Three-dimensional asymmetrical supporting system

An asymmetric, three-dimensional technology, applied in shaft equipment, shaft lining, mining equipment, etc., can solve problems that are difficult to meet the support needs of deep high-stress roadways and chamber groups, affect the production and safety of deep rock mass engineering, and difficult to support To achieve the effect of simple structure, reasonable force coordination and strong support ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

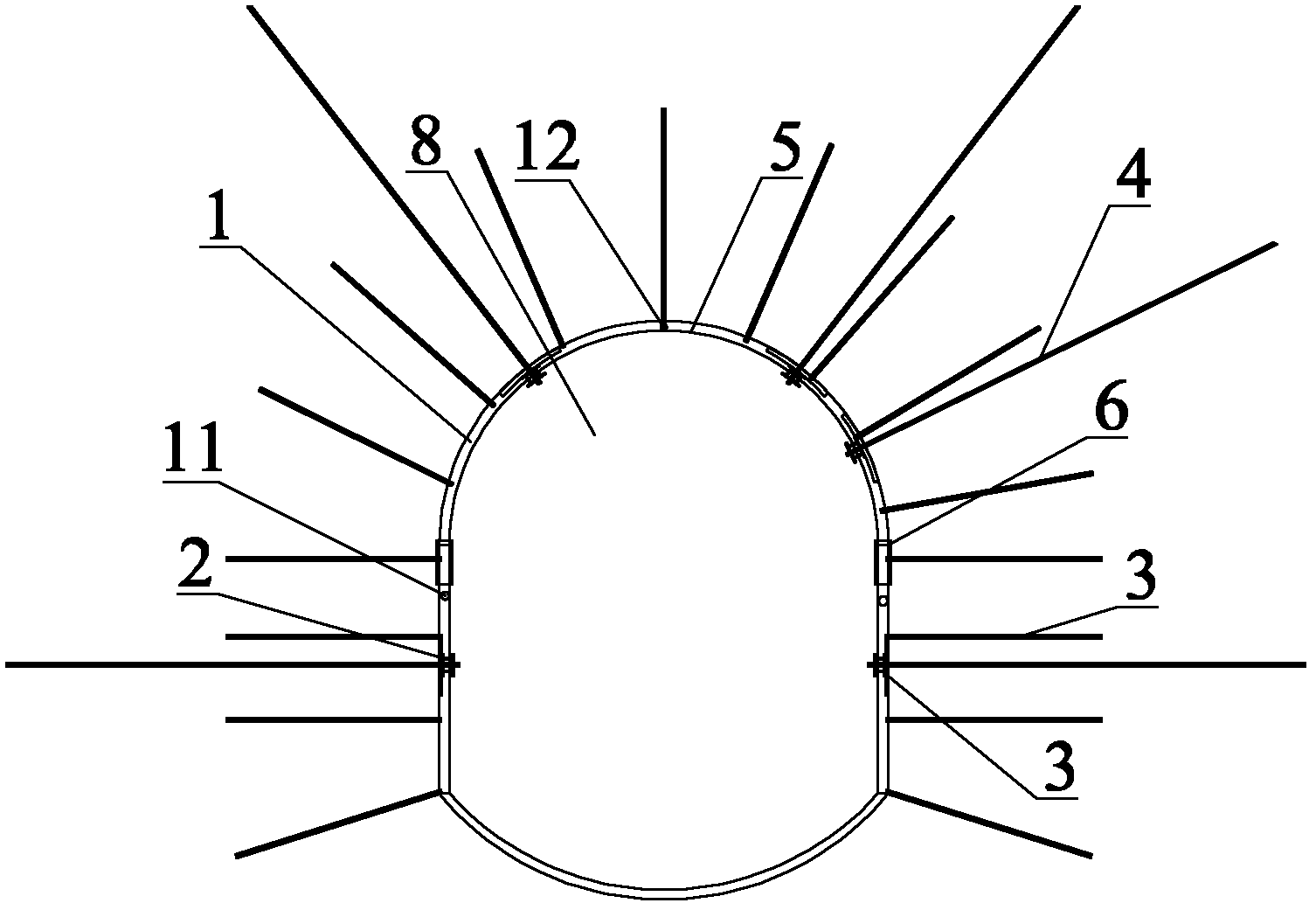

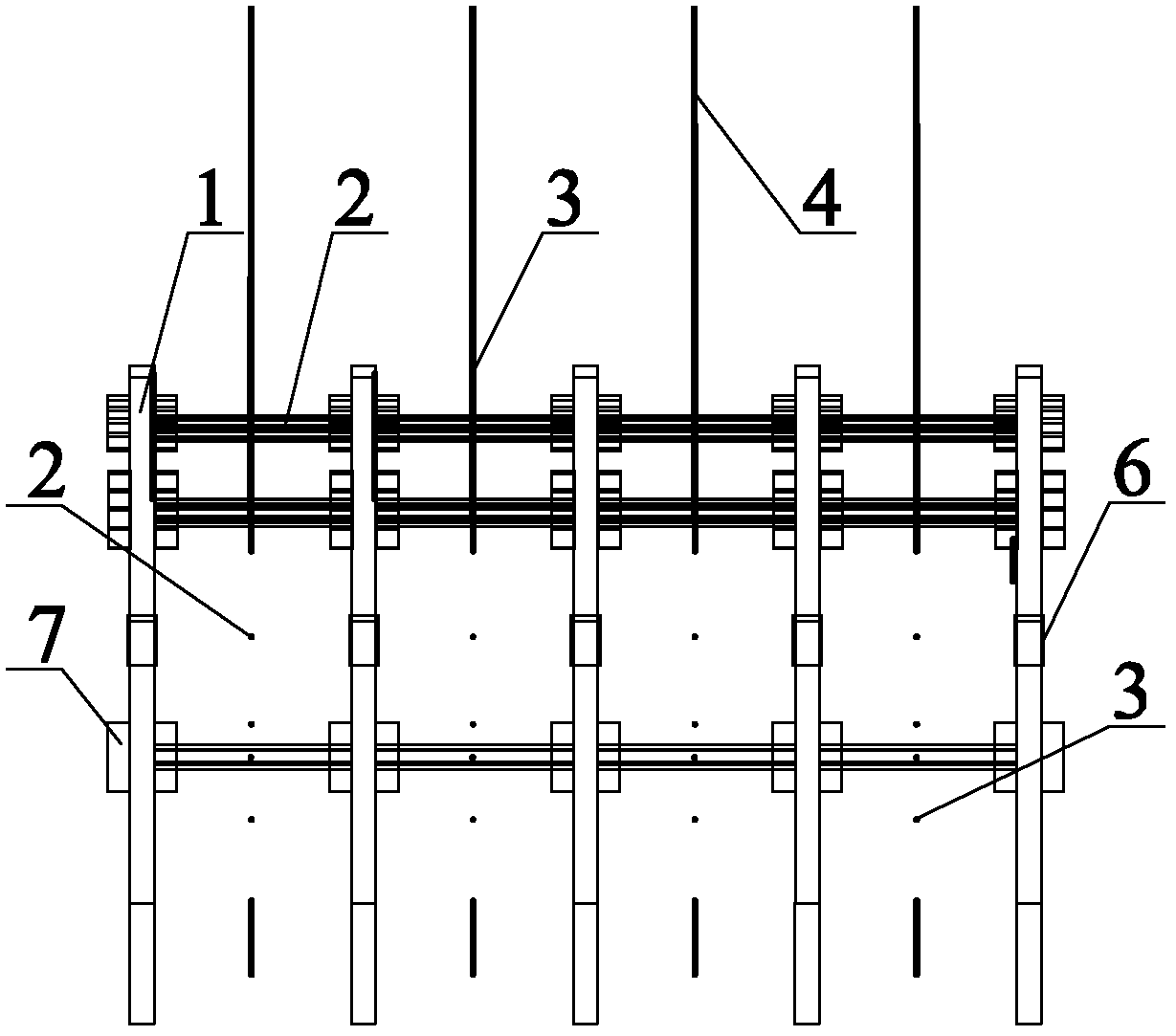

[0024] Such as Figure 1-2 , a three-dimensional asymmetric support system, including multiple concrete-filled steel tube single frames 1 (closed under normal circumstances, and