Drive device

A technology for driving equipment and driving shafts, used in driving devices, precision positioning equipment, metal processing equipment, etc., can solve the problems of expensive manufacturing, large structure, etc., achieve compact structure type, promote structure type, prevent tilting or jamming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

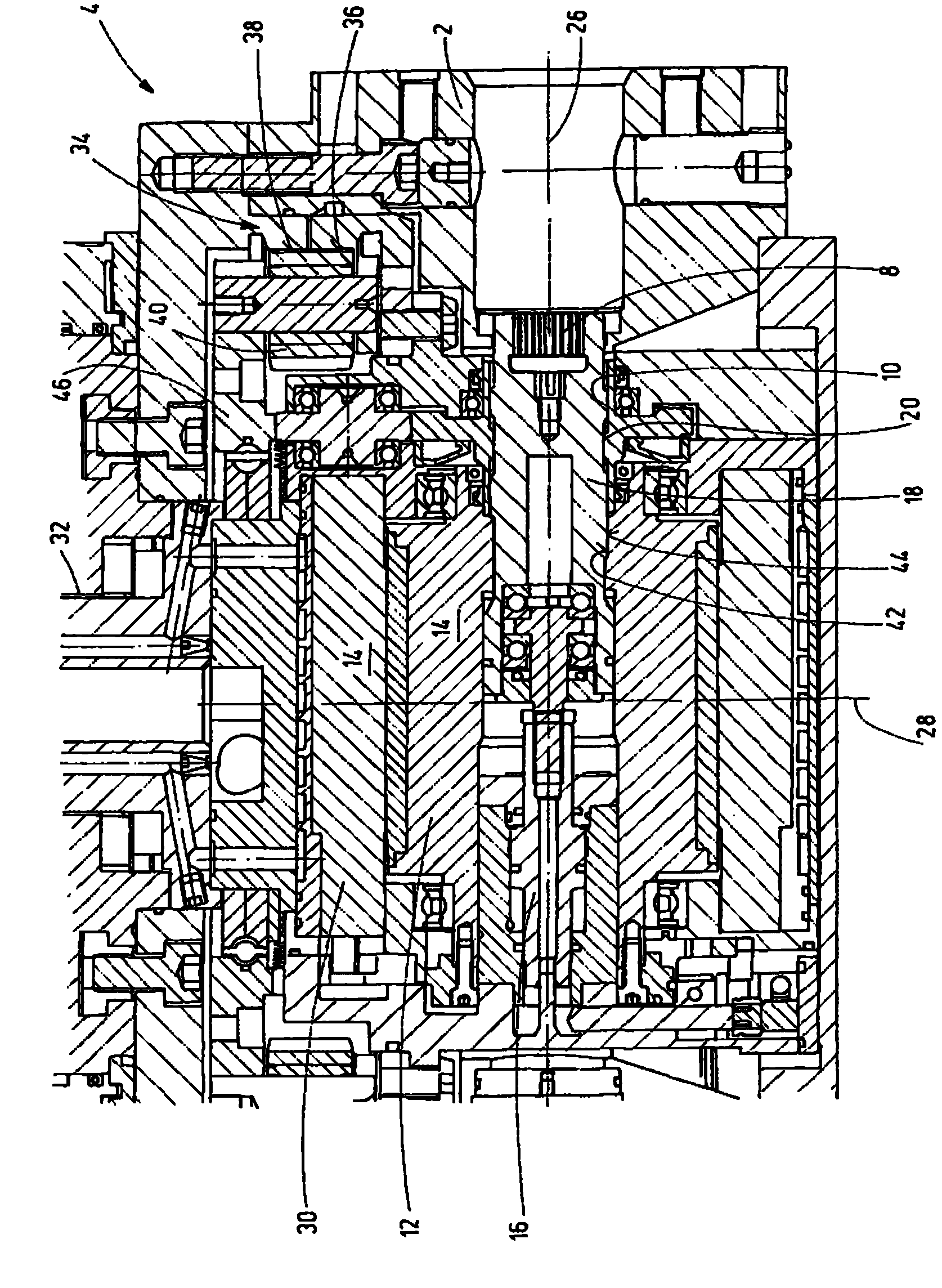

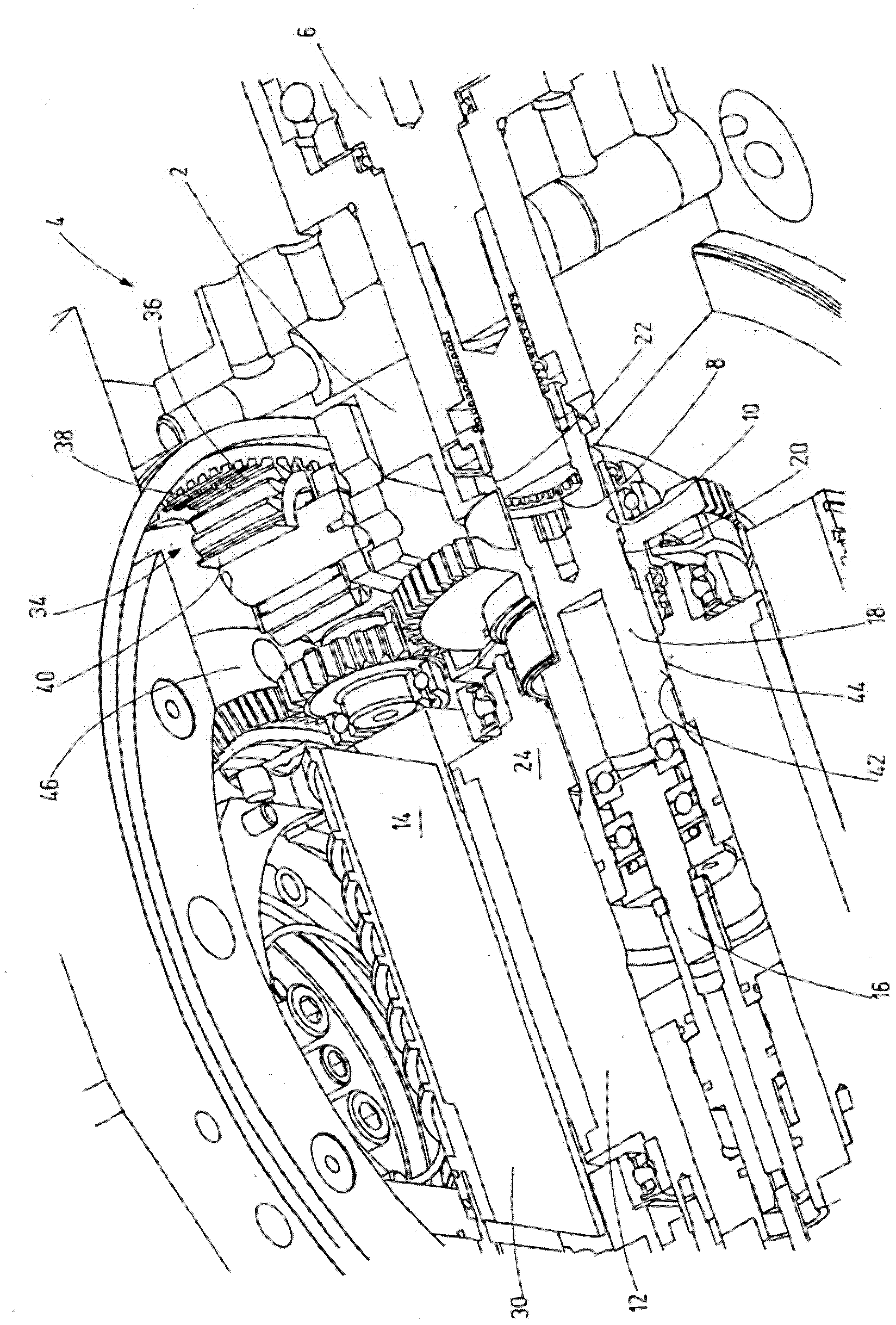

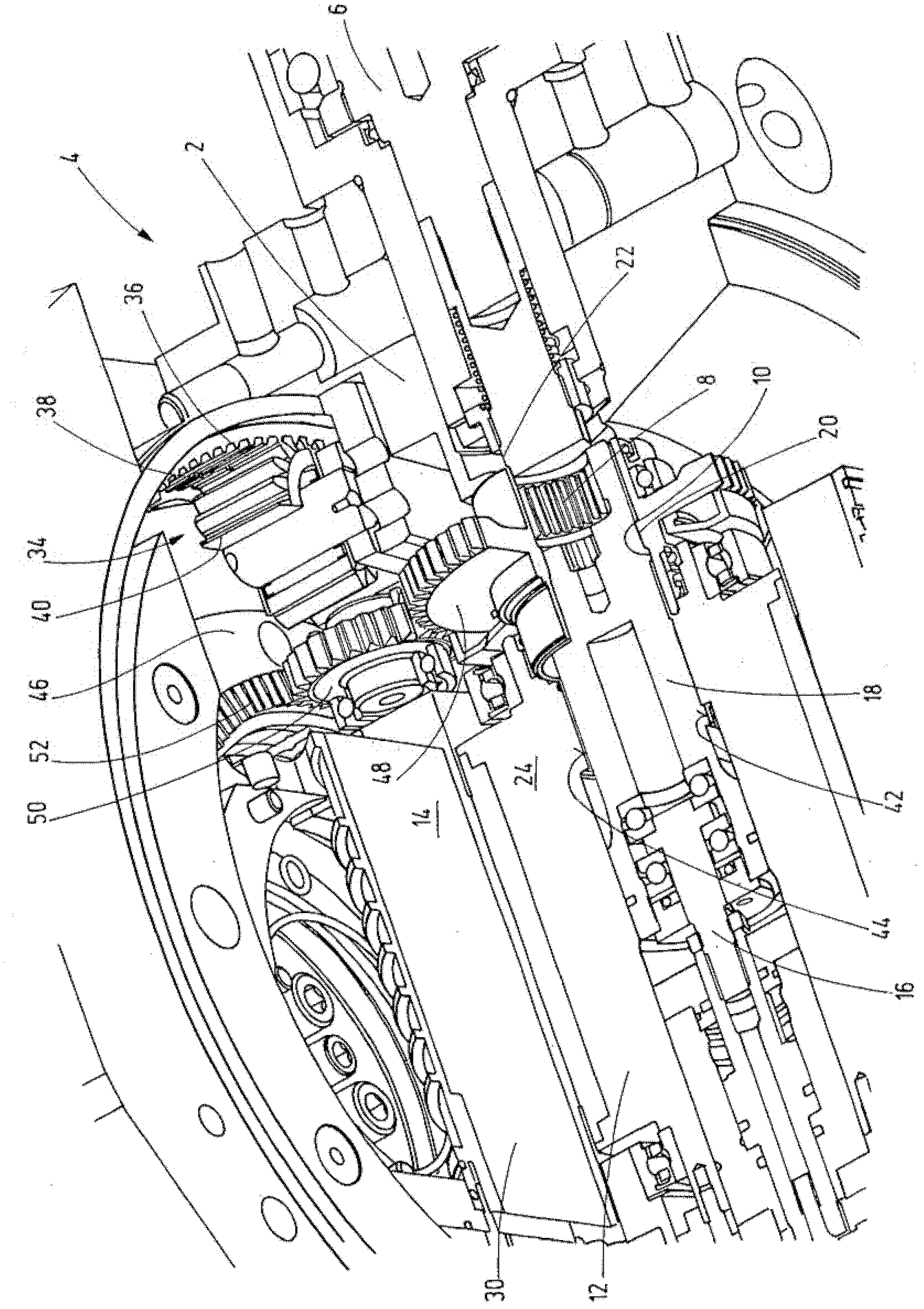

[0028] exist figure 1 In the shown drive device for selectively driving the cutter head 2 of the tool turret 4 and at least one machining tool (not shown), the driving is effected by means of two drive mechanisms 8, 10, the machining tool being driven by means of Holding device 6 (see figure 2 ) can be fixed on the cutter head 2, and the two drive mechanisms can be driven by a common drive device 14 with a drive shaft 12. The drive mechanism 8 , 10 is connectable to the output mechanism 20 , 22 via a coupling device 18 , which can be controlled in each case by at least one actuating device 16 . Here, the output mechanism 20 is used to drive the cutter head 2 , while the output mechanism 22 is used to drive the machining tool. The drive device 14 is arranged inside the cutterhead 2 together with the output mechanisms 20 , 22 .

[0029] The respective drive mechanism 20 , 22 is arranged between the drive device 14 and the machining tool to be driven in a receiving space 24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com