Artificial cardiac valve and performance analysis method based on ANSYS/LS-DYNA thereof

A technology of artificial heart valves and analysis methods, applied in the direction of heart valves, instruments, calculations, etc., can solve the problem that it is difficult to measure the internal stress distribution of valve leaflets, and the analysis of valve leaflet durability has no scientific data basis and has not reached natural Heart valve ideal standard and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Embodiment: The dynamic mechanical performance analysis of biological valve based on ANSYS / LS-DYNA, the steps are as follows:

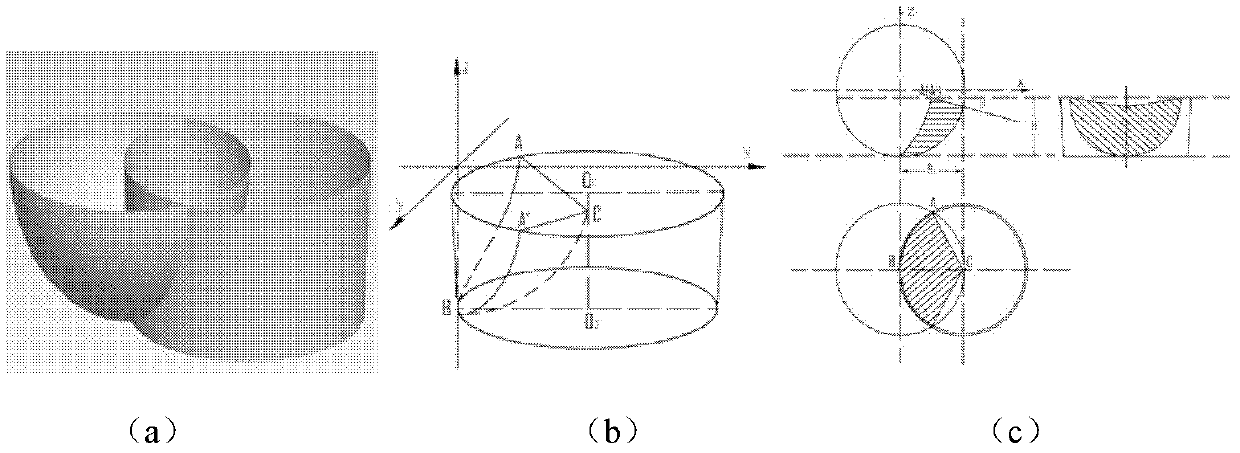

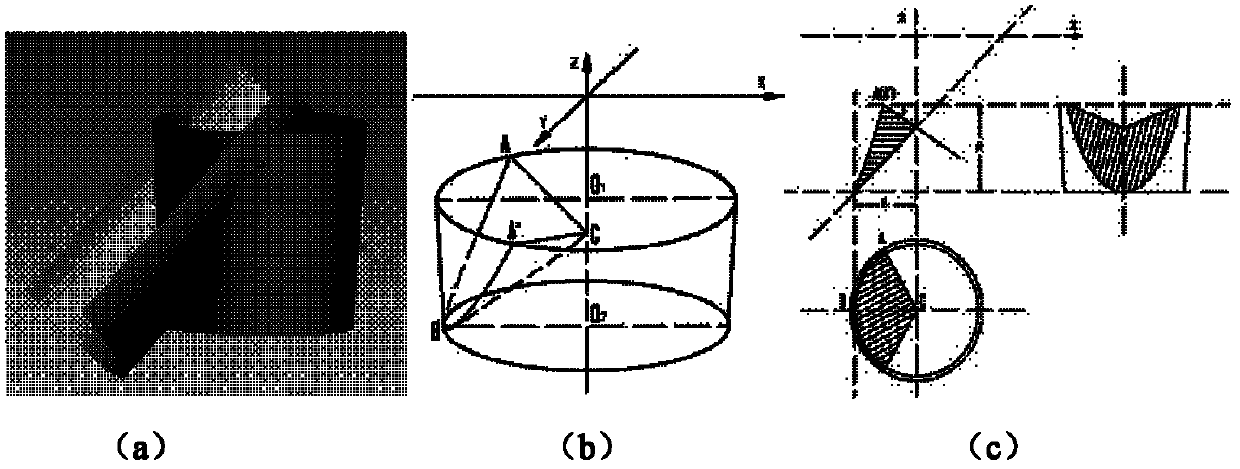

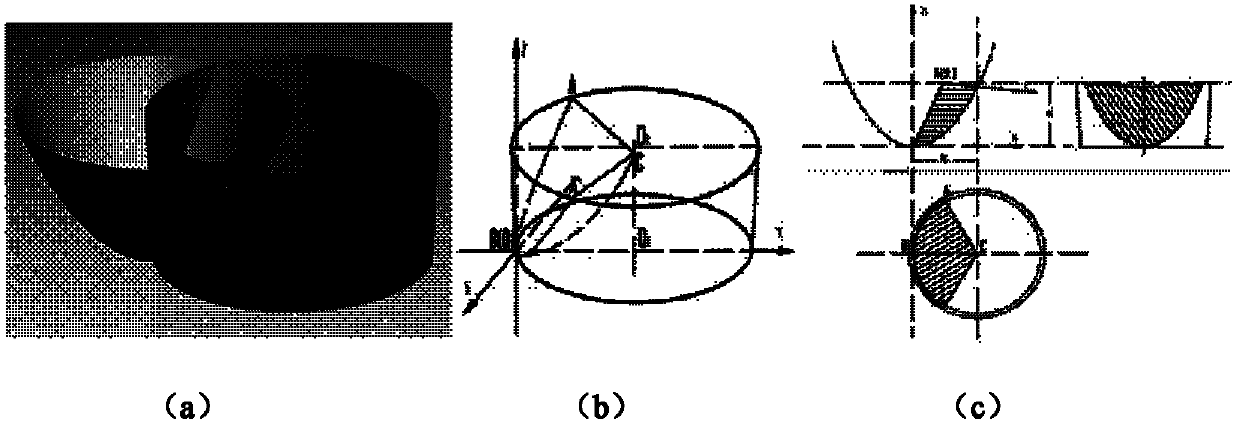

[0061] A. Geometric modeling of biological valves

[0062] In the process of modeling the valve leaflets of biological valves, we use the default Cartesian coordinate origin of Pro / E software as the modeling origin O, and create according to the geometric equations of each rotating surface (spherical surface, cylindrical surface, rotating paraboloid and ellipsoid) Surface of revolution. Take the straight line (13, 0, z) parallel to the Z axis as the axis of rotation, and make a conical surface passing through the lowest point B of the curved surface of revolution, and the half-vertex angle α of the conical surface is 3°. The conical surface is intersected with the four surfaces of revolution to obtain intersecting lines. The XOZ plane is deflected around the axis of rotation of the conical surface The intersection points A and A' of the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com