Full-automatic vacuum glass making equipment and process

A technology of vacuum glass and manufacturing process, which is applied in the field of glass product processing, and can solve problems such as incomplete pumping, vacuum degree not reaching the established standard, and vacuum failure, etc., and achieves suitable for large-scale industrial production, excellent vacuum degree and sealing performance, speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

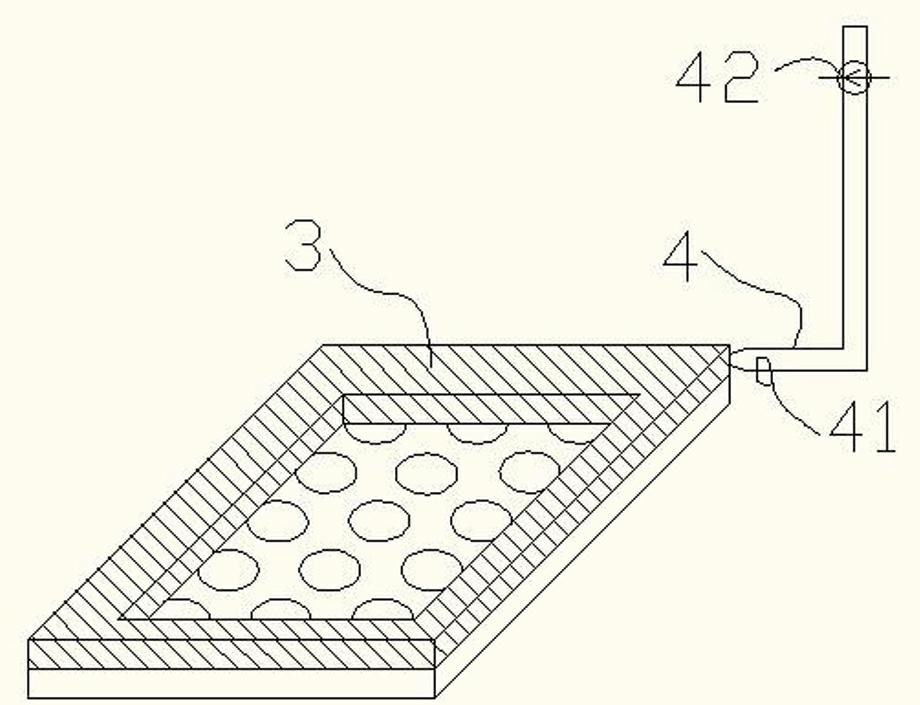

[0059] In order to clarify the technical scheme, technical features and technical effects of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

[0060] Such as Figure 1-Figure 6As shown, a vacuum glass manufacturing process specifically includes the following steps:

[0061] Step S1: Prepare two glass substrates 1;

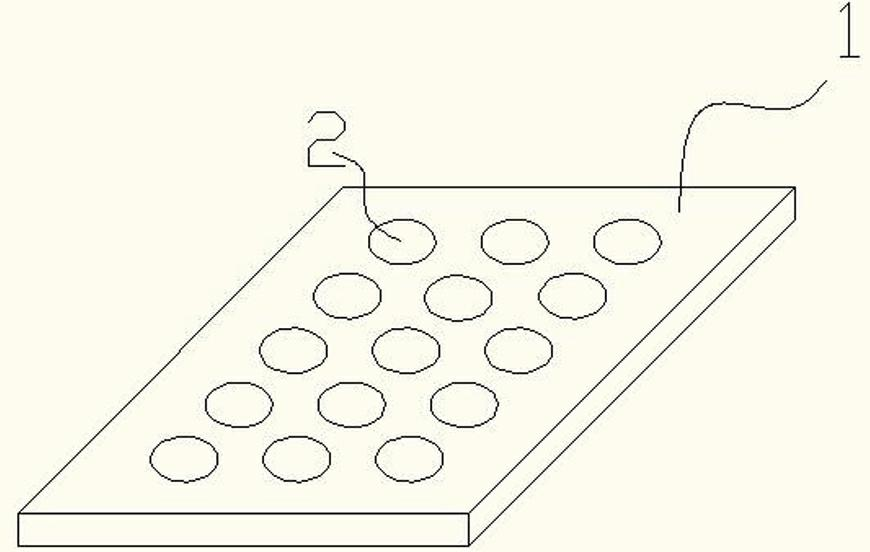

[0062] Step S2: Grab a number of supports 2 by the robot, and evenly arrange them on the upper glass surface of a glass substrate 1, so as to maintain the spacing of the vacuum chamber between the two glass substrates 1;

[0063] Step S3: In order to improve the production efficiency of the product, the position of the glass substrate 1 can be determined by setting an automatic positioning device on the conveying line. Through the setting of the program, the head of the glue gun can be automatically aligned with the position of the glass substrate 1 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com