Valve core structure of vacuum electromagnetic regulator with guide sleeve

A guide sleeve and regulator technology, which can be applied to machines/engines, adding non-fuel substances to fuel, internal combustion piston engines, etc., can solve problems such as the performance decline of vacuum electromagnetic regulators, reduce the failure of sealing rubber, and solve friction. Great, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings.

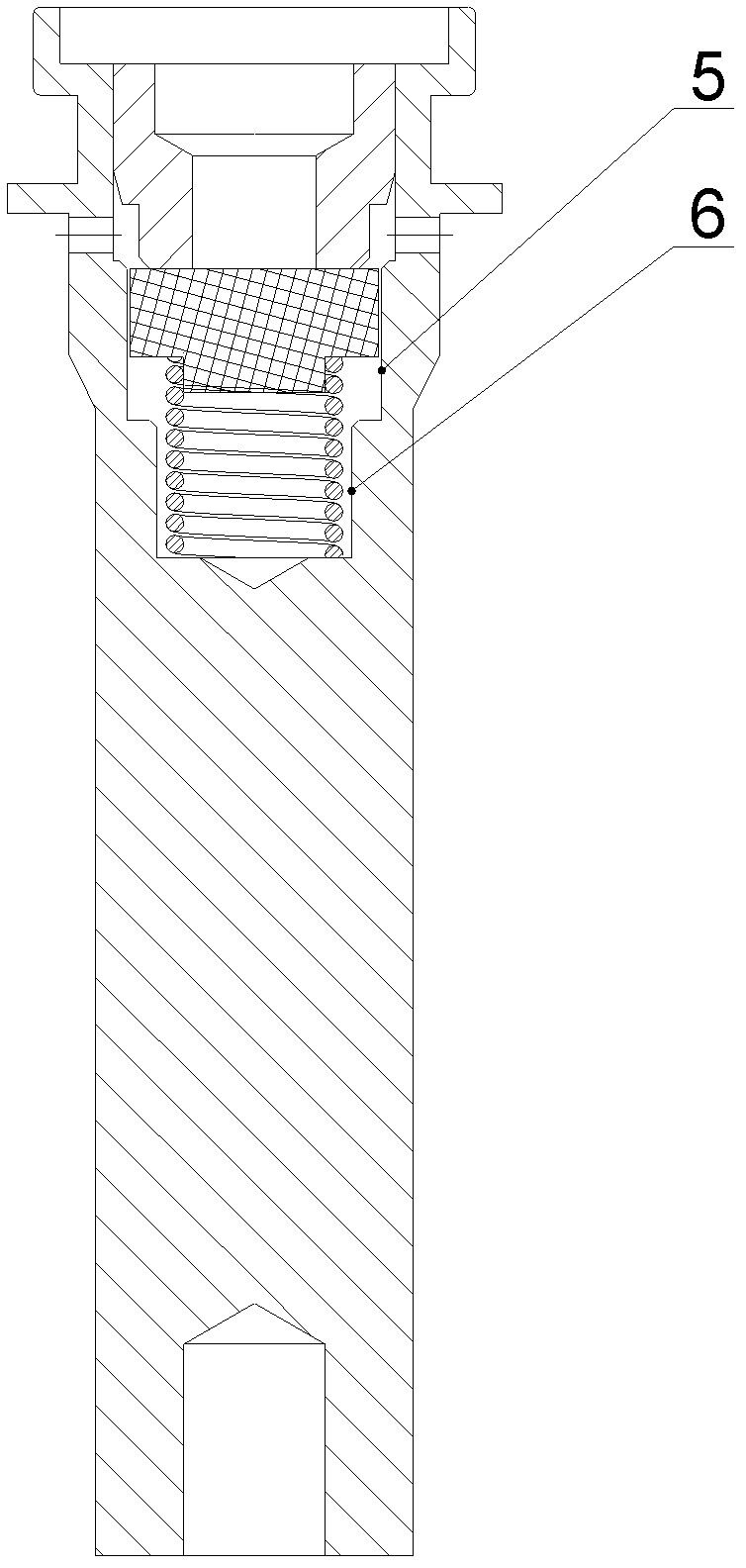

