Deep-hole plug

A technology of plugging and deep holes, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of difficult control of welding forming size, inability to achieve permanent connection, and connection failure, so as to achieve easy control and reduce service life , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

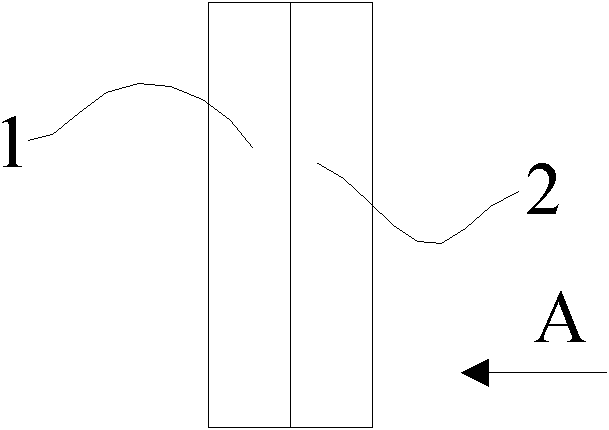

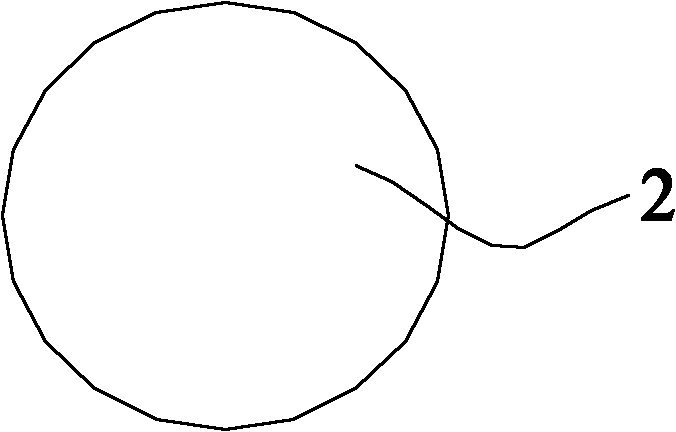

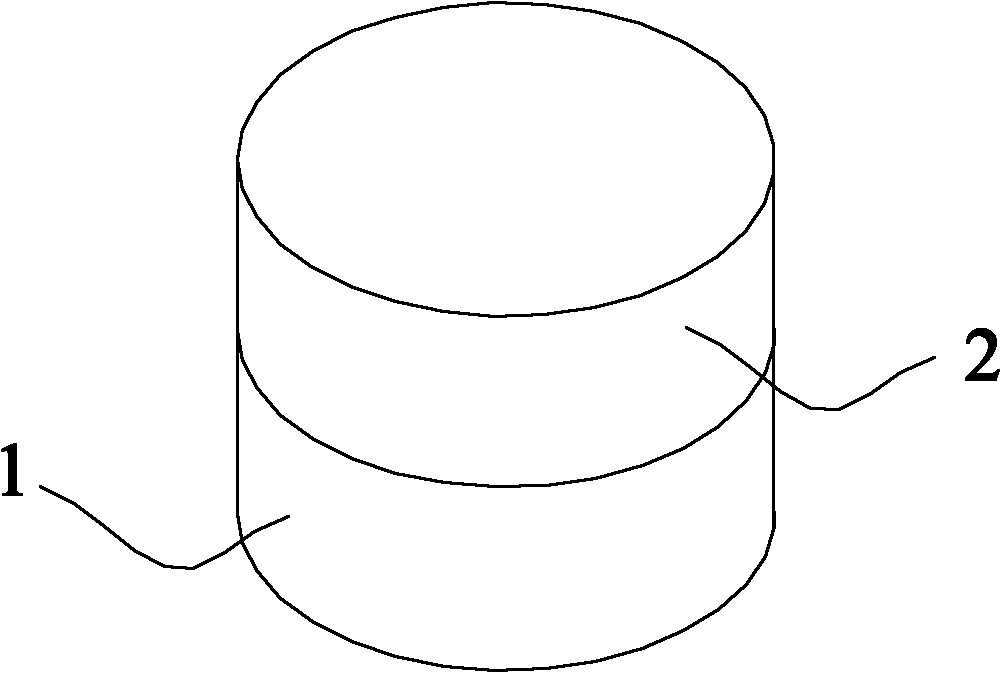

[0018] see figure 1 , figure 2 and image 3 , The present invention provides a plug for deep holes, which includes an aluminum plug end 1, and the deep hole plug also includes a second plug end 2 welded to the end of the aluminum plug 1.

[0019] The second plug end 2 can be a metal or an alloy, and when the second plug end 2 is an alloy, the second plug end 2 is a steel alloy, a titanium alloy or a nickel alloy. If the second plug end 2 is a steel alloy, the aluminum plug end 1 and the steel alloy plug end are brazed with aluminum-based solder, and the surface of the steel alloy plug end must be plated with metal before welding. The metal is copper, nickel, zinc, silver or aluminum plating. The aluminum plug end 1 is also available as a transition joint type, with the aluminum plug end 1 brazed to an aluminized steel piece and then copper brazed to the other steel end.

[0020] Due to the difference in potential, will there be galvanic corrosion in the brazed joints to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com