Filler-free impact explosive type high-efficient cooling tower

A cooling tower without filler technology, which is applied in the field of cooling towers, can solve the problems of germ growth and high energy consumption, and achieve the effects of reducing operating costs, prolonging operating life, and saving investment and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

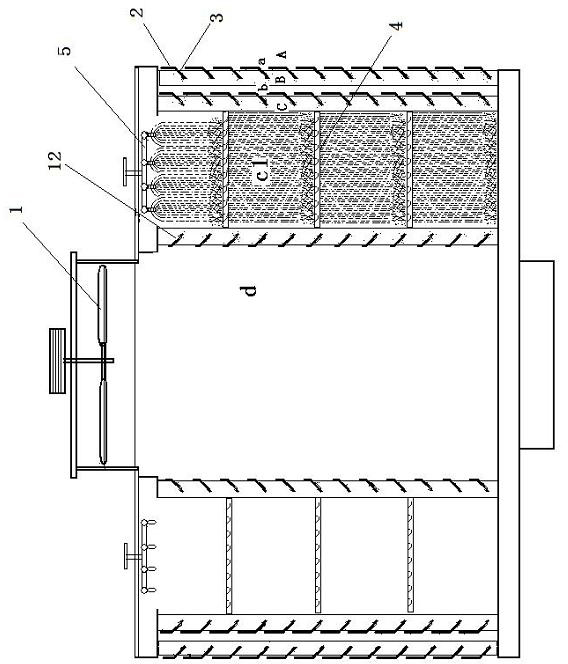

[0036] Such as figure 1 , 3 , 4, and 5.

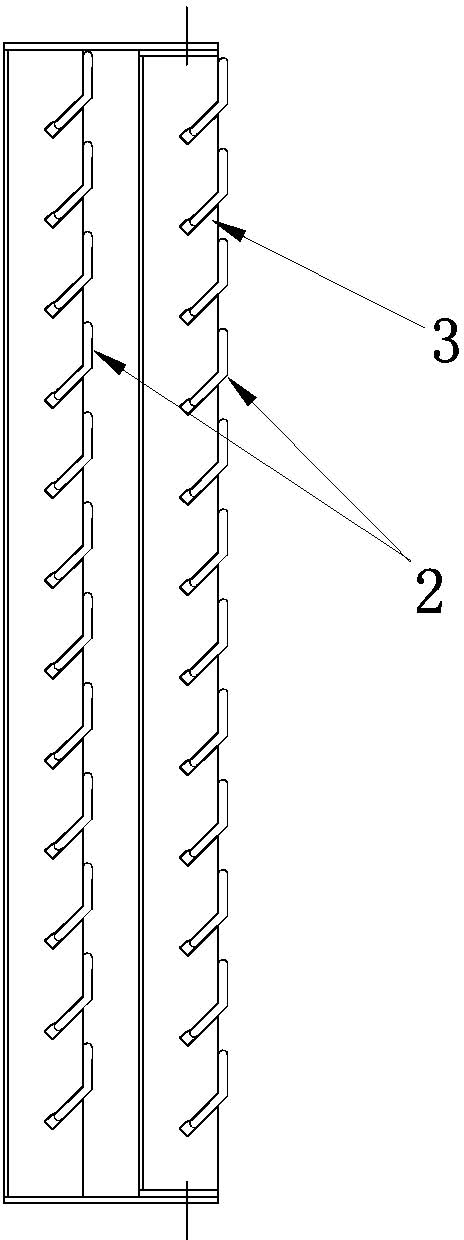

[0037] A high-efficiency cross-flow cooling tower without filler impact explosion, through low-speed, high-efficiency, low-negative-pressure axial flow fans, adding different specifications of windshields at the air inlet of the cooling tower to control the negative pressure in the cooling tower to 5-2000mm For the water column, cancel the packing in the tower: add the impact splashing board in the tower. The purpose is to increase the evaporation kinetic energy of water and reduce the cooling tower water temperature to 15-31 0 c. It mainly includes a fan 1, a windshield 2, an impact splash plate 4 and a louver watershield 12, and the louver watershield 12 is installed on the inner wall of the static pressure box in the tower body, such as figure 1 As shown, the fan 1 is installed on the upper part of the cooling tower body center, which can generate the required negative pressure of not less than 5 mm water column in the tower bod...

