Method for efficiently producing pro-TGase through fermentation

A technology for producing transglutaminase enzymes and strains is applied in the field of high-efficiency fermentation and production of transglutaminase proenzymes, which can solve problems such as low secretion of transglutaminase proenzymes, and achieve good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

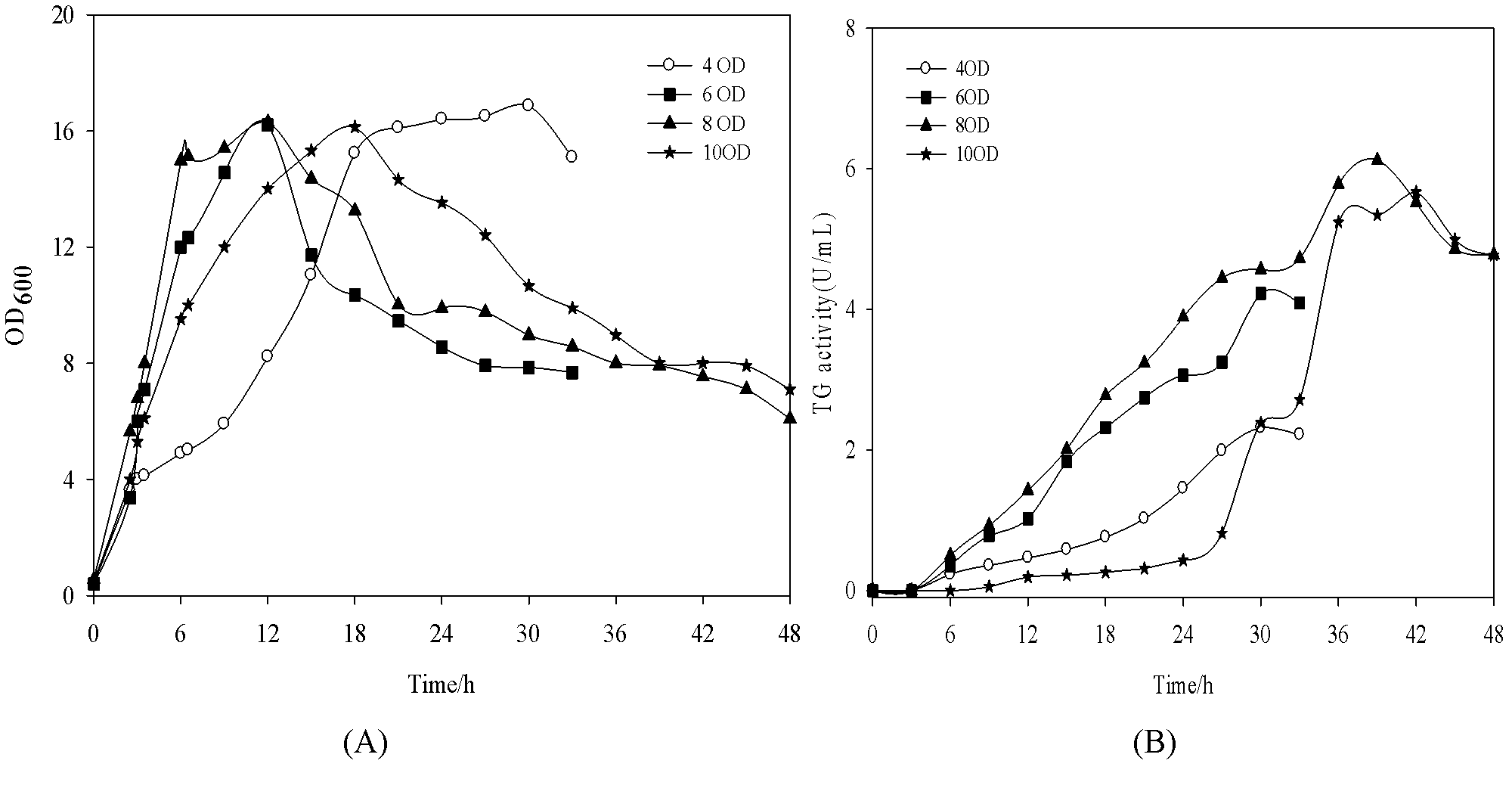

[0017] The logarithmic growth phase controls the temperature at 37°C, when the bacteria grow to OD 600 At 4, 6, 8, and 10 o'clock respectively, the temperature was lowered to 20°C and IPTG with a final concentration of 0.4mM was added to promote the high-efficiency expression of pro-TGase. Until the end of fermentation, the induced OD 600 =8, the highest enzyme activity was 6.22U / mL, and the production intensity was 0.16U / mL / h ( figure 1 ).

