Visualization debugging device for gantry machine tool

A technology for gantry machine tools and machine tools, applied in feeding devices, automatic control devices, metal processing machinery parts, etc., can solve the problems of prolonged preparation time for workpiece processing, increased labor costs, and low efficiency, so as to eliminate the influence of human factors and improve the efficiency of The effect of knife accuracy and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

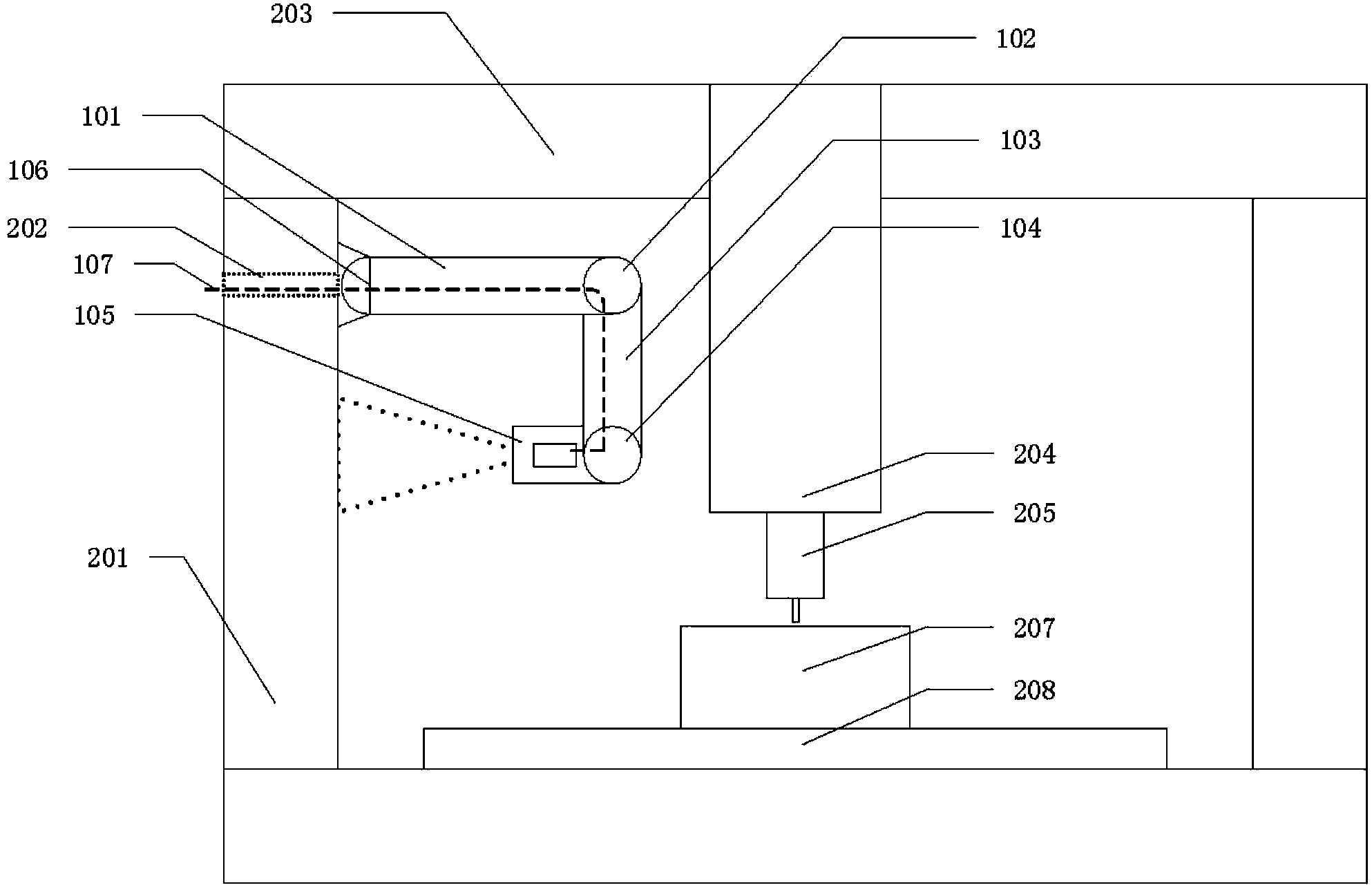

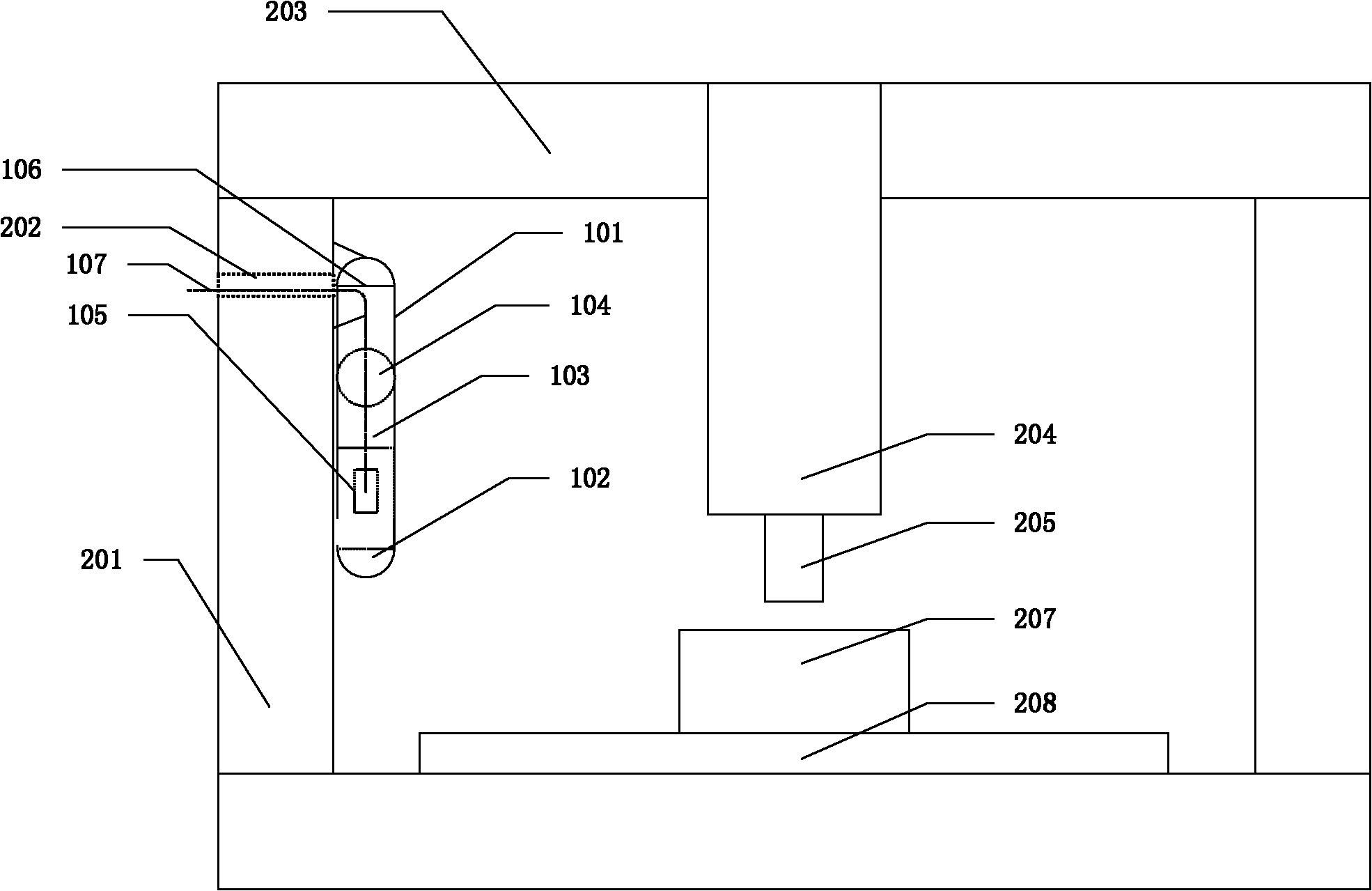

[0010] The visual debugging device of the present invention is installed on the column 201 of the machine tool to be debugged, and can be extended and contracted, which is convenient for debugging and does not affect the work of the machine tool. Such as Figure 1-2 As shown, the main frame of the gantry machine tool includes a crossbeam 203. The two ends of the crossbeam 203 are provided with uprights 201. The headstock 204 is installed longitudinally in the middle of the crossbeam. The spindle head 205 of the headstock extends from its lower end and works directly below it. Workpiece 207 on stage 208. A visual debugging device for a gantry machine tool of the present invention includes an outer cover 101, one end of the outer cover 101 is hingedly fixed to the inner side of a column 201 on one side of the machine tool through a first hinge 106, and the other end of the outer cover 101 One end of the inner bracket 103 is hinged and fixed together through the second hinge 102,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com