Washing and drying unit with function of adjusting heat pump load and drying control method for washing and drying unit

An all-in-one machine and heat pump technology, which is applied to household clothes dryers, washing devices, household appliances, etc., can solve the problems of high failure rate of compressor motors and reduced service life, so as to reduce drying time, improve service life, reduce The effect of drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

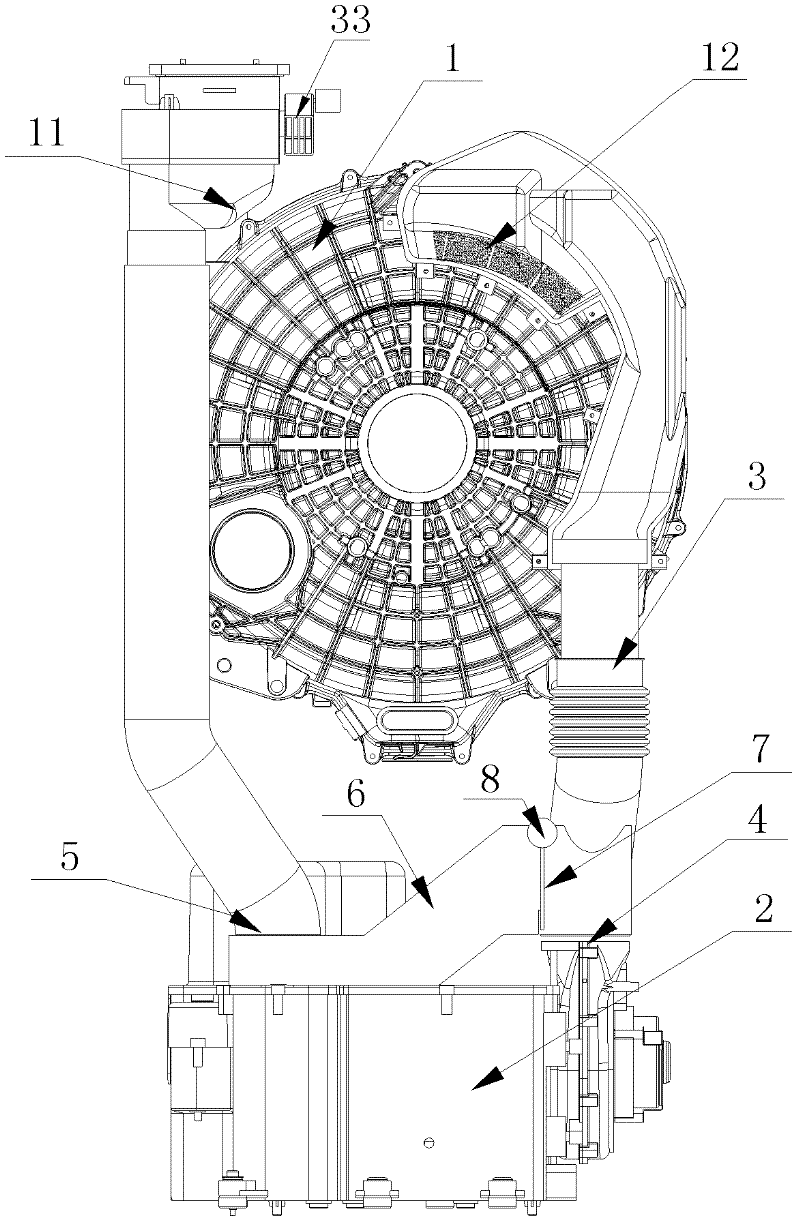

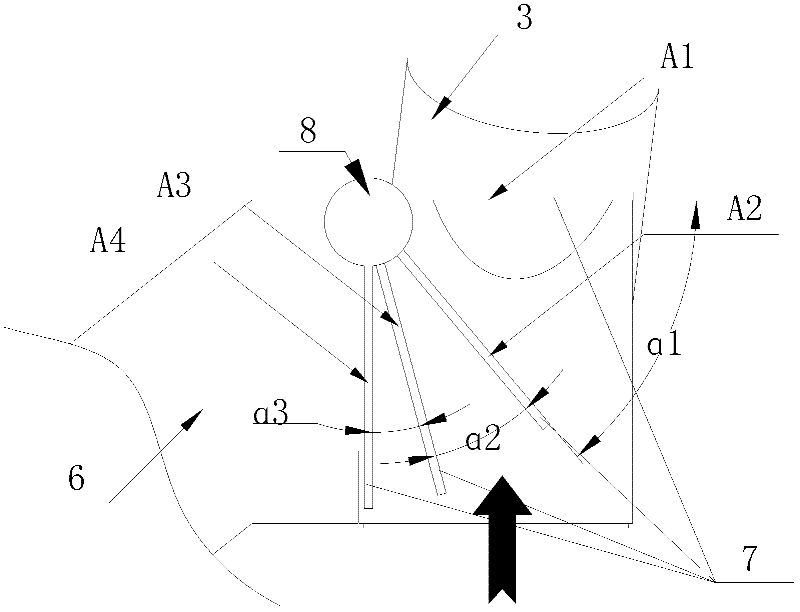

[0056] Such as Figure 1 to Figure 10 As shown, the heat pump washing and drying machine according to the present invention includes a drum 1, a heat pump module 2 and a clothes drying duct 3 connecting the drum 1 and the heat pump module 2, and also includes a heat pump outlet 4 connected to the heat pump module 2 and a heat pump The air inlet 5 is used to heat the low-temperature auxiliary air duct 6 of the working environment of the evaporator, and the air duct switching mechanism that controls the connection between the heat pump air outlet 4 and the drying air duct and / or the low-temperature auxiliary air duct 6, and the drum air outlet 11 and the heat pump module 2 A bypass air passage 33 communicating with the outside is provided on the clothes drying air passage 3 between them.

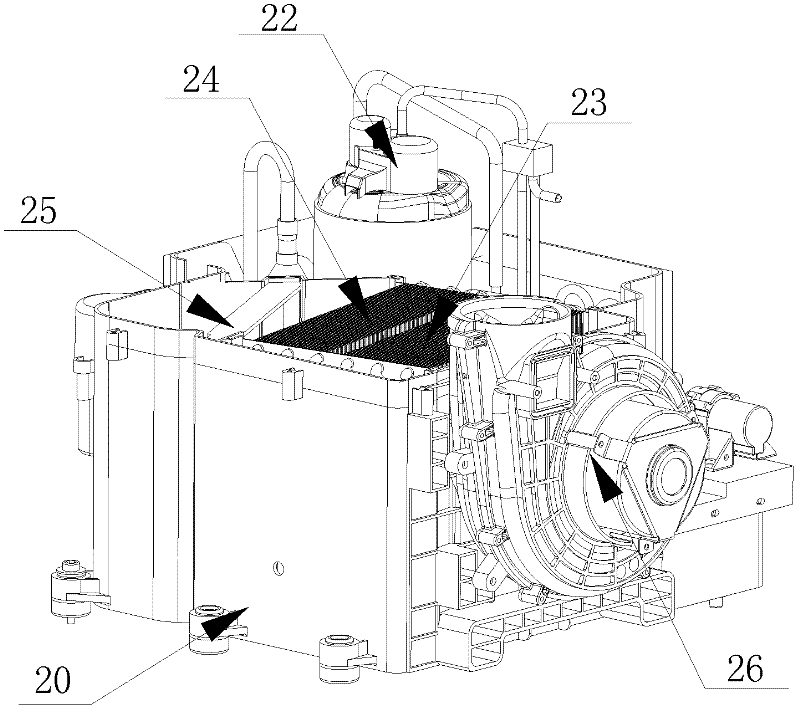

[0057] Such as figure 2 As shown, the heat pump module 2 includes a lower base 20, a heat pump system integrated on the base, and an upper cover 21 cooperating with the base to cover the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com