Automatic loading and unloading device of tire building machine

A technology of automatic loading and unloading and tire building machines, which is applied to tires, other household appliances, household appliances, etc., can solve problems such as rough and heavy appearance, lower production efficiency, and long downtime, and achieve light and beautiful structure, improve efficiency, and automate The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

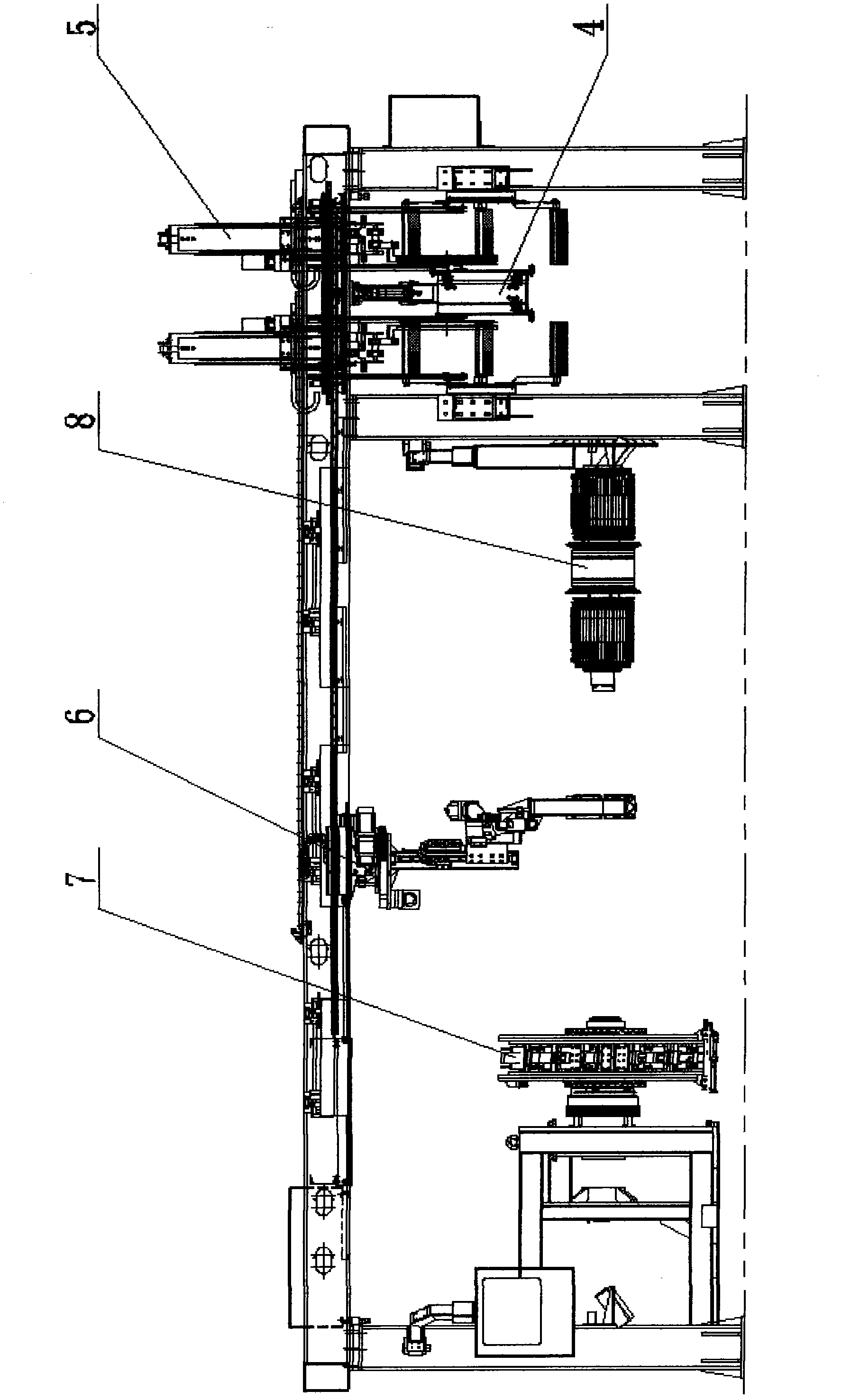

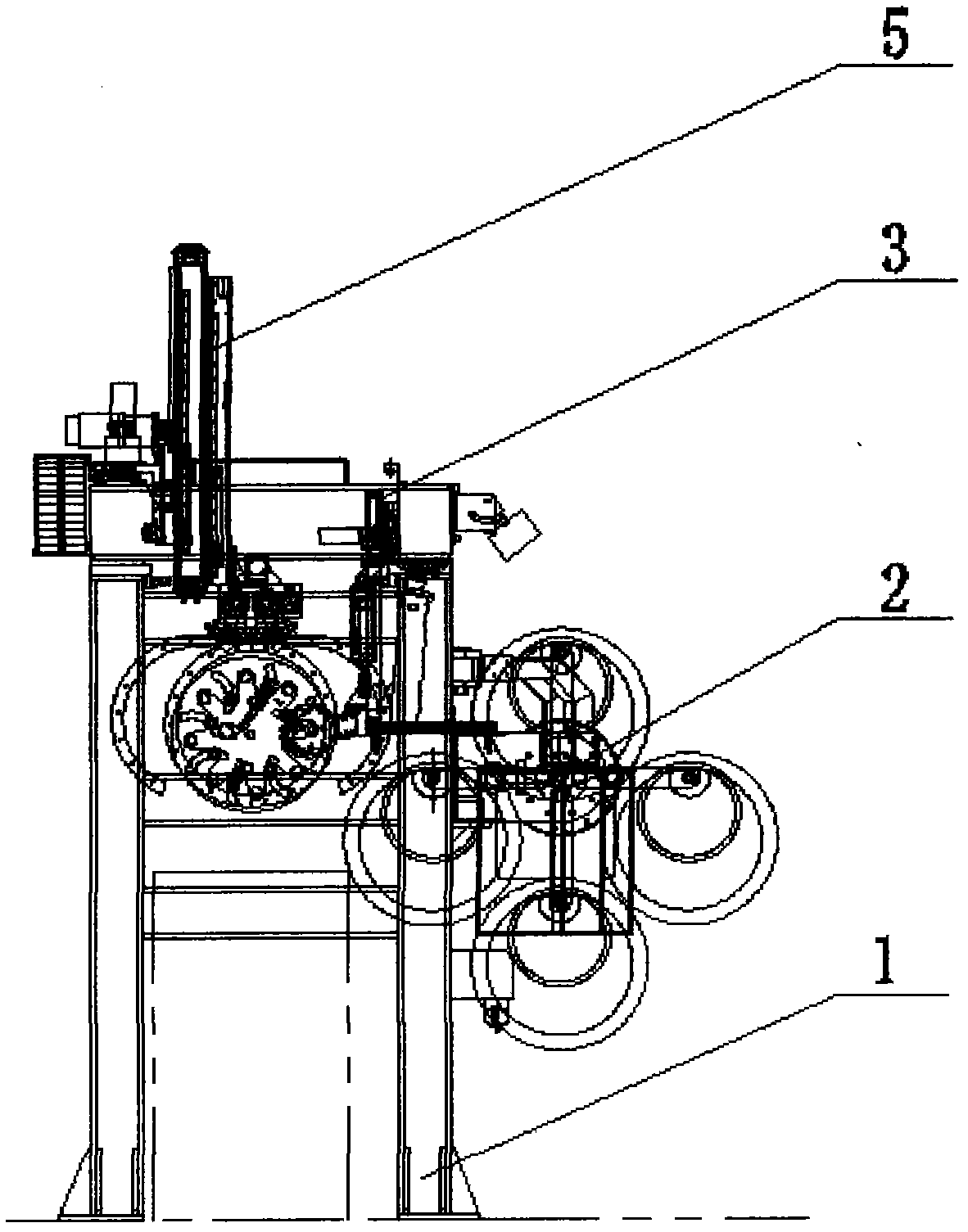

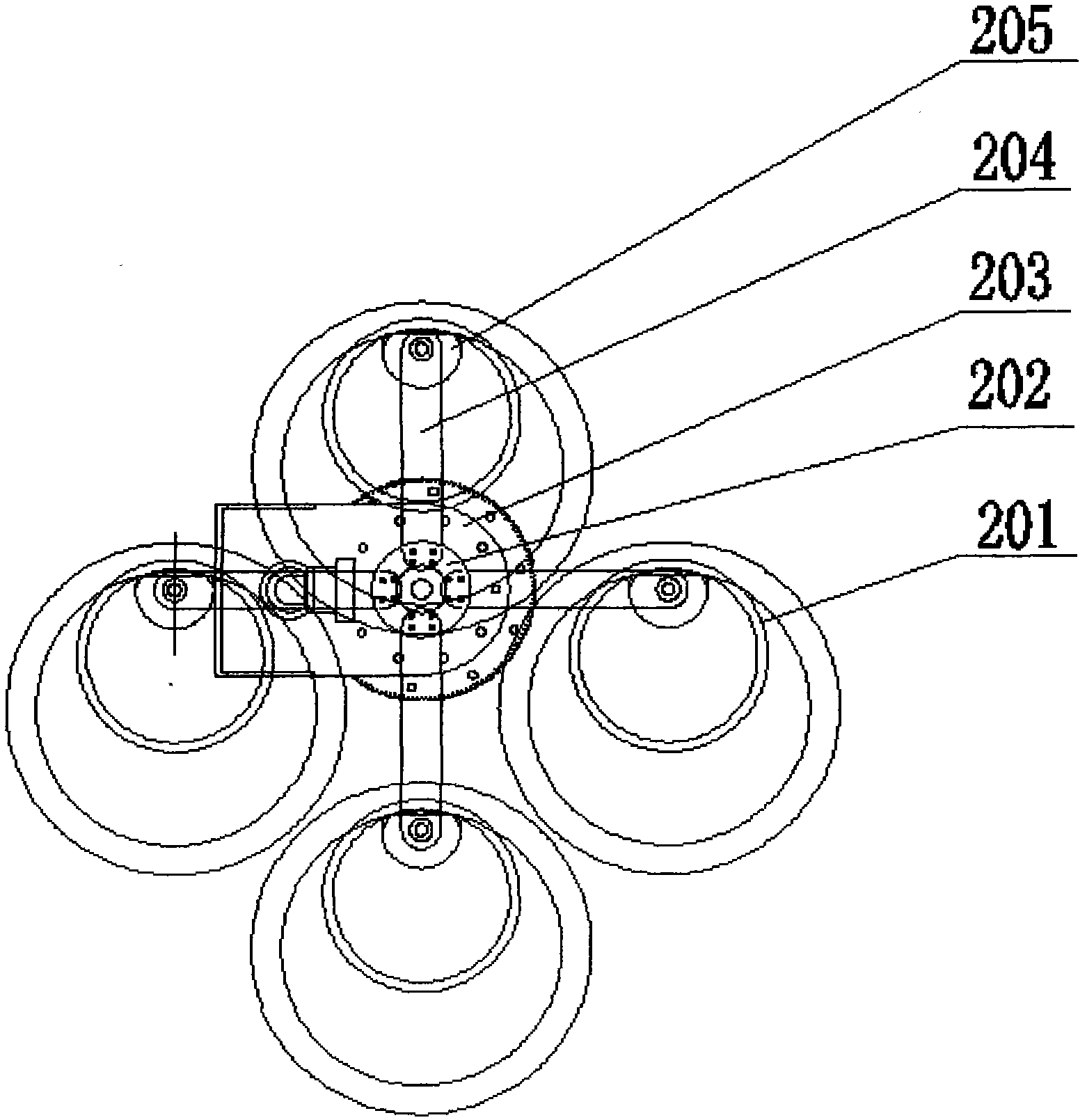

[0029] figure 1 with figure 2 It is an automatic loading and unloading device for a tire building machine, including a frame 1, a bead upper mechanism 2, a bead-removing manipulator 3, a bead holder 4, a bead-absorbing manipulator 5, and a tire-removing manipulator 6. During use, the frame is combined with the tire building machine so that the above-mentioned various manipulators are positioned above the forming drum 7 and the forming equipment 8 of the tire building machine.

[0030] The action flow of this embodiment is as follows:

[0031] The bead upper mechanism 2 realizes the upper position of the bead circulation—bead-taking manipulator 3 takes 2 beads and places them on the bead holder—the bead holder 4 spreads the 2 beads—bead suction manipulator 5 sucks 2 tire beads and put them on the building drum 7 - 1 tire is formed - take the tire manipulator 6 to take off the tire and send it out

[0032] Frame 1 is by front beam, rear beam. The two sides are composed of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com