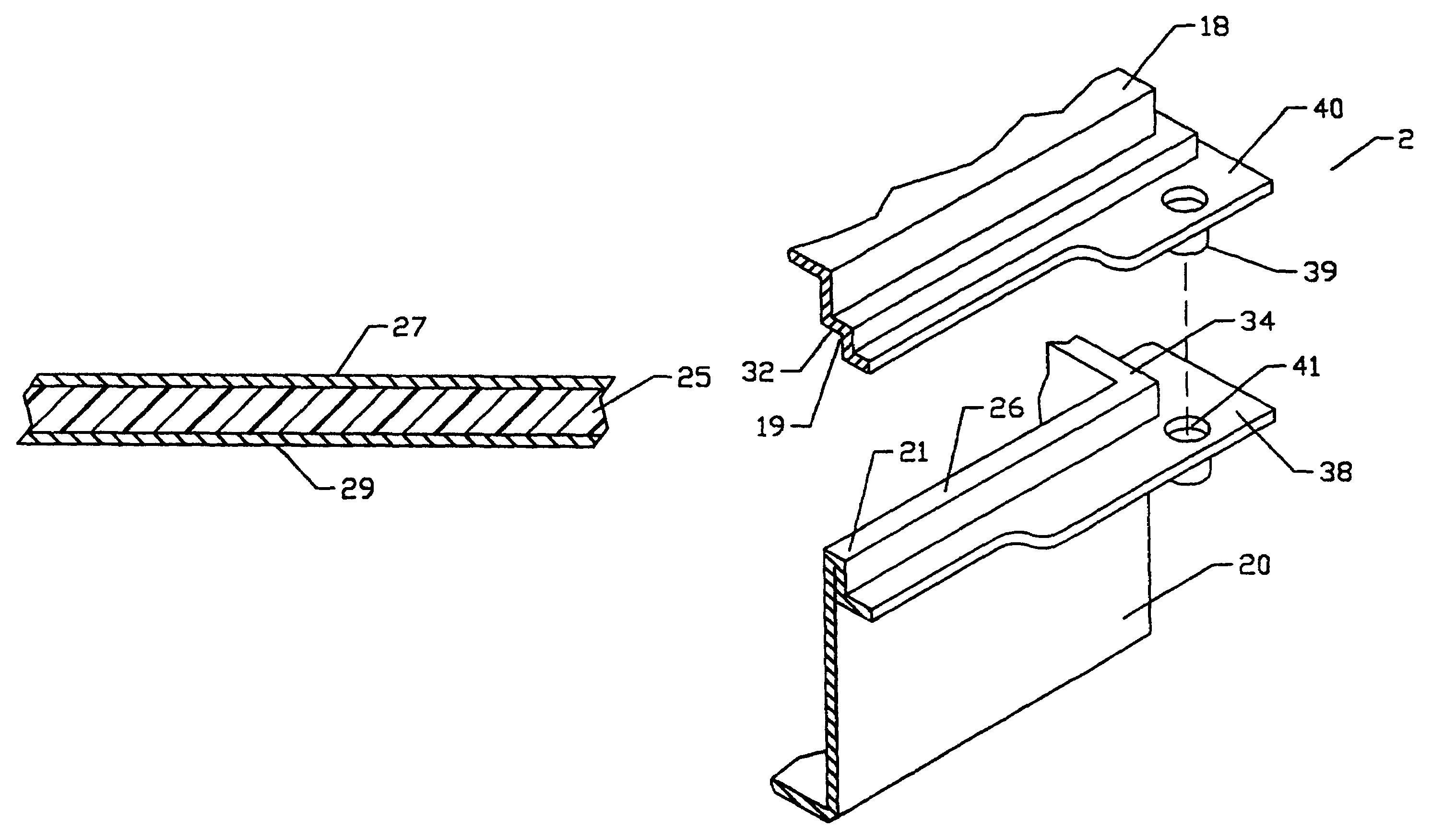

Lightweight audio system for automotive applications and method

InactiveUS20100246155A1Minimizes required handlingMinimize the numberAdhesivesElectrical apparatus interference reductionElectricityElectrical control

A housing assembly for a lightweight electronic device for vehicular application is virtually “fastenerless” and includes a one-piece case formed of a layered composite structure including polymer based, electrically insulating sheet material and electrically conductive sheet material that is compression molded or hydroformed to provide three-dimensional case details to accept one or more electronic devices such as circuit boards required for electrical control and display of vehicle based systems. The conductive sheet material is preferably a wire mesh which provides shielding from electrical anomalies and grounding of the circuit boards via exposed wire mesh pads and adjacent ground clips. Major components and subassemblies are self-fixturing during the final assembly process, eliminating the need for dedicated tools, fixtures and assembly equipment.

Owner:APTIV TECH LTD

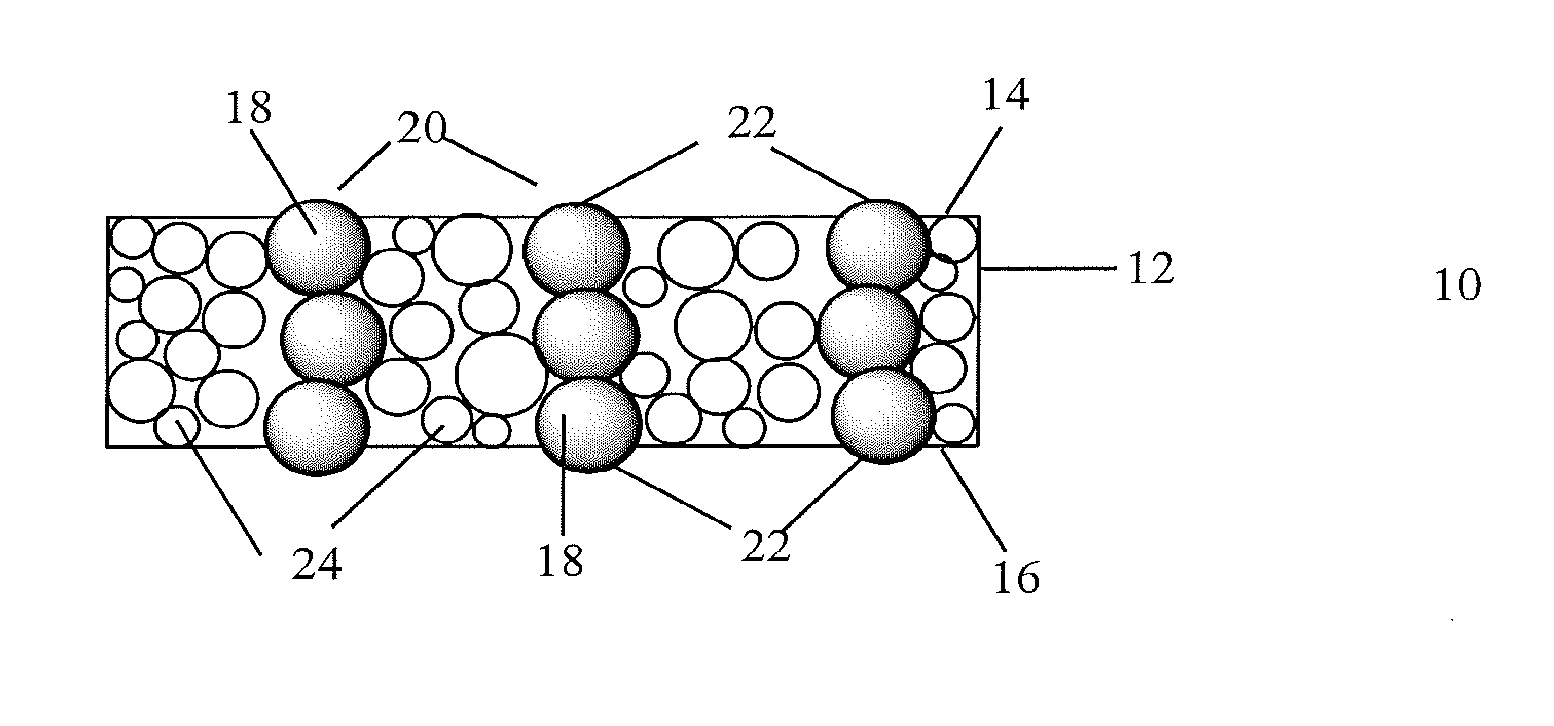

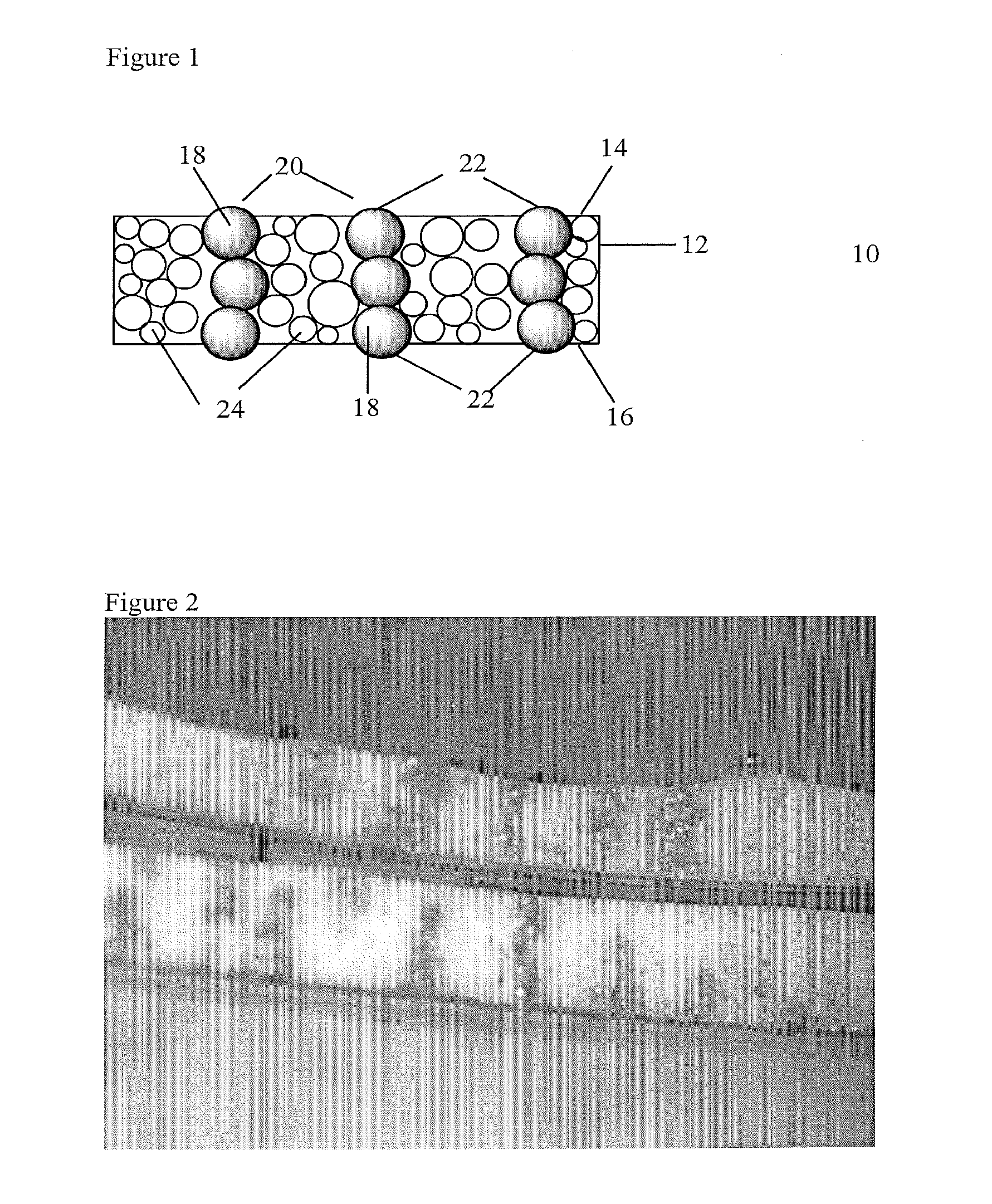

Conductive Polymer Foams, Method of Manufacture, and Articles Thereof

InactiveUS20110155946A1Synthetic resin layered productsInorganic material magnetismConductive polymerUltimate tensile strength

A method of manufacturing a polymer foam composite is described, the method comprising forming an article having a first surface and an opposite second surface from a precursor composition, the precursor composition comprising a polymer foam precursor composition, and a filler composition comprising a plurality of magnetic, electrically conductive particles; foaming the precursor composition to form a plurality of cells in precursor composition; applying a magnetic field to the foamed precursor composition, wherein the magnetic field is of a strength and applied for a time effective to align the electrically conductive, magnetic particles into mutually isolated chains between the first surface and the opposite second surface of the article; and solidifying the polymer foam precursor composition to provide a polymer foam composite having a density of about 1 to about 125 pounds per cubic foot and a volume resistivity of about 10−3 ohm-cm to about 103 ohm-cm at a pressure of 60 pounds per square inch. Polymer foam composites made by this method are also described, as well as articles formed therefrom.

