Ionomer composition, and moldings and process for production thereof

A technology of ion cross-linking and polymer, which is applied in the field of ion cross-linking polymer composition, can solve the problems of long-time molding, defective products, and limitations of molding processing methods, etc., to achieve the prevention of dirt adhesion or adhesion, good shape, inhibition oozing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Hereinafter, the present invention will be more specifically described by giving experimental examples as examples of the present invention. However, the present invention is not limited to the following experimental examples unless the gist of the present invention is exceeded. It should be noted that unless otherwise specified, "parts" are based on mass.

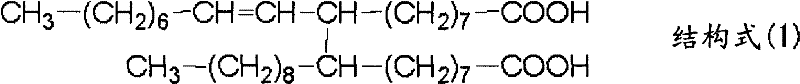

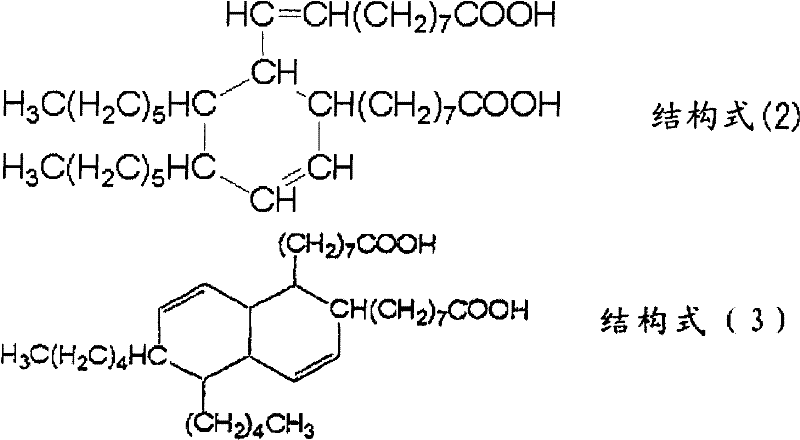

[0076] Prepare the materials shown below.

[0077] -resin-

[0078] · Ionomer 1:

[0079] Zinc ionomer (degree of neutralization: 59%, MFR: 0.9 g / 10 min) of ethylene-methacrylic acid copolymer (structural unit derived from methacrylic acid = 15% by mass)

[0080] · Ionomer 2:

[0081] Sodium ionomer (degree of neutralization: 54%, MFR: 0.9 g / 10 min) of ethylene-methacrylic acid copolymer (structural unit derived from methacrylic acid = 15% by mass)

[0082] · Ionomer 3:

[0083] Magnesium ionomer (degree of neutralization: 54%, MFR: 0.7 g / 10 min) of ethylene-methacrylic acid copolymer (structural unit derived ...

experiment example 1~3

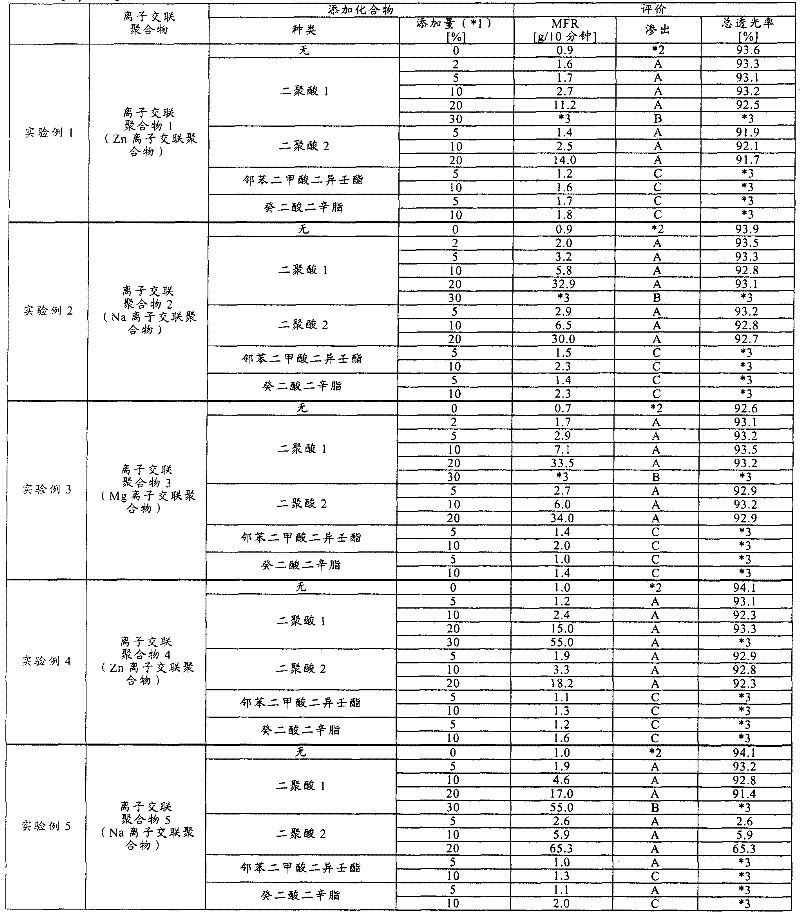

[0094] Compounds were blended and added to the prepared ionomers 1 to 3 so that the amounts shown in Table 1 below were mixed, and the compound was mixed and added at 180° C. under rotation using a Labo Plastomill (Twin-screw manufactured by Toyo Seiki Co., Ltd.). count 50min -1 Mix for 10 minutes under the same conditions.

[0095]

[0096] After mixing, the melt flow rate (MFR) was measured as an indicator of flowability. At this time, MFR was measured at 190° C. under a load of 2160 g by a method in accordance with JIS K7210-1999. The measurement results are shown in Table 1 below.

[0097] Next, the resulting mixture was press-formed into a sheet form by heating and pressing (160° C.) to obtain a 3 mm-thick press sheet sample.

[0098]

[0099] After the obtained tableted sample was left to stand for 2 weeks under the conditions of 23° C. and a relative humidity of 50%, the state of the surface of the sheet was visually observed, and the presence or absence of bleed...

experiment example 4~5

[0107] Except having used ionomer 4 or ionomer 5 instead of ionomer 1 of Experimental example 1, it mixed by the same method as Experimental example 1, obtained the mixture, and evaluated it. The measurement results are shown in Table 1 below.

[0108] [Table 1]

[0109]

[0110] * 1: content ratio of dimer acid to the total amount of ionomer and dimer acid [mass %]

[0111] * 2: Since dimer acid is not added, there is no bleeding.

[0112] * 3: Not measured.

[0113] As shown in the above Table 1, in the sample of the present invention, the addition of the dimer acid increases the MFR with little damage to the transparency. Mobility can be improved. In addition, improvement of fluidity and suppression of seepage, which are difficult to achieve simultaneously with conventional lubricants, can also be achieved at the same time. On the other hand, in the comparative sample, bleeding occurred even if a small amount of the additive compound was added, and fluidity was h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com