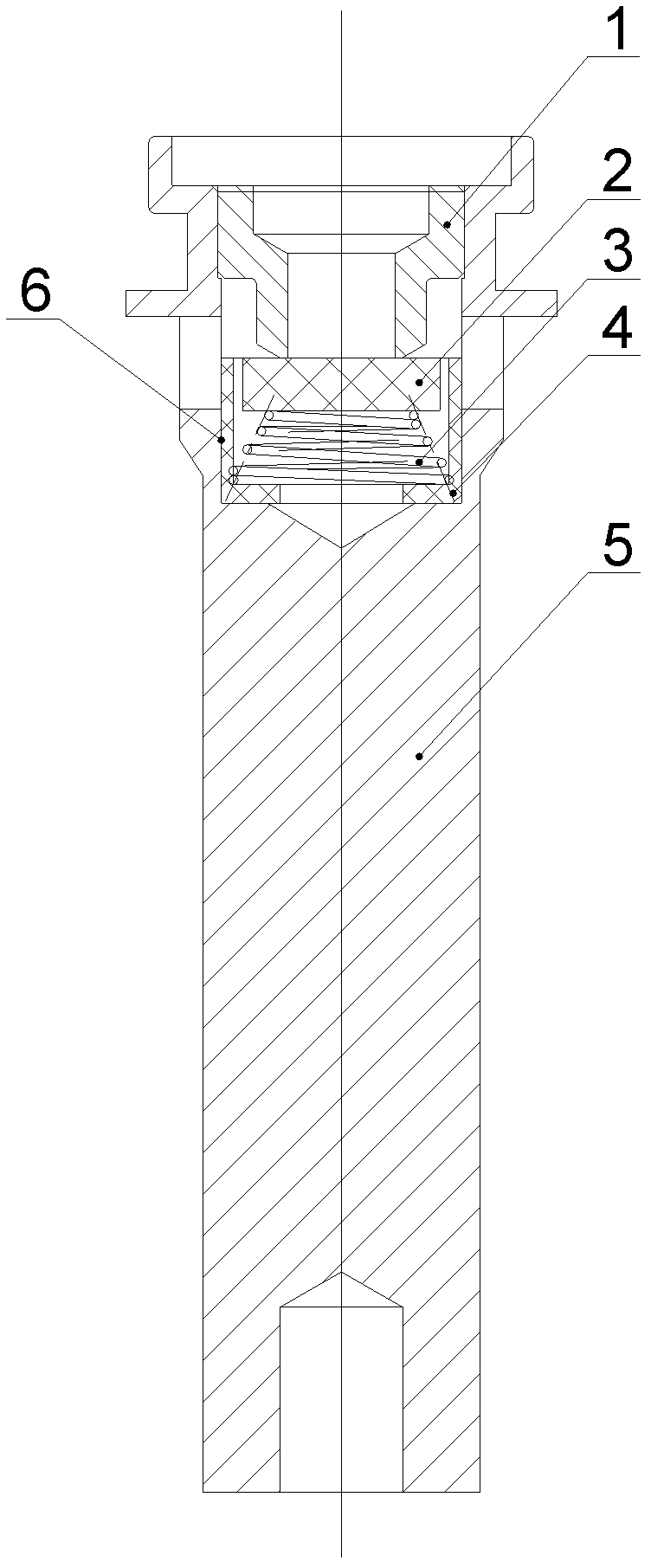

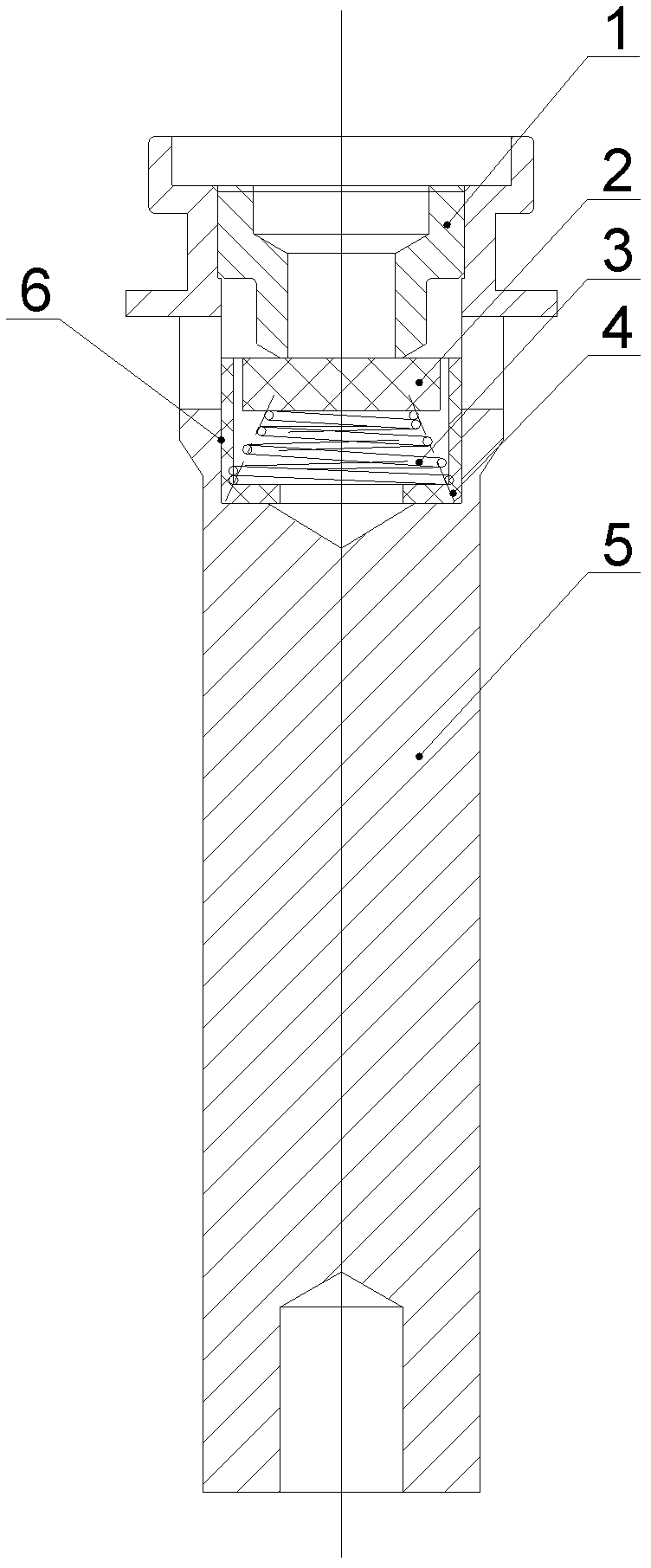

[0013] A valve core structure of a vacuum electromagnetic regulator with a guide sleeve, including a valve core 5, an inner hole 6 arranged above the valve core 5, a stopper 1, a sealing rubber 2, and a spring 3 arranged in the inner hole 6, and the inner hole 6 of the valve core The hole 6 is a straight wall hole, the bottom of the inner hole 6 is provided with a guide sleeve 4, and a spring 3 is arranged above the guide sleeve 4. Winning cooperation, the sealing rubber 2 is arranged above the spring 3 , the outer ring of the sealing rubber 2 is arranged in the inner cavity of the guide sleeve 4 , and the stopper 1 is arranged above the sealing rubber 2 .

[0014] The outer diameter of the stopper 1 and the inner hole 6 are an over-win fit, and the upper end surface of the stopper 1 is flush with the upper plane of the inner hole 6 .

[0015] As shown in the figure: the big ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com