Thermal treatment method of wide and thick plate supporting roll

A heat treatment method and technology for supporting rollers, which are applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low production efficiency and high production costs, and achieve the effects of improving service life, saving production costs, and reducing heat treatment risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

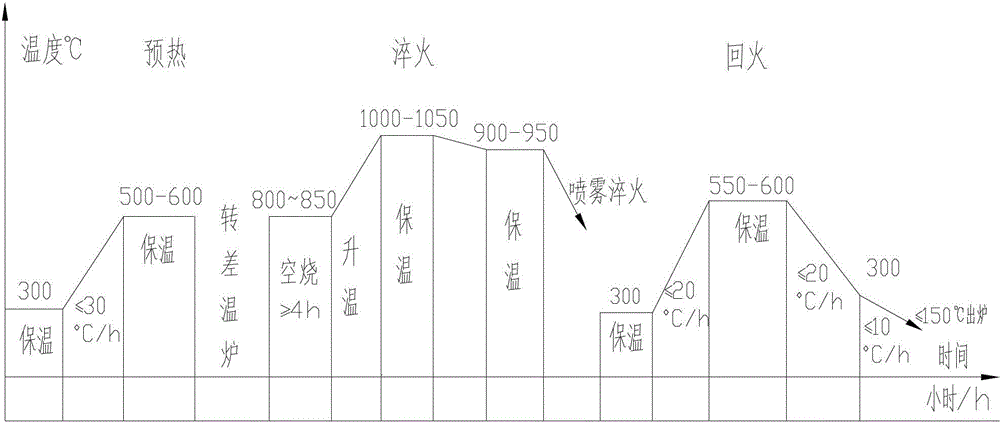

[0032] like figure 1 As shown, the heat treatment method of the wide and thick plate back-up roll of the present invention is used to heat-treat the surface of the back-up roll workpiece with a roll body length of 3500-4300 mm, comprising the following steps:

[0033] The first step is to warm up;

[0034] Keep the workpiece at a temperature of 300±10°C for 10-20 hours, then preheat the workpiece to 500-600°C at a heating rate of ≤30°C / h, and keep it warm. The holding time is ≥35 hours, so that the internal and external temperatures of the workpiece are uniform ;

[0035] The back-up roll workpiece must be preheated as a whole before rapid heating, so as to reduce the phenomenon of excessive internal and external stress of the roller body caused by subsequent rapid heating and cracking, and at the same time ensure the heating speed of differential temperature heating; the preheating temperature is 500~ 600°C is appropriate, and the preheating time should be able to ensure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com