Owner:WORLD PROPERTIES

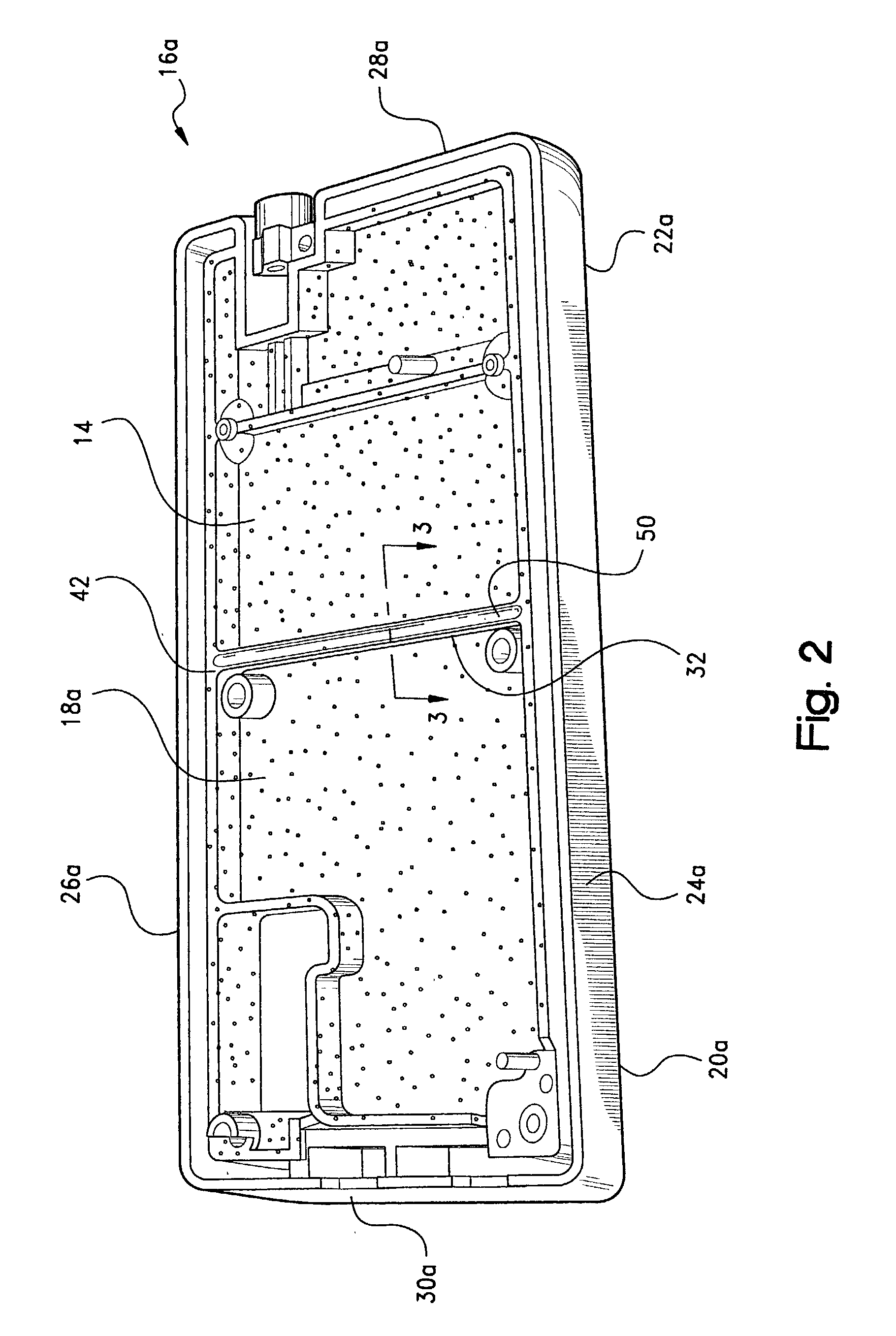

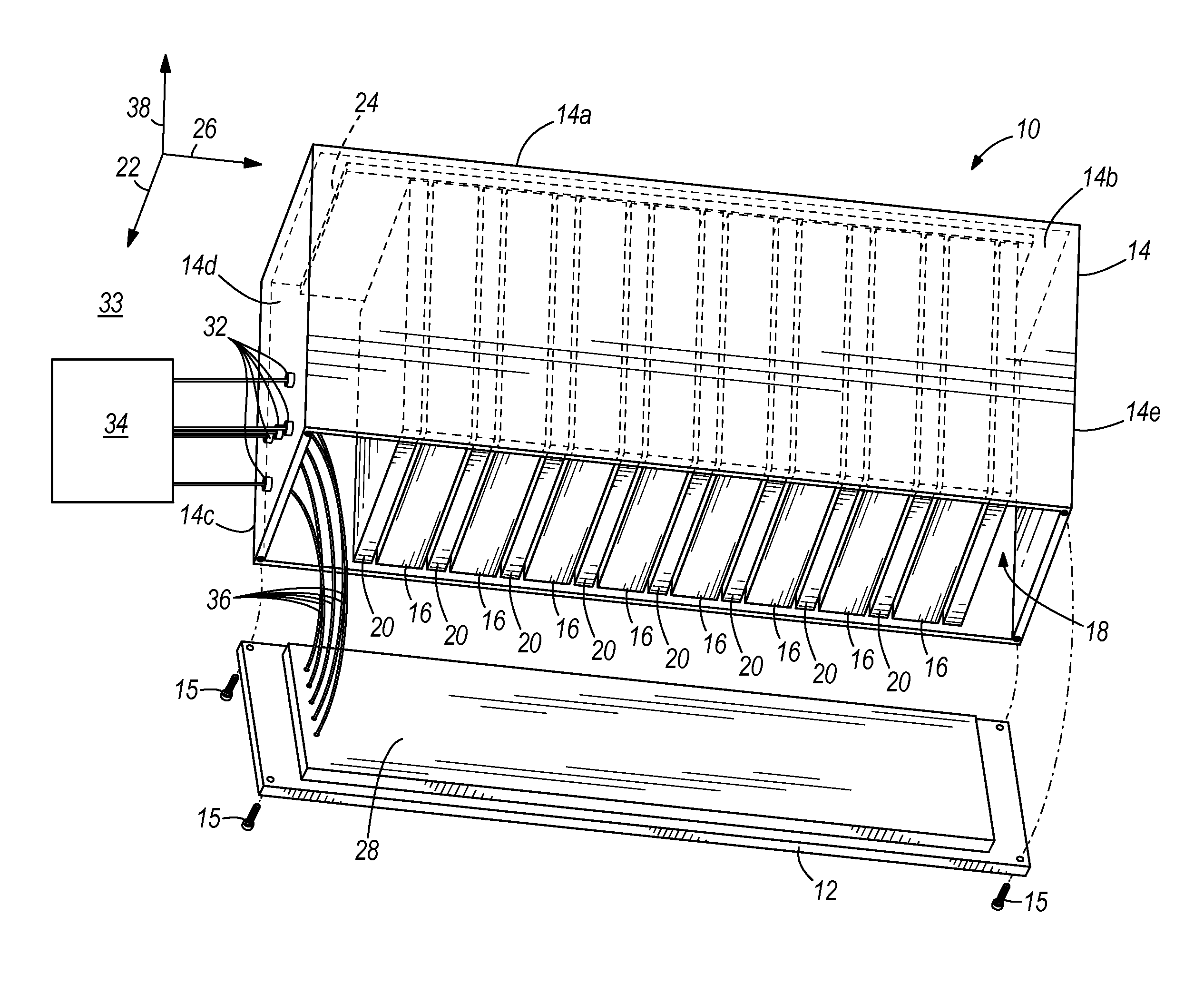

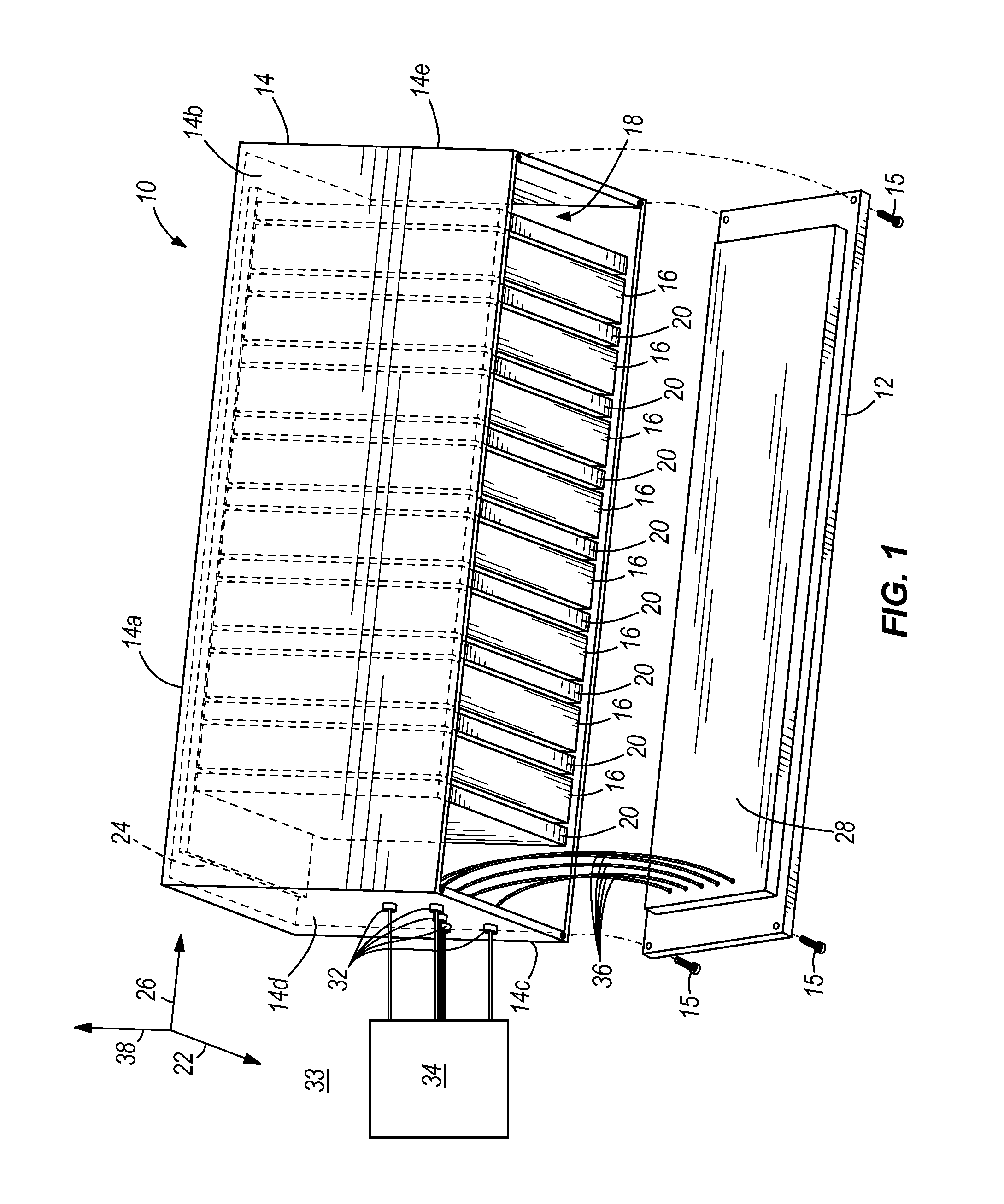

Flexible electronic circuit enclosure assembly

ActiveUS20130333941A1Substantial costSubstantial labor savingWave amplification devicesSupport structure mountingElectrical controlFlexible electronics

A flexible enclosure assembly for an electronic device for vehicular application is virtually “fastenerless” and includes a preform blank of conductive sheet material such as wire screen mesh or the like which defines upper, lower and a plurality of side wall portions flexibly interconnected by living hinges. A framework of resilient elastomeric material is insert molded to the preform blank to provide three-dimensional case details to accept one or more electronic devices such as circuit boards required for electrical control and display of vehicle based systems. The conductive sheet material is preferably a wire mesh which provides shielding from electrical anomalies and grounding of the circuit boards via exposed wire mesh pads and adjacent ground clips. Major components and subassemblies are self-fixturing during the final assembly process, eliminating the need for dedicated tools, fixtures and assembly equipment.

Owner:APTIV TECH LTD

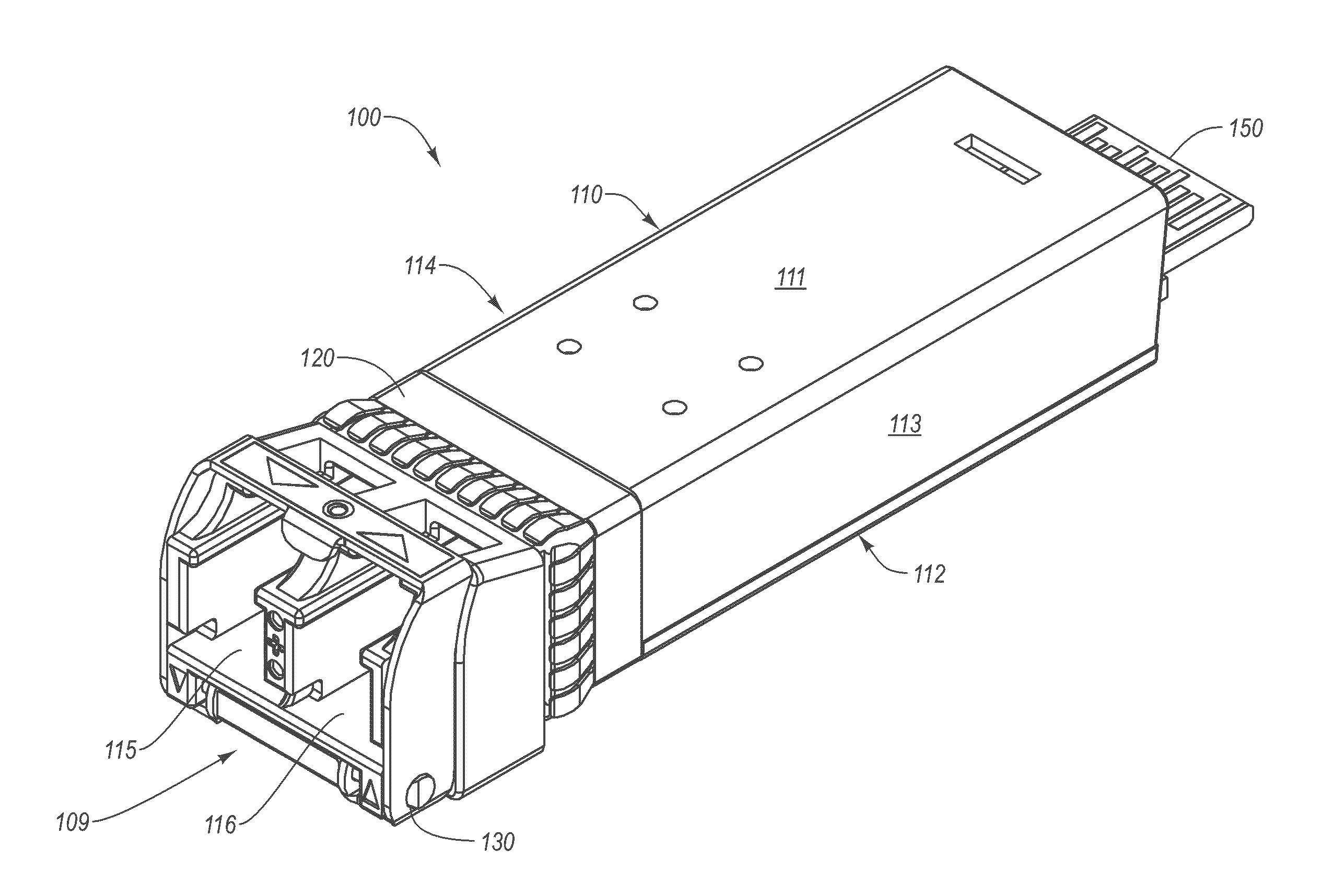

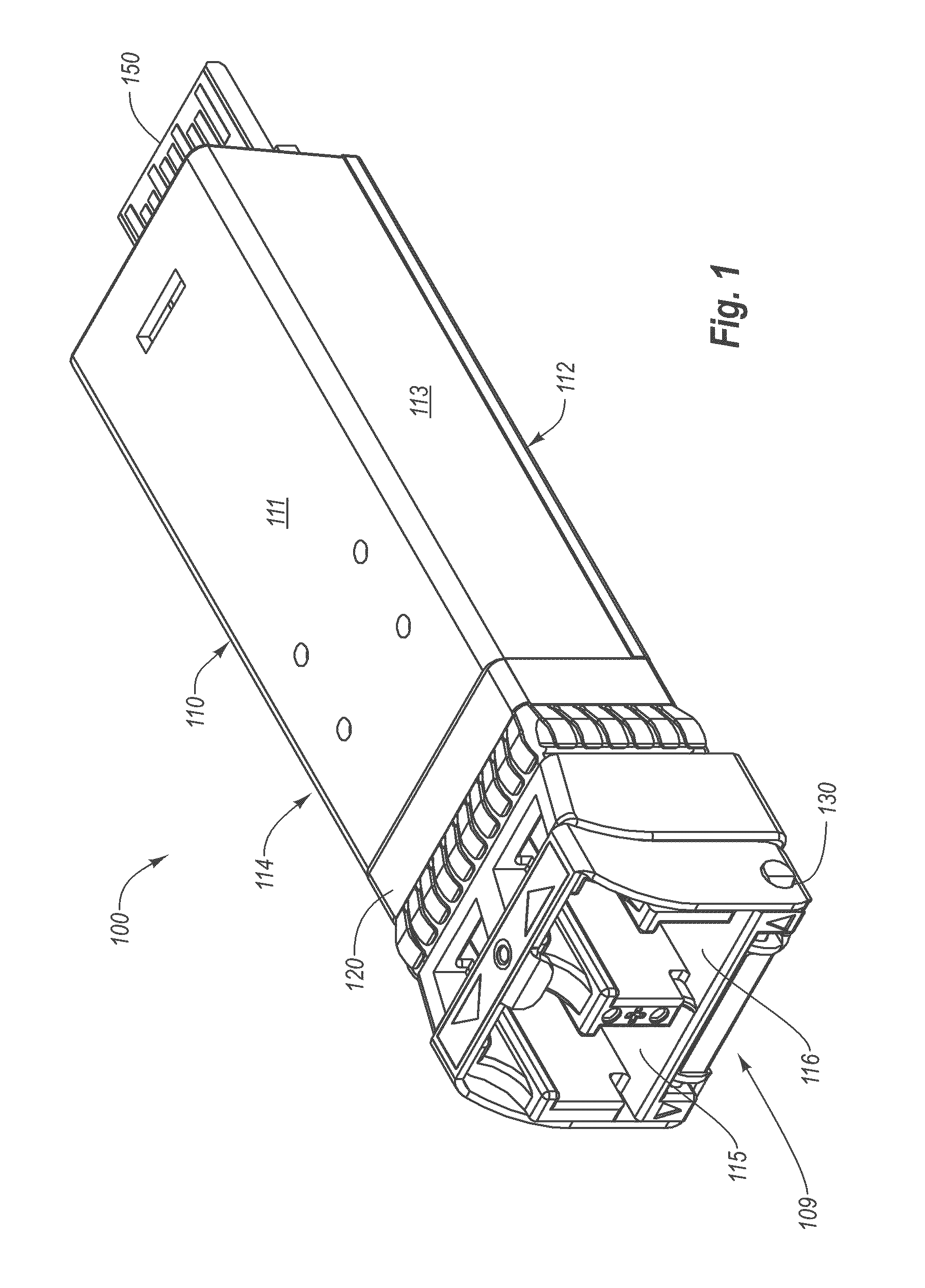

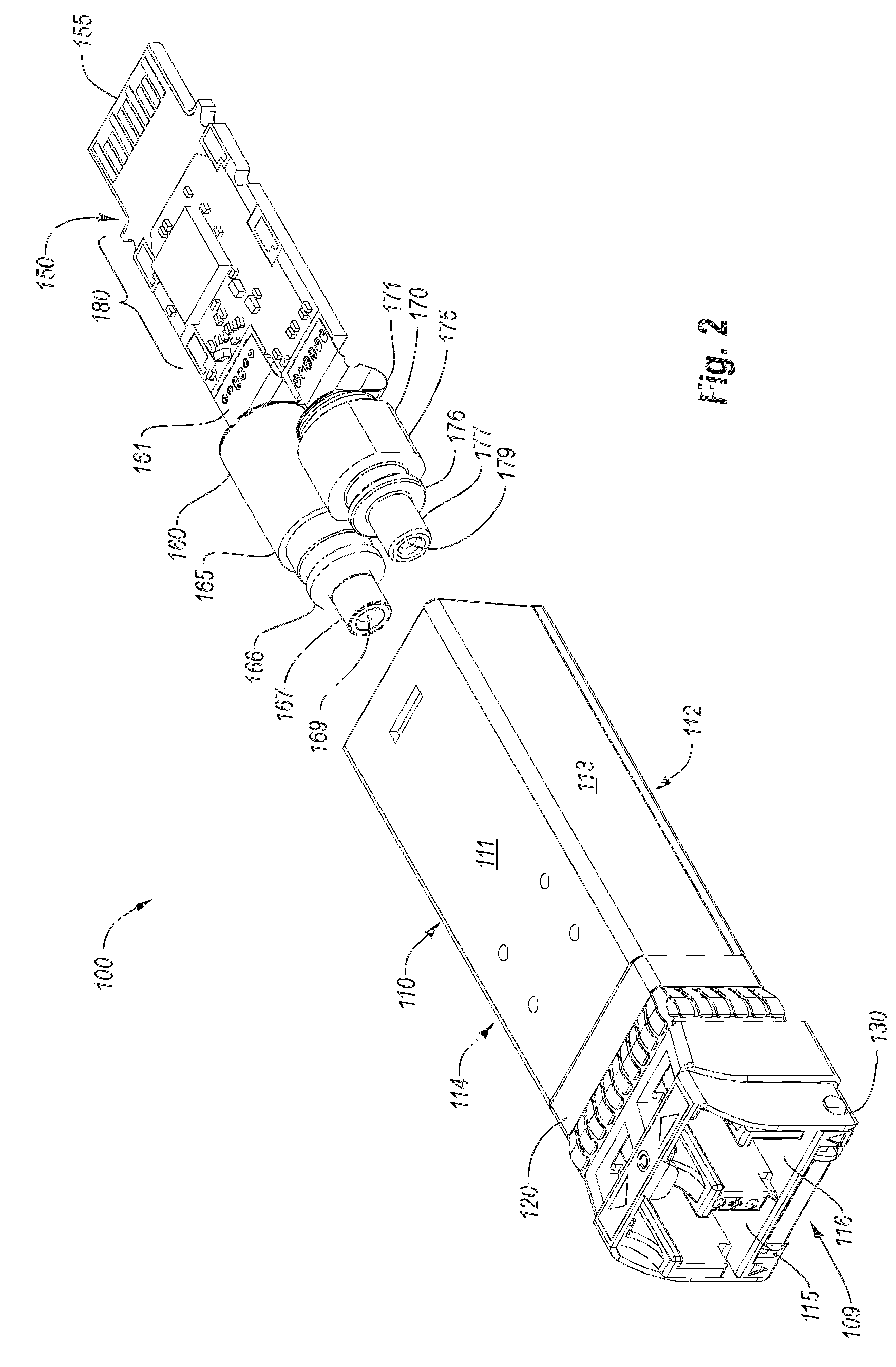

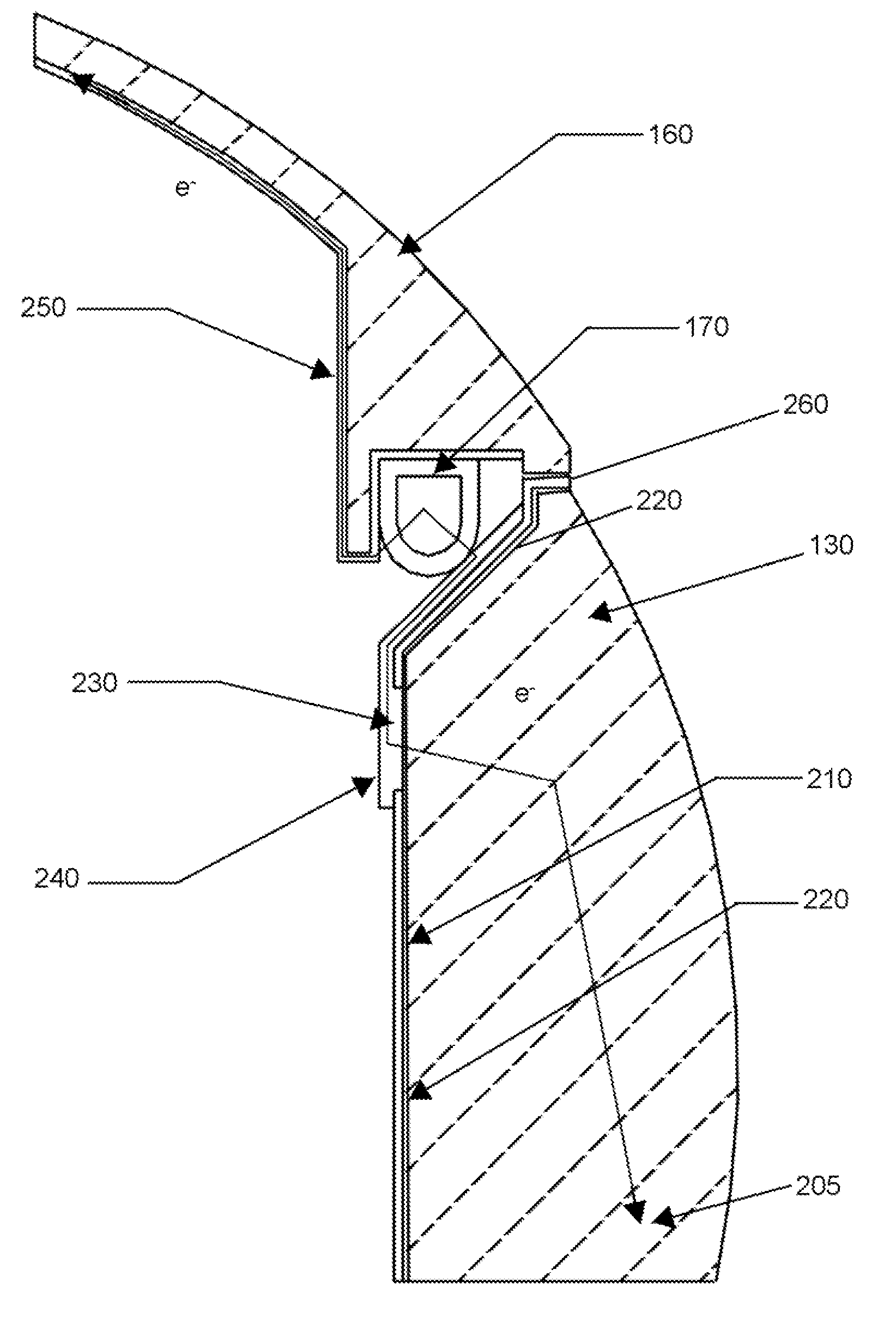

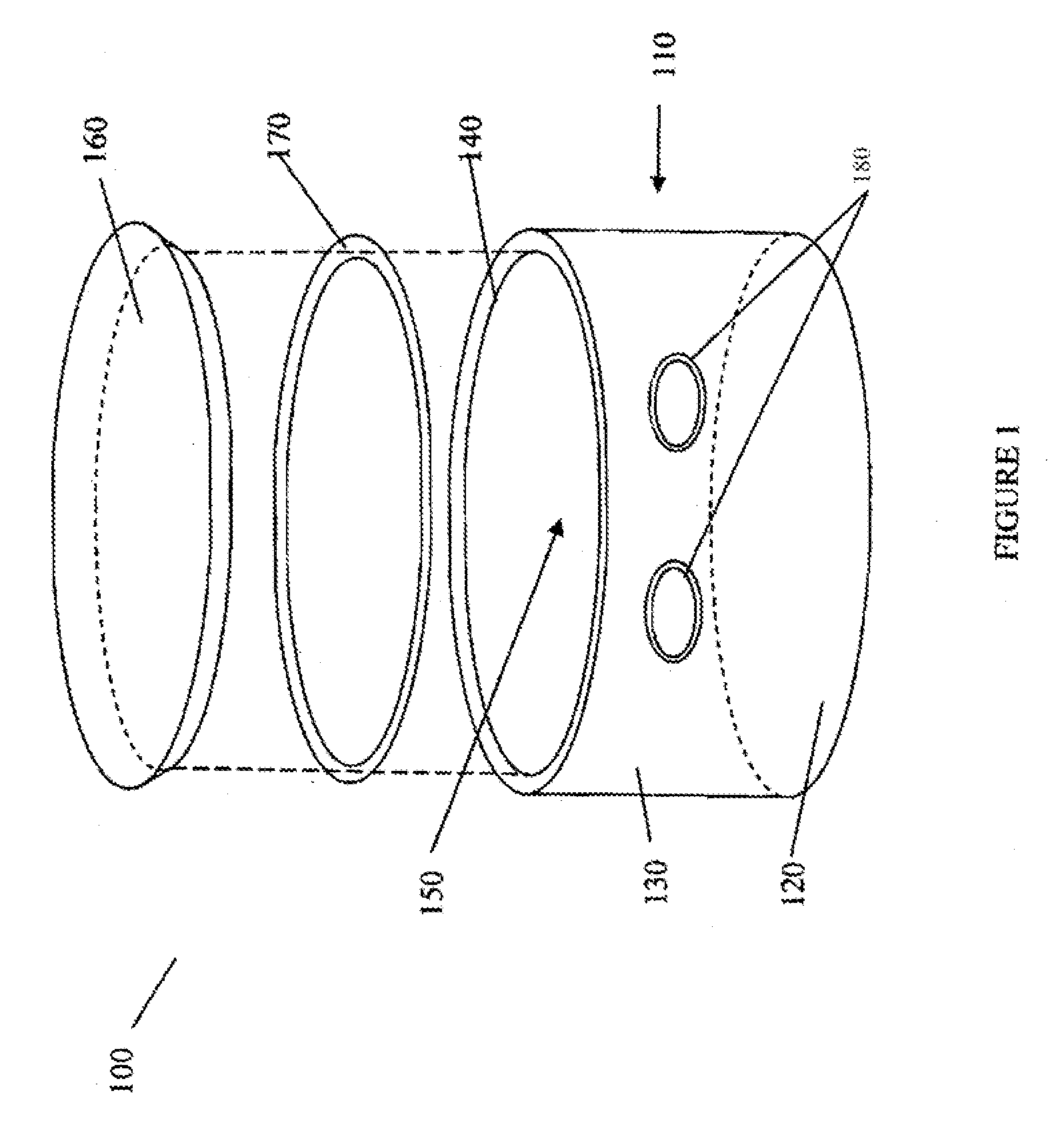

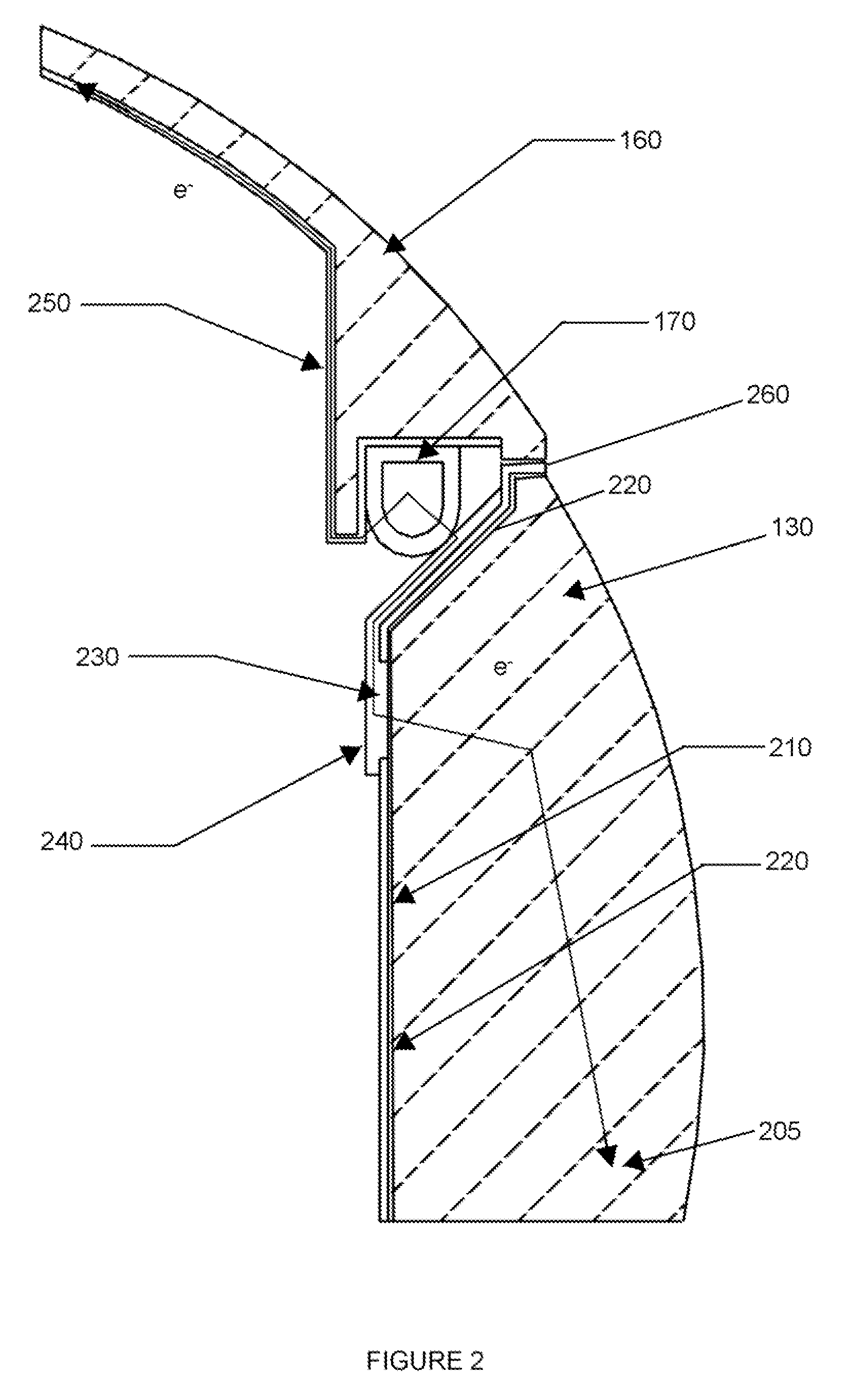

Monolithic shell for an optical electrical device

An optoelectronic transceiver module. The optoelectronic module is a monolithic, one-piece module shell that includes a top portion, a bottom portion, a first side portion, a second side portion, and a front portion. The top portion, bottom portion, first side portion, second side portion and the front portion define a cavity configured to enclose electro-optical circuitry. In addition, the top portion and the bottom portion are configured such that the top portion is not separable from the bottom portion. Further, the front portion defines at least one of an optical transmit port or an optical receive port.

Owner:II VI DELAWARE INC

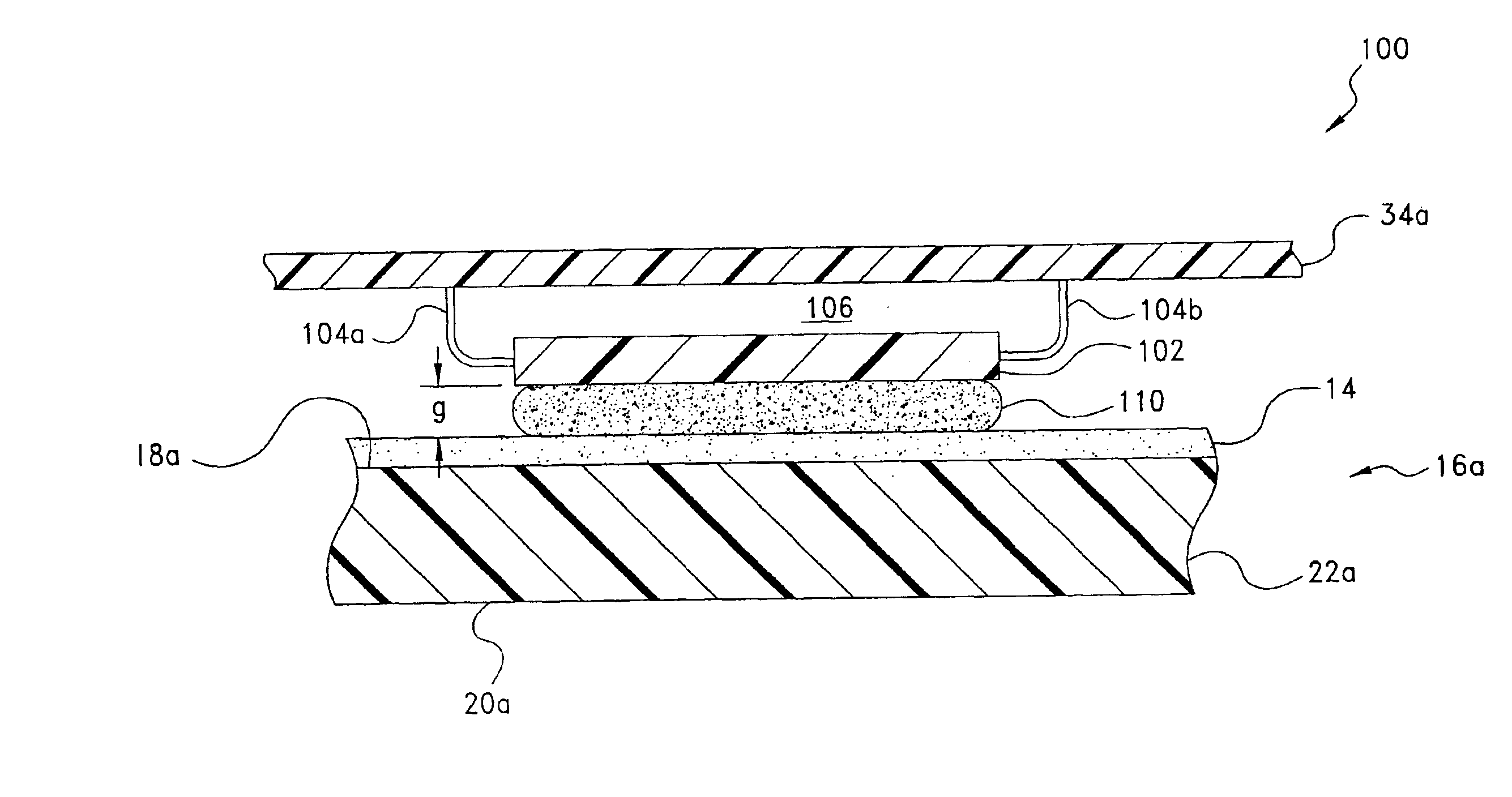

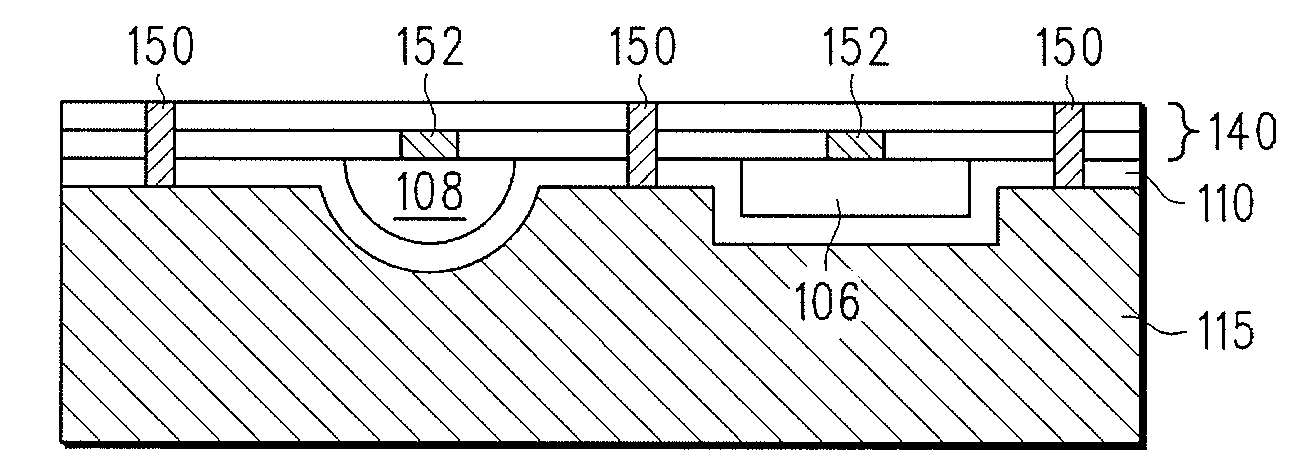

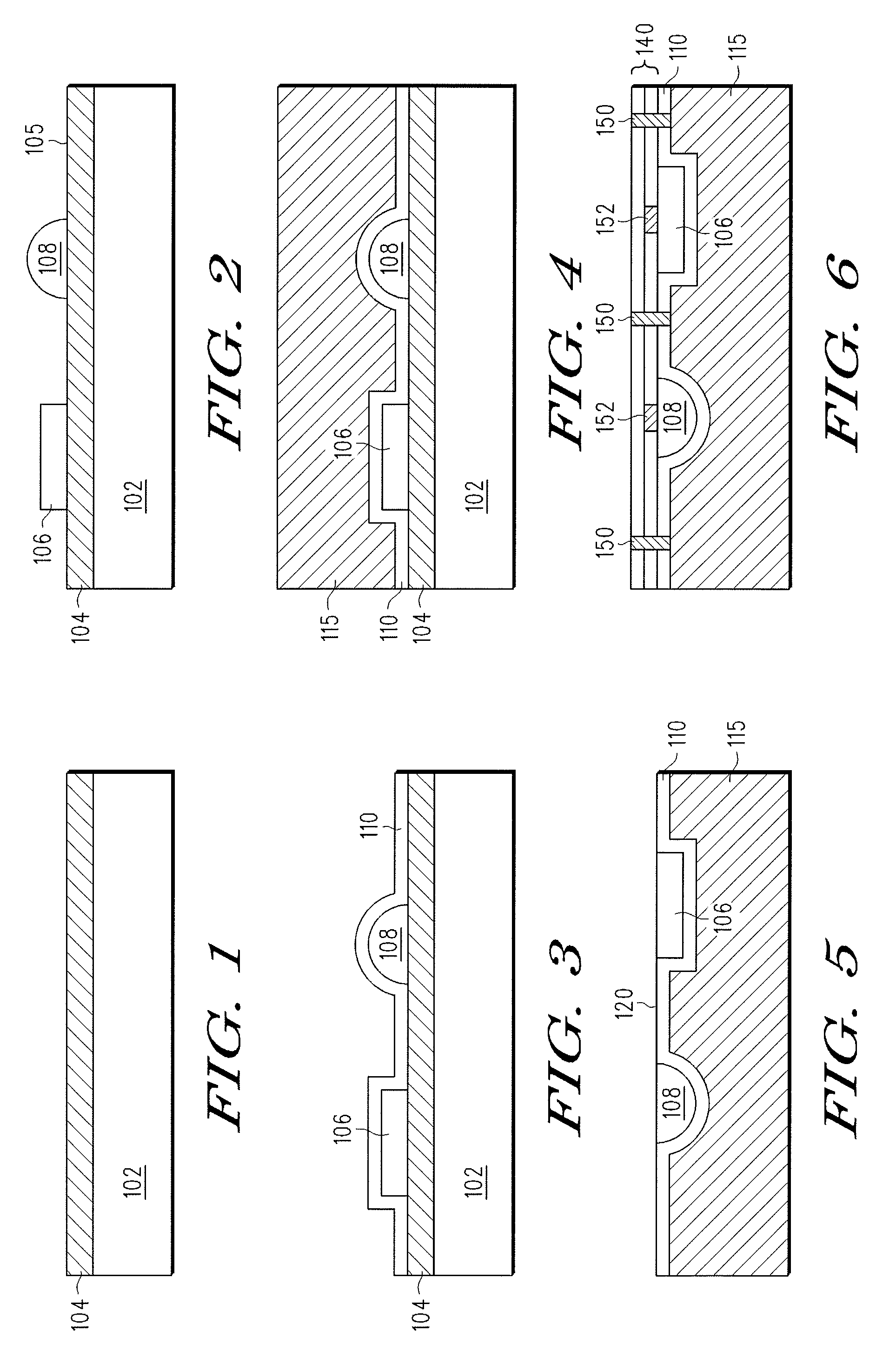

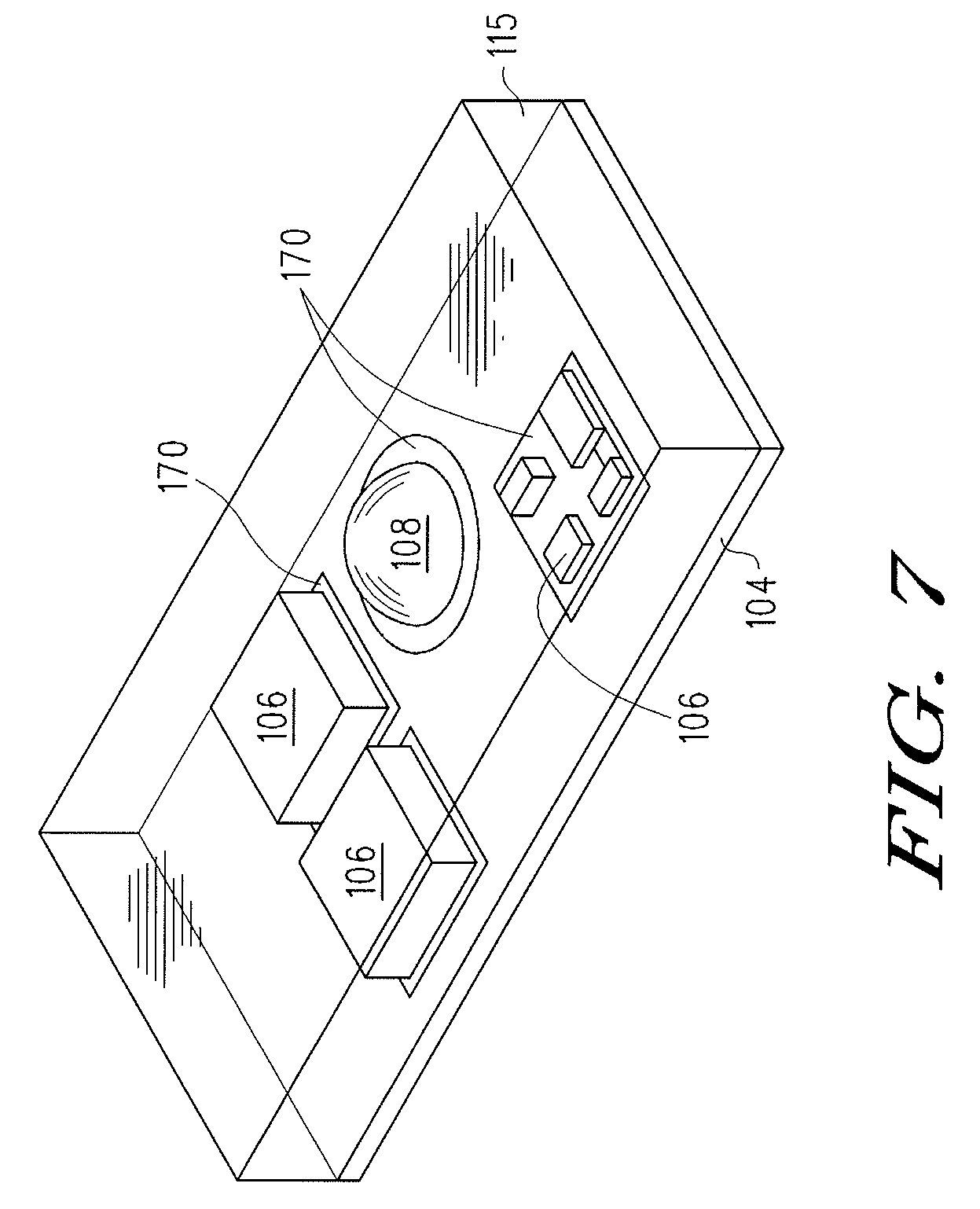

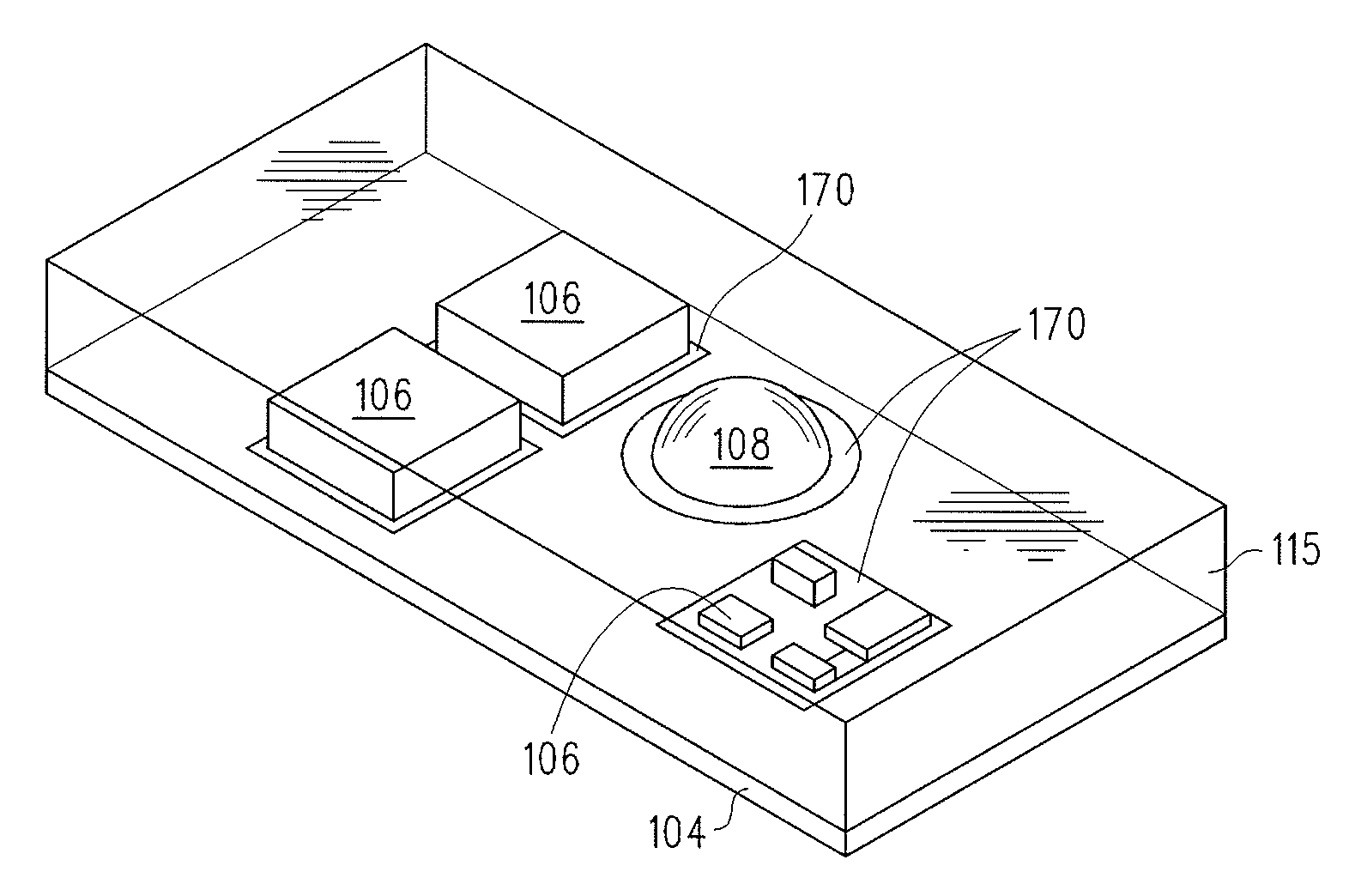

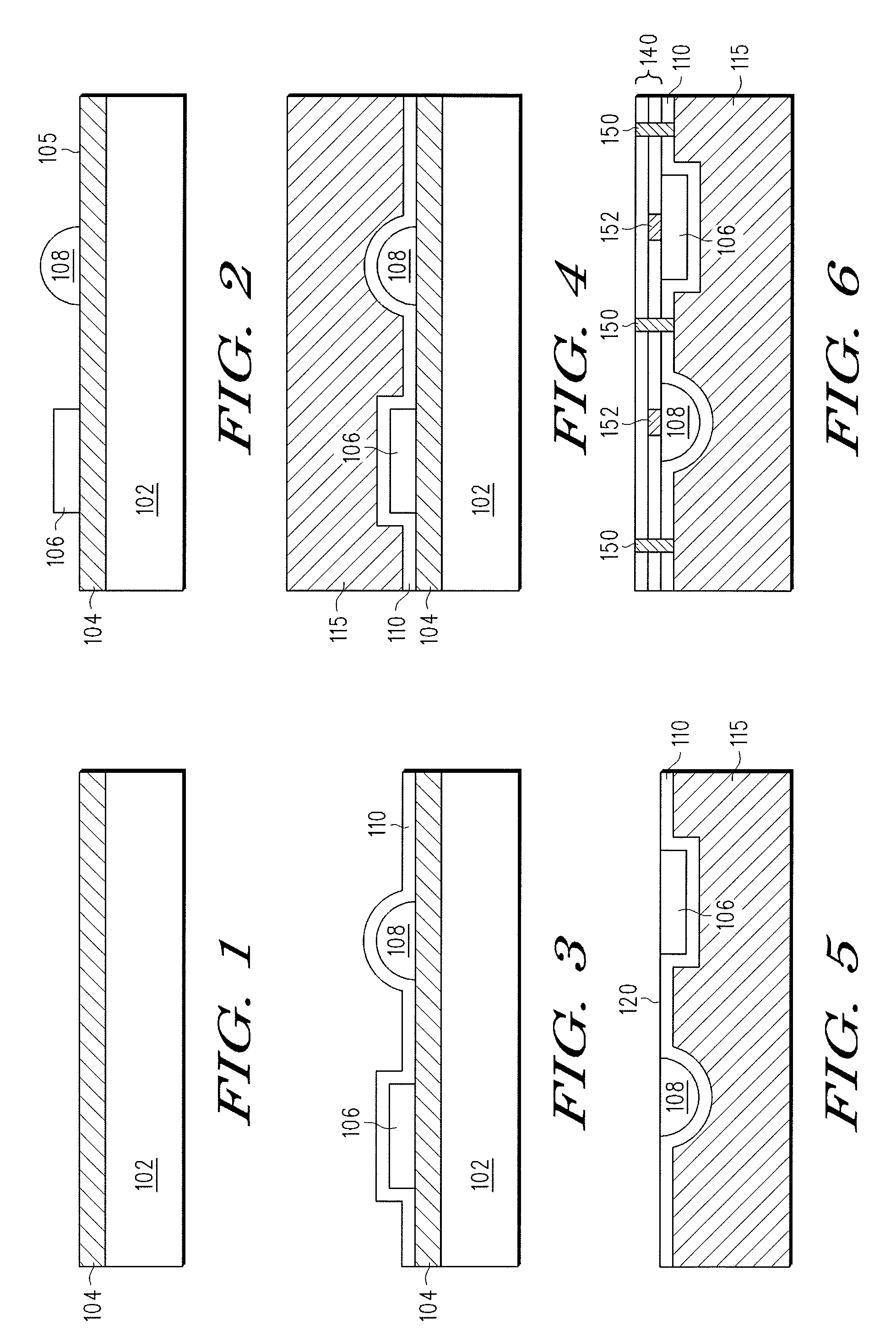

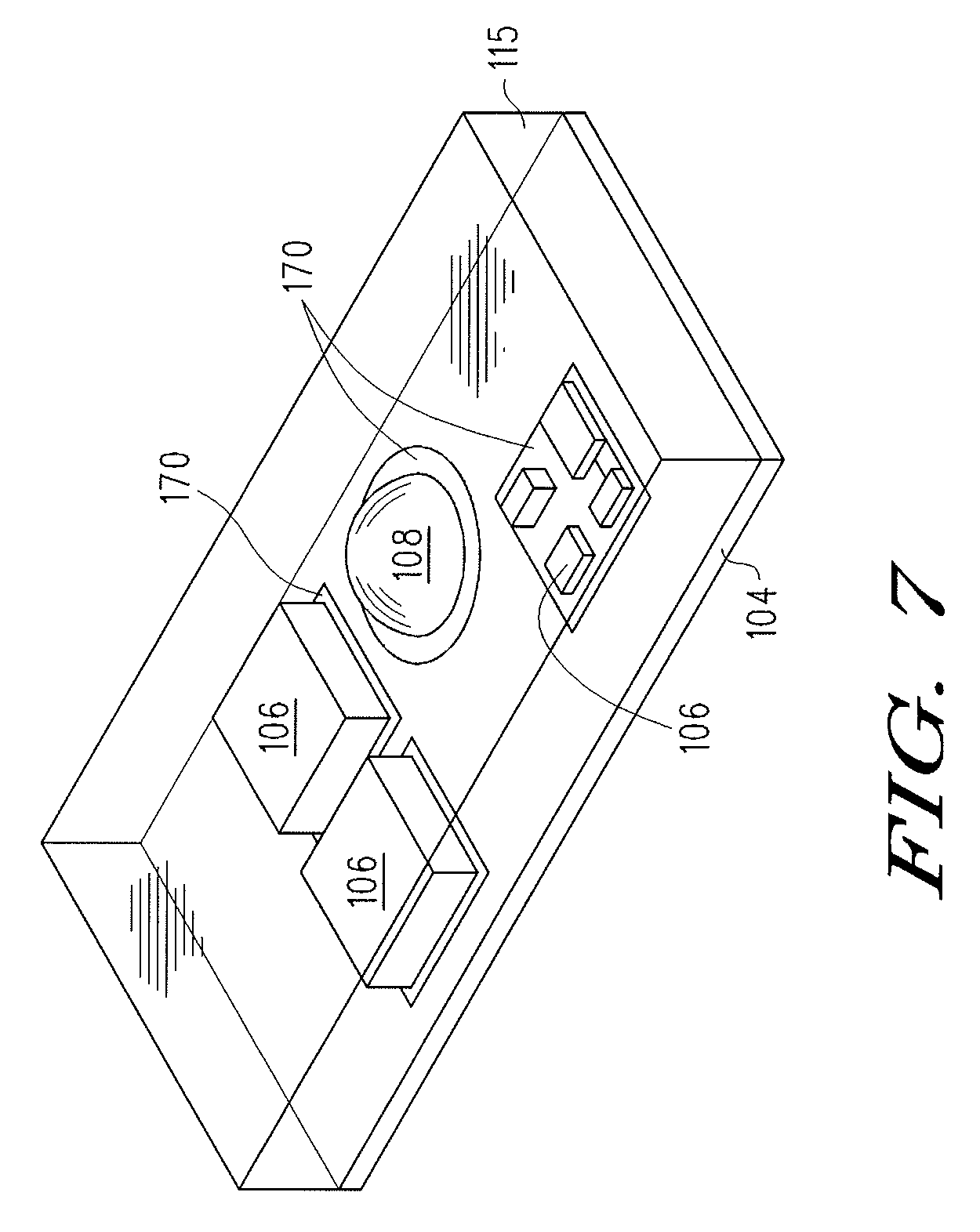

Methods and apparatus for EMI shielding in multi-chip modules

InactiveUS20080315371A1Cross-talk/noise/interference reductionSemiconductor/solid-state device detailsElectronic componentChip carrier

Methods and structures provide a shielded multi-layer package for use with multi-chip modules and the like. A substrate (102) (e.g., chip carrier) has an adhesive layer (104), where electronic components (106, 108) are attached. An insulating layer (110) is formed over the plurality of electronic components, and a conductive encapsulant structure (115) is formed over the insulating layer. The adhesive layer is detached from the electronic components, and multi-layer circuitry (140) is formed over, and in electrical communication with, the plurality of electronic components. A shielding via (150) is formed through the multilayer circuitry such that it contacts the conductive encapsulant.

Owner:TAIWAN SEMICON MFG CO LTD

Case structure having conductive pattern and method of manufacturing the same

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

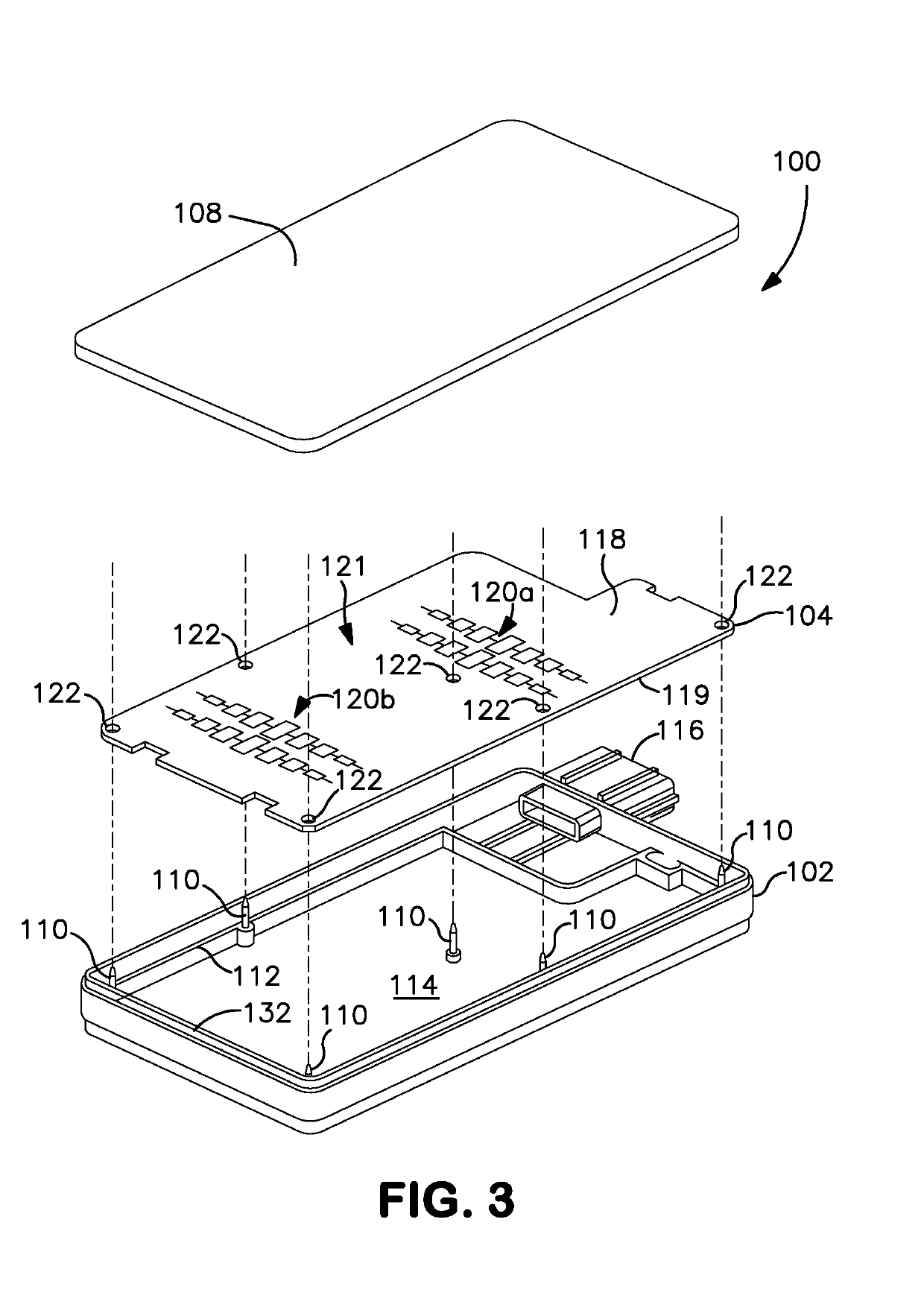

Electronic Package

ActiveUS20100128456A1Electrically conductive connectionsScreening rigid plastic containersElectronic systemsElectromagnetic interference

The present invention relates to a device package, such as an electronic system package, that is suitable for use in harsh military or commercial environments. The package components, including a base enclosure and mating cover, comprise a series of interconnected electrically conductive materials, forming a tortuous electrically conductive path, that advantageously shield electromagnetic interference (“EMI”). The electrically conductive, EMI-shielding layers and other coated layers (e.g., insulative electrocoated paint layers) are smooth layers that provide corrosion resistance to the interior and exterior surfaces of the package. The package is also designed such that its components form a water tight seal. Thus, innovatively, the package comprises a combination of components that synergistically shield electromagnetic interference, resist interior and exterior corrosion, and form a water tight seal. The package is configured to pass military specification EMI and salt fog standard testing.

Owner:TELEDYNE FLIR LLC

EMI shielded thermoset article

InactiveUS20120107538A1Conductive materialCeramic shaping apparatusConductive materialsElectromagnetic radiation

A conductive thermoset material is provided that provides shielding against electromagnetic radiation. The conductive thermoset material includes an intermixed conductive material dispersed essentially throughout. An antisettling additive is present in the conductive thermoset material to support dispersion, optionally, homogenous dispersion of the conductive material in the resin. The conductive thermoset material is formable into one or more articles. The articles may be transportable and resistant to significant conductivity changes by contact with other surfaces.

Owner:PLASTICS RES

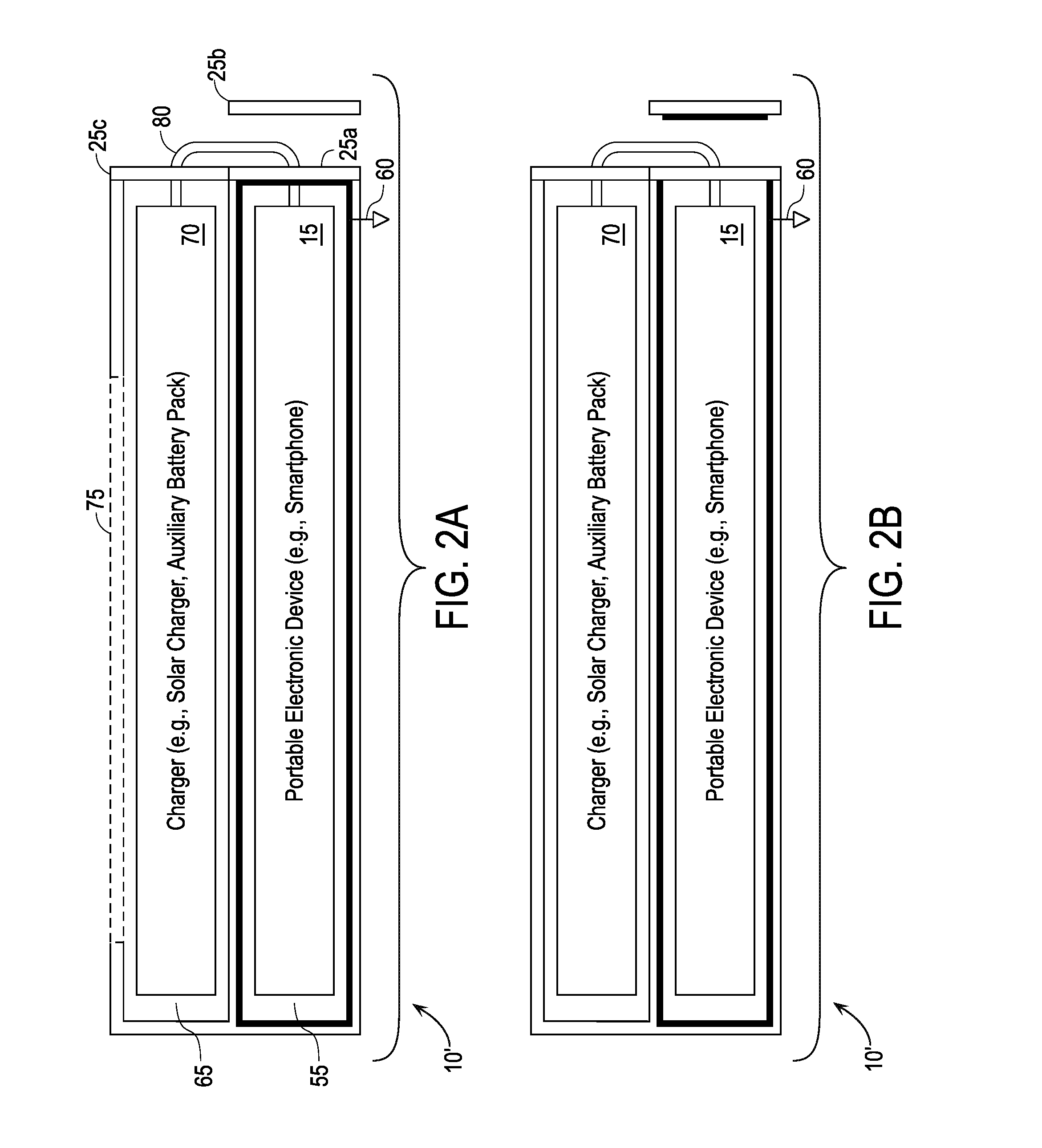

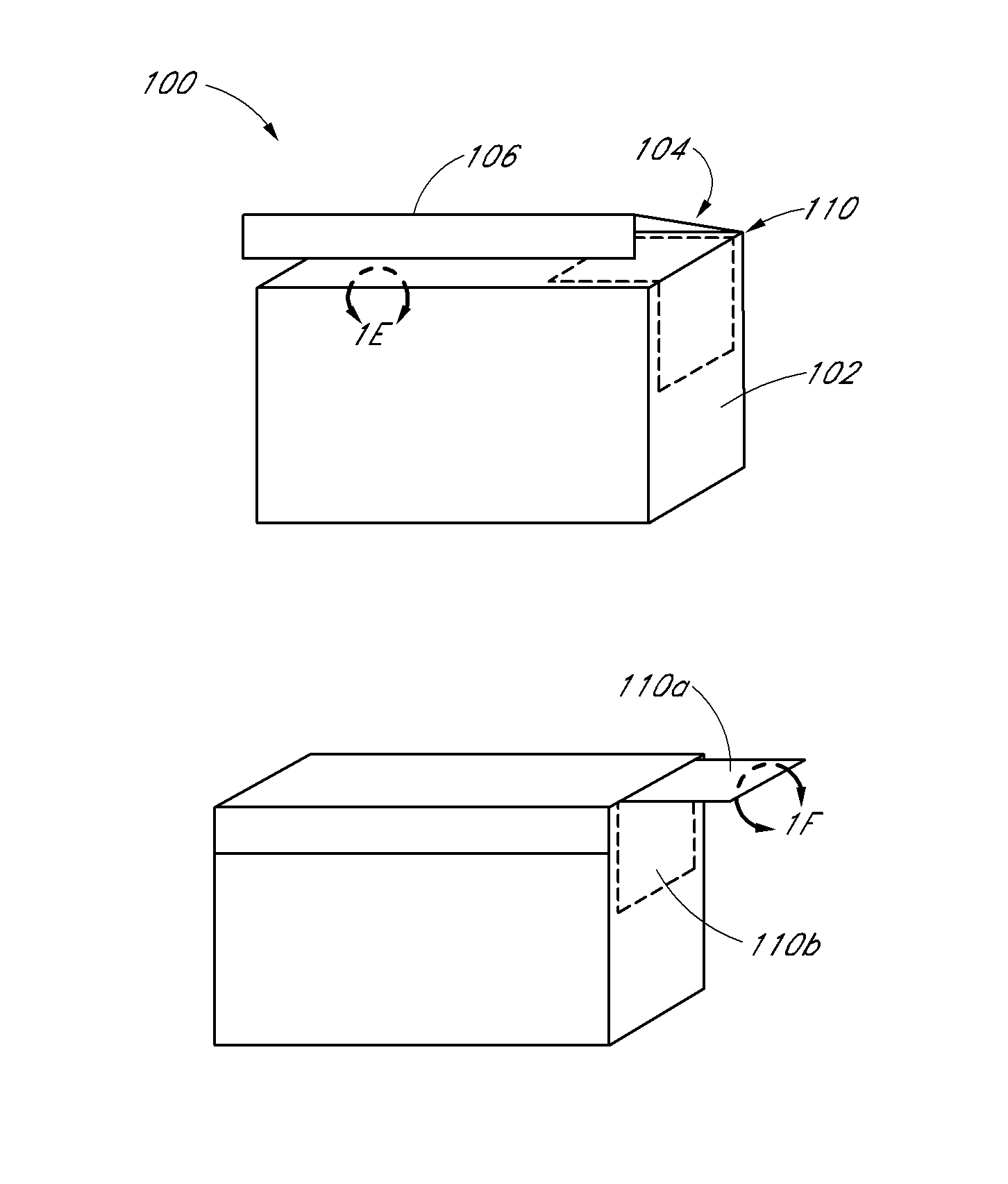

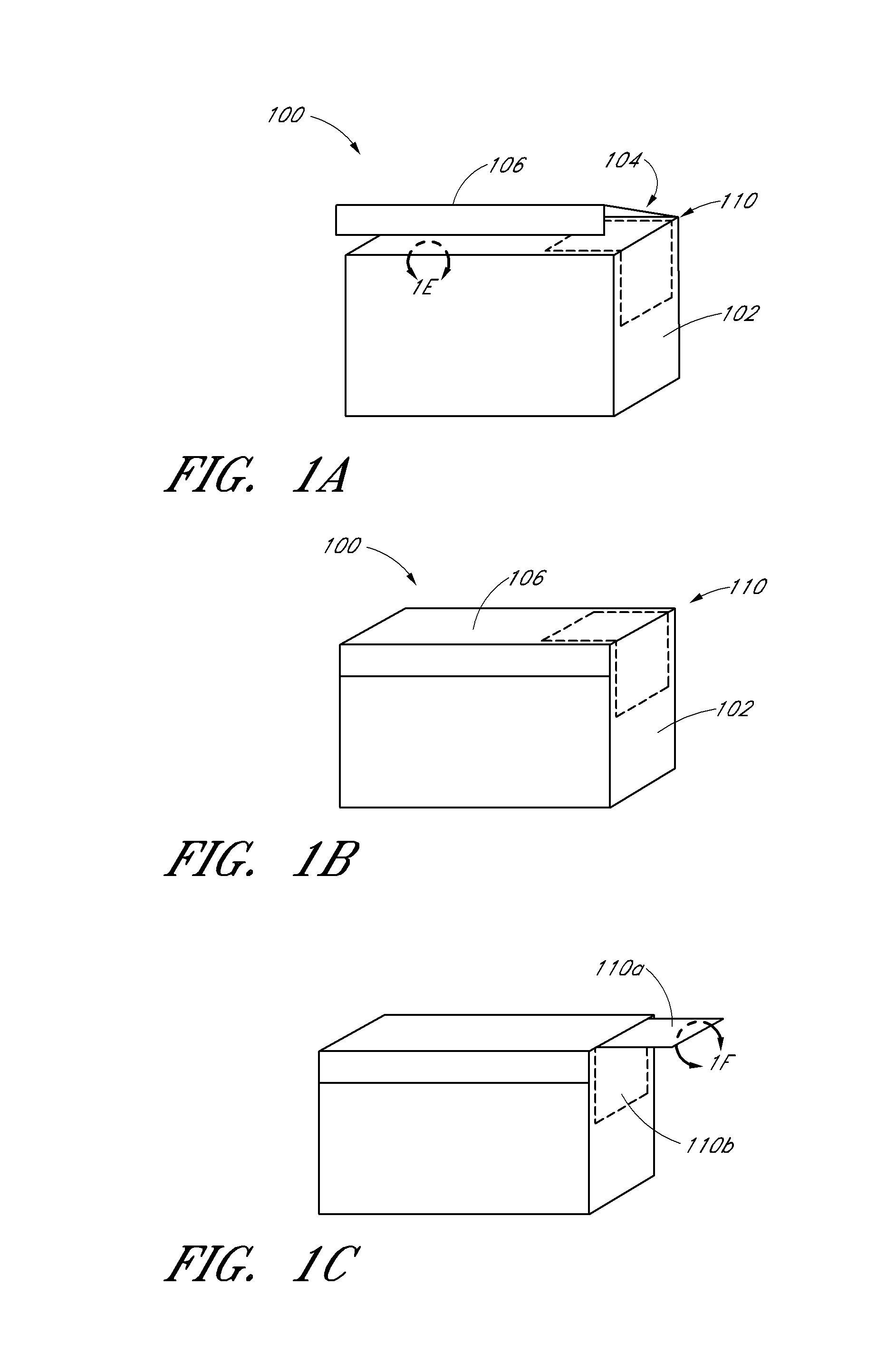

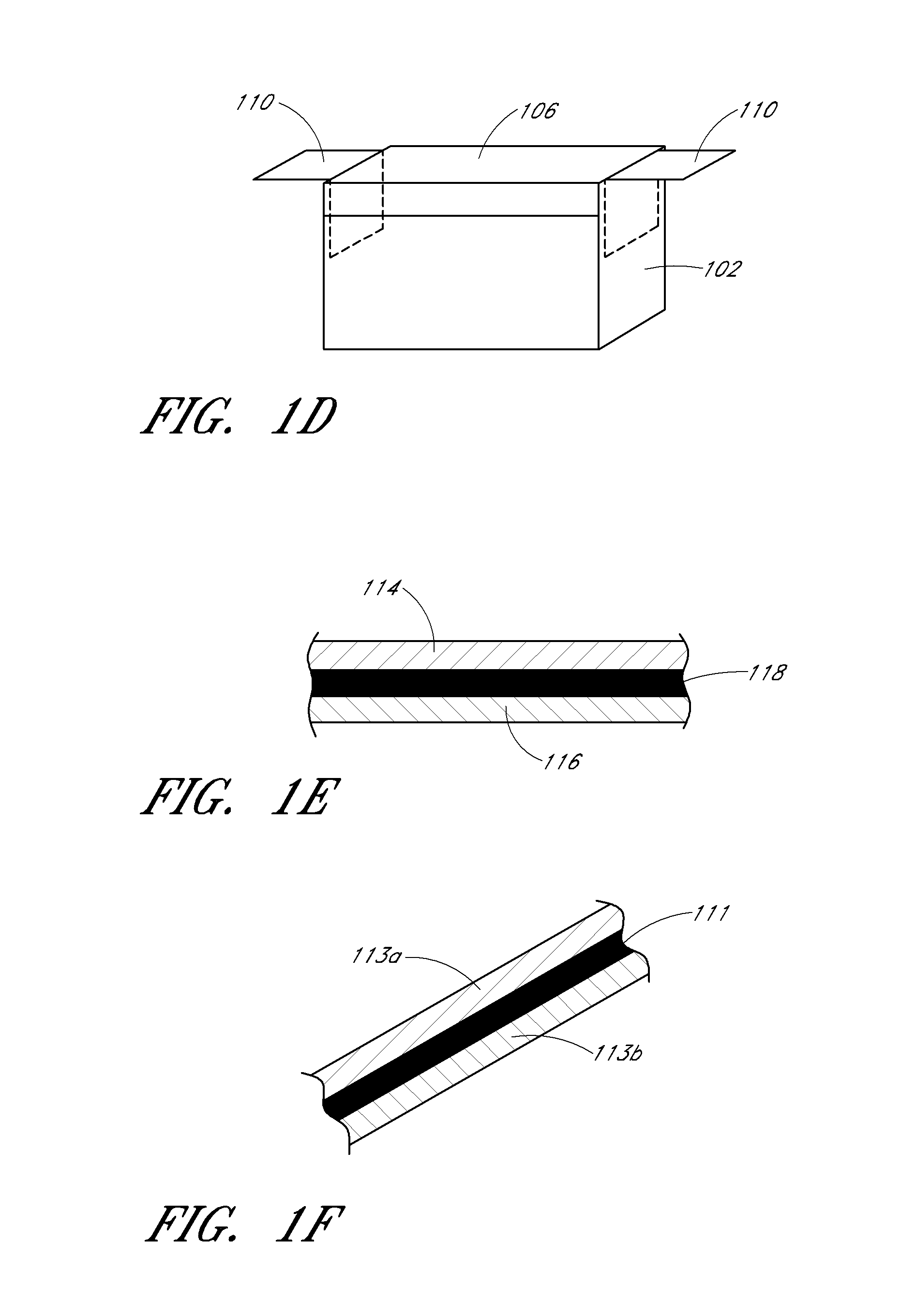

Configurable shielded enclosure with signal transfer element

InactiveUS9002288B1Easy to controlAperture leaage reductionEMI leakage reductionInterior spaceElectronic equipment

An enclosure that has an interior space sized to receive a portable electronic device. The enclosure has a shielding layer that can shield and prevent communications between the interior space and the outside world in a first configuration. In a second configuration, communication is allowed. A signal transfer element is attached to the enclosure housing that can be moved between an isolation configuration and a communication configuration.

Owner:REIBLE JAMES PATRICK

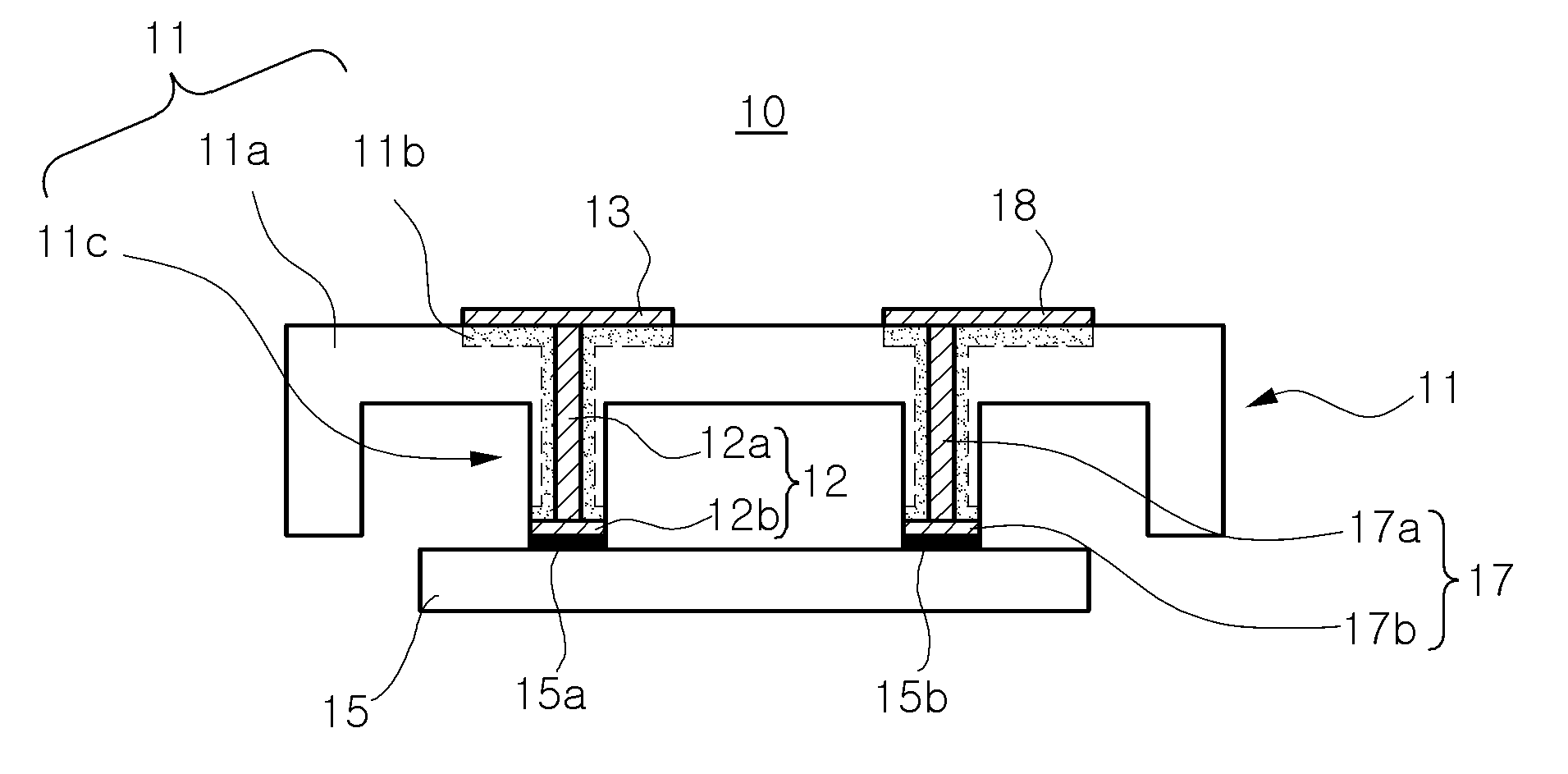

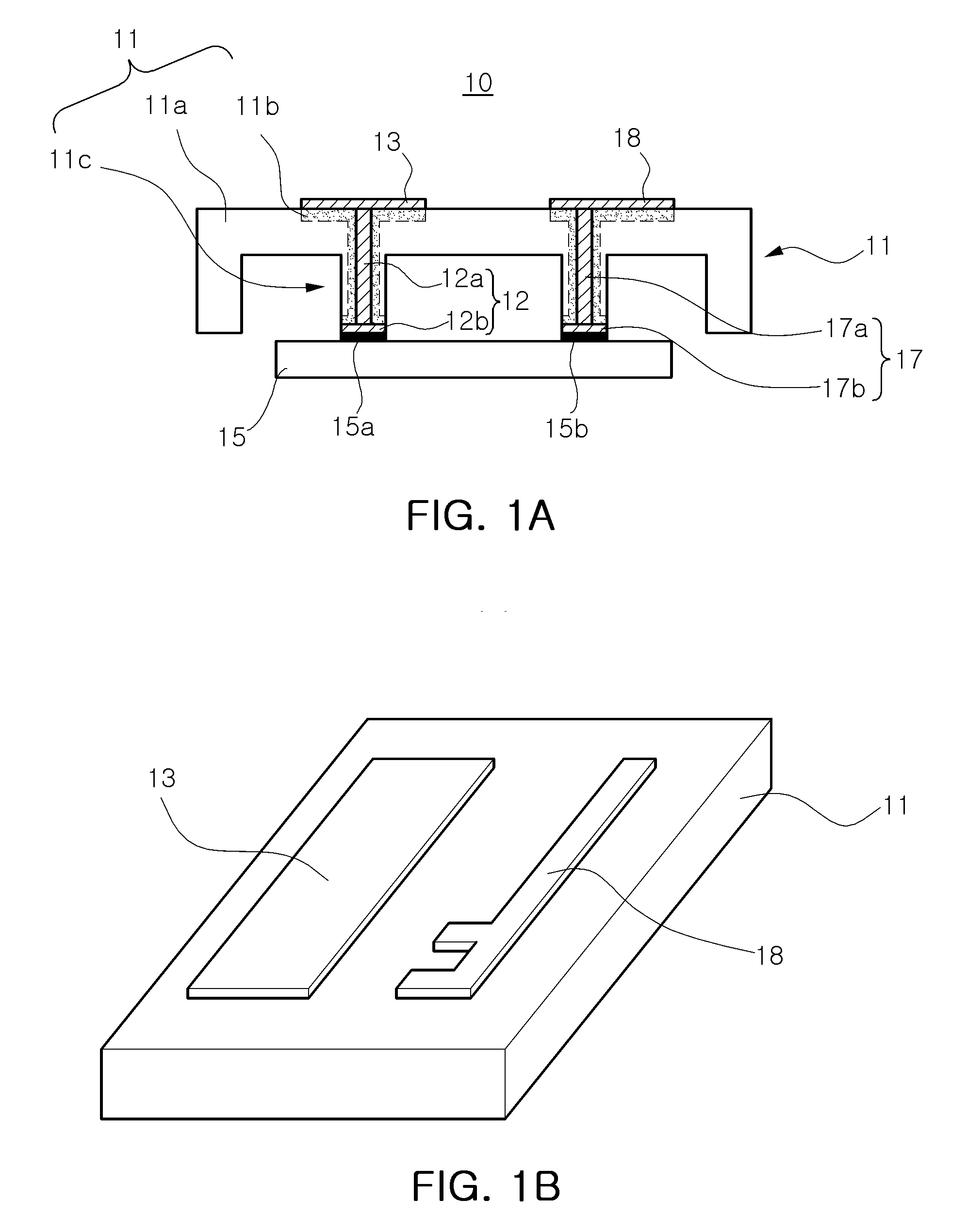

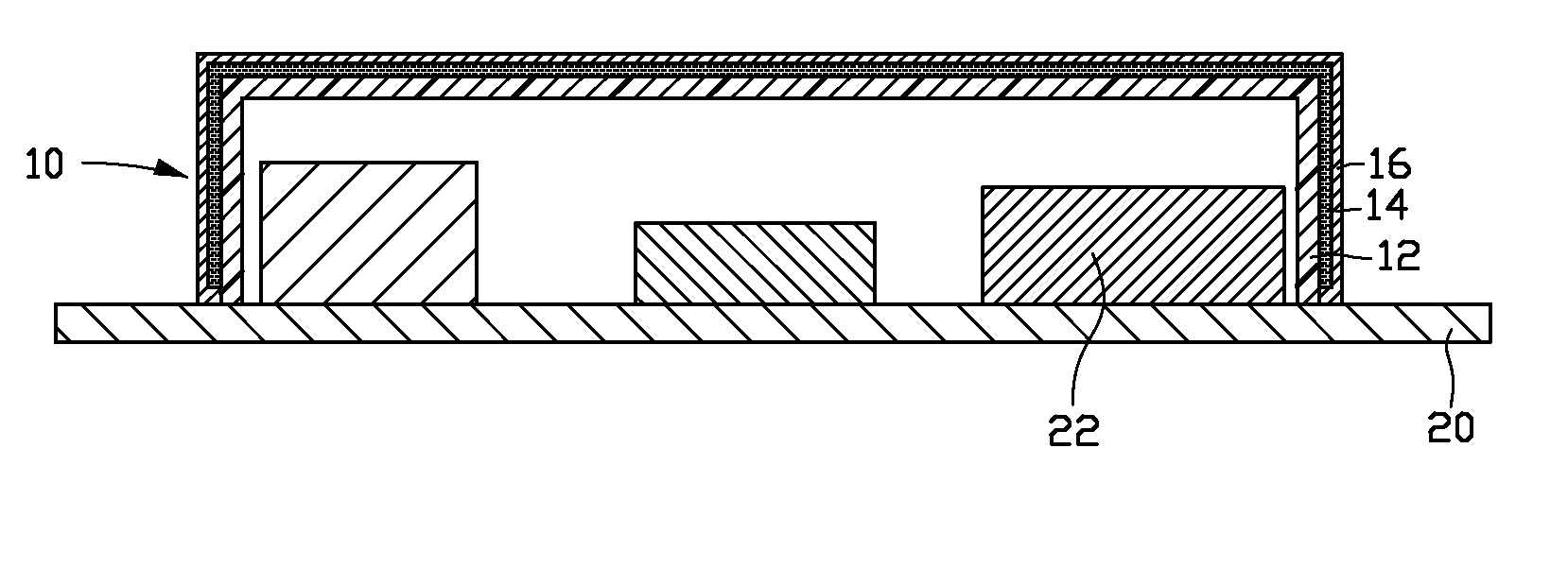

Shielding assembly

InactiveUS7999196B2Modifications by conduction heat transferScreening rigid plastic containersMetal foilEngineering

