Iron sealing glass powder slurry and preparation method thereof

A glass powder and slurry technology, which is applied to the configuration of iron-sealed glass powder water-based slurry system and the field of iron-sealed glass granulation powder, can solve the problems of undisclosed, unmentioned, and easily broken glass bodies, and achieves Good process performance, stable dispersibility, volatile removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

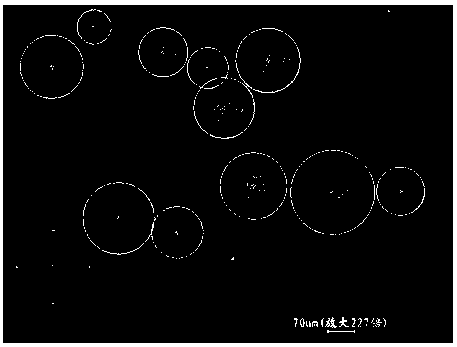

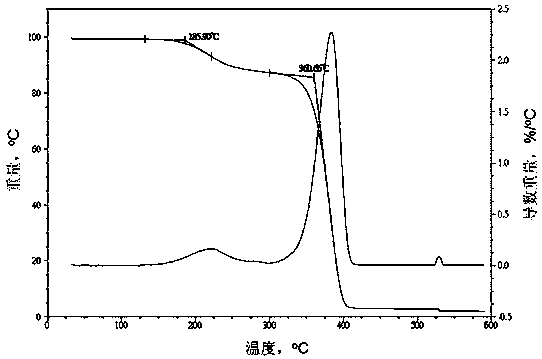

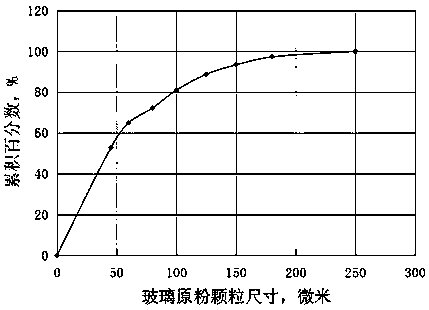

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0035] Mix deionized water, glass raw powder, binder, dispersant, release agent, defoamer, etc. according to the following mass percentages, that is, deionized water 30%-60%, glass raw powder 34%-65%, viscose Binder 0.25%-5%, dispersant 0.05%-1%, release agent 0.01%-1%, defoamer 0.001%-0.025%. n-octanol (C 8 h 18 O), stearic acid for demoulding machine (CH 3 (CH 2 ) 16 COOH), carboxymethyl cellulose (CMC for short; molecular weight 240.2078 ) for dispersant, polyethylene glycol (HO(CH 2 CH 2 O) n H, the molecular weight is 4000).

[0036] Glass slurry preparation process of the present invention:

[0037] Step 1: Mix the ball-milled and sieved glass raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com