Integral type drive controller for vehicle air compressor

A technology for drive controllers and vehicle air conditioners, applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of difficult heat dissipation of drive controllers, large assembly space requirements, and reduced installation space, saving materials and improving Labor efficiency, the effect of reducing assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

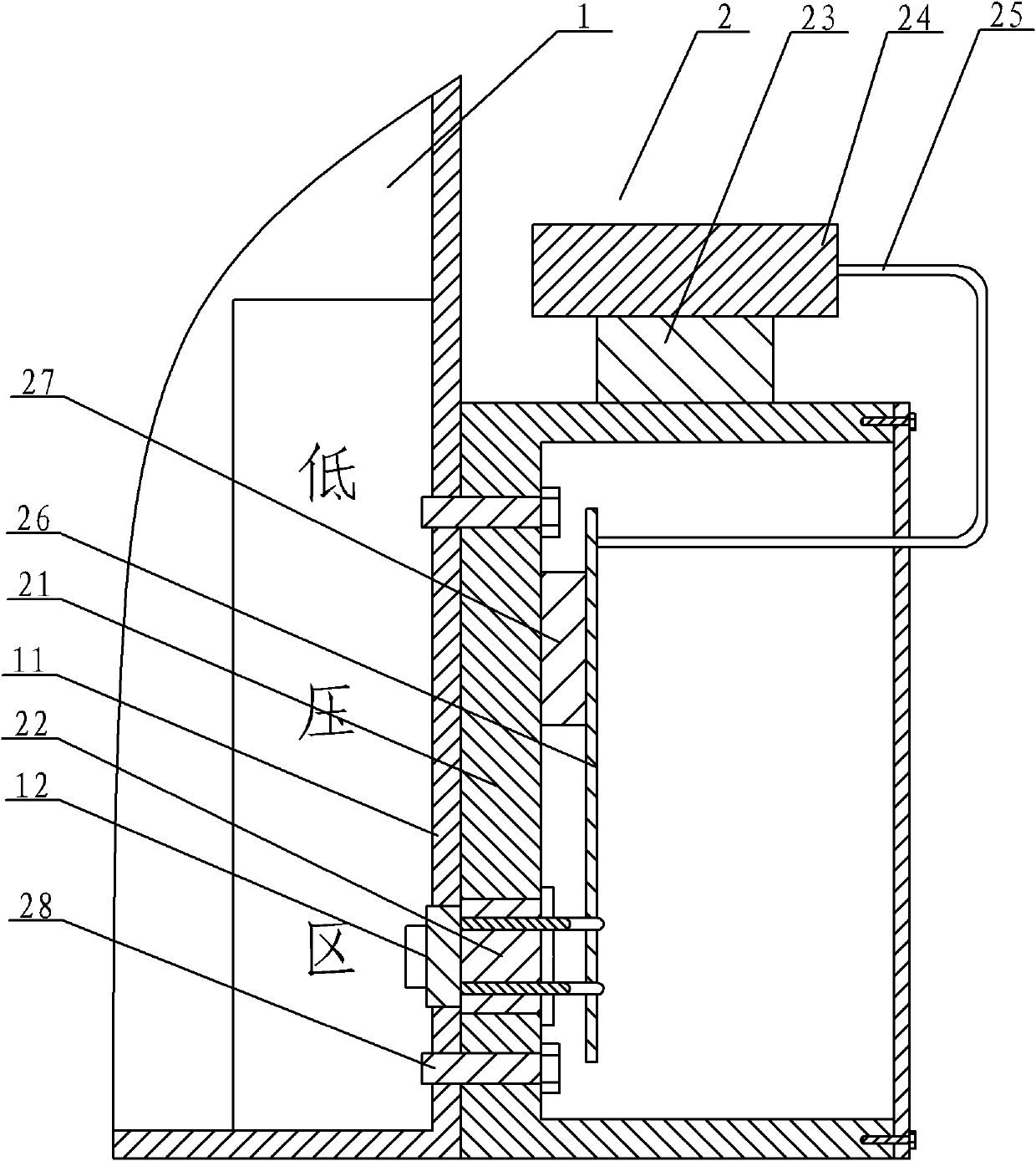

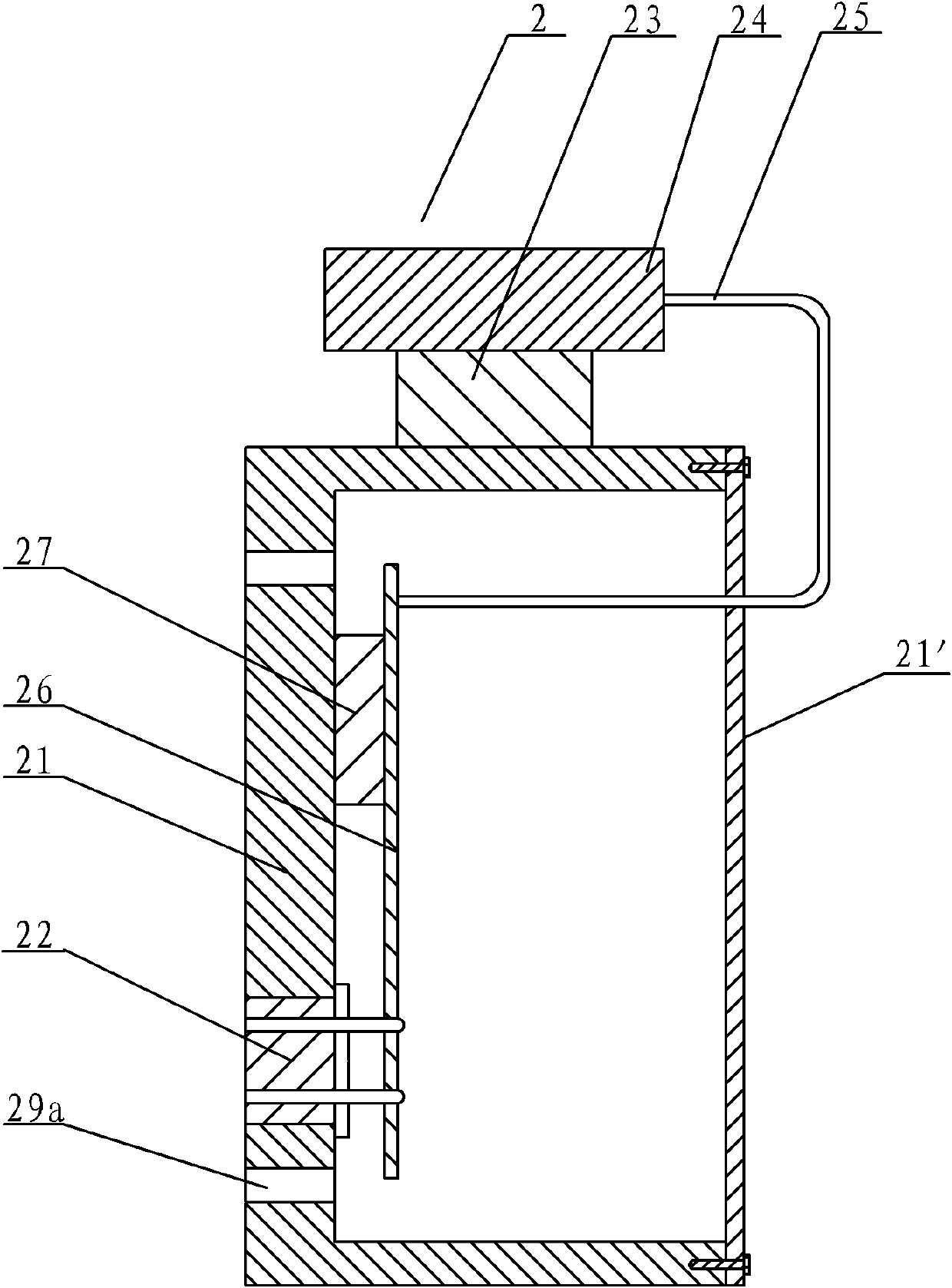

[0026] An integrated drive controller for a vehicle air-conditioning compressor, including a control circuit, a power device 27 and a heat sink 21 of the control circuit, such as figure 1 and figure 2 As shown, the outer side of the cooling part 21 is attached to the outer side of the housing 11 in the low-pressure area of the compressor 1; Device 27 dissipates heat. Since the temperature of the low-pressure intake area of the compressor 1 is relatively low, it can effectively help the drive controller 2 to dissipate heat, thereby solving the heat dissipation problem of the drive controller 2 .

[0027] Wherein, the heat dissipation part 21 is a part of the casing of the drive controller 2 used to adhere to the casing of the low pressure area of the compressor 1 .

[0028] Wherein, the compressor casing 11 and the drive controller heat sink 21 are fastened and connected by bolts 28, such as figure 1 As shown, the cooling part 21 of the drive controller 2 is closely a...

