Automatic deviation correcting device used for flexible film conveying

An automatic deviation correction device and flexible film technology, applied in transportation and packaging, thin material handling, winding strips, etc., can solve the problems of short contact length, poor openness, and inability to automatically correct deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described now in conjunction with the preferred implementation examples of the accompanying drawings.

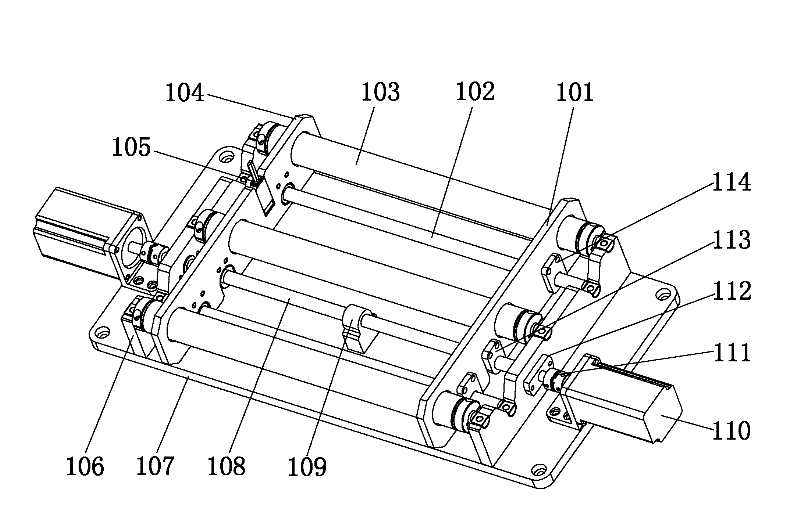

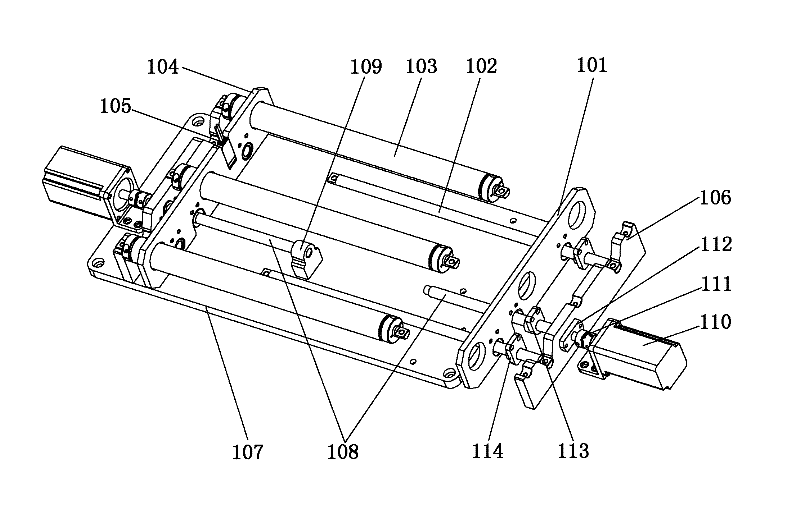

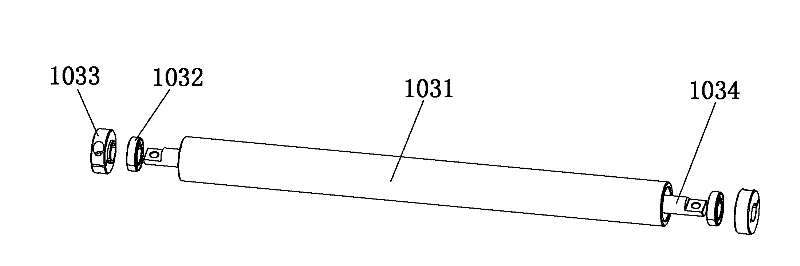

[0021] see figure 1 and figure 2 , a preferred embodiment of the present invention includes a support assembly, a deviation correction assembly, a drive assembly and a film guide assembly, wherein the support assembly is composed of a bottom plate 107 and two brackets 106, and the deviation correction assembly is composed of two guide rods 102, a first deviation correction plate 101, a second deviation correction Two rectifying plates 104, four guiding flanges 114 and a distance measuring sensor 105 are formed, and the driving assembly is composed of two motors 110, two shaft couplings 111, two flange bearings 112, two screw nuts 113, two screw rods 108 and screw rod supports Seat 109 forms, and guide assembly is made up of three sets of row rollers 103.

[0022] The support assembly completes the installation of the deviation correction de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com