Fan motor and air conditioner with same

A fan motor and three-phase motor technology, which is applied in mechanical equipment, electrical components, machines/engines, etc., can solve the problems of larger fan motors and larger housings, and achieve the effect of improving design freedom and large ventilation channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

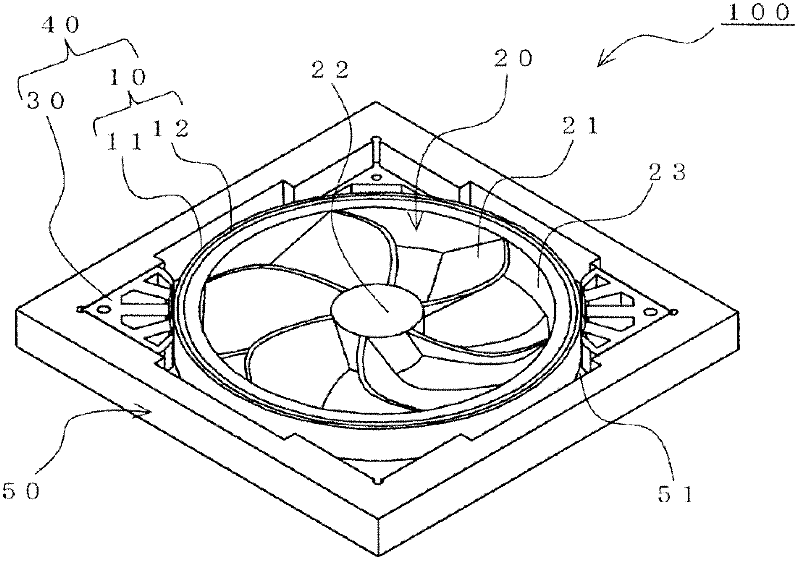

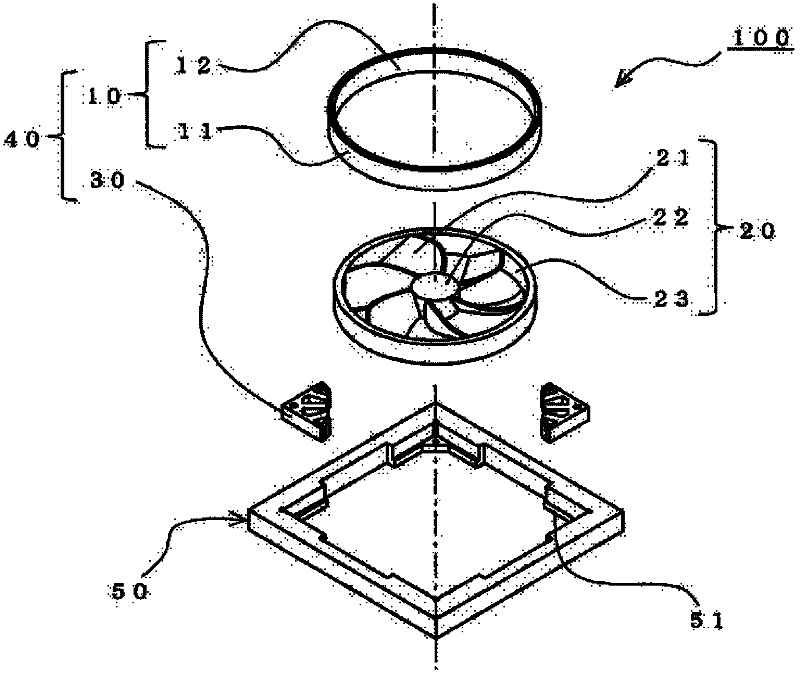

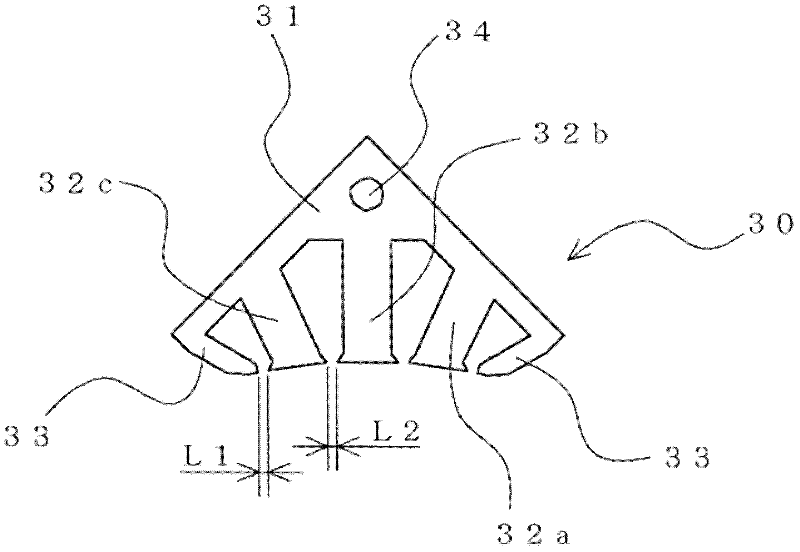

[0025] figure 1 It is an external perspective view showing the fan motor according to the first embodiment of the present invention. figure 2 is an assembled perspective view of the fan motor. in addition, image 3 is a front view showing the stator of the fan motor.

[0026] The fan motor 100 is an axial fan structure, and is composed of a blade portion 20 , a motor 40 having a rotor 10 and a stator 30 , and a housing 50 .

[0027] The casing 50 has a substantially quadrilateral frame shape, and the blade portion 20 is provided inside.

[0028] The blade portion 20 has a fan hub portion 22 and a plurality of blades 21 . Fan hub portion 22 serves as the rotation center of blade portion 20 , and blade 21 is formed on its outer peripheral portion. In addition, a substantially annular ring 23 is formed on the outer peripheral portion of the blade 21 . Blade portion 20 (blade 21 , fan hub portion 22 , and ring 23 ) is integrally formed of, for example, a resin material. In...

no. 2 approach

[0057] For example, the arrangement position of the stator 30 and the formation position of the auxiliary teeth 33 may be set as follows. In addition, about the item which is not described especially in 2nd Embodiment, it is the same as 1st Embodiment.

