Forging method for martensitic stainless steel pressure springs of nuclear power equipment reactor internals

A martensitic stainless steel, compression spring technology, applied in mechanical equipment, engine components, etc., can solve the problems of short forging time, narrow forging temperature range, and difficult forging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

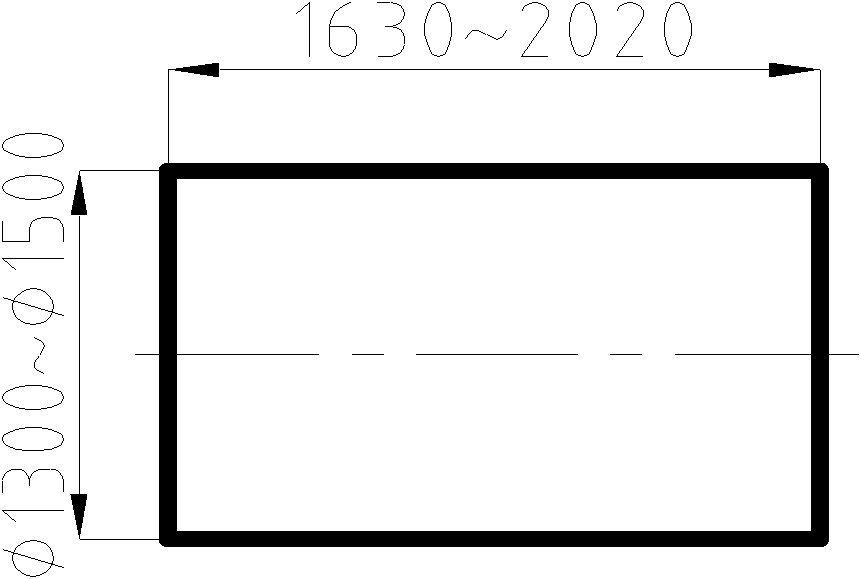

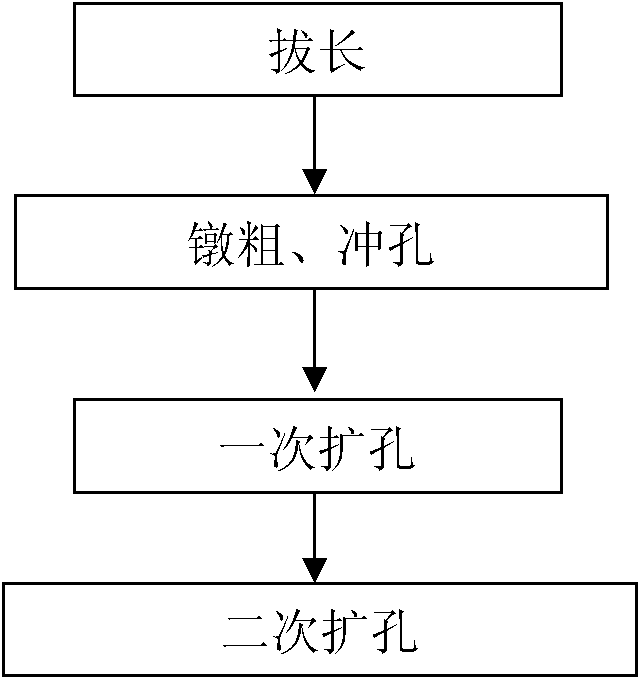

[0022] Such as image 3 Shown, the forging forming method of the martensitic stainless steel compression spring of nuclear power equipment internal component of the present invention, with as figure 1 The 17-21 tons of electroslag ingot shown is used as the raw material, the diameter of the electroslag ingot is Φ1300-1500mm, and the length is 1630-2020mm, including the following steps:

[0023] The first step is to elongate;

[0024] Heat the electroslag ingot to 1200±10°C and keep it warm; use a 28MN hydraulic press to elongate it to Φ1100mm; then cut off the bottom and riser, the cutting ratio is ≥3%; the forging ratio is ≥1.4;

[0025] The second step is upsetting and punching;

[0026] Return to the furnace and heat to 1200±10°C, keep warm; use a 165MN hydraulic press to upset the circular backing plate; then use a Φ650mm hollow punch to punch holes on the drain plate; forging ratio ≥ 4.3;

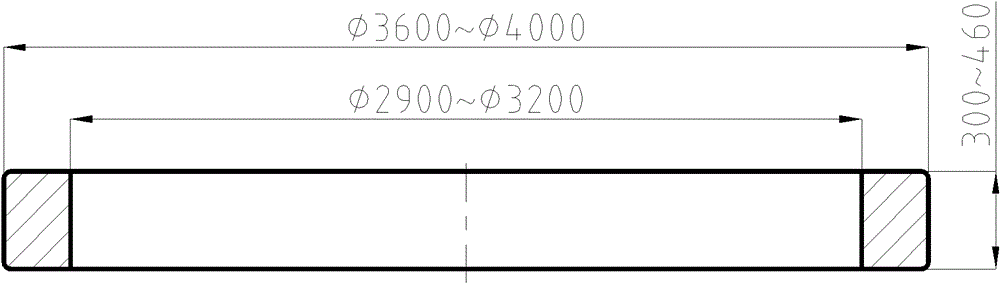

[0027] The third step is to ream the hole once; return to the furnace and heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com