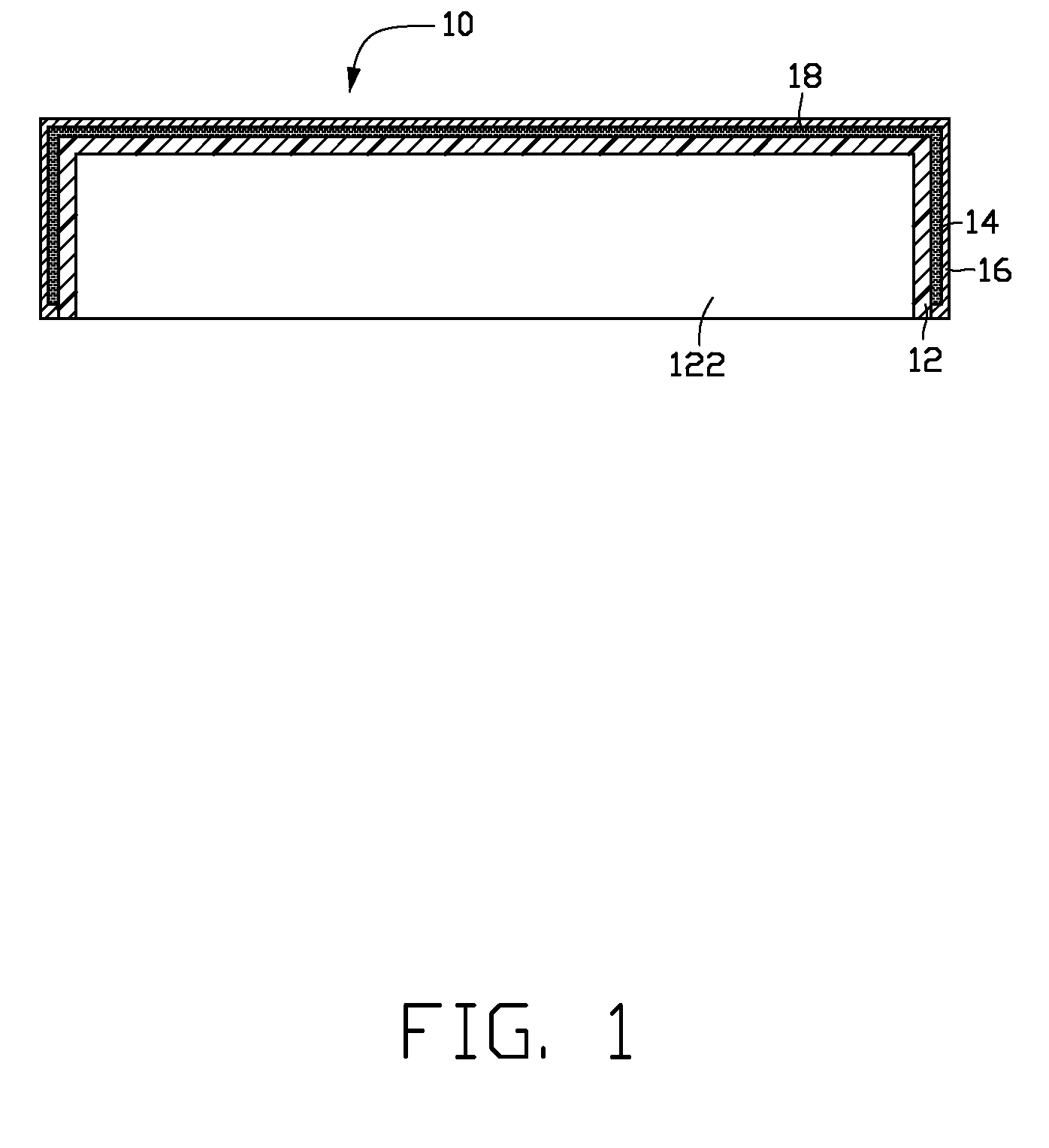

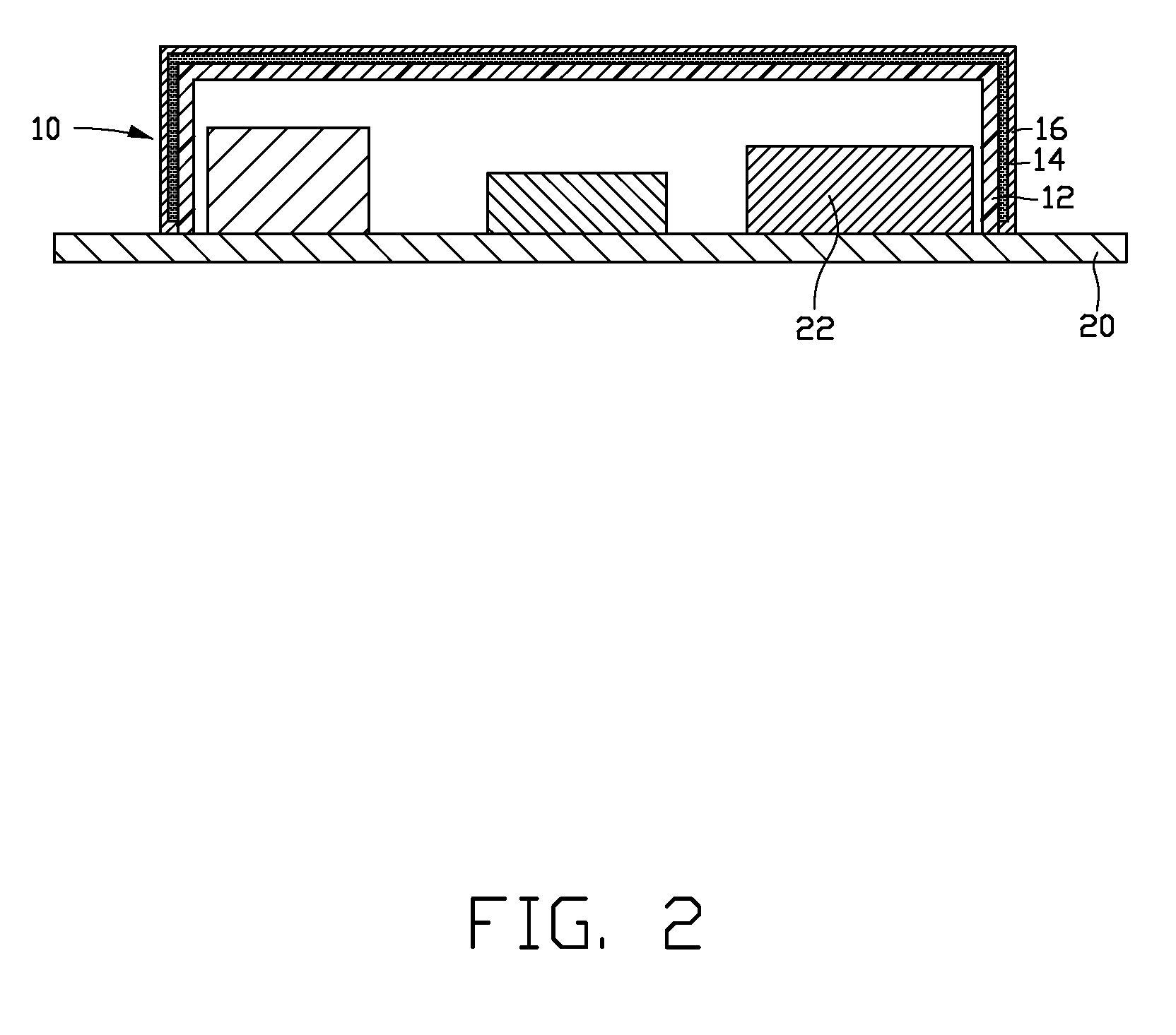

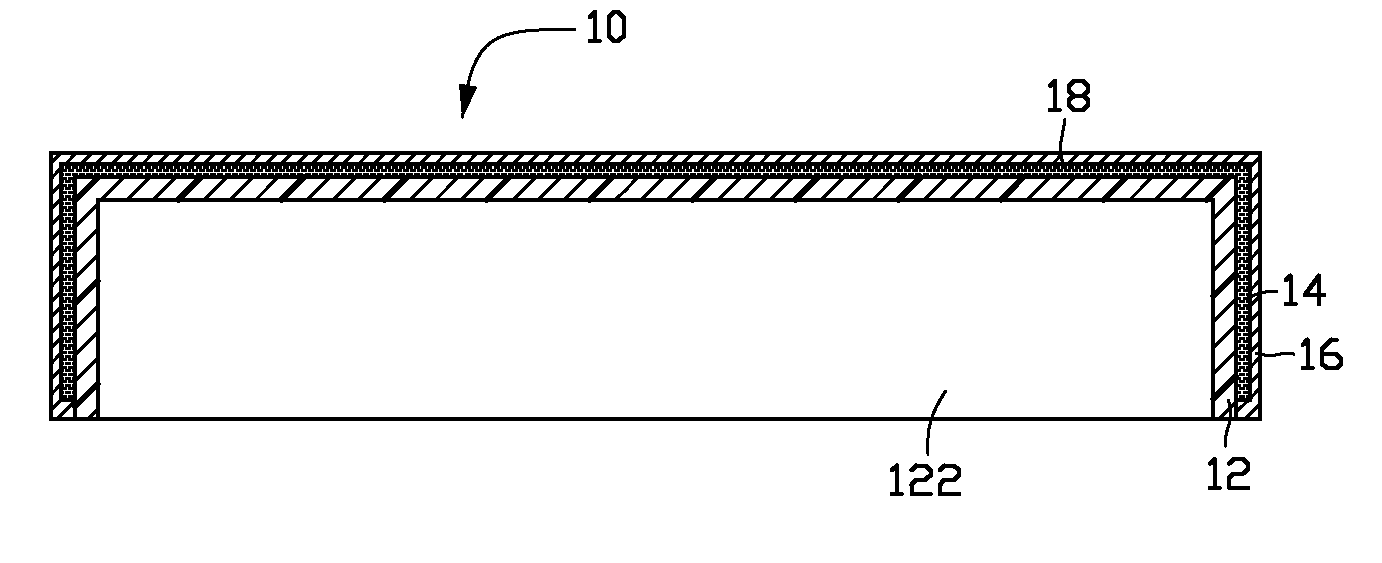

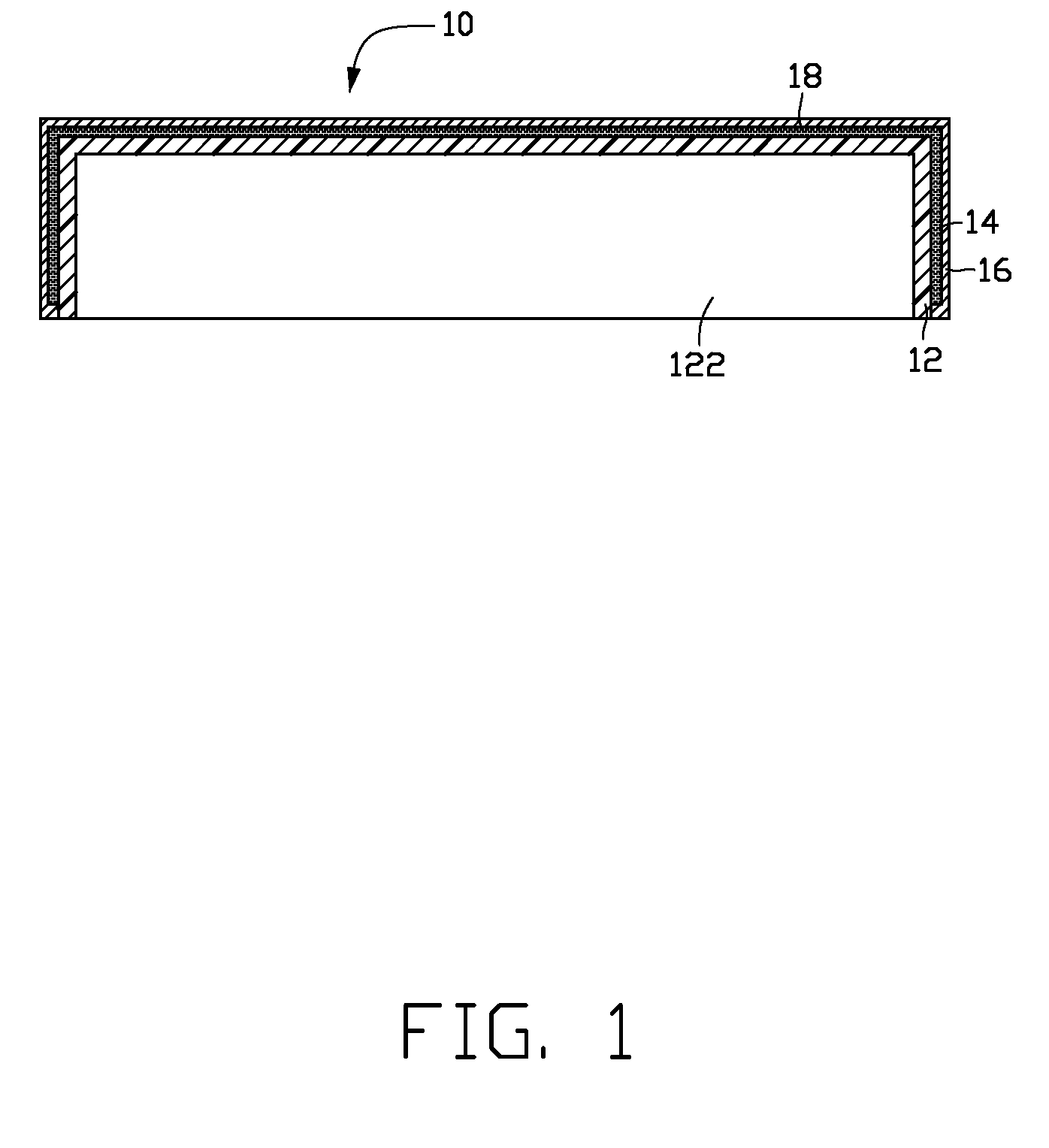

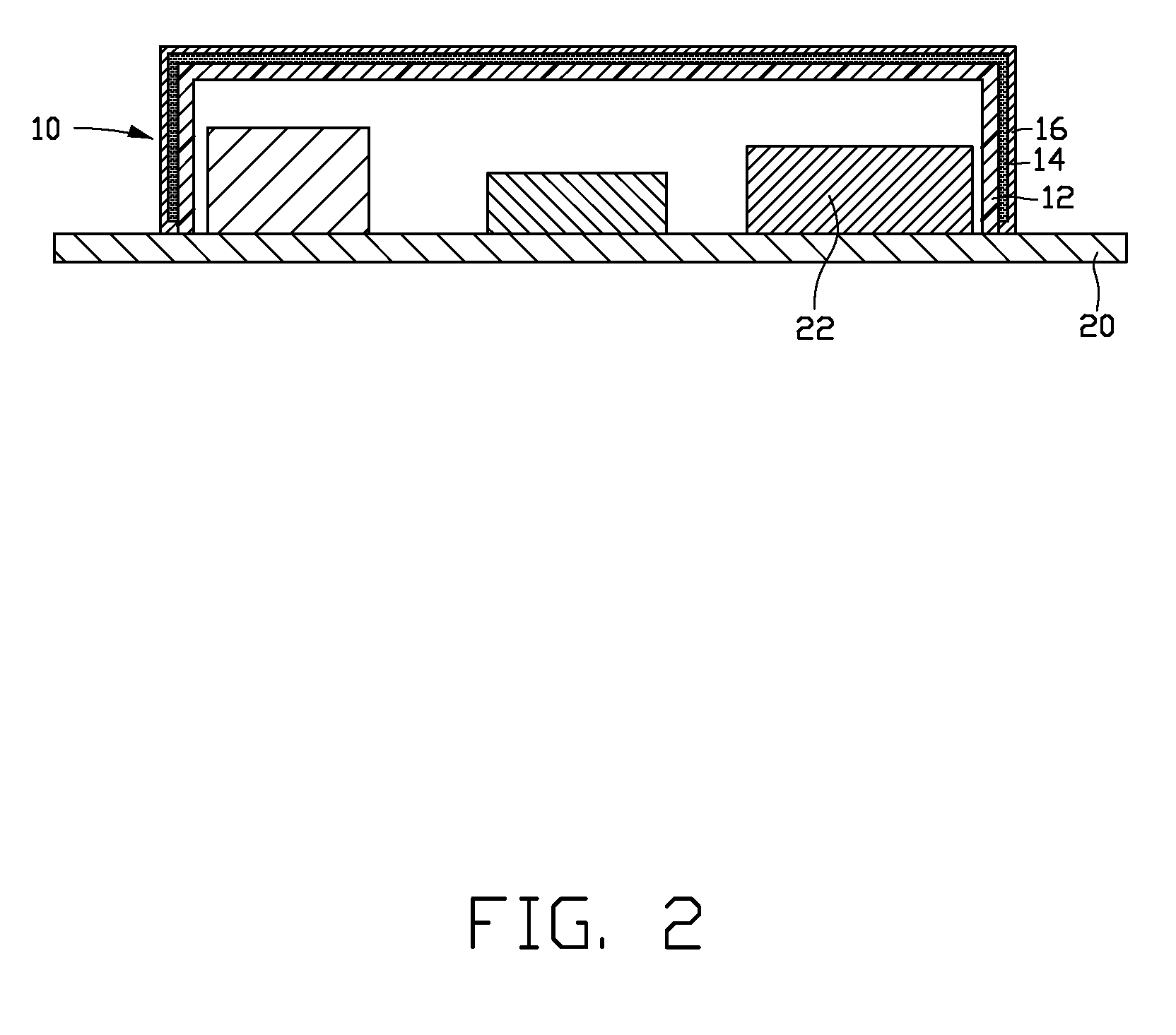

A shielding assembly (10) for electronic device is provided. The shielding assembly (10) comprises a plastic layer (12), a metal foil (16) mounted to the plastic layer (12), and a coolant (14) is formed between the plastic layer (12) and the metal foil (16). An electronic device using the shielding assembly is also provided.

Owner:FIH (HONG KONG) LTD

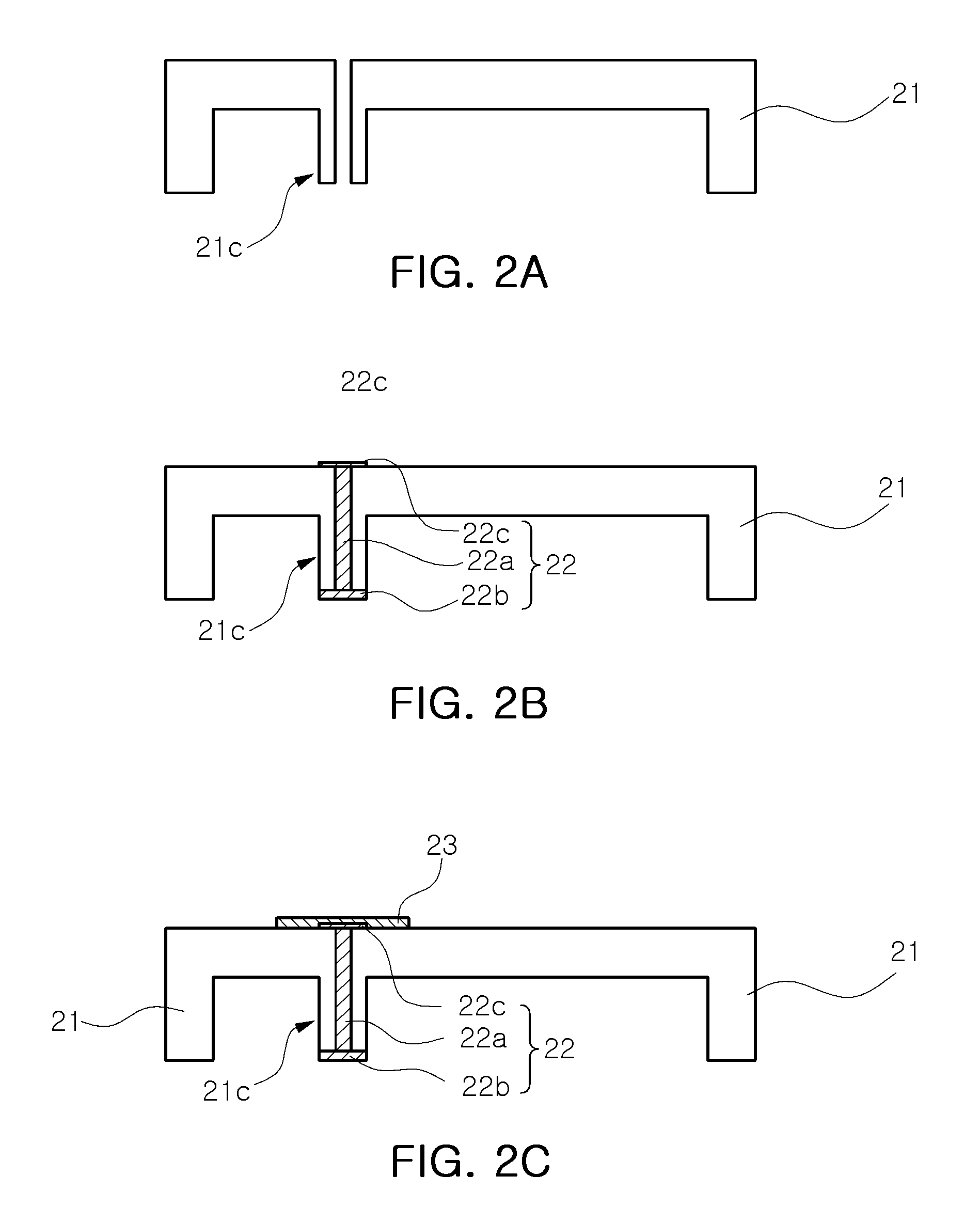

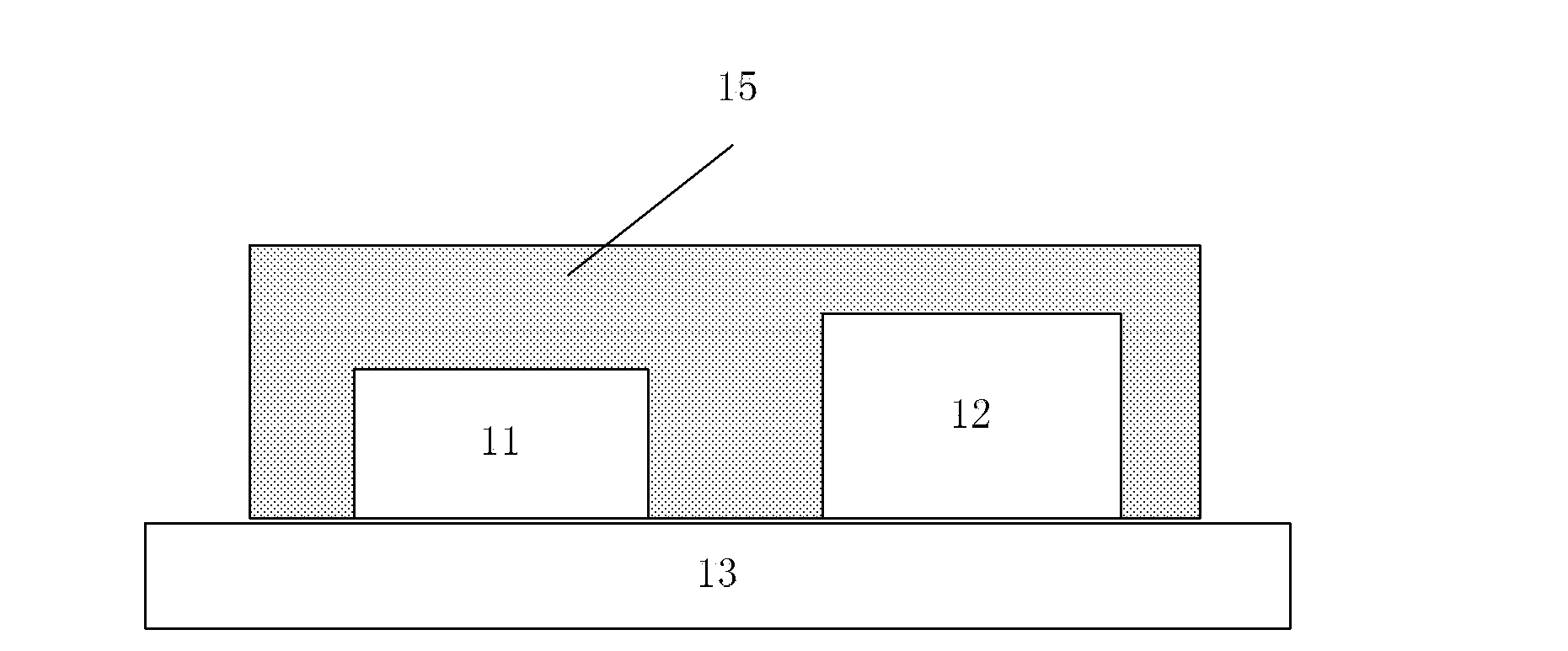

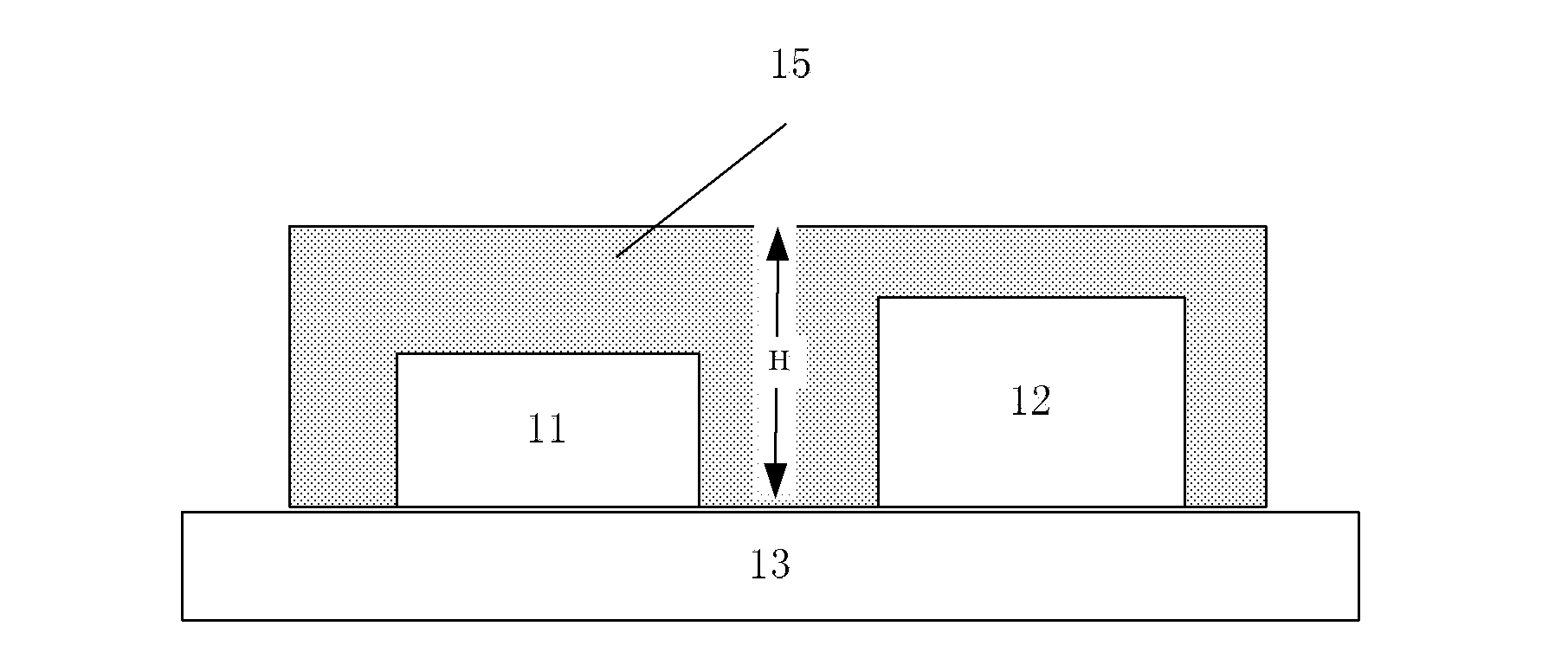

Method for manufacturing PCB (Printed Circuit Board), PCB and electronic equipment

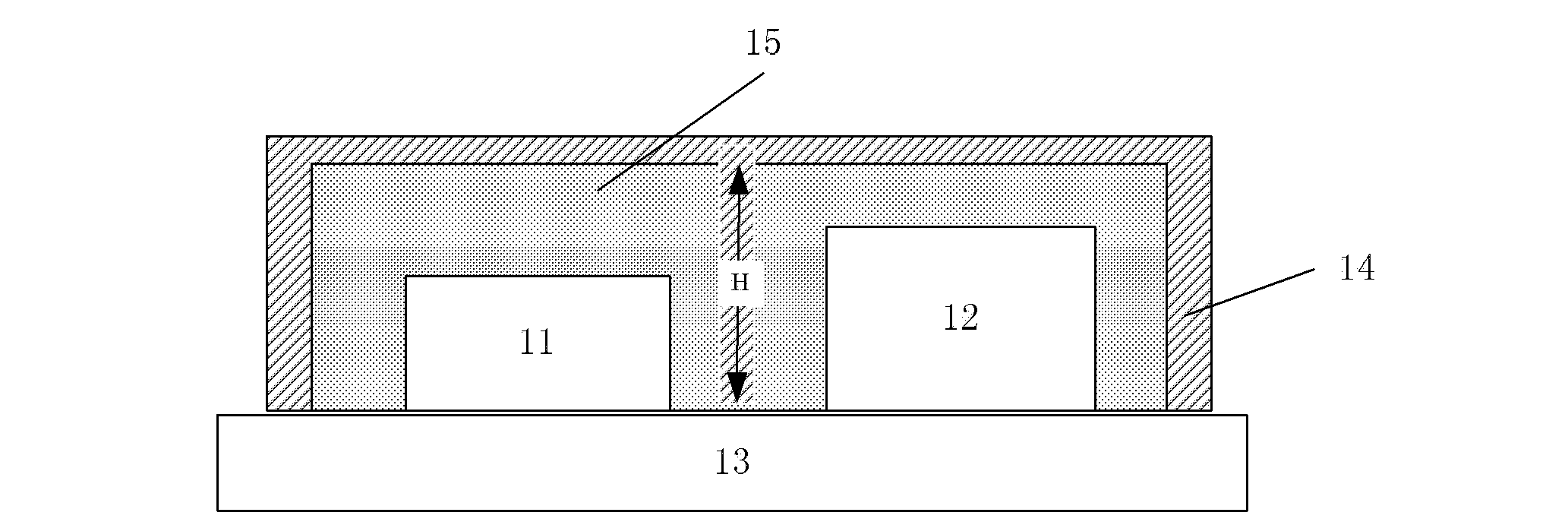

InactiveCN102548239ACutting height reductionPrinted circuit assemblingLocalised screeningComputer moduleEngineering

The embodiment of the invention discloses a method for manufacturing a PCB (Printed Circuit Board), the PCB and electronic equipment. The method comprises the following steps that: at least two functional modules and a shielding frame are respectively fixed on the PCB, wherein the shielding frame is positioned between the at least two functional modules; the at least two functional modules and the shielding frame can be subjected to plastic package by using a plastic package material; the plastic package material on the shielding frame can be cut to the surface of the shielding frame; and electric conduction material can be covered at the outer surface of the plastic package material and on the shielding frame, and insulation material can be covered at the surface of the electric conduction material. According to the invention, a branch cavity part is shielded by using the shielding frame, other parts comprising edge parts and surface parts of a complete machine are shielded by adopting the electric conduction material, the influence on the size of the whole machine is less, the cutting height is changed into the height formed by directly cutting to the surface of the shielding frame from the original height formed by directly cutting to the surface of the PCB, the height is greatly lowered, the processing time is low, and the good manufacturability is provided.

