Dyeing technology without sewage discharging for jean

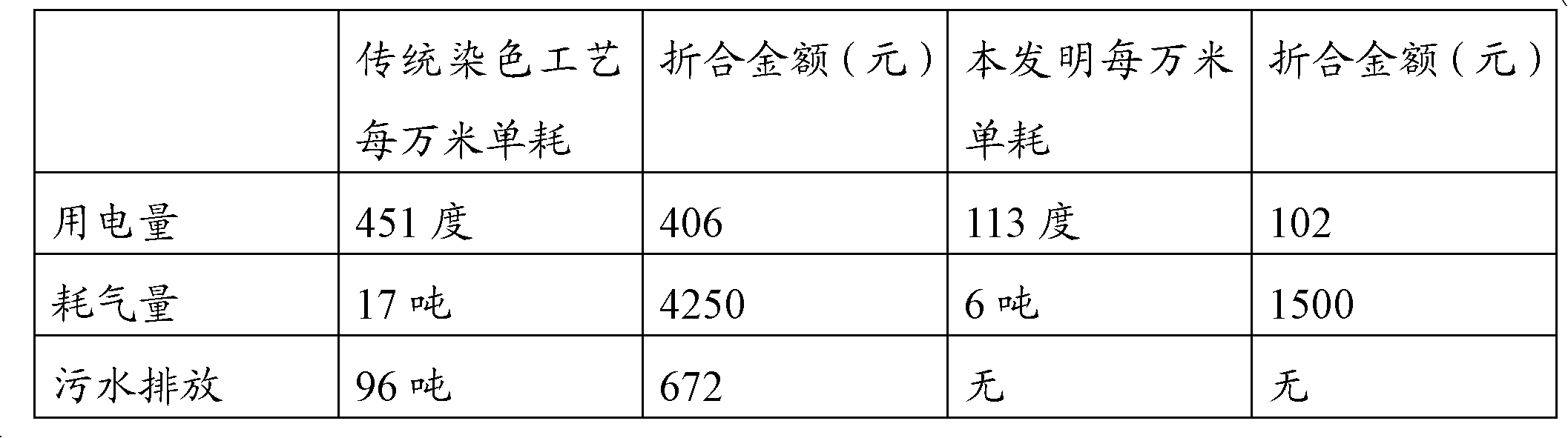

A technology for sewage discharge and denim, which is applied in the field of cloth dyeing, can solve the problems that cannot meet the requirements of environmental protection and competitiveness, large quantities, sewage, etc., and achieve significant social and economic benefits, simple equipment, and energy saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of non-sewage discharge dyeing process for denim, comprising the following preparation steps:

[0028] Step A, deploying dyes:

[0029] First, the indigo raw material and the biological reducing agent are uniformly mixed at normal temperature according to the weight ratio of 1:1 to prepare the indigo mixture;

[0030] Calculated by weight percentage, mix 0.01% of the indigo mixture, 0.5% of the diffusing agent and water; the prepared dyestuff is transferred to the dye vat for subsequent use;

[0031] Step B, drying the yarn with a drying drum to make the moisture content below 10%; using 110°C steam as a heat source in the drying drum;

[0032] Step C, dyeing the yarn dried in step B through a dyeing vat;

[0033] Step D, passing the indigo-dyed yarn obtained in step C over the rollers, exposing the dyed yarn to the air, and utilizing the air to oxidize and solidify the indigo on the yarn;

[0034] Step E, drying the oxidized yarn in step D with a drying cylin...

Embodiment 2

[0038] A kind of non-sewage discharge dyeing process for denim, comprising the following preparation steps:

[0039] Step A, deploying dyes:

[0040] First, the indigo raw material and the biological reducing agent are uniformly mixed at normal temperature according to the weight ratio of 1:1.1 to prepare the indigo mixture;

[0041] Calculated by weight percentage, mix 0.05% of the indigo mixture, 0.7% of the diffusing agent and water; the prepared dyestuff is transferred to the dye vat for subsequent use;

[0042] Step B, drying the yarn with a drying drum to make the moisture content below 10%; using 115°C steam as a heat source in the drying drum;

[0043] Step C, dyeing the yarn dried in step B through a dyeing vat;

[0044] Step D, passing the indigo-dyed yarn obtained in step C over the rollers, exposing the dyed yarn to the air, and utilizing the air to oxidize and solidify the indigo on the yarn;

[0045] Step E, drying the oxidized yarn in step D with a drying cyl...

Embodiment 3

[0049] A kind of non-sewage discharge dyeing process for denim, comprising the following preparation steps:

[0050] Step A, deploying dyes:

[0051] First, the indigo raw material and the biological reducing agent are uniformly mixed at normal temperature according to a weight ratio of 1:1.3 to obtain an indigo mixture;

[0052] Calculated by weight percentage, mix 0.1% indigo mixture, 0.8% diffusing agent and water; prepare dyestuffs and transfer them to dye vats for subsequent use;

[0053] Step B, drying the yarn with a drying drum to make the moisture content below 10%; using 120°C steam as a heat source in the drying drum;

[0054] Step C, dyeing the yarn dried in step B through a dyeing vat;

[0055] Step D, passing the indigo-dyed yarn obtained in step C over the rollers, exposing the dyed yarn to the air, and utilizing the air to oxidize and solidify the indigo on the yarn;

[0056] Step E, drying the oxidized yarn in step D with a drying cylinder;

[0057] Step F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com