New pretreatment method for transfer printing

A technology of transfer printing and cold transfer printing, which is applied in the direction of transfer printing, transfer partial treatment, printing, etc. It can solve the problems of printing pattern distortion, fabric elongation, and product quality, and achieve the effect of improving elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A new pretreatment method for transfer printing; it is a pretreatment method for transfer printing carriers (paper, plastic film and metal aluminum foil).

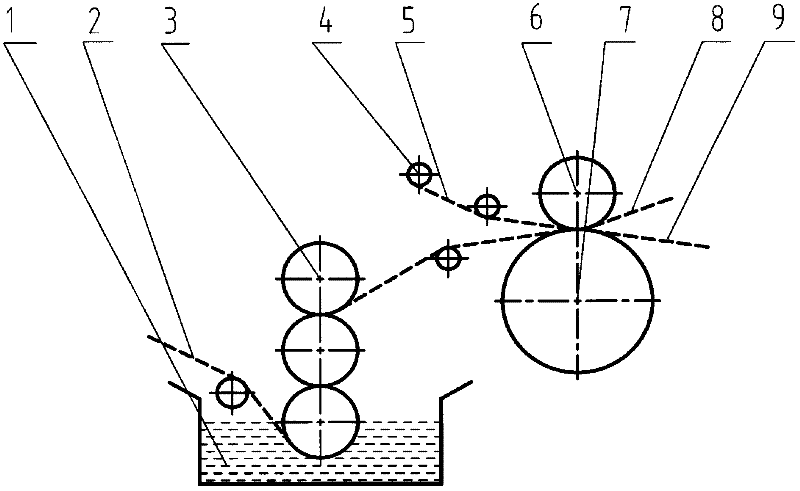

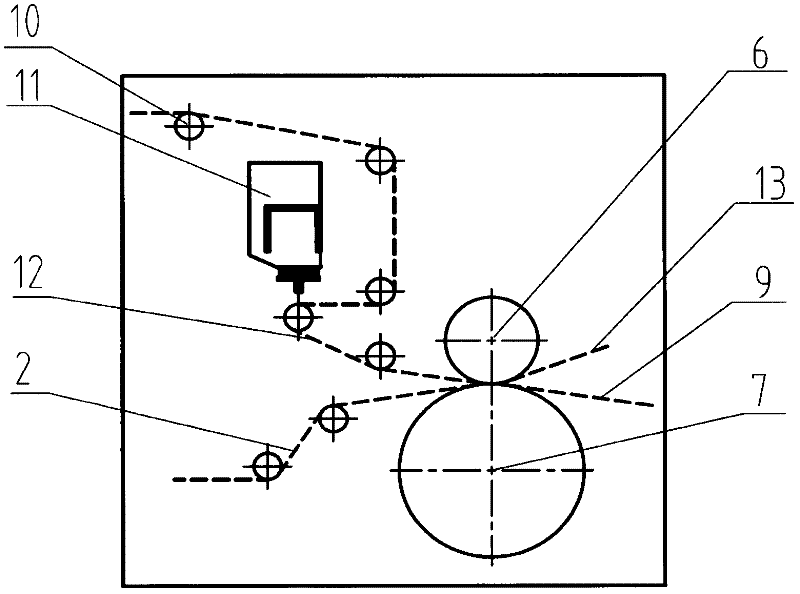

[0033] see you first figure 1 As shown, this is a schematic diagram of the commonly used transfer printing pretreatment method at present, and it is a schematic diagram of the pretreatment process of the printed fabric. The printed fabric 2 is sent to the pre-treatment device by the conveying device of the transfer printing machine, and is treated by the pre-treatment liquid in the pre-treatment liquid rolling tank 1 and the padding of the three rolls 3; the processed printed fabric is sent to the transfer through the guide roll The transfer printing device of the printing machine is close to the transfer printing paper 5 fed by the guide roller 4 at the entrance of the transfer printing device, and the transfer printing task is completed by the transfer printing device with the pressing roller 6 on the bottom and t...

Embodiment 2

[0036] One of the contact coating treatment methods of transfer printing carrier is "roller coating method".

[0037] The base materials suitable for transfer printing carrier are paper and plastic film; and suitable for woven (shuttle) fabrics, knitted fabrics and non-woven fabrics to be printed.

[0038] The roller coating method is to use a liquid tank to add pretreatment liquid to the anilox roller, and through the rolling contact between the anilox roller and the ink receiving roller and the transfer printing carrier, the pretreatment liquid is uniformly coated on the transfer printing carrier simultaneously.

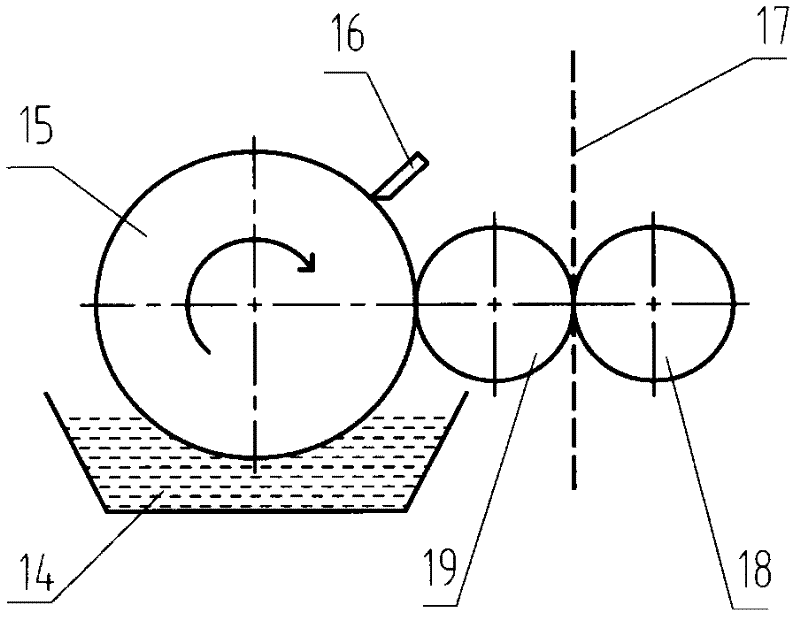

[0039] See the specific implementation method image 3Shown: transfer printing carrier 17 (adopting base material to be paper now) is to pass between ink bearing roller 19 and support roller 18, is to be in contact with the circumferential surface of ink bearing roller 19 because of being printed on the transfer printing carrier and the circumferential surface of i...

Embodiment 3

[0041] The second contact coating treatment method of transfer printing carrier is "circular net coating method".

[0042] The base materials suitable for transfer printing carrier are paper and plastic film; and suitable for woven (shuttle) fabrics, knitted fabrics and non-woven fabrics to be printed.

[0043] The circular screen coating method is a method of circular screen printing, which uses a scraper to add pretreatment liquid to the circular screen roller, and through the rolling contact between the circular screen roller and the transfer printing carrier, the transfer printing carrier is synchronously and evenly coated with pretreatment. liquid.

[0044] See the specific implementation method Figure 4 As shown: in the garden net coating method, the pretreatment liquid is sent into the cavity of the garden net roller 20 through the cavity opening scraper 21 by the delivery pump, and the pretreatment liquid is evenly distributed by the scraper 21; The garden screen ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com