can also be designed as non-closed single frames in special cases), and multiple concrete-filled steel tube single frames 1 are connected by longitudinal connecting beams 2 A support in the shape of a roadway 8 is formed together, a metal mesh 5 is laid between the support and the surrounding rock of the roadway, and the anchor cable hole is arranged on the longitudinal connecting beam 2, and the anchor cable 4 passes through the anchor cable hole of the longitudinal connecting beam 2 and the metal mesh 5 Extend outward, and at the same time, anchor rods 3 are arranged in the surrounding rock of the roadway according to the design row spacing.

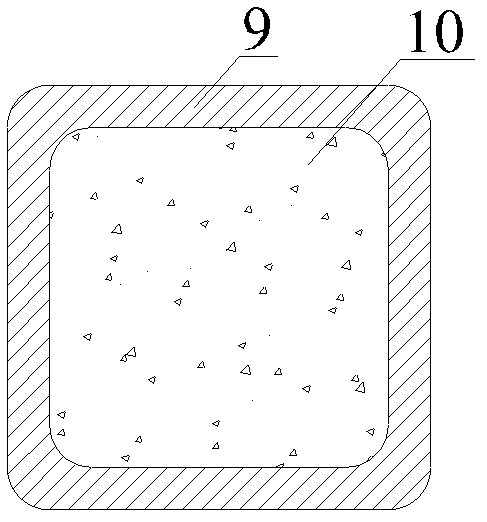

[0025] The concrete-fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com