Embodiment 2

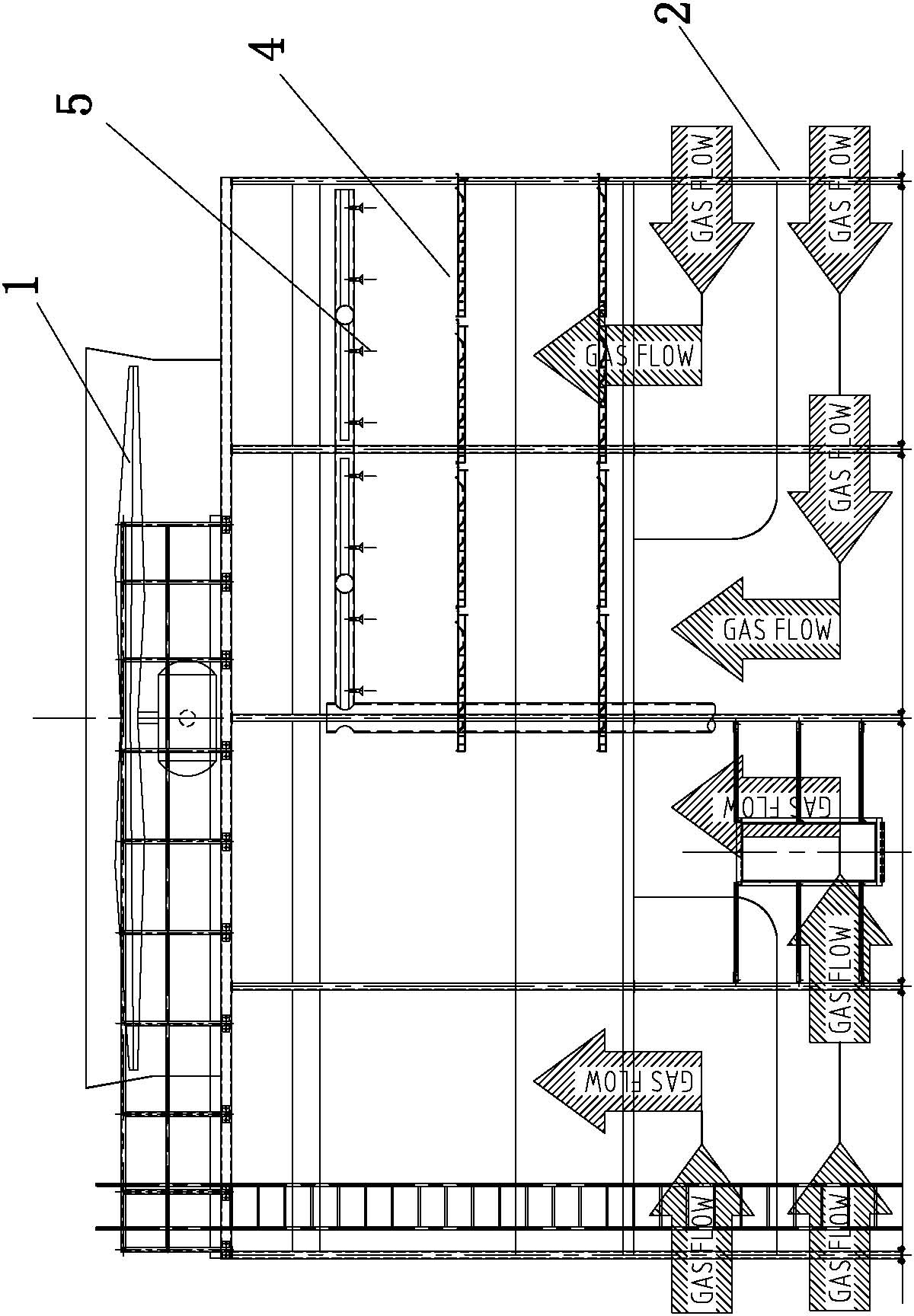

[0063] Such as Figure 2-5 shown.

[0064] A high-efficiency counterflow cooling tower with no filler impact explosion, through low-speed, high-efficiency, low-negative-pressure axial flow fans, adding different specifications of windshields to the air inlet of the cooling tower to control the negative pressure in the cooling tower to 5-2000 mm For the water column, cancel the packing in the tower: add the impact splashing board in the tower. The purpose is to increase the evaporation kinetic energy of water and reduce the cooling tower water temperature to 15-31 0 c. It mainly includes fan 1, windshield 2 and impact splash plate 4, such as figure 2 as shown, figure 2 The direction of the middle arrow indicates the direction of air flow. The fan 1 is installed on the upper part of the center of the cooling tower body, which can generate the required negative pressure of not less than 5 mm water column in the tower body. The windshield 2 is installed on the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com