[0058] Figure 5 It is a front view showing the fan motor of the second embodiment of the present invention.

[0059] In the fan motor 101 of the second embodiment, stators (one stator 30 , three stators 30 a ) are provided at all corners (four locations) of the casing 50 . In addition, among these stators, one stator 30 is provided with auxiliary teeth 33 at both ends thereof, and the other three stators 30a are not provided with auxiliary teeth. These points are the differences between the fan motor 101 of the second embodiment and the fan motor 100 of the first embodiment, and the other structures are the same.

[0060] That is, the fan motor 101 cancels and reduces the cogging effect generated by the ends of the stator ...

no. 3 approach

[0064] In addition, the arrangement position of the stator 30 and the formation position of the auxiliary teeth 33 may be set as follows, for example. In addition, in 3rd Embodiment, the item which is not described especially is the same as 1st Embodiment or 2nd Embodiment.

[0065] Figure 6 It is a front view showing the fan motor of the third embodiment of the present invention. in addition, Figure 7 is a front view showing the stator.

[0066] In the fan motor 102 of the third embodiment, the auxiliary teeth 33 are provided only at one end of the stator 30b. Other configurations are the same as those of the fan motor 100 of the first embodiment.

[0067] More specifically, among the stators 30b provided at opposite corners of the casing 50, one stator 30b ( Figure 6 The upper right stator 30b) in FIG. 2 is provided with auxiliary teeth 33 adjacent to the W-phase teeth 32c. In addition, among the stators 30b provided at opposite corners of the casing 50, the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com