Process and device for treating sewage through denitrification and dephosphorization by anaerobic-anoxic-oxic-anoxic (AAOA) plus membrane bioreactor (MBR) process

A sewage treatment, nitrogen and phosphorus removal technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Waste the energy consumption of blast aeration and other issues, and achieve the effect of improving the utilization rate of carbon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

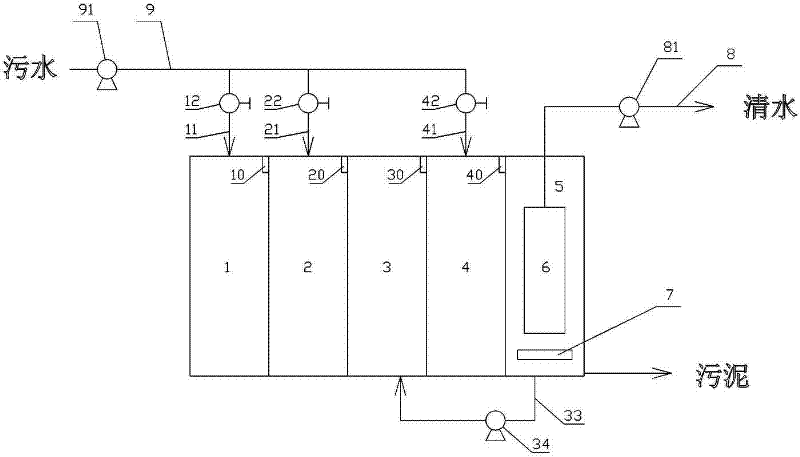

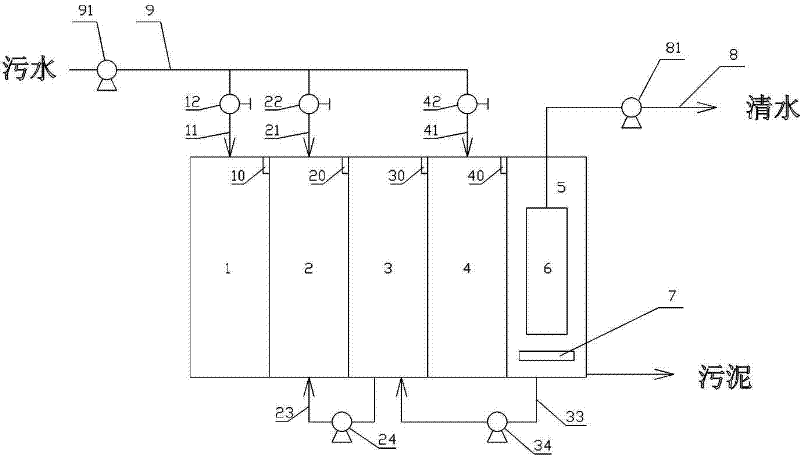

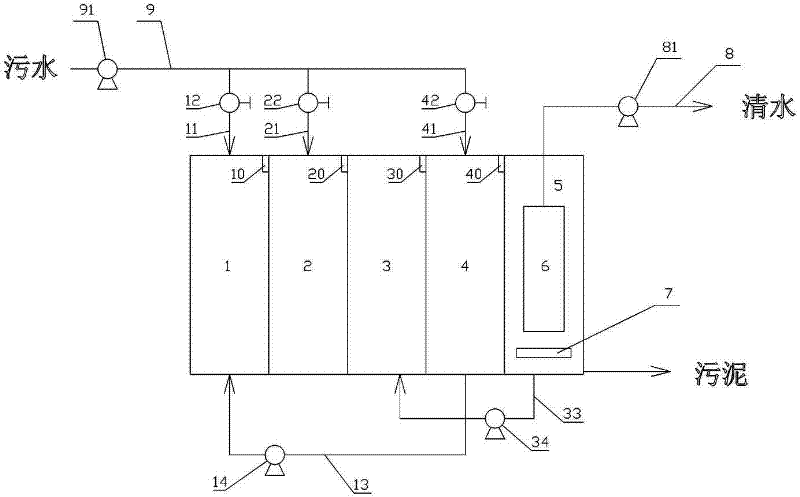

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] refer to figure 1 , figure 2 , image 3 and Figure 4 , a kind of AAOA+MBR denitrification and dephosphorization sewage treatment process and device provided by the present invention, comprising anaerobic pool 1, anoxic pool 2, aerobic pool 3, rear anoxic pool 4 and MBR membrane pool connected in sequence 5. The anaerobic pool 1 and the anoxic pool 2 are connected by the first water delivery port 10, the anoxic pool 2 and the aerobic pool 3 are connected by the second water delivery port 20, and the aerobic pool 3 and the anoxic pool 4 are connected by the second water delivery port. The three water delivery ports 30 are connected, and the rear anoxic tank 4 and the MBR membrane tank 5 are connected by the fourth water delivery port 40. The MBR membrane tank 5 is provided with an MBR membrane module 6 and an aeration device 7, and the water outlet of the MBR memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com