Resin composition exhibiting high performance in terms of inhibition of ice and frost formation, and laminated metal plate on which an ice/frost-formation inhibition layer is formed

A technology of resin composition and metal plate, applied in the direction of metal layered products, coating, deicing, etc., can solve the problems of peeling, tools, mold wear, hardening of coating film, etc., to reduce energy loss and prevent condensation Frost, excellent hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

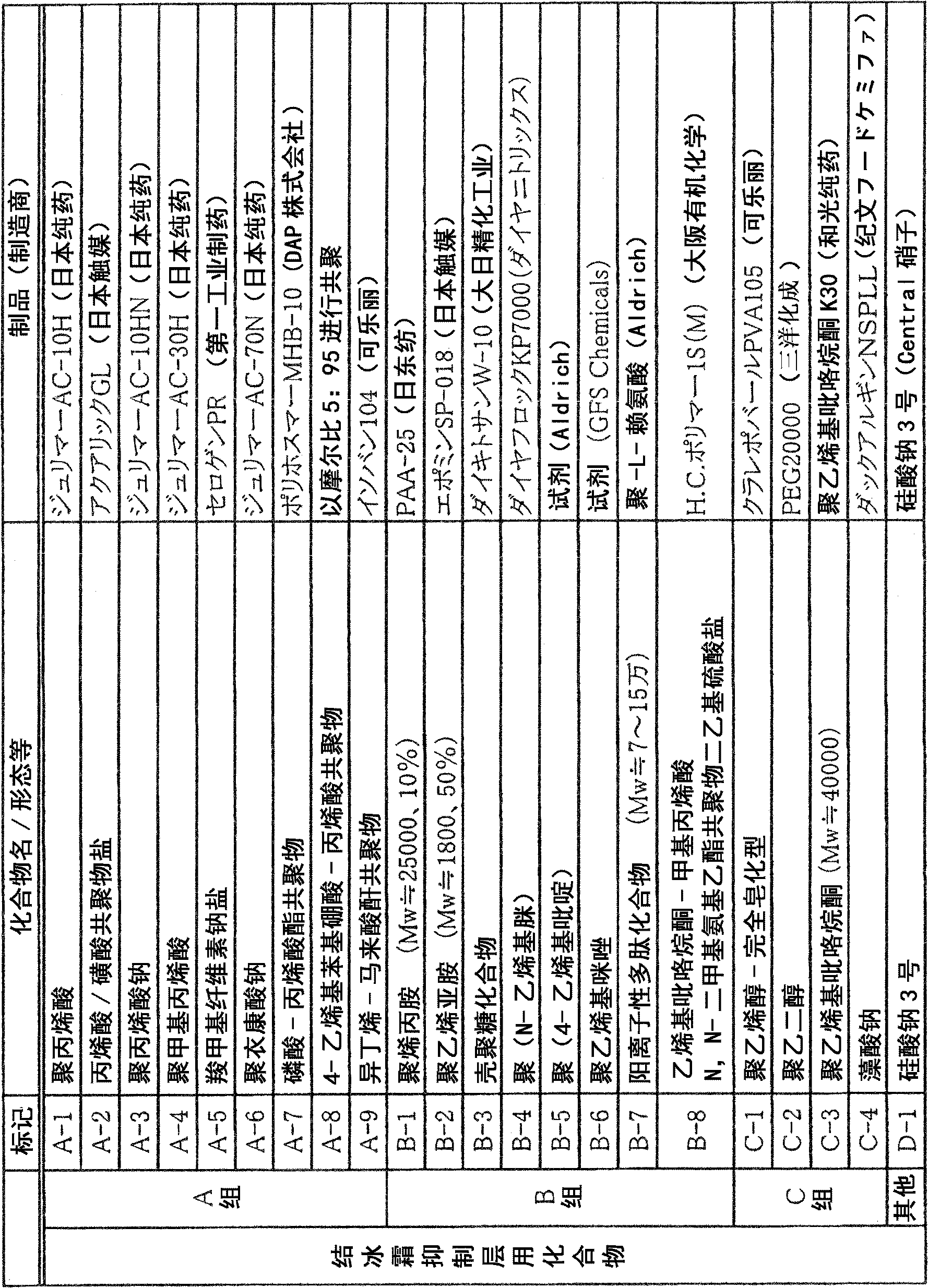

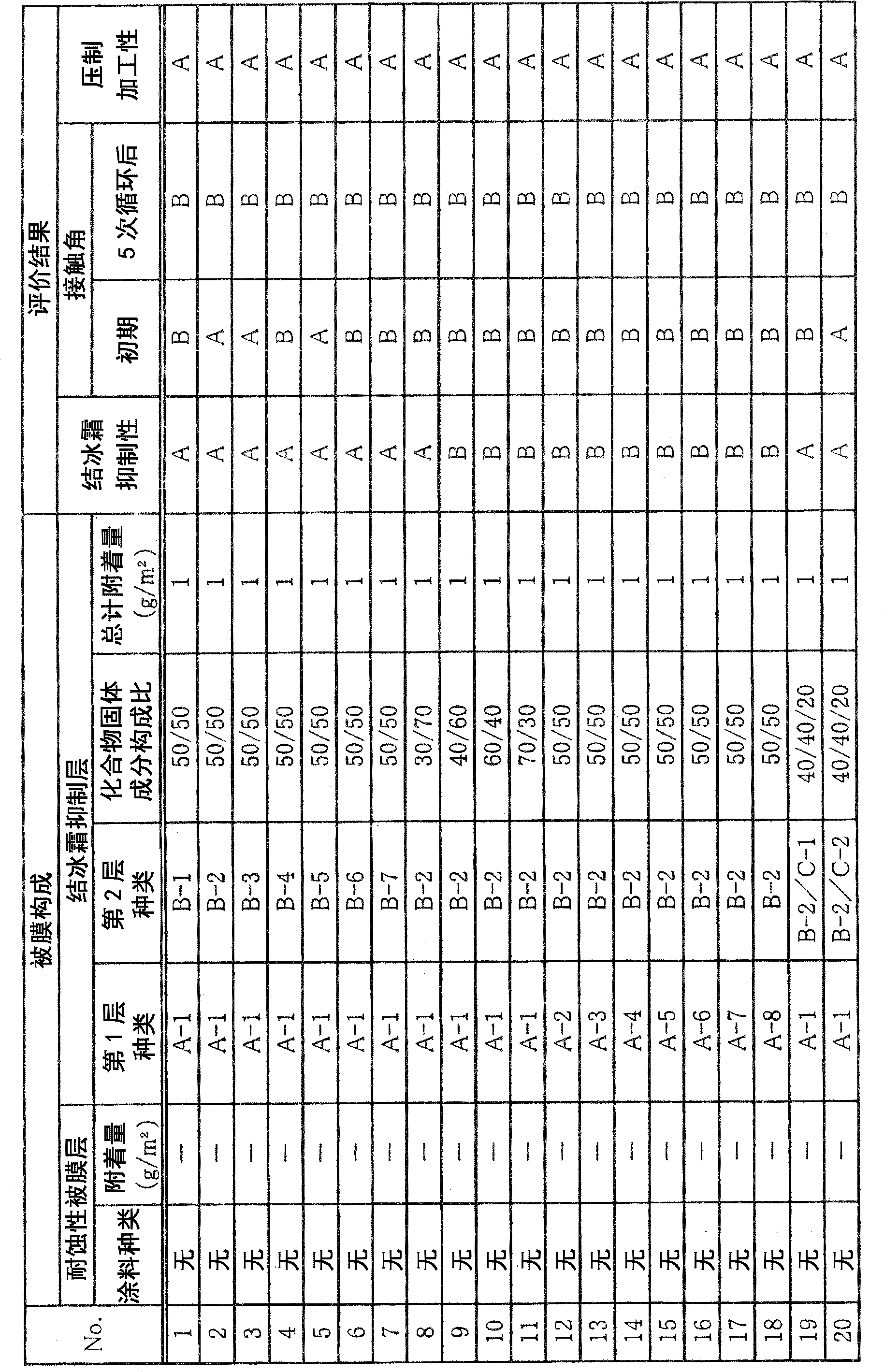

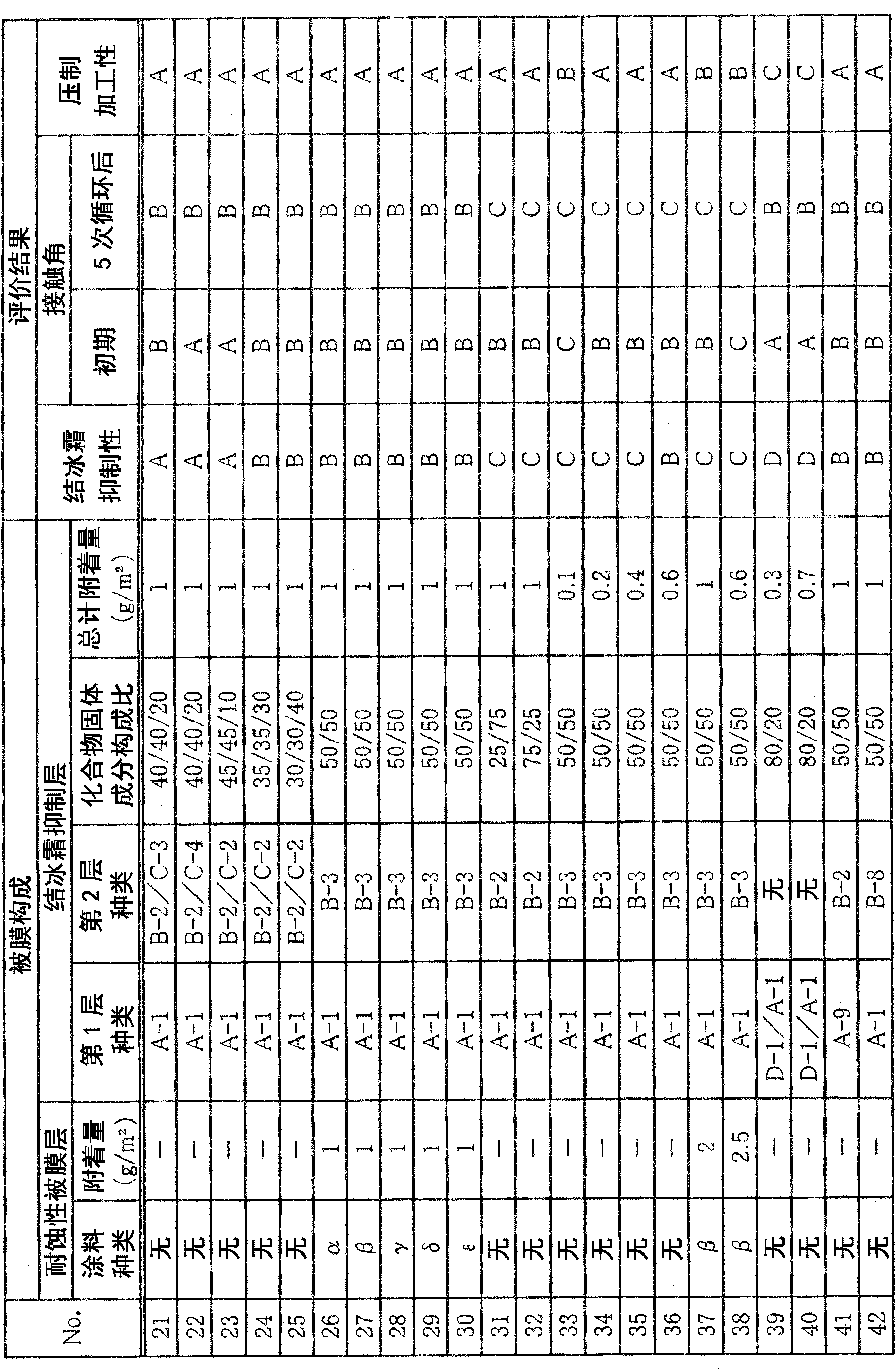

[0104] The following examples are given to describe the present invention more specifically, but the present invention is not limited by the following examples, and it is of course possible to appropriately modify and implement within the scope of adapting to the gist of the foregoing and the following, and these include Within the technical scope of the present invention.

[0105] Aluminum heat dissipation sheets were produced under the following conditions, and their performance was evaluated. First, the metal plate used for the production of the aluminum heat dissipation sheet, the resin composition for the frost formation suppression layer, and the coating material for the corrosion-resistant film layer will be described.

[0106] [manufacturing method of metal plate]

[0107] An aluminum plate (sheet thickness: 0.10 mm) formed of pure aluminum-based A1200 (JIS H4000) was produced by a conventionally known production method. That is, an ingot of pure aluminum was produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap