Carbon dioxide recovery method and carbon-dioxide-recovery-type steam power generation system

A carbon dioxide and power generation system technology, applied in the direction of direct carbon dioxide emission reduction, chemical instruments and methods, separation methods, etc., can solve problems such as excessive reduction of power station output, increase of turbine output, insufficient condensate to recover the total heat of carbon dioxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

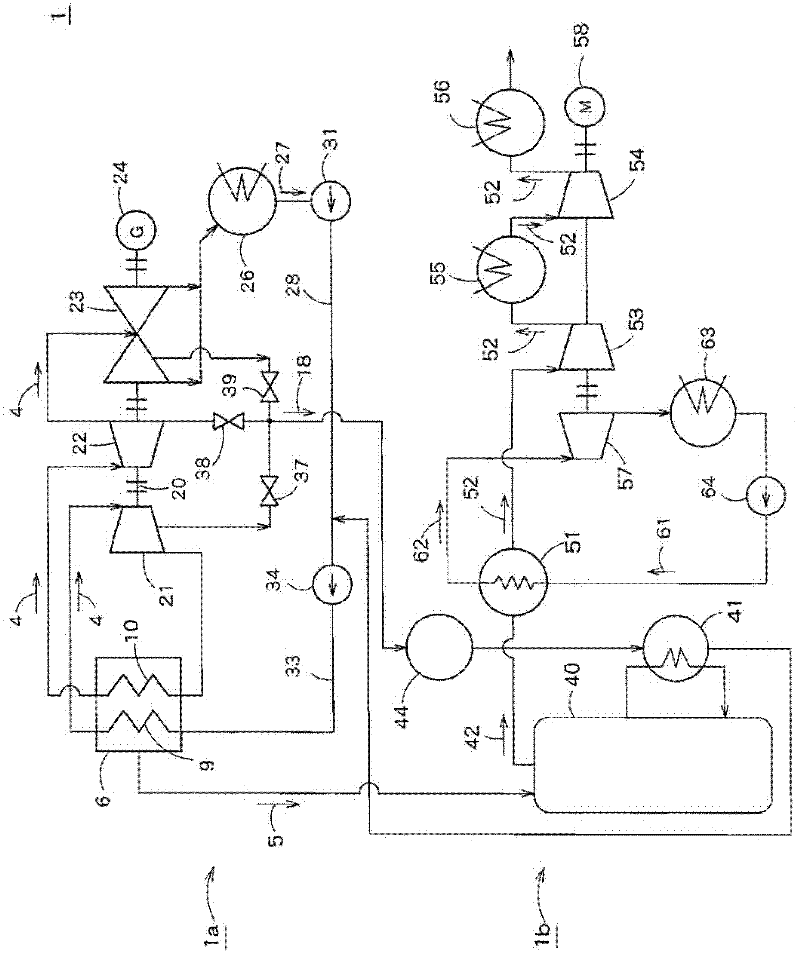

[0016] figure 1 The general structure of the carbon dioxide recovery type steam power generation system according to the first embodiment of the present invention is illustrated. The carbon dioxide recovery type steam power generation system 1 includes: a steam power generation device 1a that generates turbine steam 4 through combustion of fuel and rotates the turbine to generate power; and a carbon dioxide recovery device 1b that absorbs carbon dioxide contained in exhaust gas 5 by use The absorbing liquid is used to recover carbon dioxide from the exhaust gas 5 generated in the boiler 6.

[0017] The boiler 6 is supplied with fuel and air for combustion, and the fuel is burned in the furnace, thereby generating turbine steam 4 and generating exhaust gas 5. The boiler 6 includes: a superheater 9 that generates main steam by heating the turbine steam 4 through combustion in the furnace; and a reheater 10 that is arranged adjacent to the superheater 9 and the reheater 10 The turb...

no. 2 example

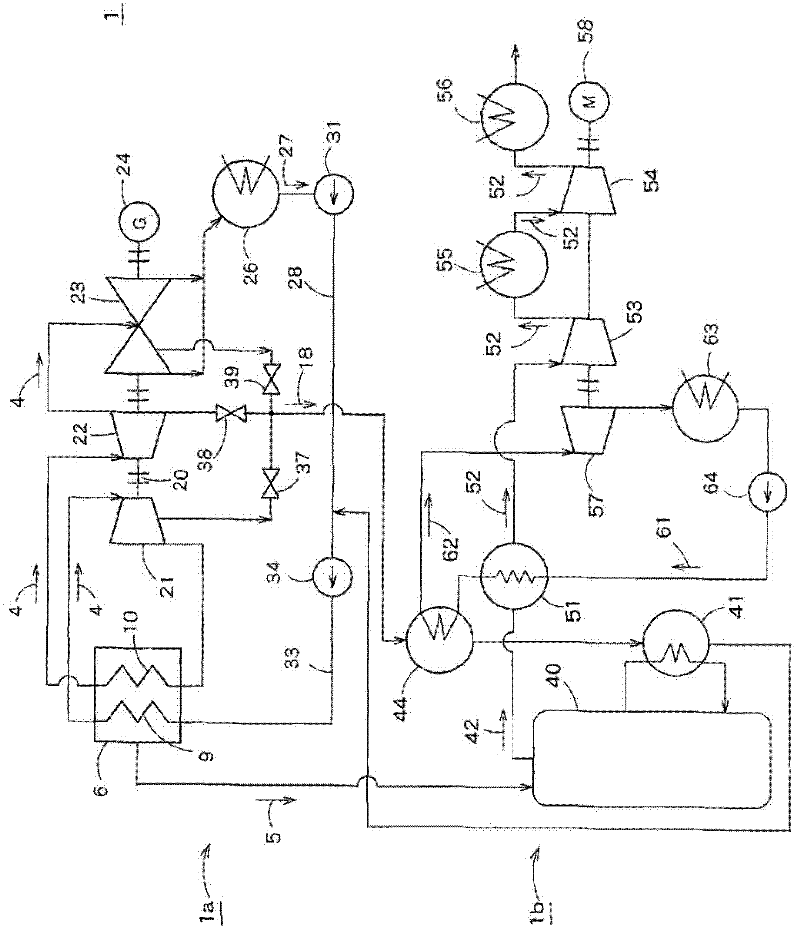

[0032] figure 2 The schematic structure of the carbon dioxide recovery type steam power generation system according to the second embodiment of the present invention is illustrated. This embodiment is the same as figure 1 The difference of the first embodiment shown in is that the cooling water 61 performs heat exchange between the carbon dioxide gas 42 containing water vapor and the steam 18 for heating the reboiler. in figure 2 In, and figure 1 The same parts as those of the first embodiment shown in are indicated by the same reference numerals. The description will not be repeated.

[0033] Such as figure 2 As shown, the cooling water 61 is in CO 2 The condenser 51 exchanges heat with the carbon dioxide gas 42 containing water vapor, and then exchanges heat with the steam 18 as the heat source of the reboiler 41 in the temperature reduction unit 44. The steam 62 generated by the heat exchange between the carbon dioxide gas 42 containing water vapor and the steam 18 is supp...

no. 3 example

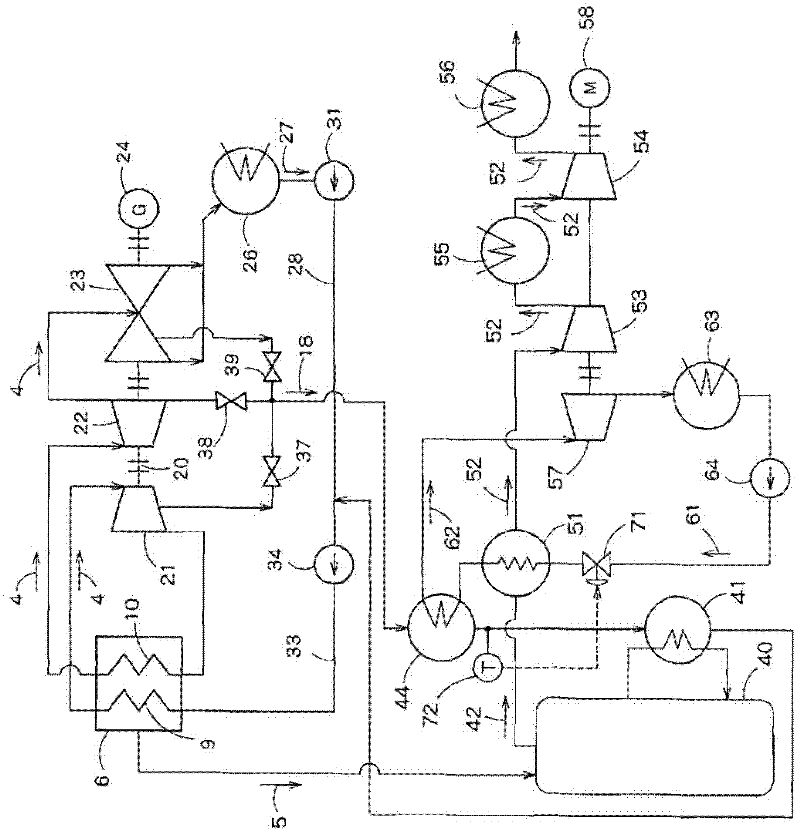

[0036] image 3 The schematic structure of the carbon dioxide recovery type steam power generation system according to the third embodiment of the present invention is illustrated. This embodiment is the same as figure 2 The difference in the second embodiment shown in is that the system includes a valve 71 that adjusts the flow rate of the cooling water 61, and a control unit that measures the temperature of the steam 18 whose temperature is lowered by the temperature reduction unit 44 and controls the opening degree of the valve 71 72. in image 3 In, and figure 2 The parts that are the same as those of the second embodiment shown in are indicated by the same reference numerals. The description will not be repeated.

[0037] Valve 71 is set at pump 64 and CO 2 Between the condenser 51, and according to the opening degree of the valve 71, the valve 71 can change the supply to the CO 2 The flow rate of the cooling water 61 of the condenser 51 and the temperature reducing unit ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap