Ratchet-type tensioner

A tensioner, ratchet-type technology, applied in the directions of machines/engines, belts/chains/gears, valve devices, etc., can solve the problems of easy generation of hitting sound, large-scale tensioner, inability to reduce hitting sound, etc., to achieve stable The effect of starting, actually starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

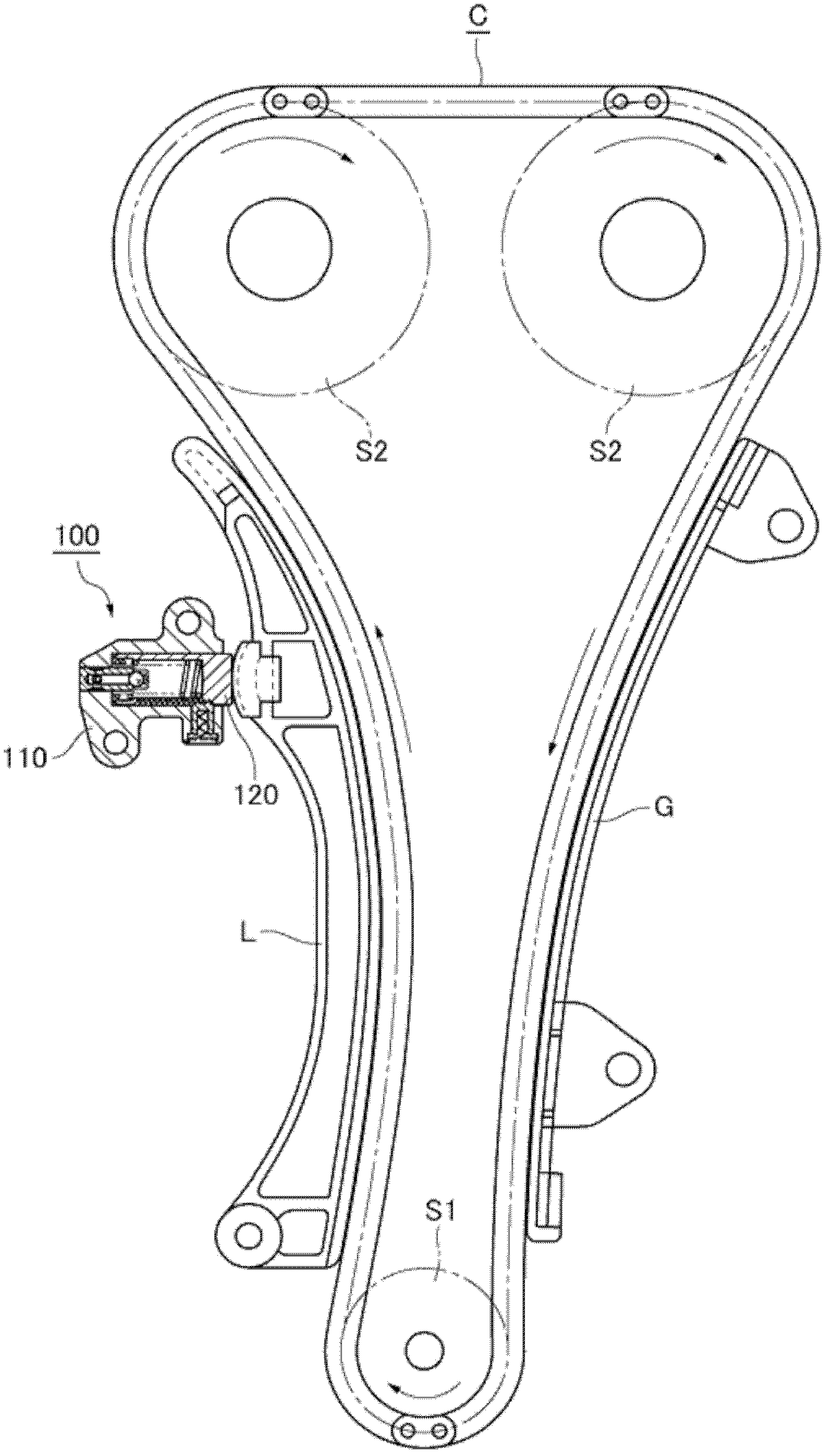

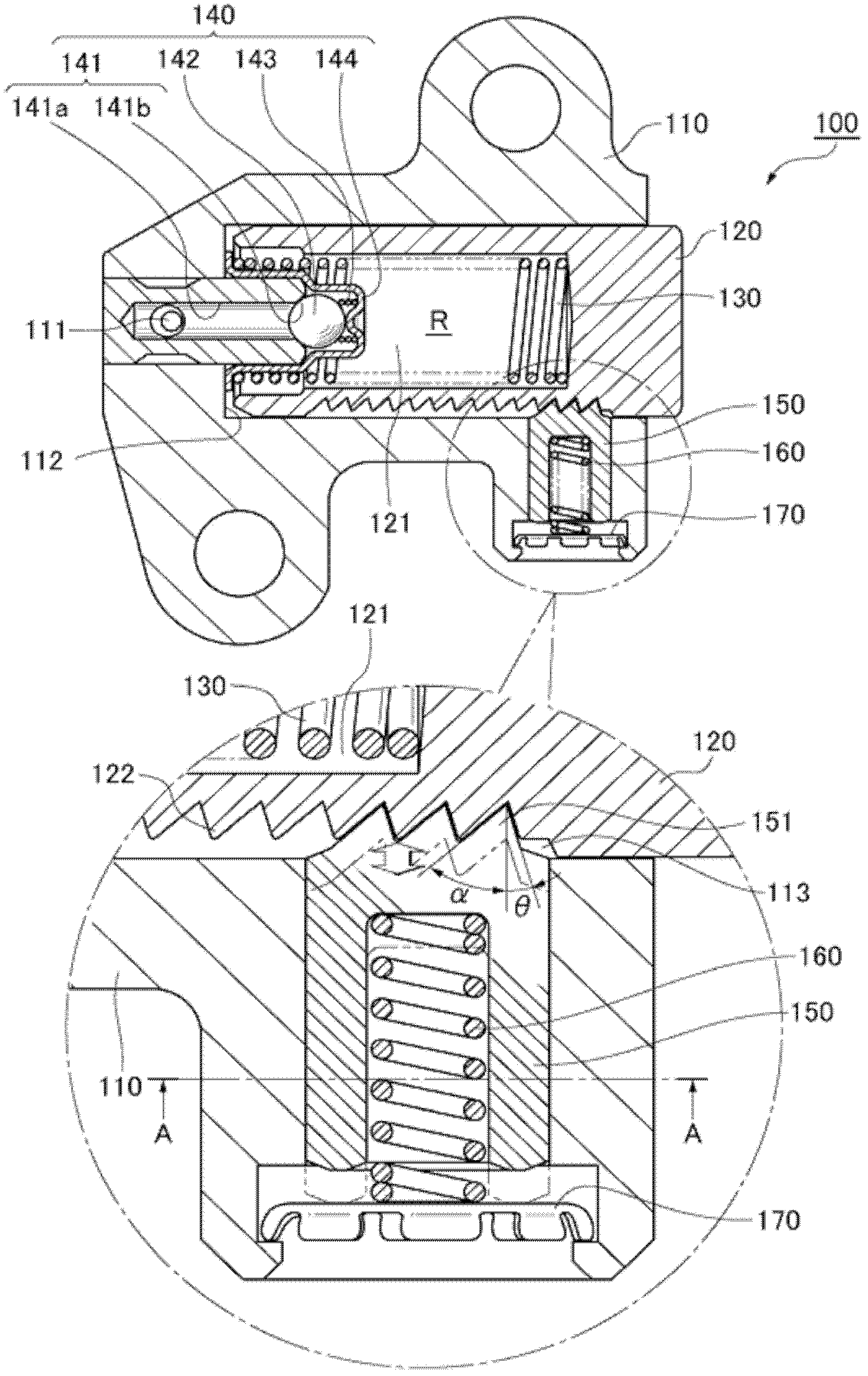

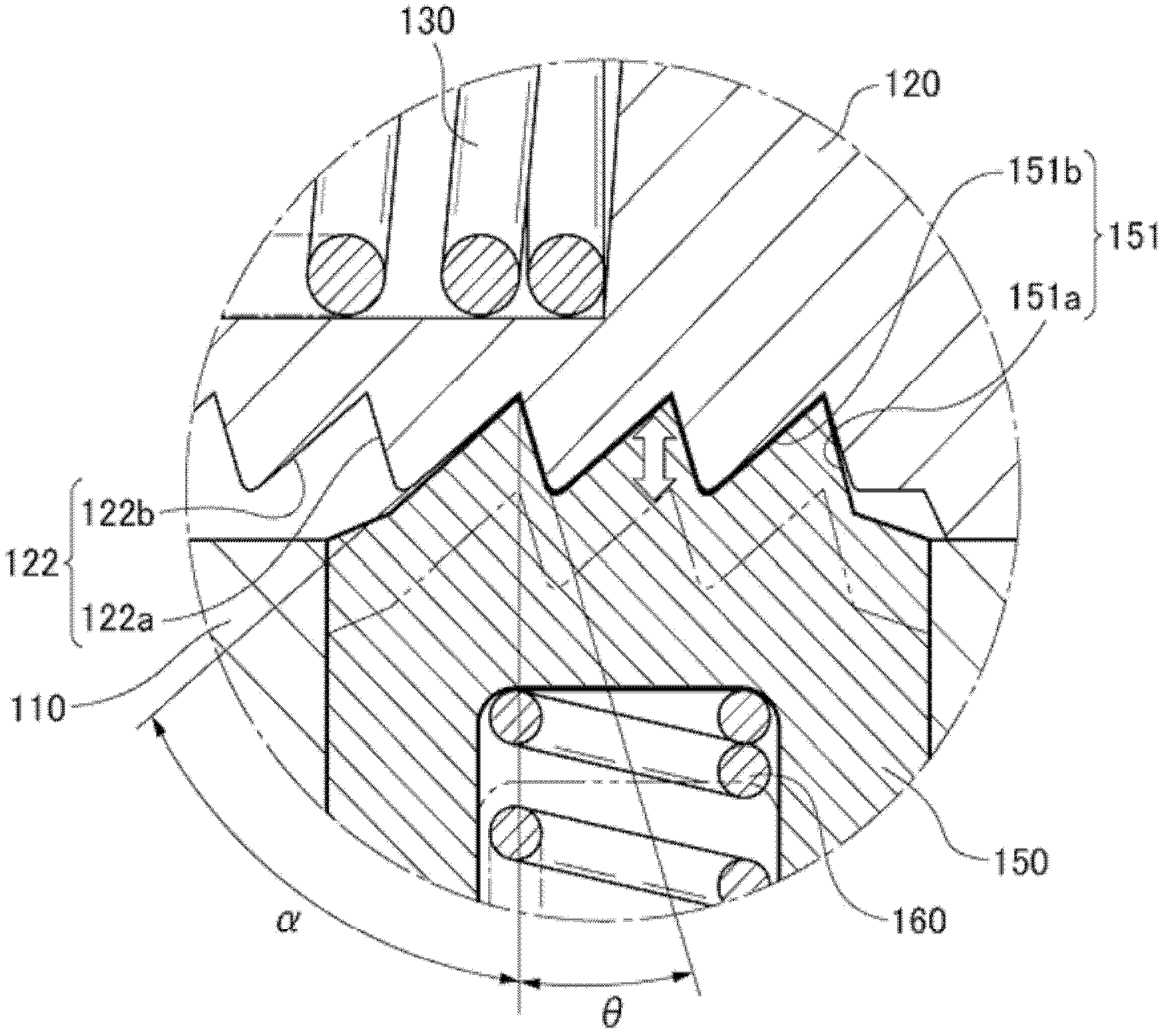

[0111] Below, combine Figure 1 to Figure 8 A ratchet tensioner 100 according to one embodiment of the present invention will be described.

[0112] figure 1 It is the use state diagram of the ratchet tensioner 100 of the first embodiment of the present invention; figure 2 for figure 1 An enlarged cross-sectional view of significant portions of the illustrated ratchet tensioner 100; image 3 It is an enlarged view of rack teeth and ratchet teeth; Figure 4 for figure 2 Enlarged view of A-A shown; Figure 5 Exploded view of the ratchet, the spring for applying force to the ratchet and the plug for locking the spring; Image 6 It is a schematic diagram of the meshing state accompanied by the protruding action of the plunger when the engine is started; Figure 7 It is a schematic diagram of the meshing state accompanying the plunger retreat action when the engine is started; Figure 8 It is a schematic diagram of the meshing state when the plunger starts to retreat du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com