Powder spraying chamber convenient to clean

A powder spraying room and studio technology, applied in the field of electrostatic powder coating equipment, can solve the problems of powder spillage, harmful to health, pollution of the environment, etc., achieve the effect of physical health and environmental protection, and avoid flying dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

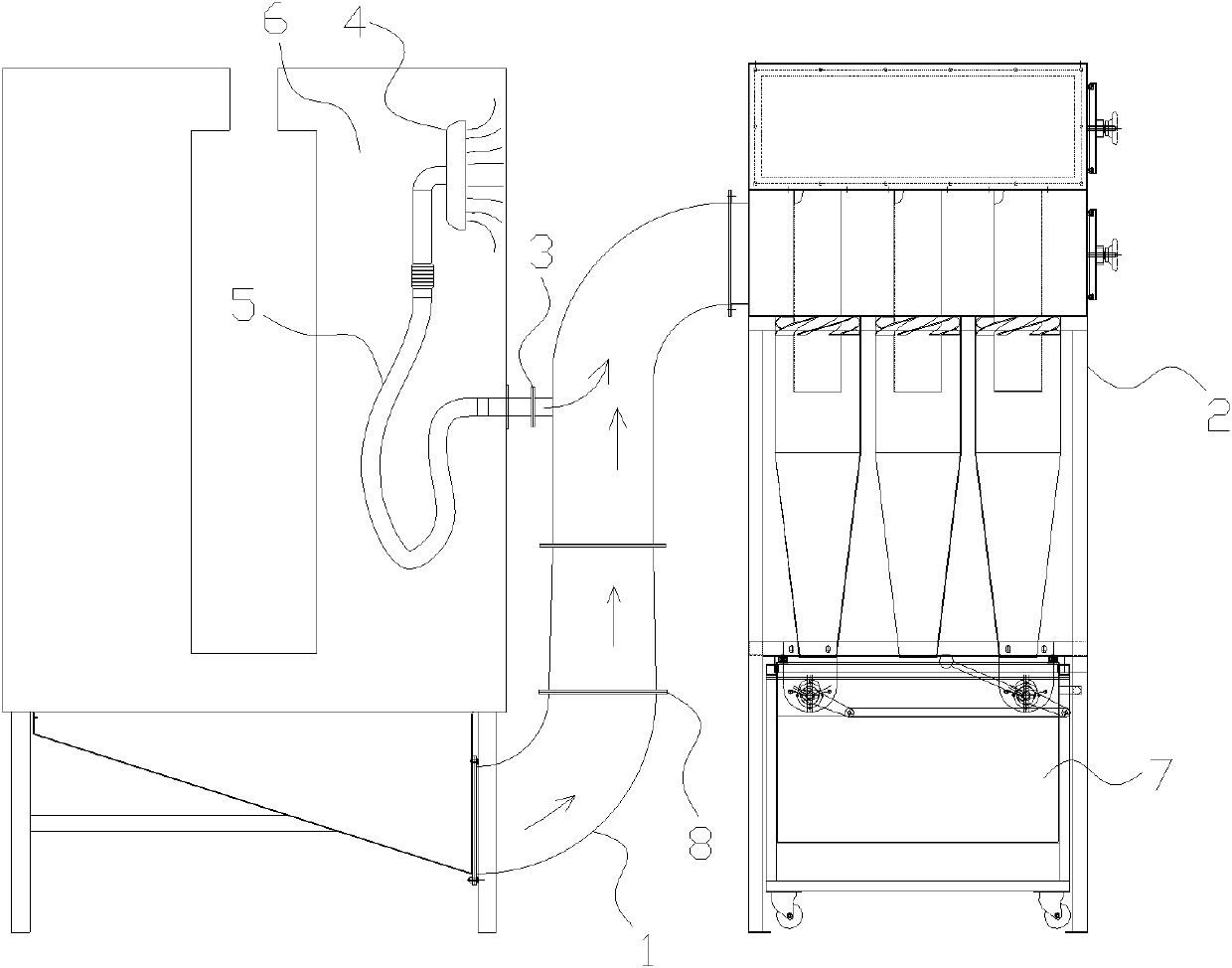

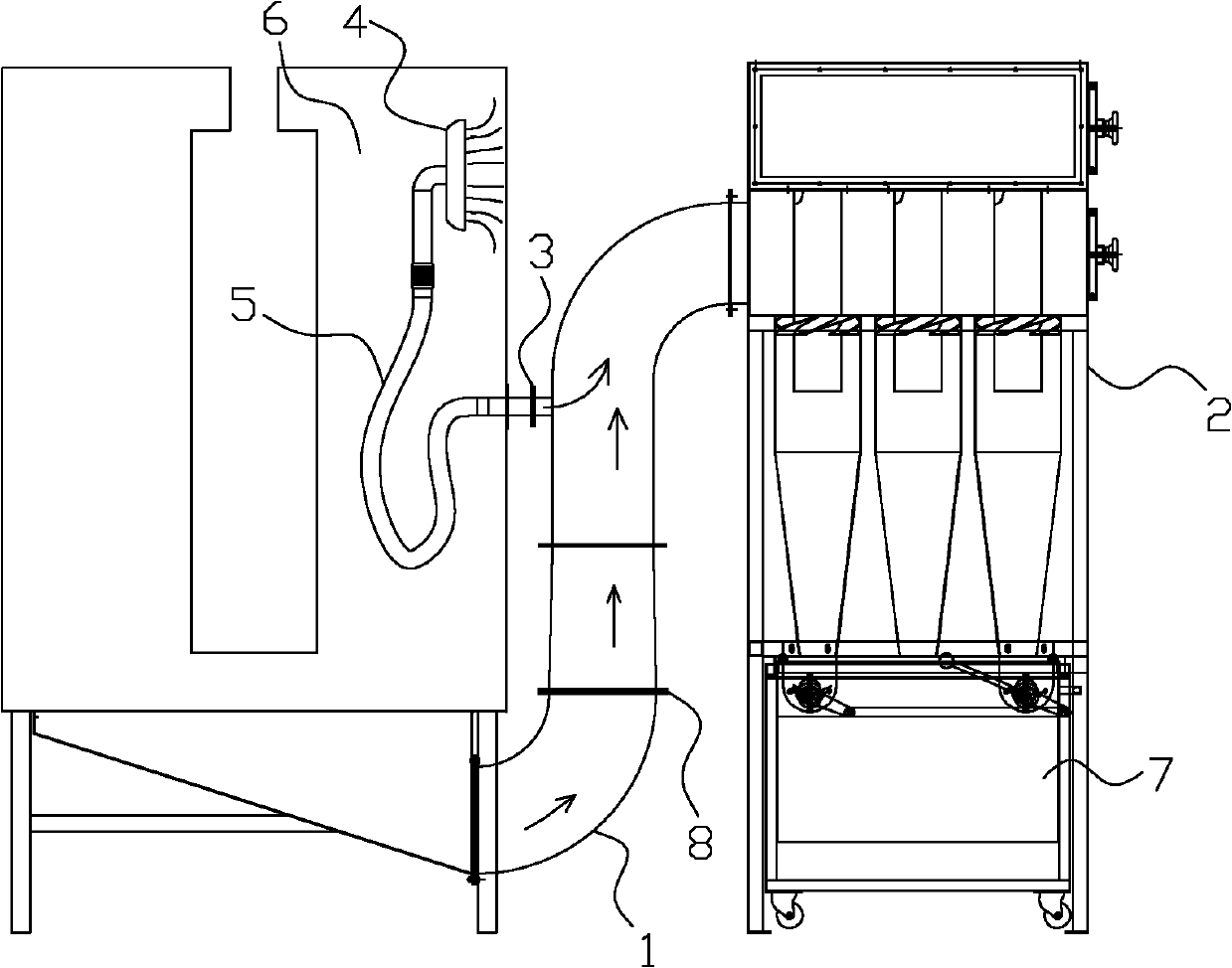

[0012] Referring to the accompanying drawings, the present invention is an easy-to-clean powder spraying chamber, which includes a working chamber 6 with a suction port at the bottom and a suction pipeline 1 communicating with the suction port.

[0013] The side wall of the working chamber 6 has a second air suction port, and a communication pipeline is provided between the second air suction port and the suction pipeline 1. A valve 3 is provided on the communication pipeline, and the second air suction port is located in a part of the working chamber. Side is connected with suction powder brush 4 by flexible pipe 5.

[0014] The powder suction brush 4 includes a cavity communicated with the hose 5 and bristles on the outer surface of the cavity, wherein the cavity wall with the bristles is provided with suction holes.

[0015] A pipeline switch 8 is provided at a position between the air suction pipe 1 and the second air suction port.

[0016] There is a filter and dust remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com