Magnesium alloy sheet different temperature drawing mold

A technology of differential temperature deep drawing and magnesium alloy, which is applied in forming tools, manufacturing tools, metal processing equipment, etc., and can solve problems such as poor plasticity at room temperature and difficult stamping and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

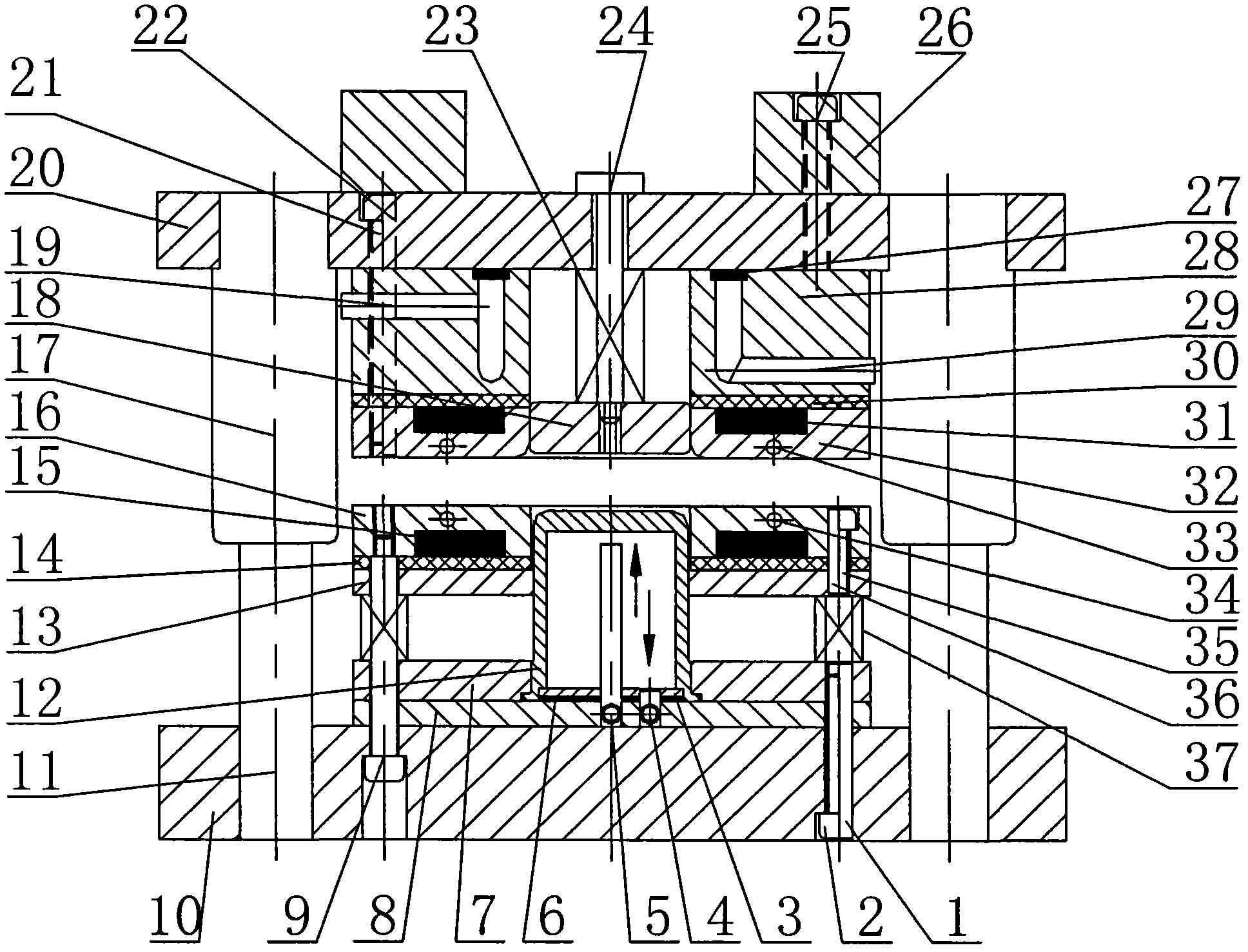

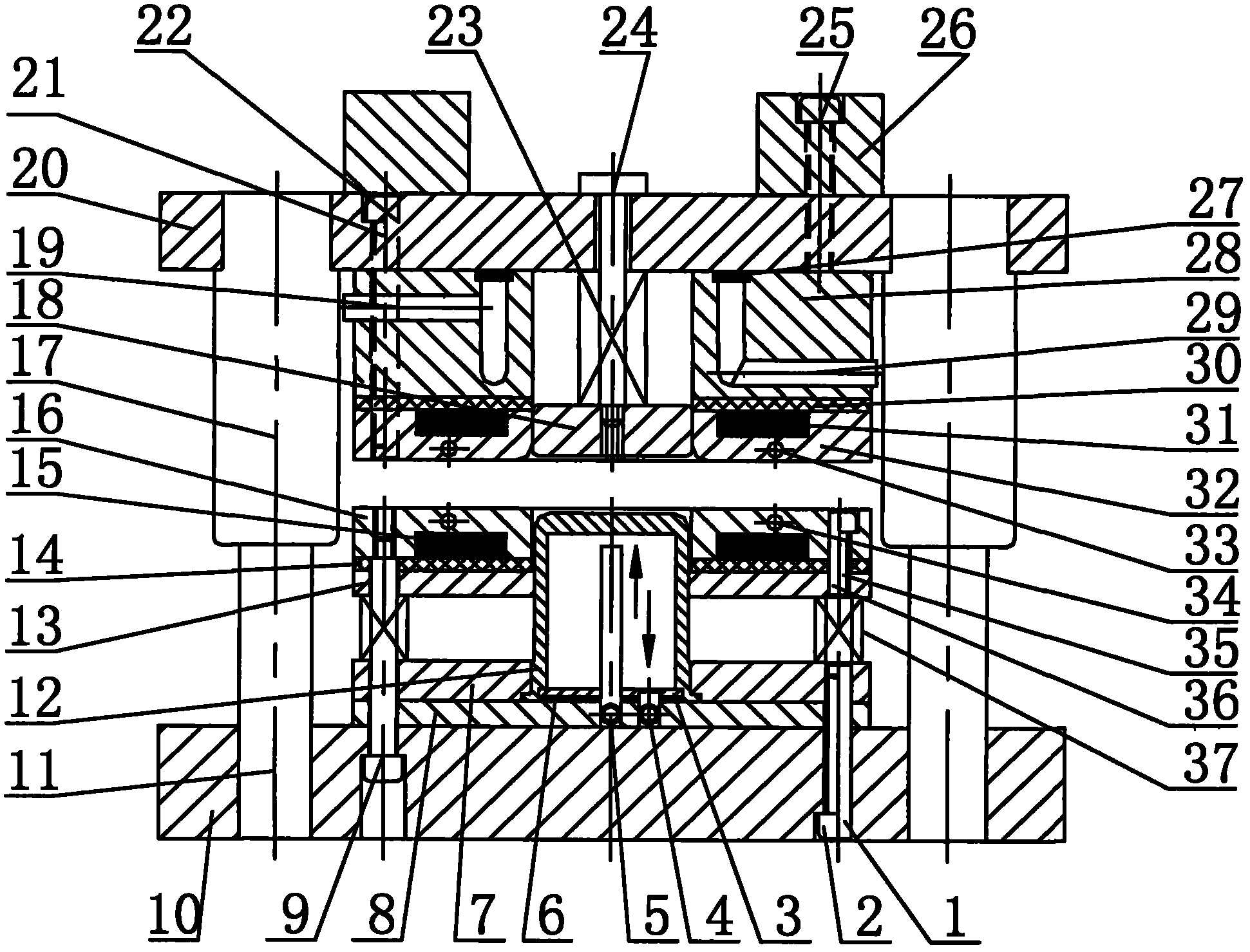

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

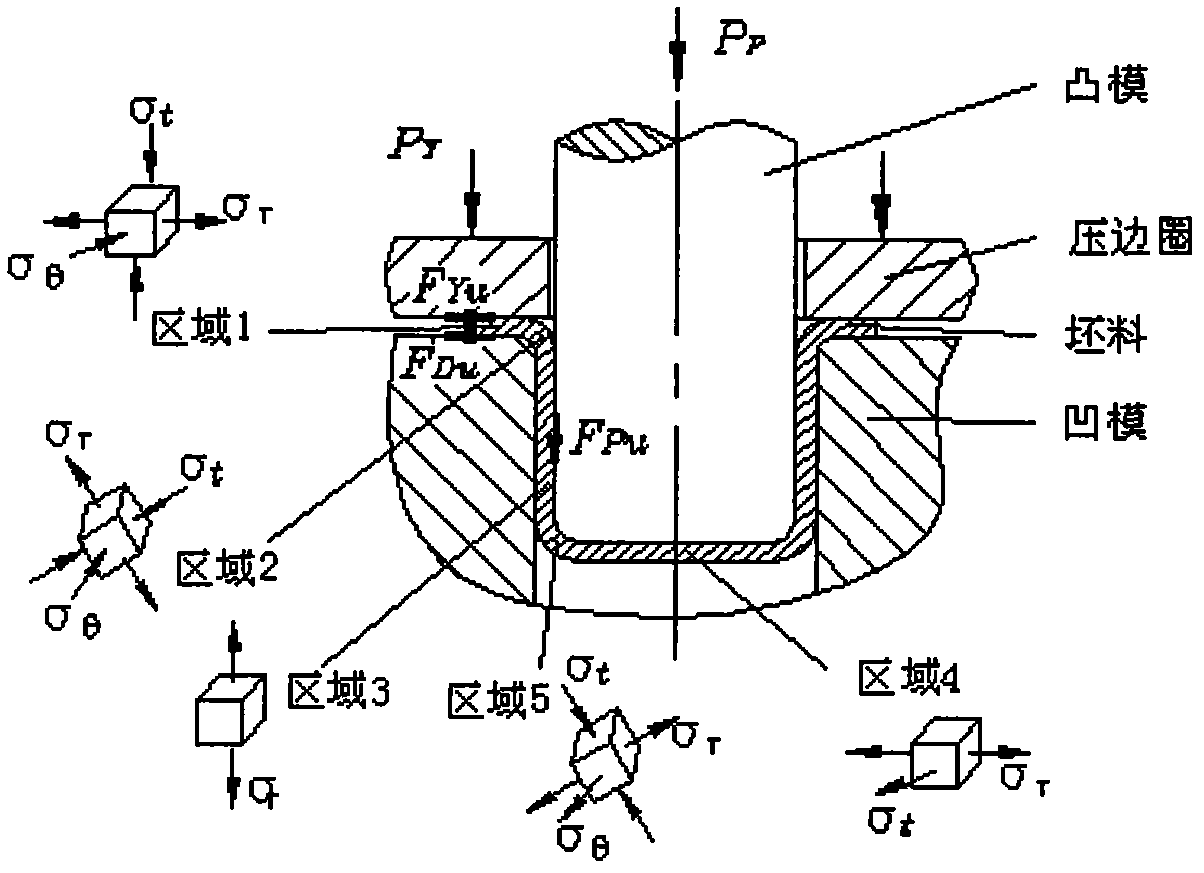

[0014] Magnesium has a close-packed hexagonal crystal structure, and there are five slip systems including basal plane slip, prismatic plane slip, and cone twinning. At room temperature, only the base plane slips, so the cold formability is poor. When the temperature rises, the number of slip coefficients involved in deformation increases, and recovery and recrystallization can also eliminate part of the work hardening generated during plastic deformation, increasing its plasticity. Most wrought magnesium alloys are suitable for stamping at 200°C to 400°C. In terms of cost performance, AZ31B magnesium alloy sheet is suitable for the production of stamping parts, and it has good plasticity when the temperature reaches a certain range. From the stress-strain curves of AZ31B thin plates at different temperatures studied by E. Doege, Zhang Xianh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com