Preparation method of in-situ vertically grown titanium dioxide nanosheet film

A vertical growth, titanium dioxide technology, applied in the field of nanomaterials science, can solve the problems of lack of large-area uniformity of film thickness, difficulty in fixing nano-catalysts, and low bonding strength between film and substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

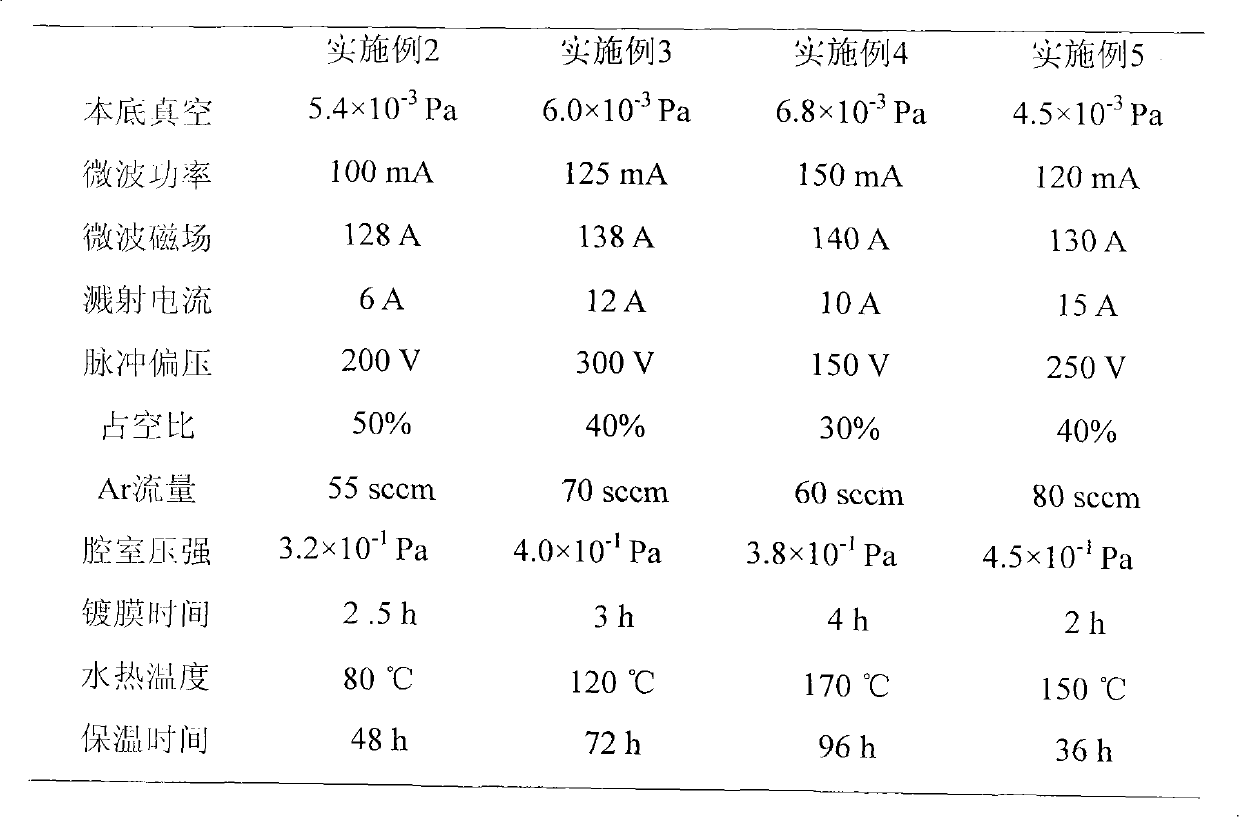

Examples

Embodiment 1

[0015] Cleaning: The substrate (glass sheet, silicon wafer or stainless steel sheet) is ultrasonically cleaned with acetone, absolute ethanol, and double-distilled water in sequence, each ultrasonic time is 15 minutes, and dried for later use.

[0016] Sample placement: place the cleaned substrate on the sample holder in the coating device.

[0017] Vacuuming the background: vacuuming the background to 4.0×10 -3 Pa.

[0018] Plasma cleaning the surface of the sample: turn on the microwave magnetic field, adjust the magnetic field current to 140A, turn on the microwave power supply, adjust the microwave power to 150mA, pass Ar gas into the reaction chamber, 65sccm, make the chamber pressure ~0.4Pa, start the turntable , turn on the pulse bias power supply, adjust the bias value to 200V, and the duty cycle to 50%. Generate plasma to clean the sample surface for 20 min.

[0019] Sputtering coating: reduce the Ar gas flow rate to 85 sccm. Microwave power 150mA. Turn on the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com