Composite fixture

A fixture and fixture technology, which is applied in the field of material processing, can solve problems that affect the manufacturing process level of railway vehicles and castings that cannot meet the quality requirements, and achieve the effects of improving the manufacturing process level, avoiding bumps, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

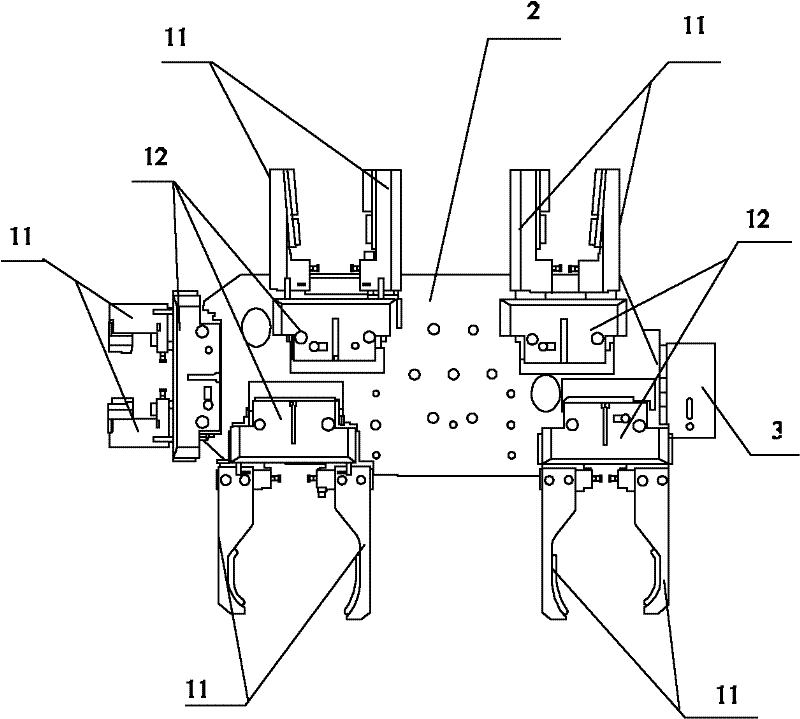

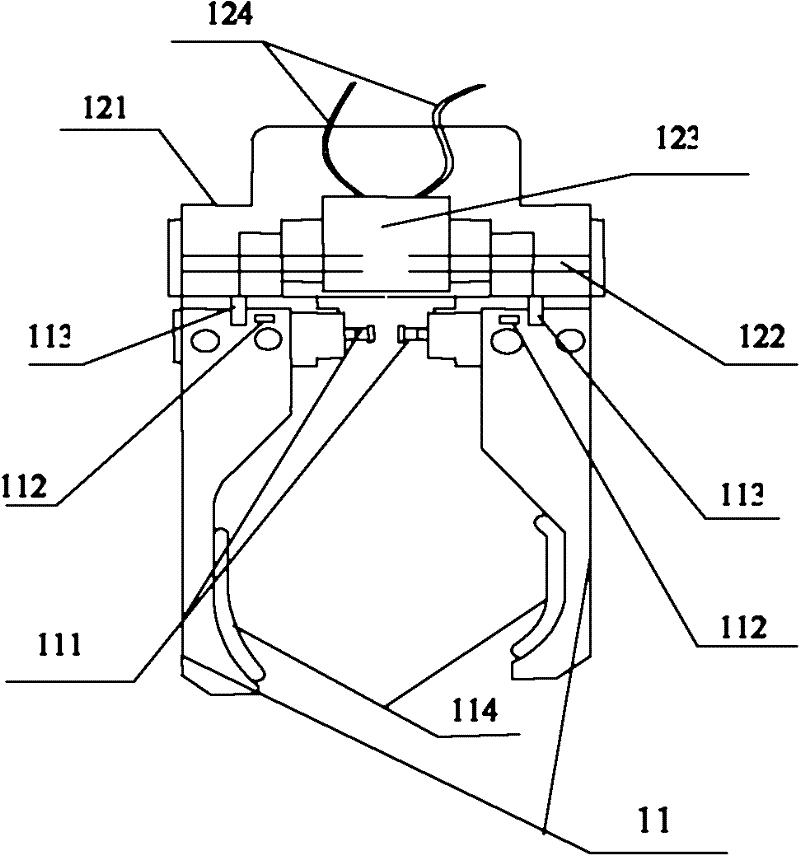

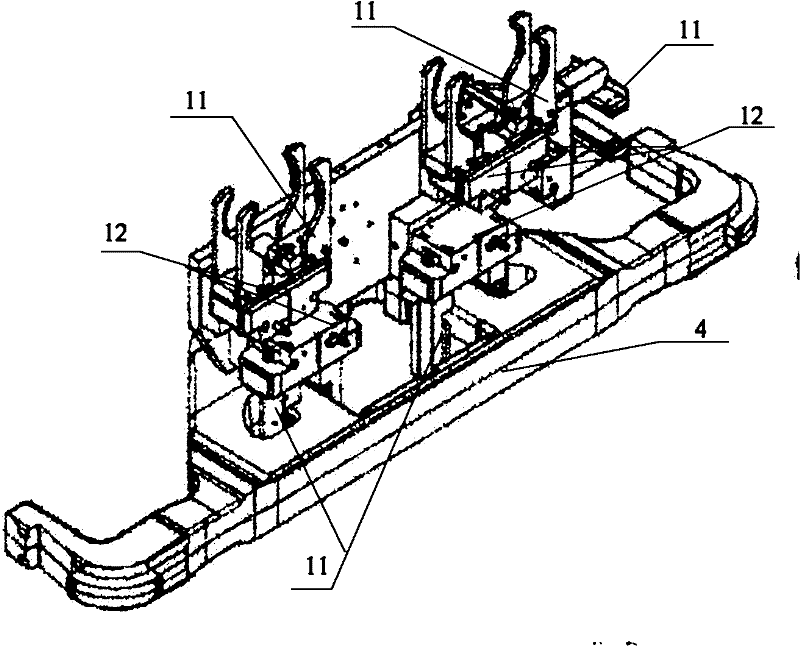

[0022] figure 1 It is a structural front view of an embodiment of a composite fixture of the present invention. figure 2 It is an enlarged view of a clamping tool in an embodiment of a compound clamp of the present invention. Please also refer to figure 1 and figure 2 , The composite clamp of the present invention includes: a vertical plate-shaped clamp body 2 and at least one clamping tool. The clamping tool consists of two clamping claws 11 and a cylinder driving system 12 arranged at the tail ends of the two clamping claws. The cylinder driving system 12 includes a box body 121 and a cylinder 123 arranged inside it, and the piston rod of the cylinder 123 is connected to the The clamping jaws 11 are connected. In this embodiment, the cylinder 123 is a double-piston cylinder, and its two pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com