Owner:HUAWEI DEVICE CO LTD

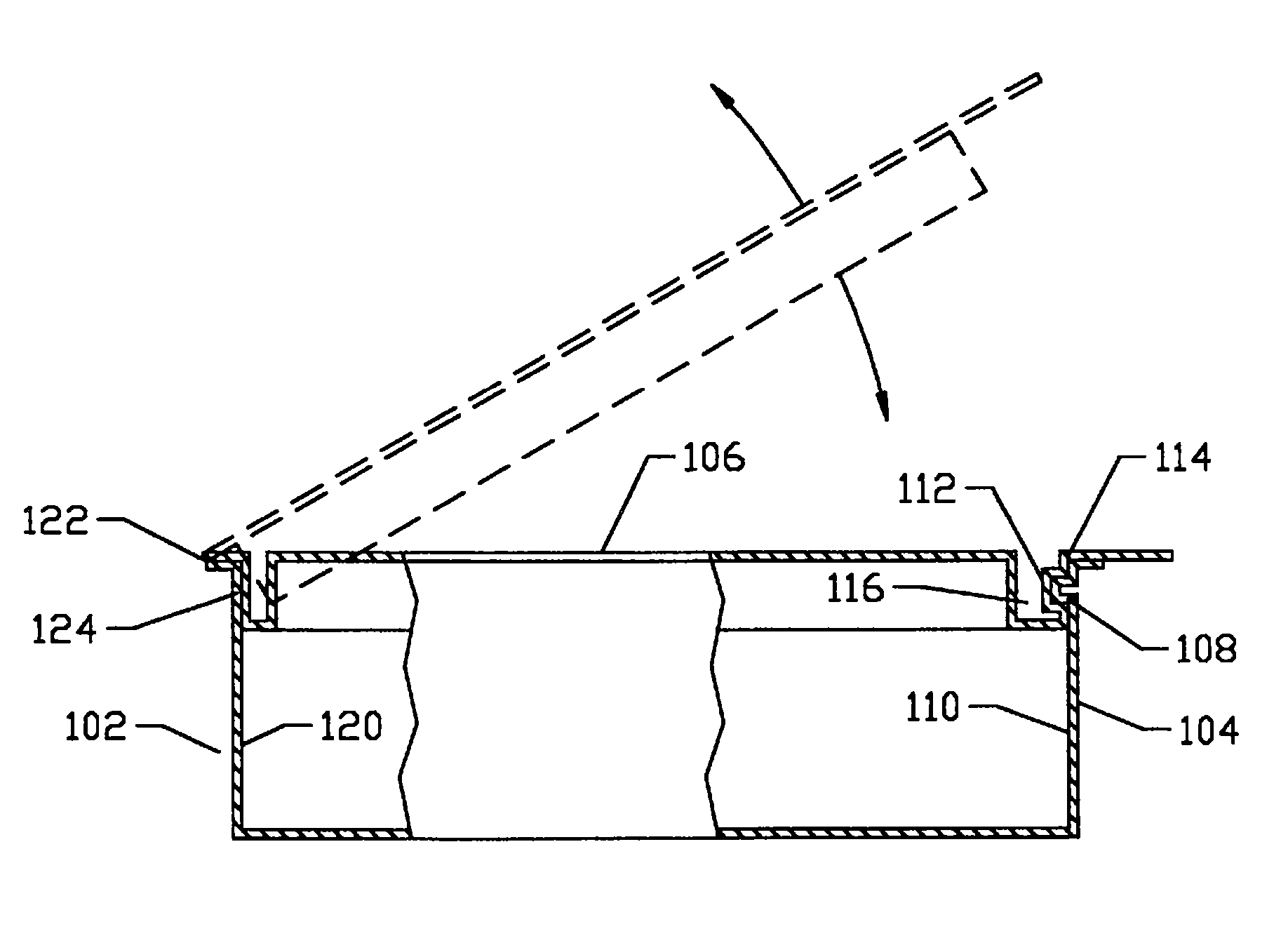

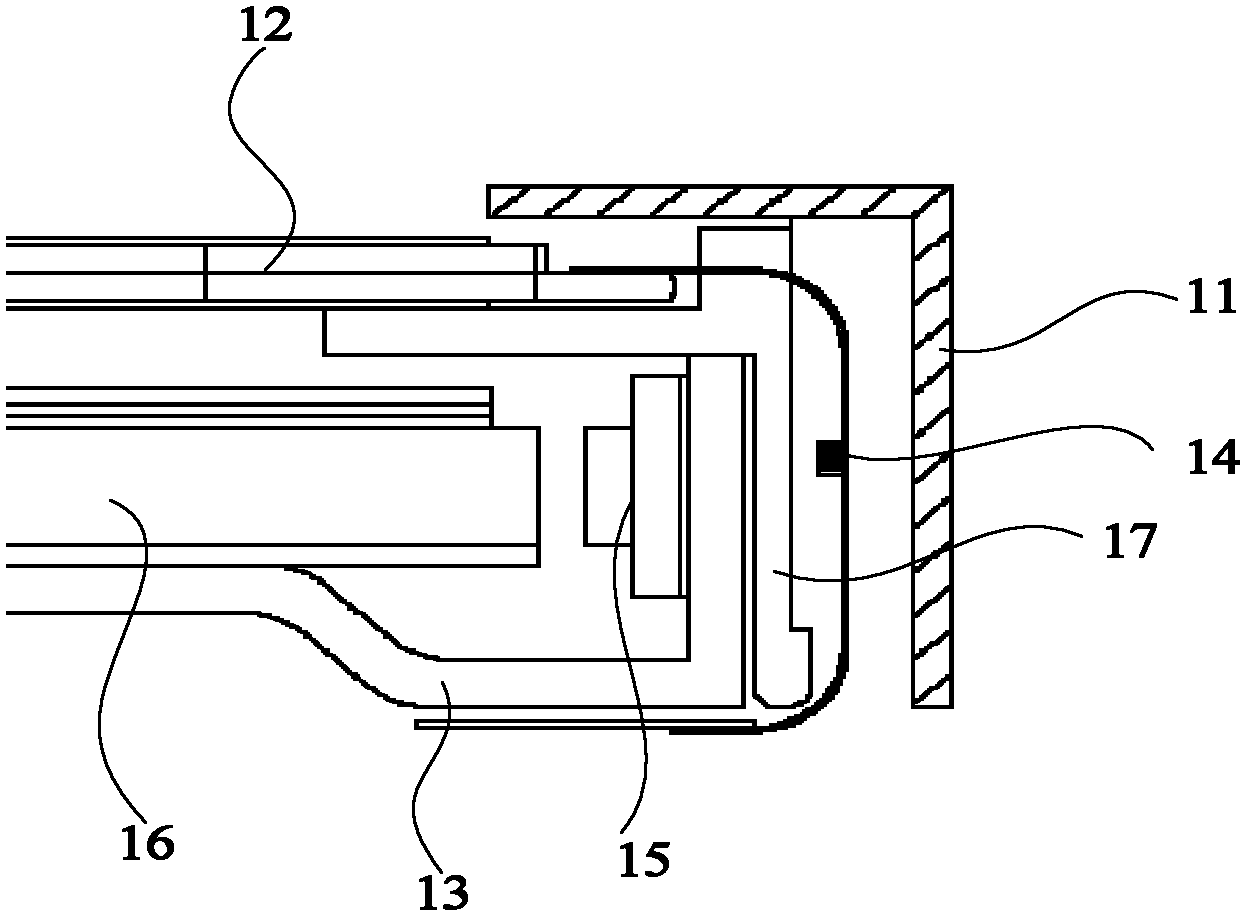

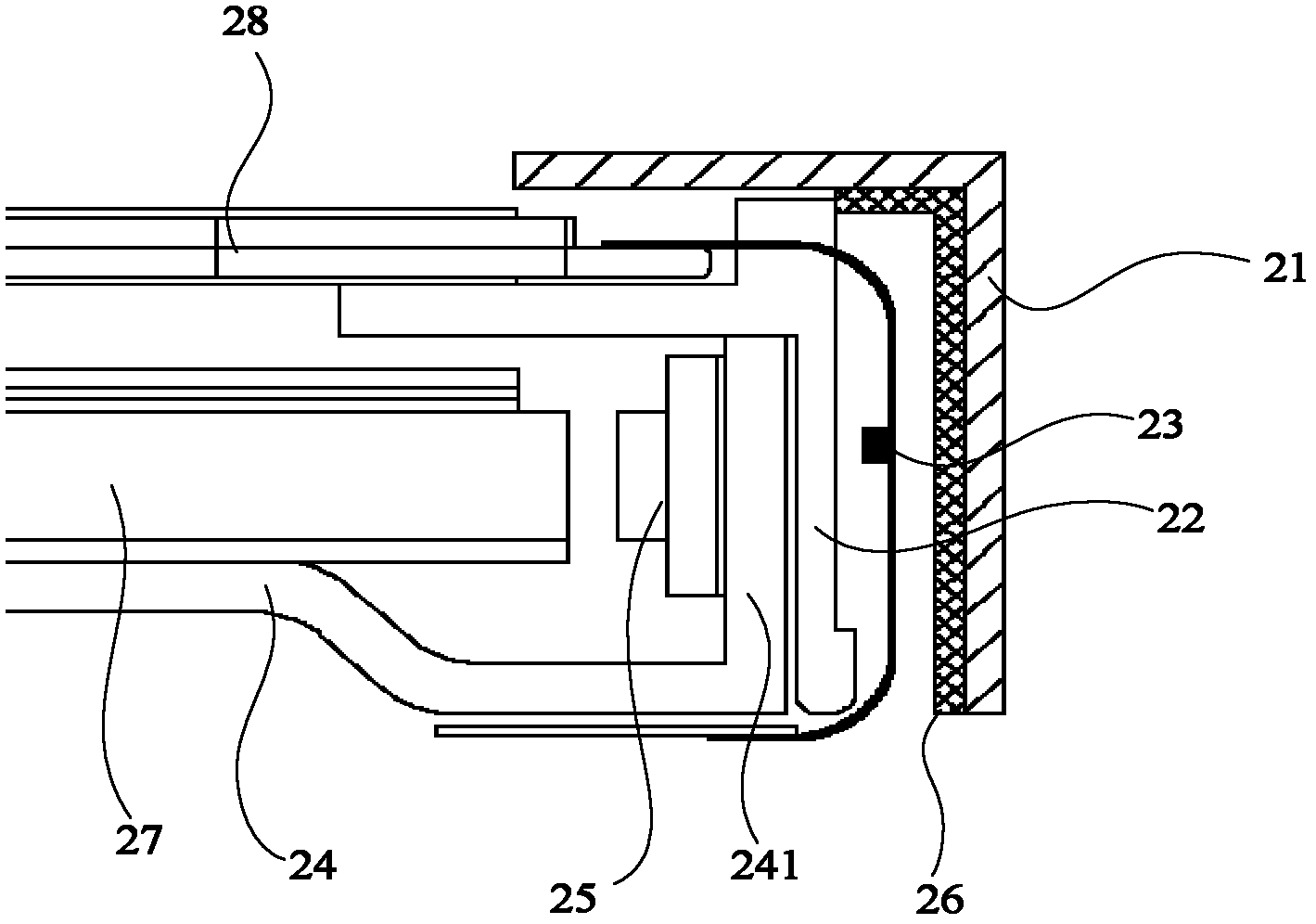

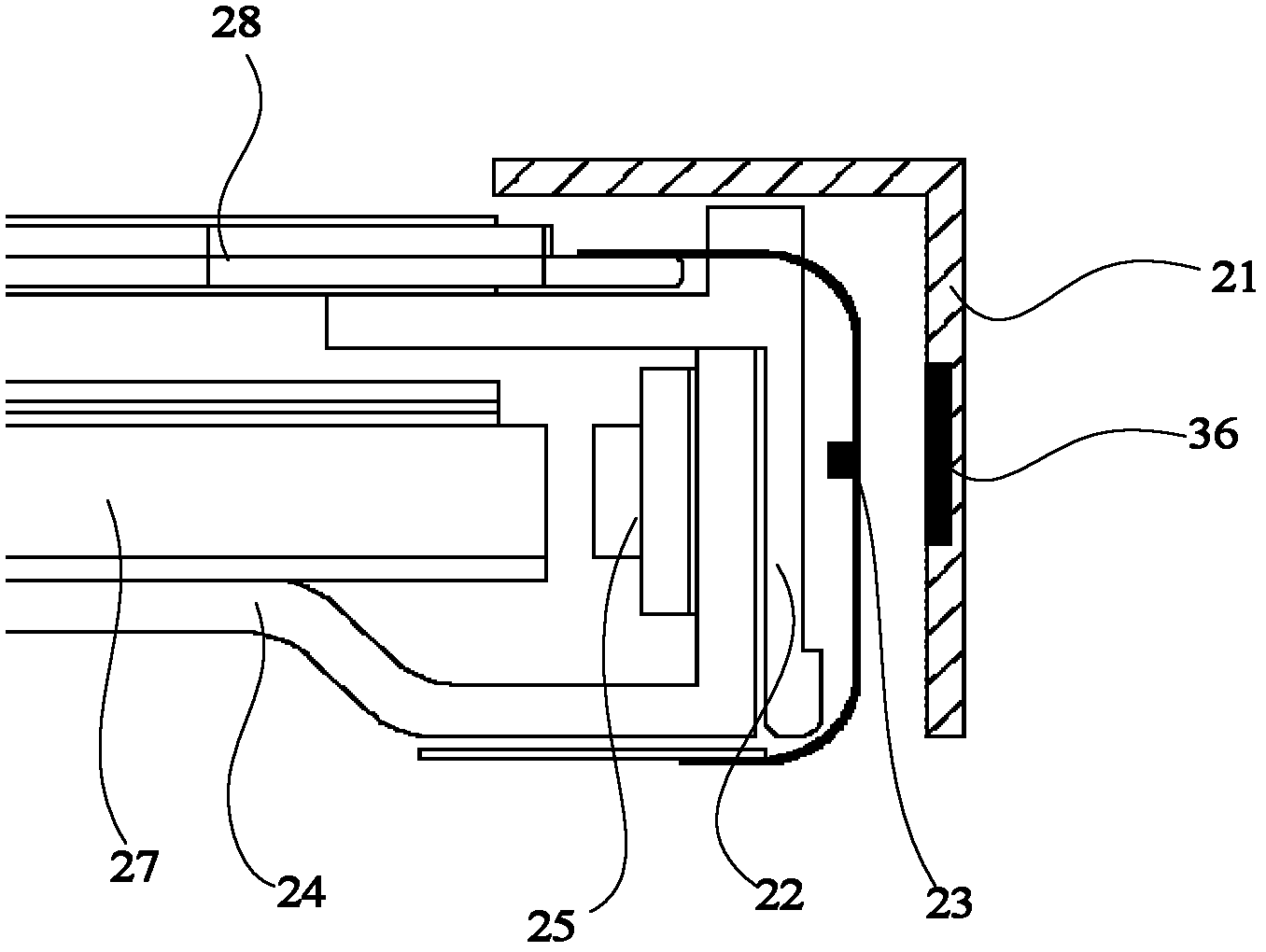

Backlight module and liquid crystal display

ActiveCN102620195AAvoid interferenceGuaranteed stabilityOptical light guidesNon-linear opticsLiquid-crystal displayElectromagnetic shielding

The invention discloses a backlight module and a liquid crystal display. The backlight module comprises a front plastic frame, a rubber frame, a chip component and an electromagnetic shielding part, wherein the chip component is arranged between the front plastic frame and the rubber frame; the electromagnetic shielding part is arranged around the chip component and used for isolating the interference of external electromagnetism to the chip component. When the front frame of the backlight module is made of plastics, the interference of the external electromagnetism to the chip component can be prevented through the electromagnetic shielding part, so that the stability of a control signal of the chip component is ensured, and furthermore, the picture display quality is ensured.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Shielding assembly

InactiveUS20090283319A1Modifications by conduction heat transferScreening rigid plastic containersMetal foilEngineering

A shielding assembly (10) for electronic device is provided. The shielding assembly (10) comprises a plastic layer (12), a metal foil (16) mounted to the plastic layer (12), and a coolant (14) is formed between the plastic layer (12) and the metal foil (16). An electronic device using the shielding assembly is also provided.

Owner:FIH (HONG KONG) LTD

Popular searches

Solid-state devices Gaseous cathodes Electric discharge lamps Cooling/ventilation/heating modifications Semiconductor devices Electrical apparatus casings/cabinets/drawers Support structures on hinges/pivots Semiconductor/solid-state device manufacturing Printed circuit manufacture Vehicle components

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com