Double-outlet rod magnet rheologic elastic body damper

A magnetorheological elastomer, double-rod technology, applied in the direction of magnetic springs, springs/shock absorbers, springs, etc., can solve the difficulty of dynamic sealing, the failure of magnetorheological dampers, and the performance degradation of magnetorheological dampers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

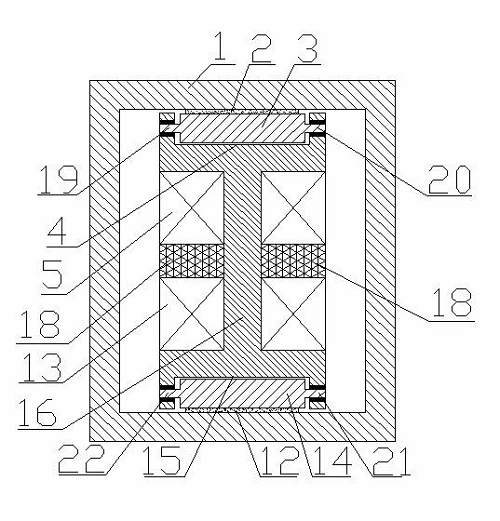

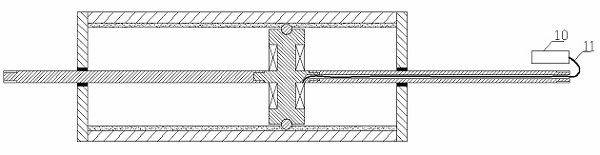

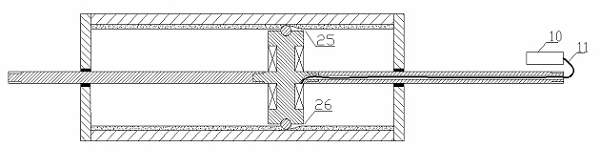

[0016] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0017] see figure 1 and figure 2 , which is a specific structure of the present invention, a double rod magnetorheological elastomer damper, which includes: two damping rods 8 and 23 made of non-magnetic materials, damping blocks 16 made of magnetic materials, The two damping rollers 3 and 14 are made of magnetically conductive material, and the working cylinder 1 is made of magnetically conductive material; the cross section of the inner cavity of the working cylinder 1 is rectangular, and the two ends of the working cylinder 1 are fixed with baffle plates 6 and 17. There are holes in the middle of the plates 6 and 17, and sliding bearings 7 and 24 are fixed in the holes, and a layer of magnetorheological elastomers 2 and 12 are fixed on the surfaces of the two short sides in the working cylinder 1; the section of the damping block 16 It is I-shaped, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com