Method for preventing split membrane bio-reactor (MBR) flat membrane pollution

A separate, flat-plate membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as removal of surface adsorbates, increase ton water treatment cost, affect sludge properties, etc., to achieve enhanced shear Cutting force, prolonging the interval time, improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Method 1 for preventing fouling of split-type MBR flat-panel membranes

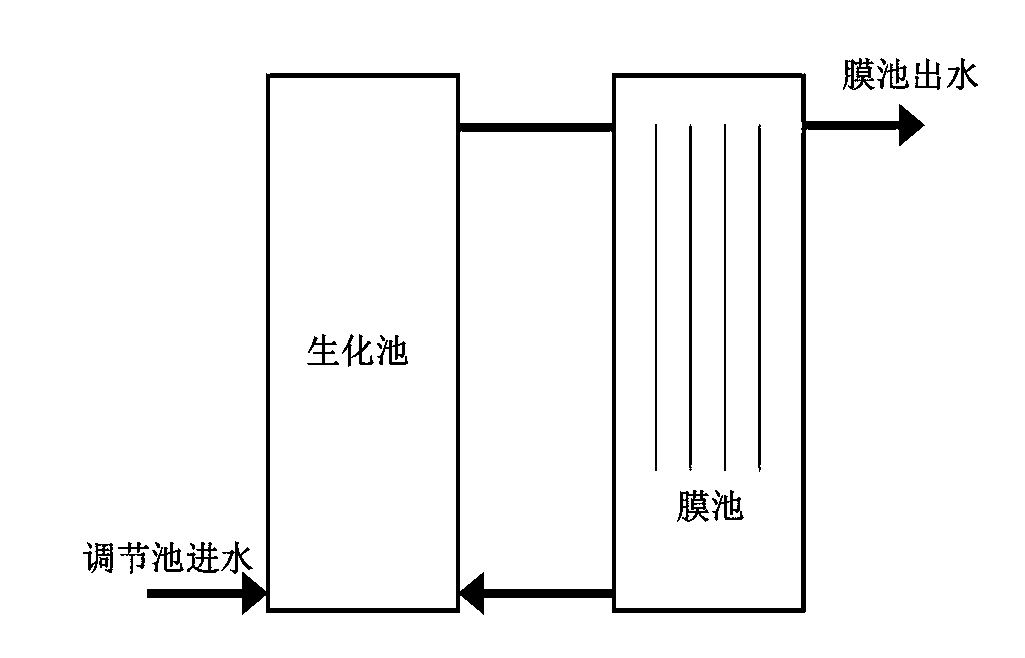

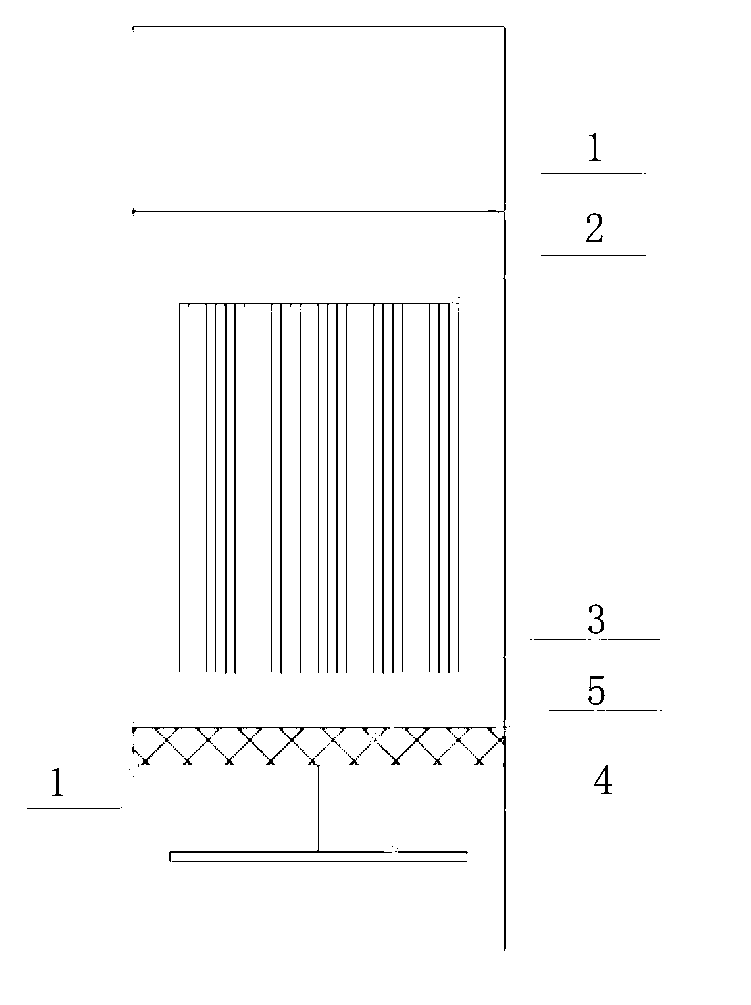

[0042] A separate membrane bioreactor, which consists of two parts: a biochemical pool and a membrane pool, and the membrane module box is placed in the membrane pool (see figure 1 ). Such as figure 2 As shown, the present invention arranges a layer of screen 1 at the bottom and top of the membrane module box, a flat membrane group 2 is placed in the box between the two layers of screens, and a granular filler 3 is added in the box between the two layers of screens. , the diameter of the granular filler is larger than the mesh diameter of the screen, the aeration pipe 4 is placed under the bottom screen, and the membrane module box is provided with a filler replacement window 5 for replacement of the filler and cleaning of the screen.

[0043] In this embodiment, the mesh diameter of the screen is 2mm; the particle filler used is round ceramsite with a density of 1.1kg / m 3 , the...

Embodiment 2

[0052] Embodiment 2 Method 2 for preventing fouling of split-type MBR flat-panel membranes

[0053] In this example, for the separate membrane bioreactor, the mesh diameter of the screen is 1.5mm; the particle filler used is round fruit shell filler (mainly hickory shell), and the density range is 1.1~1.25 kg / m 3 , with an average density of 1.15 kg / m 3 , with a diameter of 1.8~3mm and an average diameter of 2.2mm. The total volume of the filler is 20% of the volume of the box between the upper and lower screens; the flat membrane group used, the gap between each flat membrane is 20mm. The bottom aeration adopts high-pressure aeration, which reduces the intake air volume and increases the intake air pressure. Increase the circulation and agitation of the aeration to the filler.

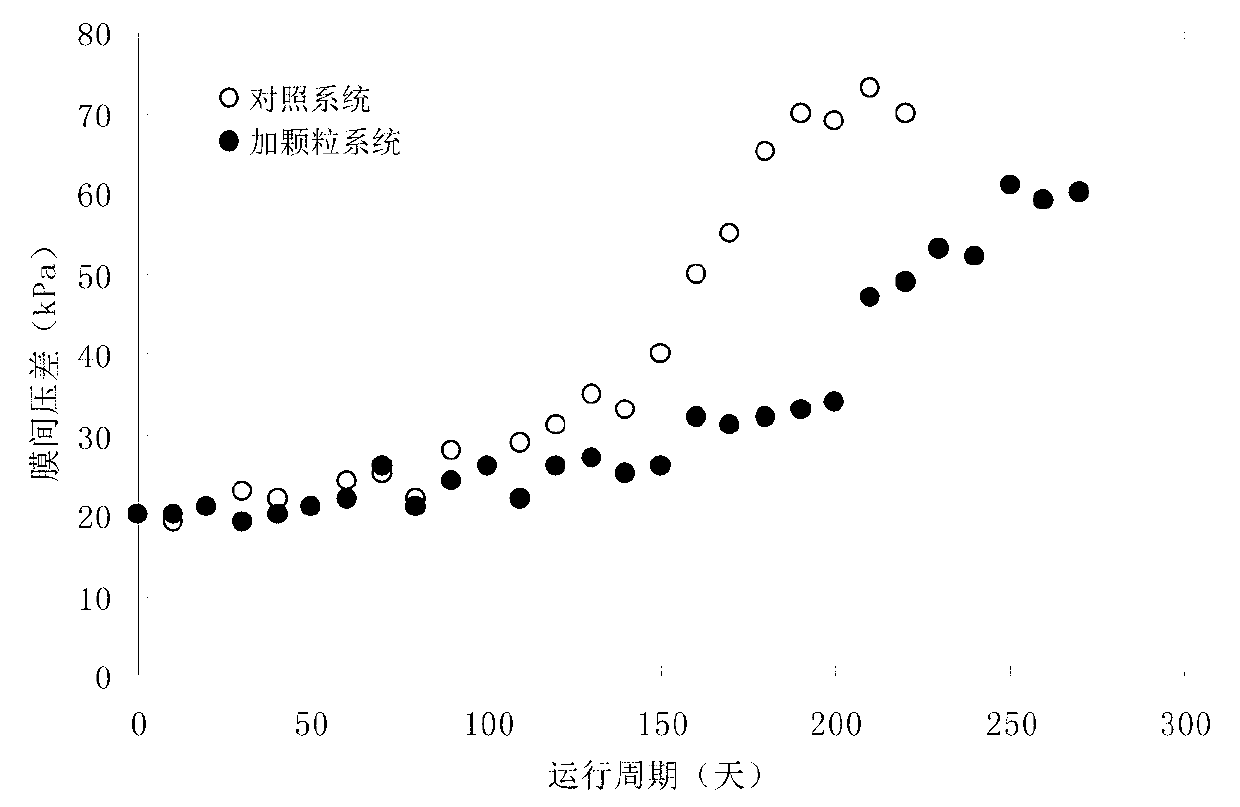

[0054] The pressure difference between the membranes under the condition of the same permeate flow in the membrane bioreactor

[0055] Depend on Figure 6 It can be seen from the figure that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com