Space-division system for highly effectively using cold energy of liquefied natural gas

A technology of liquefied natural gas and air separation system, which is applied in liquefaction, cold treatment separation, refrigeration and liquefaction, etc. It can solve problems such as the limitation of conversion efficiency of booster turbo expander, safety threat of main cooling equipment, leakage and pollution of liquid nitrogen products, etc. Achieve the effect of sharp reduction of explosion-proof measurement and control components, avoid irreversible loss, and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

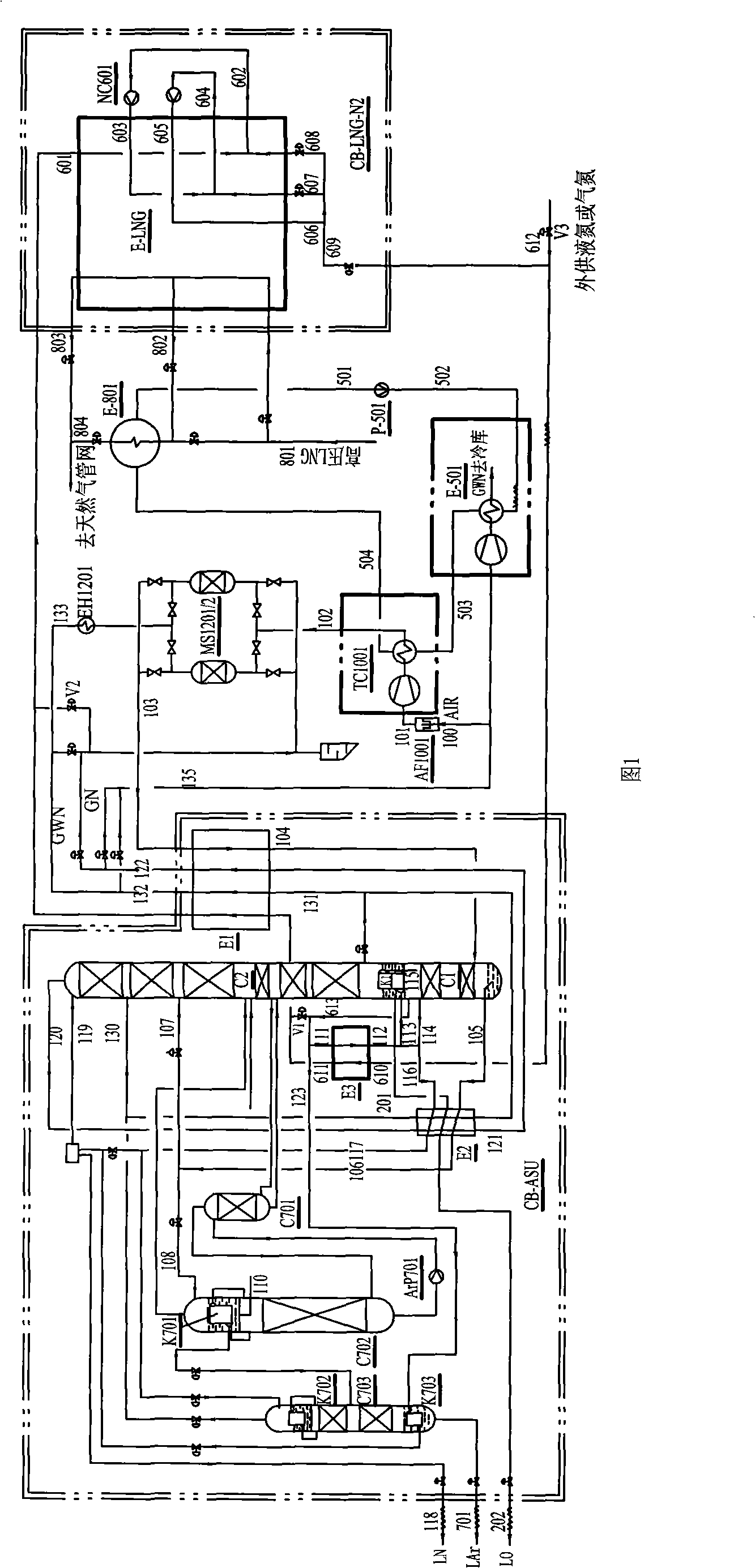

[0039] like figure 1 Shown is a typical device for producing liquid oxygen, liquid nitrogen, and liquid argon according to the present invention.

[0040] 1 air separation system

[0041] 1.1 Compression cooling and purification

[0042] The external air 100 is filtered by the air filter AF1001, and enters the air compressor TC1001 for compression and cooling, and the coolant is cooled by low-temperature circulating coolant.

