Sowing plow

A seeder and seeding ditch technology, applied in the direction of sowing, sowing seeder, application, etc., can solve the problem of reducing the spacing of seeding grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

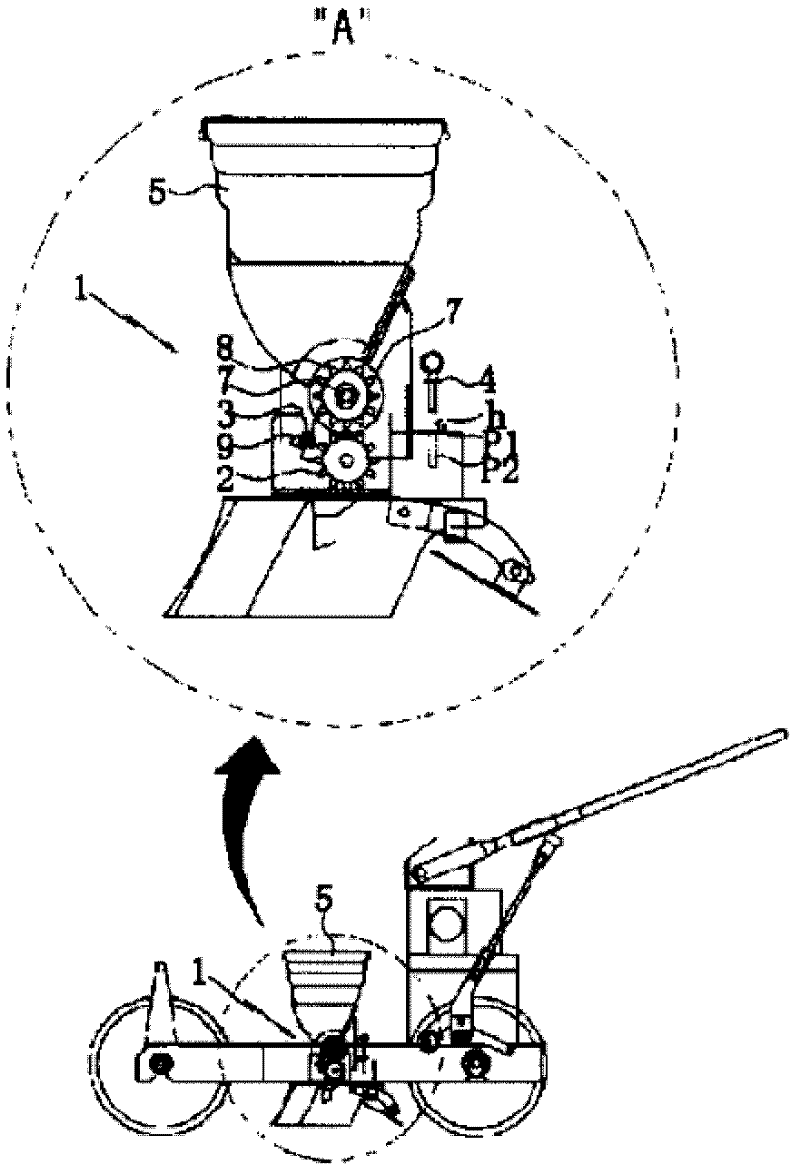

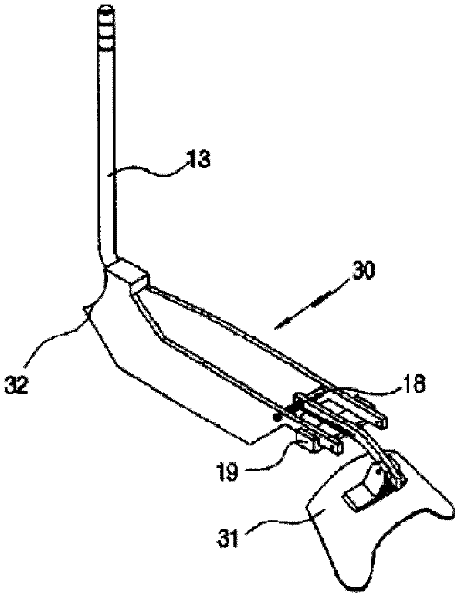

Method used

Image

Examples

no. 2 example

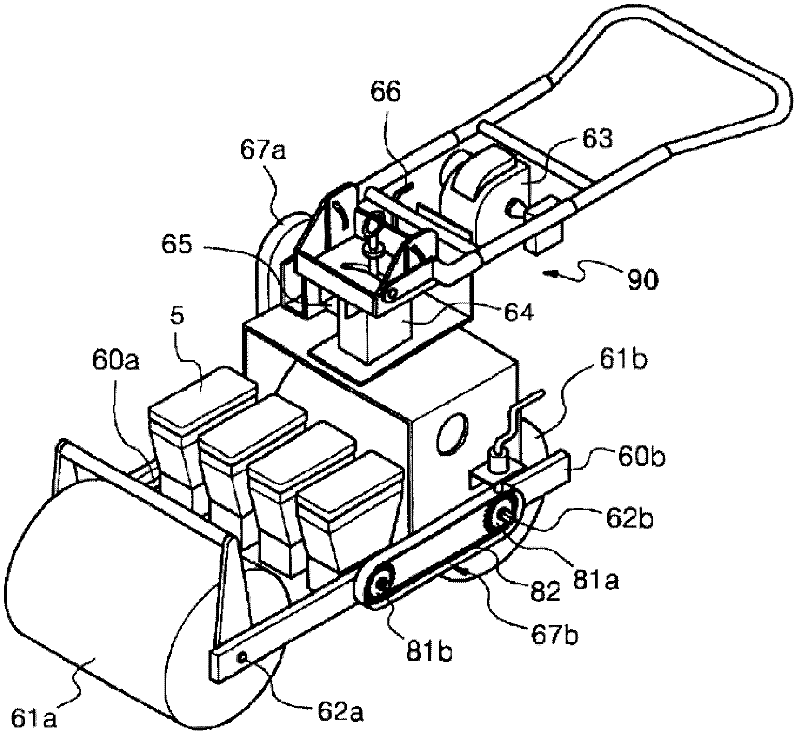

[0079] Figure 14 is a perspective view of a transmission unit of a planter with a one-touch detachable hopper depicting a second embodiment of the present invention, Figure 15 is a schematic diagram of a planter with a one-touch detachable hopper describing a second embodiment of the present invention. To describe this in detail, the first roller 61a and the second roller 61b are driven by an engine 63, wherein the driving force from the engine 63 is transmitted via a speed reducer 64, a first clutch 65 for selectively transmitting rotational driving force, and power transmission The device 67a rotates the second roller shaft 62b of the second roller 61b provided at the rear. The second power transmission device 67b is configured to connect the first roller shaft 62b and the first roller shaft 62a in a transmission manner, and the third power transmission device 67c is configured to connect the first roller shaft 62a and the first roller shaft 62a in a rotatable manner. Th...

no. 3 example

[0090] Figure 16 is a schematic diagram describing a third embodiment of the present invention of a planter with a one-touch detachable hopper, which is manually driven.

[0091] The first roller 61a and the second roller 61b are configured to be rotatable by a driving force generated when the first roller 61a and the second roller 61b are pushed or pulled forward. The driving force is directly transmitted to the hopper installation unit driving shaft 52 through the fourth transmission chain 134 wound on the first roller shaft 62a.

[0092] With this arrangement, the first sprocket 53a, the second sprocket 53b, and the second transmission chain 54 of the hopper installation unit 1 mounted on the drive shaft are driven, so that the driven gear 43 of the hopper 5 loaded and unloaded by the latch 57 Rotation, thus realizing sowing or fertilizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com