Magnetic valve with emptying function

A magnetic and valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of technical difficulty of processing methods, dripping, material waste, etc., and achieve the effect of low processing and production cost, easy production and processing, and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

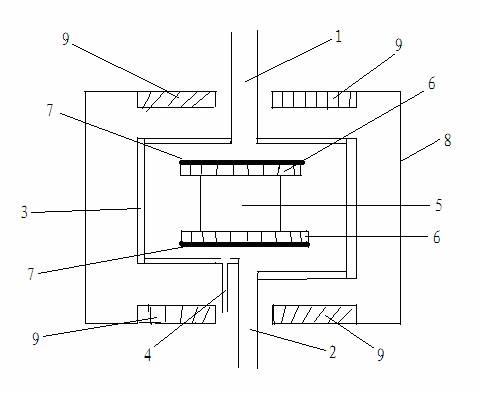

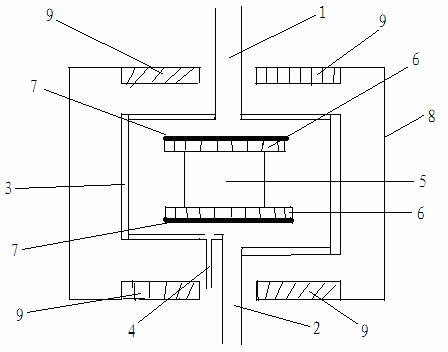

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a valve chamber 3 with an inlet 1 and an outlet 2 respectively at both ends, an air inlet 4 on the same side as the outlet 2 is arranged on the valve chamber 3, and the air inlet 4 and the outlet 2 are not on the same plane, the valve chamber 3 is provided with a free-swimming movable column 5, and both ends of the movable column 5 are provided with powerful magnets 6, and the outside of the powerful magnet 6 is wrapped with a silicone gasket 7; the outside of the valve chamber 3 is wrapped with a plastic link body 8. The two ends of the plastic link body 8 are provided with a magnetic control 9, and the middle of the magnetic control 9 passes through the inlet 1 or the outlet 2; the valve chamber 3 is a closed plastic cylinder, and the plastic cylinder is divided into upper and lower halves, and the middle is provided with a Connect the thread; the powerful magnets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com