[0043] The process air 102 enters the adsorber MS1201 / 2 which is used to absorb and remove moisture, carbon dioxide and some hydrocarbons, one absorbs, and the other is regenerated by heating the GWN dirty nitrogen gas 133 from the cold box through the heater EH1201 .

[0044] 1.2 Air distillation

[0045] The clean process air 103 (~460KPaG) exiting the air purification system enters the main heat exchanger E1 in the air separation cold box CB-ASU, is cooled by the gas that flows back out, and the air 104 close to the dew point enters the bottom of ...

Embodiment 2

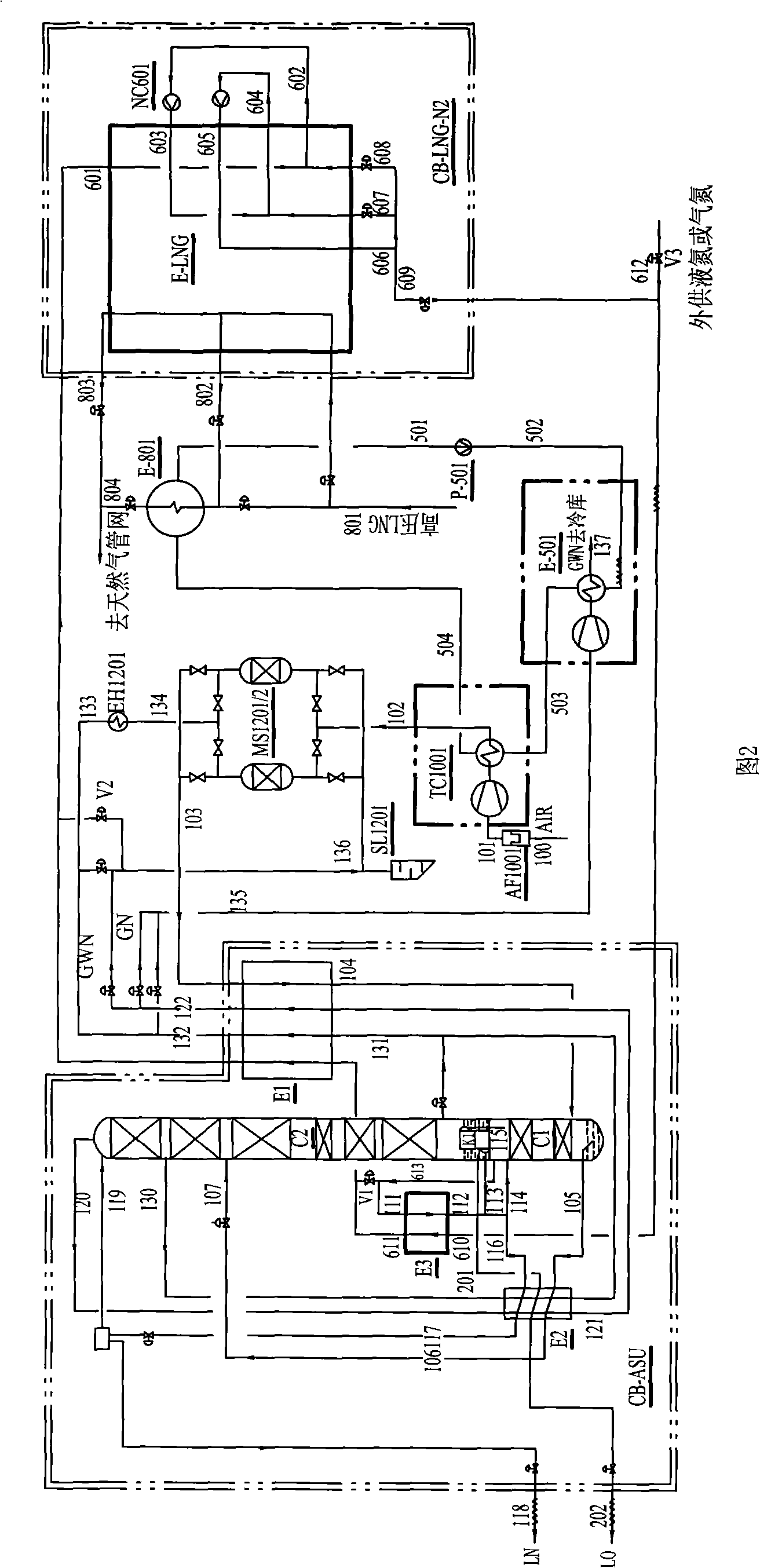

[0068] like figure 2 As shown, compared with Example 1, there is no argon production system, and the others are the same as Example 1. The obtained air separation products are liquid oxygen and liquid nitrogen.

