Laser cutting machine

A laser cutting machine and laser head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of long focal length, plate thickness limitation, and inconvenient feeding process of cutting machine, etc., to achieve efficient and accurate feeding process, The effect of slowing down the fit error and improving the cutting working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

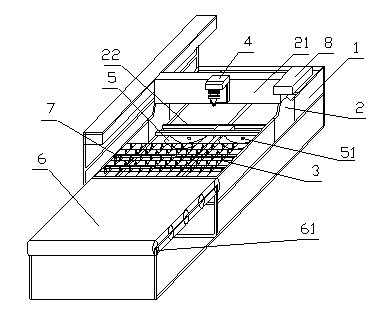

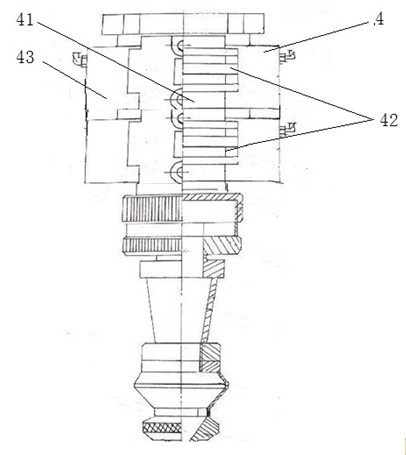

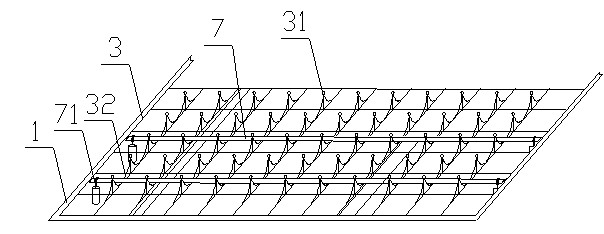

[0017] combine figure 1 , figure 2 as well as image 3 , the laser cutting machine includes a bed frame 1, a transverse support 2, a mesh plate 3 and a laser head 4, the transverse support 2 is slidably arranged on the bed frame 1, and the laser head 4 is placed on the beam 21 in the middle of the upper end of the transverse support 2. The plate 3 is placed in the working part of the middle of the bed frame 1, the grid nodes 31 of the screen plate 3 are raised, and a valley 32 is formed between the adjacent nodes of the grid. The laser cutting machine also includes a vacuum hopper 5, a feeding Roller mechanism 6, a number of driving rollers 7, the driving roller 7 is arranged above the screen plate 3 of the bed frame and corresponds to the feeding roller mechanism 6, and the two ends of the driving roller 7 are respectively connected with the pneumatic (or hydraulic) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com