Light and convenient resistance meeting preventive pressured cable lowering conveyor

A conveying device and cable technology, which is applied in wellbore/well components, earthwork drilling, construction, etc., can solve problems such as oil field economic loss, cable twisting, cable breakage, etc., to achieve structural optimization and reasonable prevention of twisting and breaking Reliable effect of stripping and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

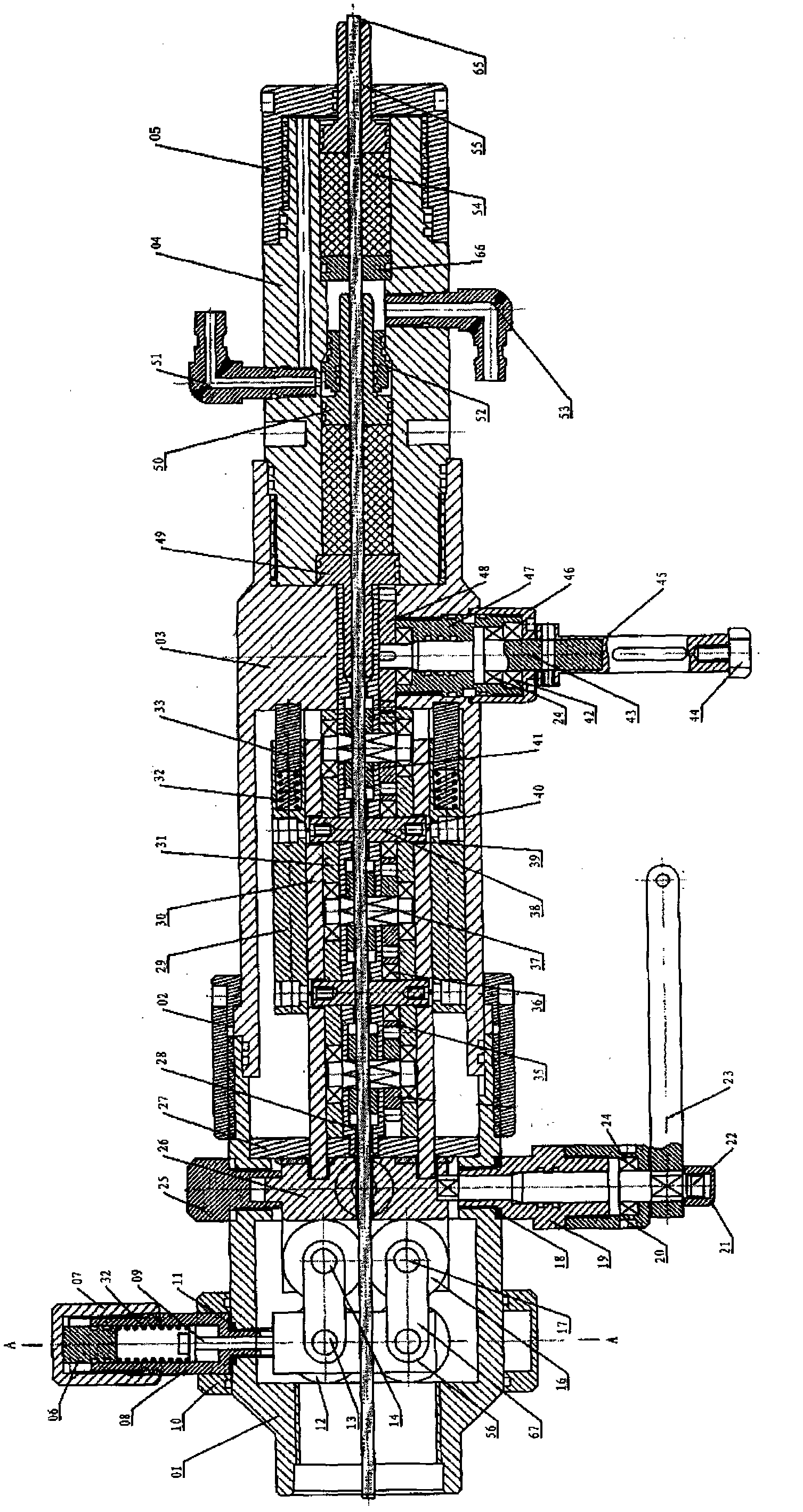

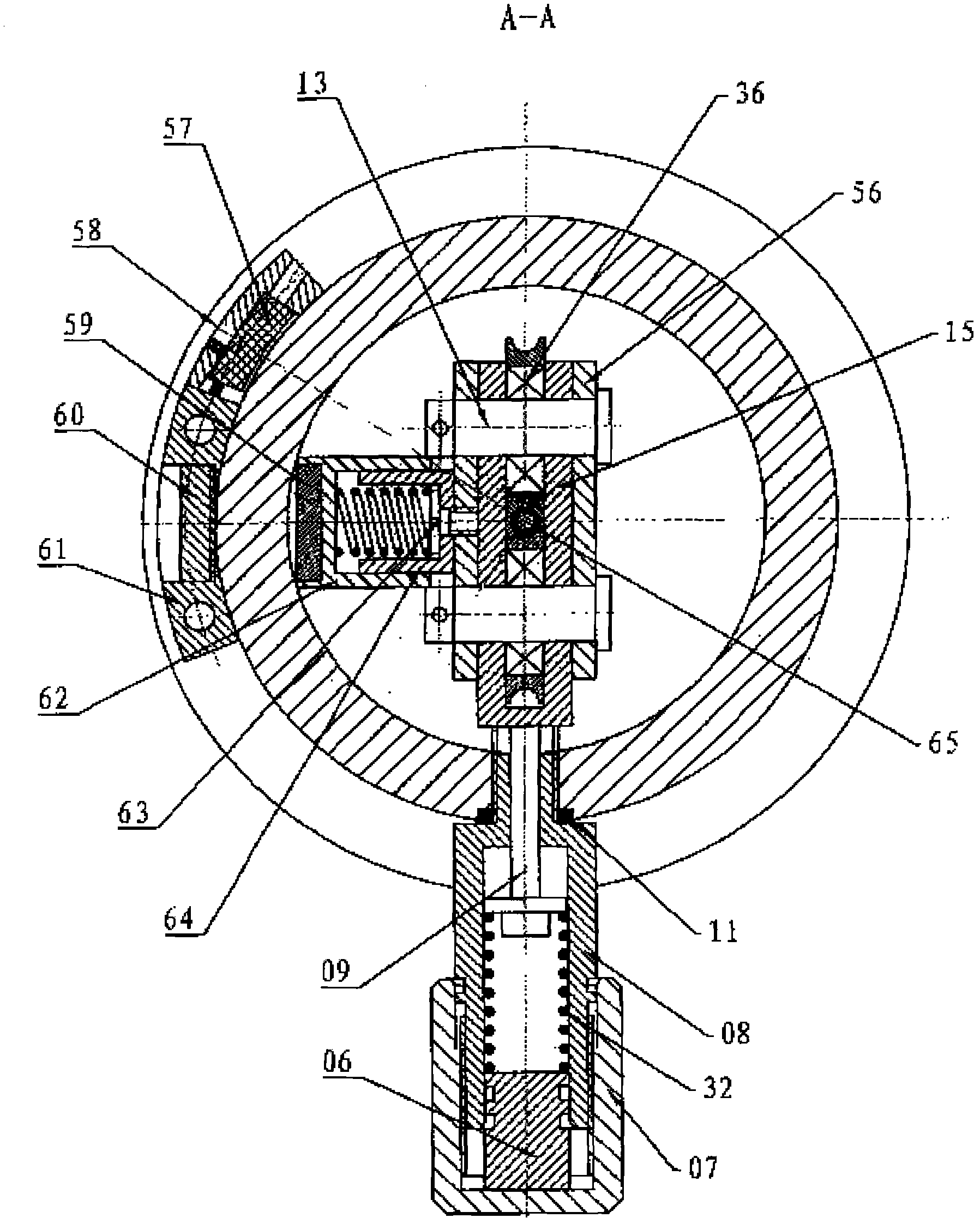

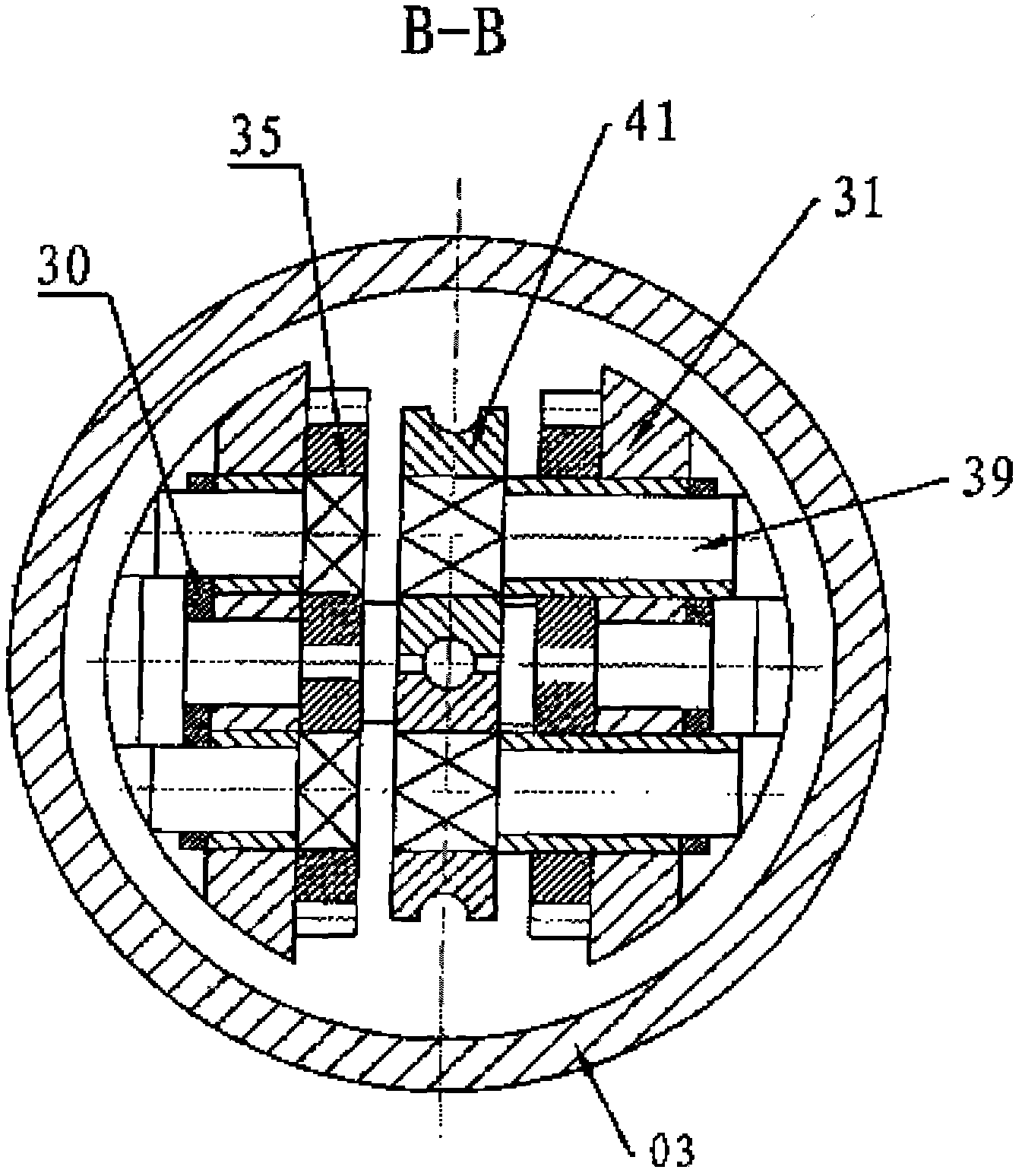

[0040] The invention includes a blowout prevention sealing mechanism, a cable pressure-down well conveying mechanism and a cable resistance alarm mechanism, and is characterized in that the blowout prevention sealing mechanism is designed on the upper part, the cable pressure well conveyance mechanism is designed on the middle part, and the cable resistance alarm mechanism is designed on the lower part , the three mechanisms form a cylindrical structure; it consists of the following Composed of components, the anti-blowout sealing structure includes a hydraulic cylinder block 04, an upper screw plug 05 connected with a screw on the upper end of the hydraulic cylinder block, a large and small head-shaped upper piston 55 passing through the center of the plug plug, and a sealing packing pressed on the lower part of the upper piston 54. The lower piston 50 located in the middle and lower part of the hydraulic cylinder, the sealing sleeve 52 located on the outer periphery of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com