Method for connecting wallboard components of precast concrete shear wall structure

A technology of prefabricated concrete and connection method, which is applied in the direction of building components, walls, building structures, etc., can solve the problems that the reliable and effective connection of wall panel components cannot be completely guaranteed, the anchorage of steel bars is insufficient, and the number of steel bars is too small, so as to achieve the purpose of strengthening internal force transmission and The effect of interface shear force transmission, simple design concept and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

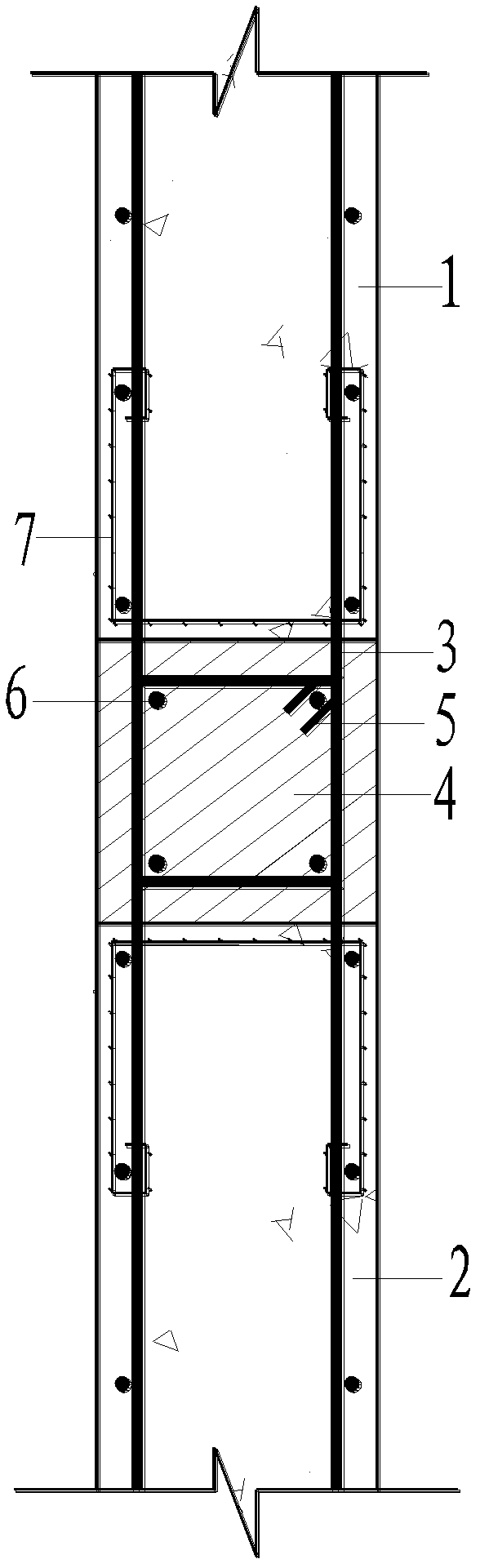

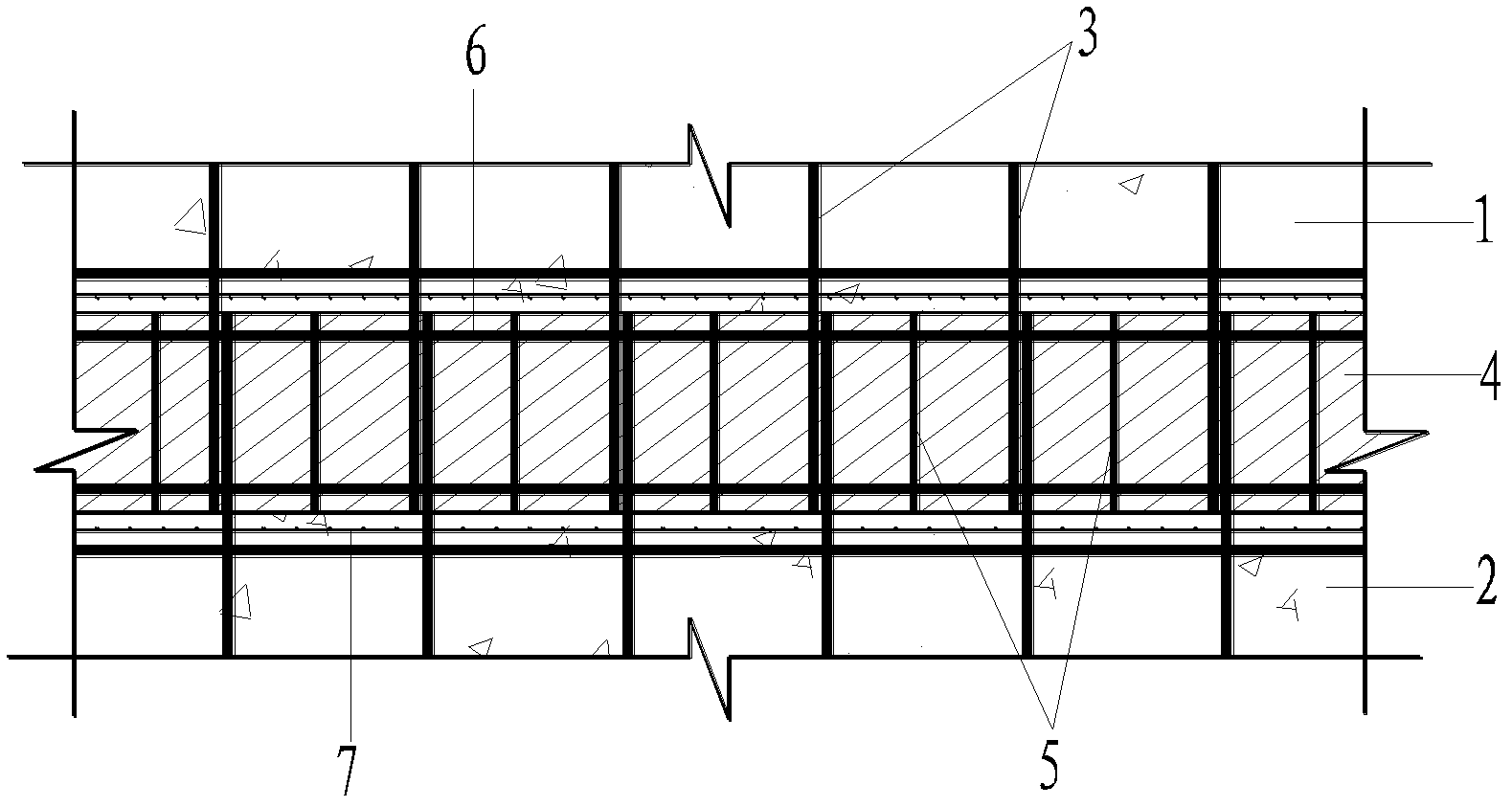

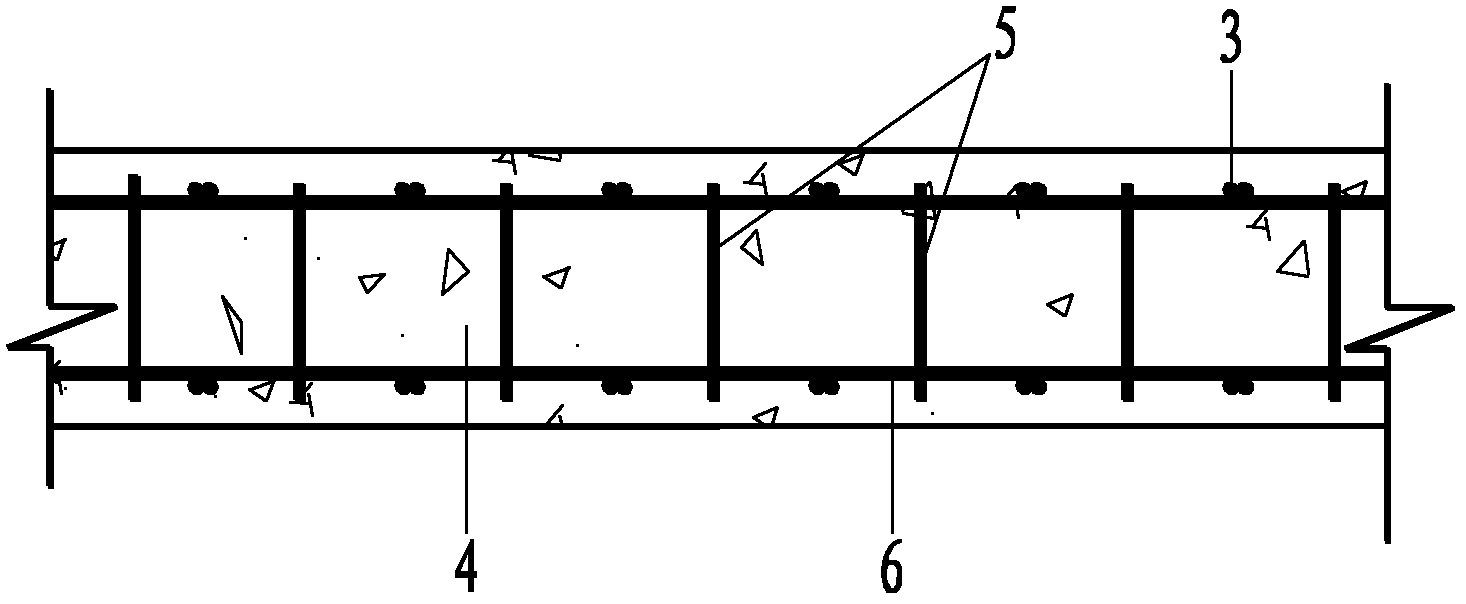

[0027] like Figure 1-3 as shown, figure 1 It is a schematic diagram of the overall structure of the connection method of a prefabricated concrete shear wall panel member of the present invention, figure 2 It is the left view of the connection method of the prefabricated concrete shear wall structure wall panel members of the present invention, image 3 It is a top view of the connection method of the prefabricated concrete shear wall structure wall panel members of the present invention.

[0028] A method for connecting prefabricated concrete shear wall structural wall panels, the method comprising the following steps: the first prefabricated concrete shear wall panel 1 and the second prefabricated concrete shear wall panel 2 respectively protruding from the side edge of the wall panels The reinforced steel bars are bent along the thickness direction of the wallboard to form a closed rectangular steel bar ring 3 and then cross and overlap, and then the jointed reinforced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com