Embodiment 2

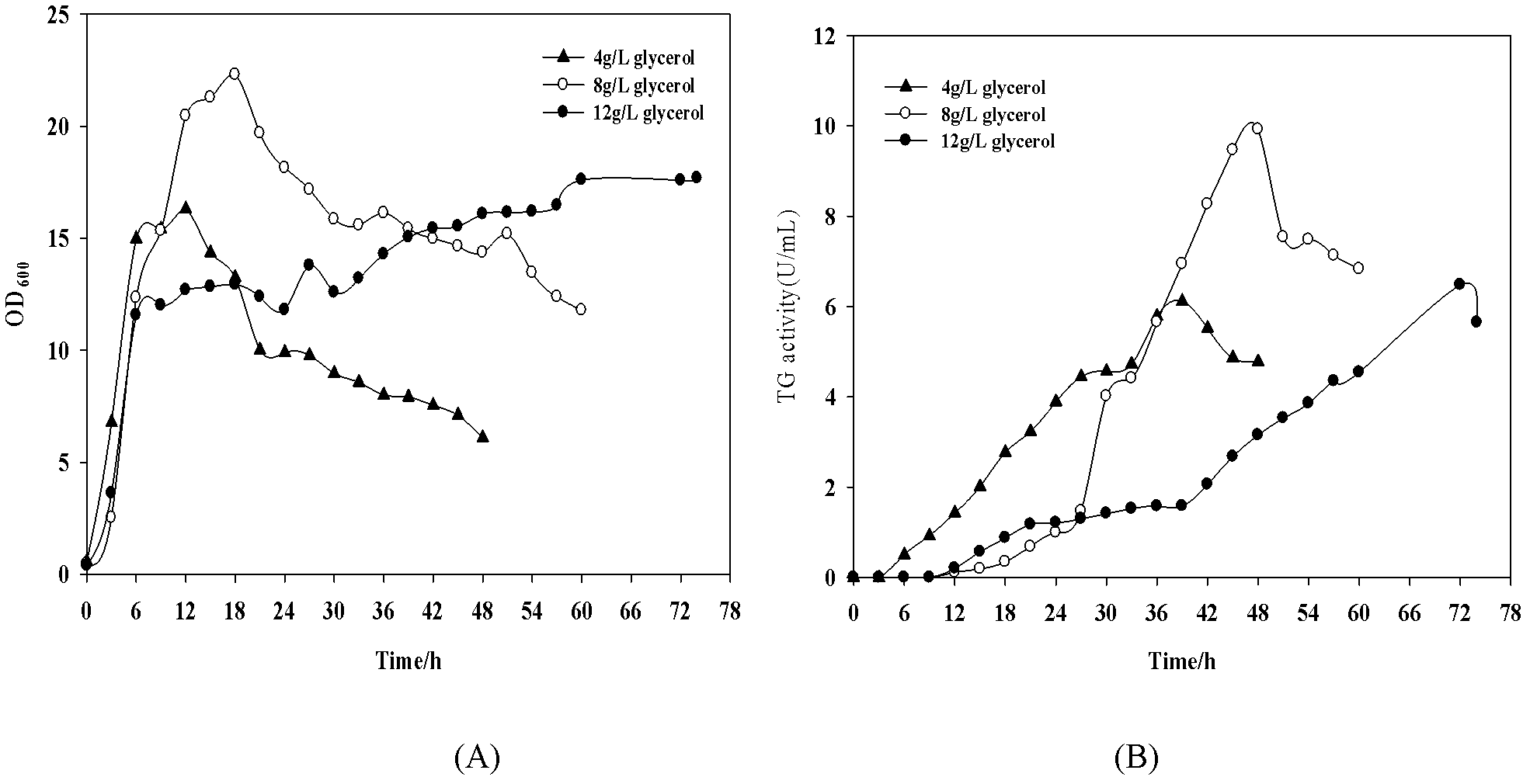

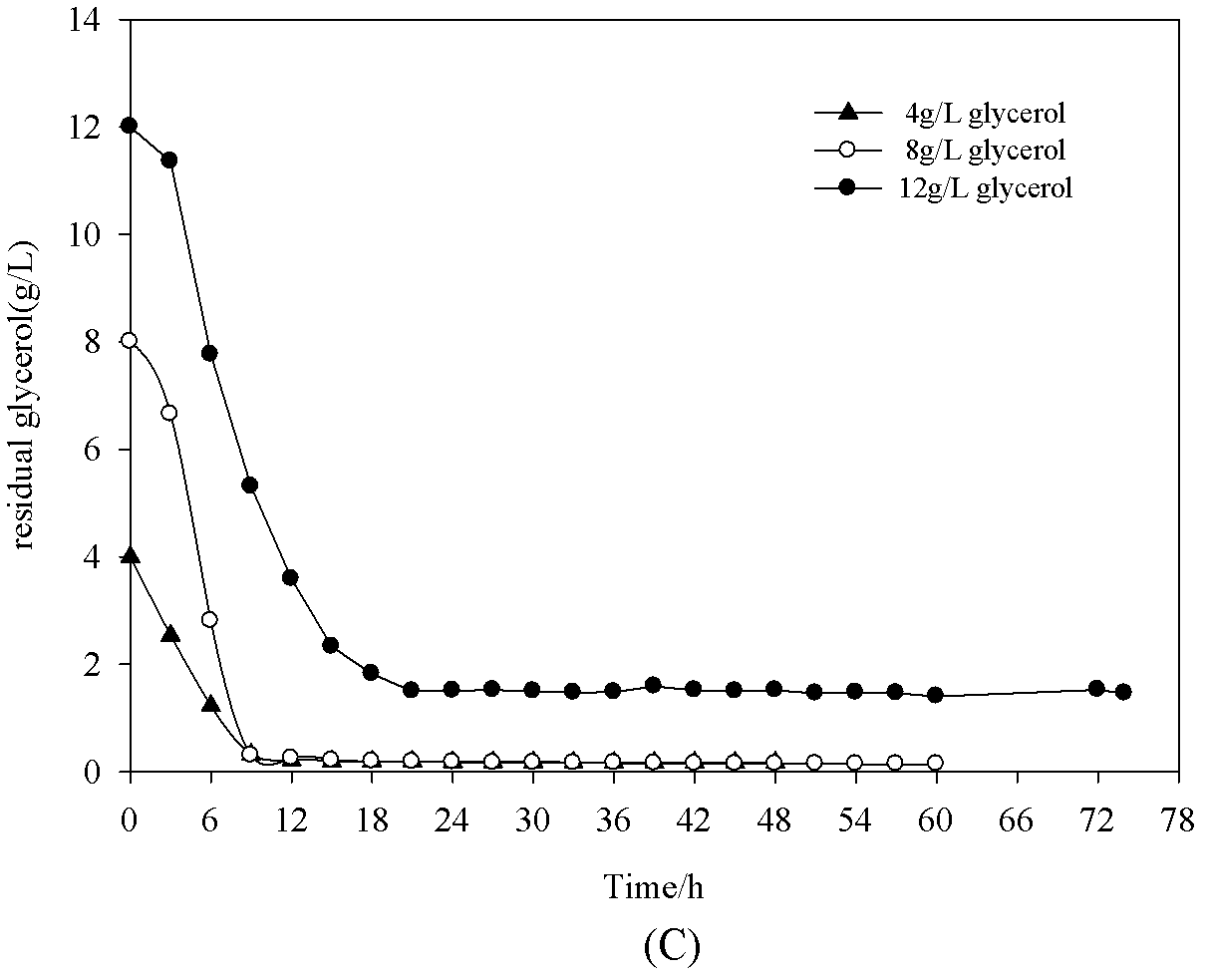

[0019] Change the initial glycerol concentration to 4g / L, 8g / L and 12g / L respectively, at OD 600 = Induction at 8 hours. Culture condition is the same as example 1, until fermentation finishes ( figure 2 ). When the initial glycerol concentration was 8g / L, the highest enzyme activity was 9.92U / mL, and the production intensity was 021U / mL / h, which was 31.25% higher than the previous production intensity ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com