Embodiment 2

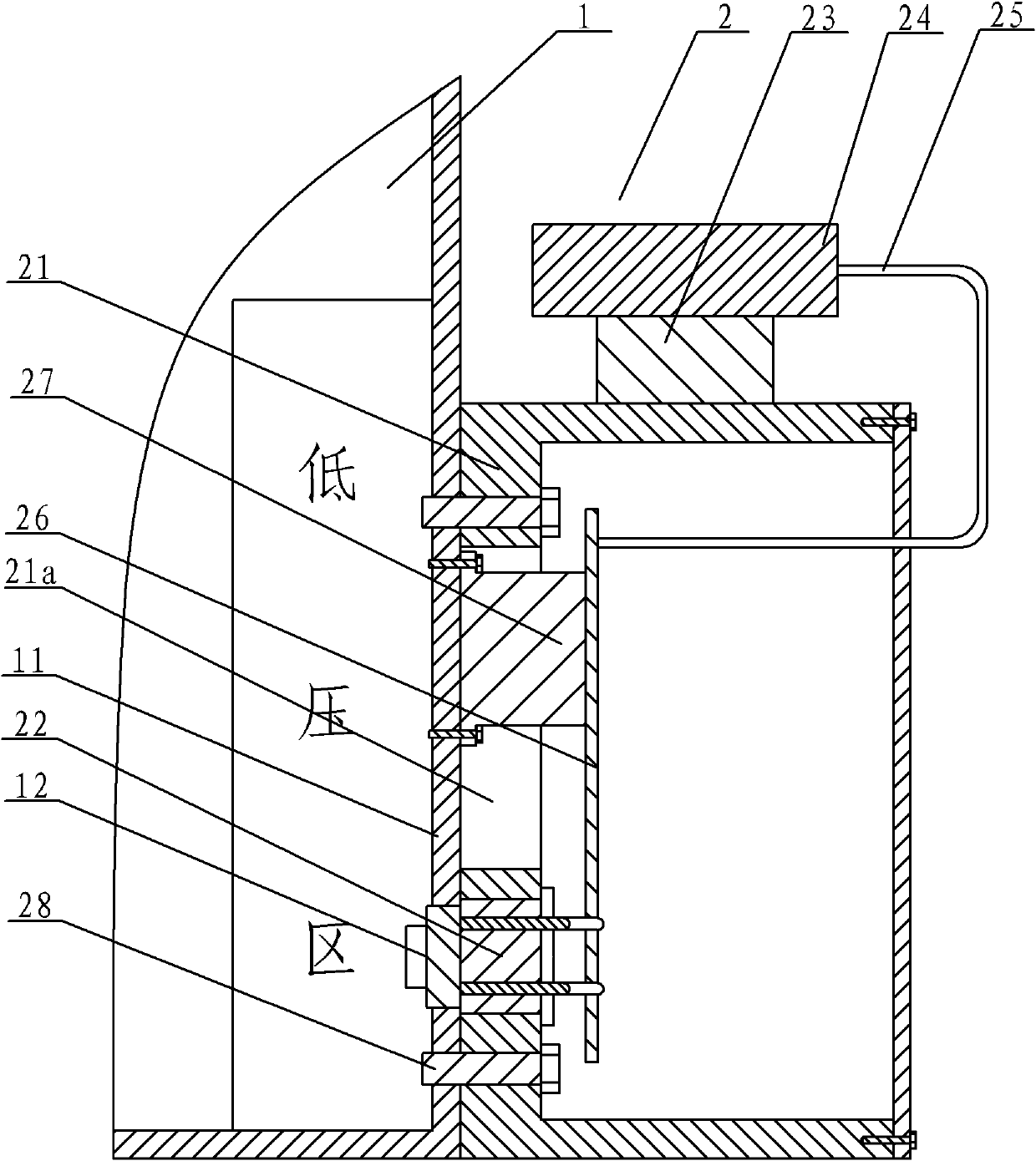

[0034] The present invention also provides another integrated drive controller for a vehicle air conditioner compressor, including a control circuit, a power device 27 and a heat sink 21 of the control circuit, such as image 3 and Figure 4 As shown, the outer side of the heat dissipation part 21 is attached to the outer side of the housing 11 in the low pressure area of the compressor 1, and the heat dissipation part has a through hole 21a leading to the outer side of the housing in the low pressure area; the power device 27 passes through the heat dissipation part 21 The through hole 21a of the compressor 1 is attached to the outer side of the housing 11 in the low pressure area, and the low temperature in the low pressure area of the compressor 1 is used to dissipate heat from the power device 27 .

[0035] Wherein, the power device 27 of the drive controller 2 is fixed on the outside of the housing 11 in the low-pressure area of the compressor 1 by bolts, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com