Embodiment 3

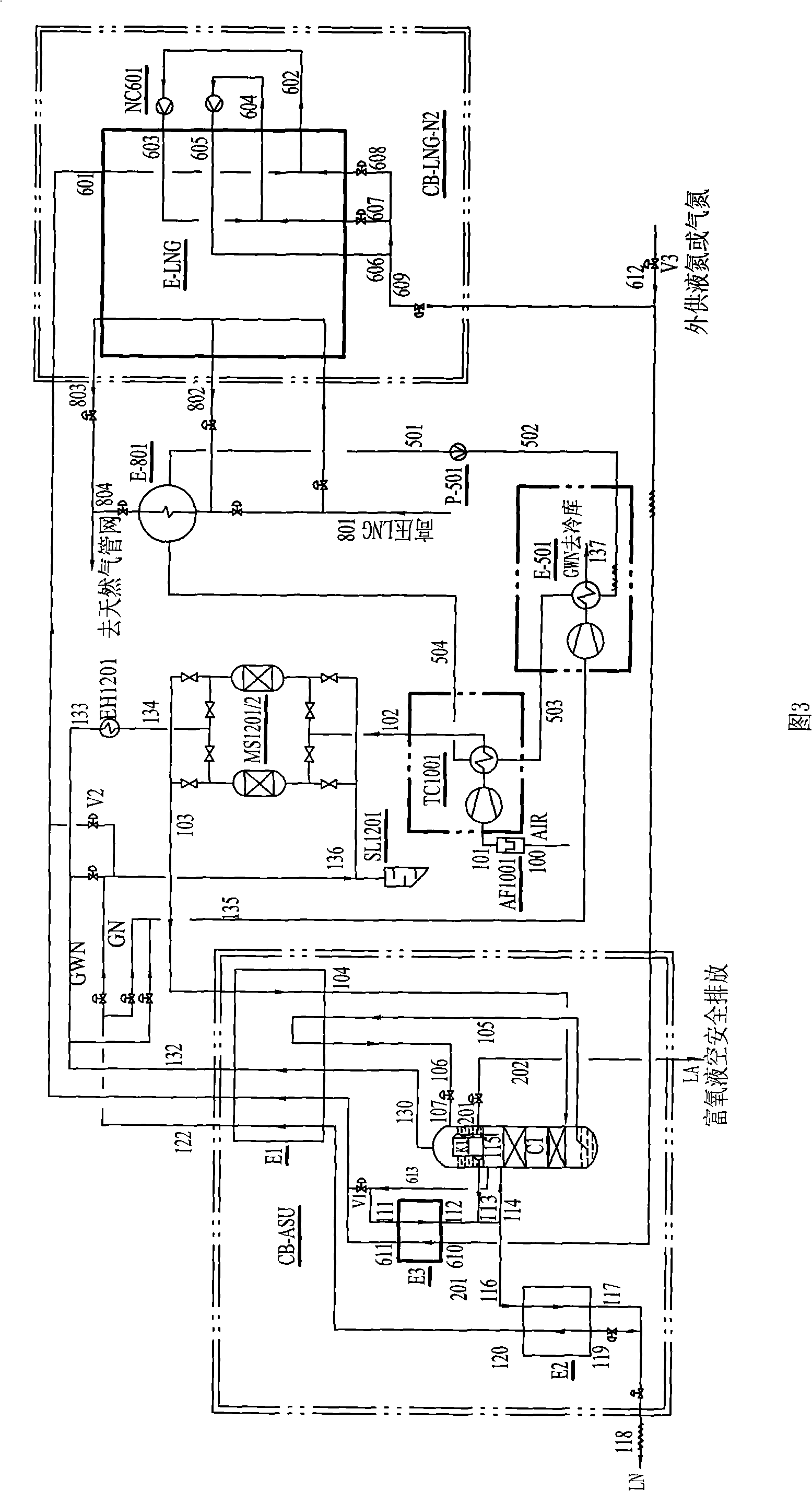

[0070] like image 3 As shown, compared with Example 1, the fractionation tower C1 is a single tower, and after the air enters the fractionation tower, the partial pressure gas nitrogen 111 obtained from the top of the fractionation tower enters the nitrogen-nitrogen heat exchanger E3 to condense into liquid nitrogen 112, and the natural gas nitrogen exchange The liquid nitrogen 610 from the hot and cold box CB-LNG-N2 is vaporized into gas nitrogen 611 (~180KPaG), and enters the main heat exchanger E1 to be reheated as circulating nitrogen 601 (~170KPaG); part of the pure nitrogen 115 enters the top of the fractionation tower The main condensation evaporator K1 is condensed into liquid nitrogen 113 . A part of liquid nitrogen 114 flows down as the reflux liquid of the lower tower, another part of liquid nitrogen 116 is supercooled by cooler E2, and part of it is extracted as product liquid nitrogen 118, and the rest of liquid nitrogen 119 is throttled and passed through cooler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com